Device for assisting boring machine to process long conical through hole

A technology of boring machine and long taper, which is applied in the field of devices for auxiliary boring machine processing long taper through holes, can solve the problems of hidden danger, excessive rotation radius, insufficient space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

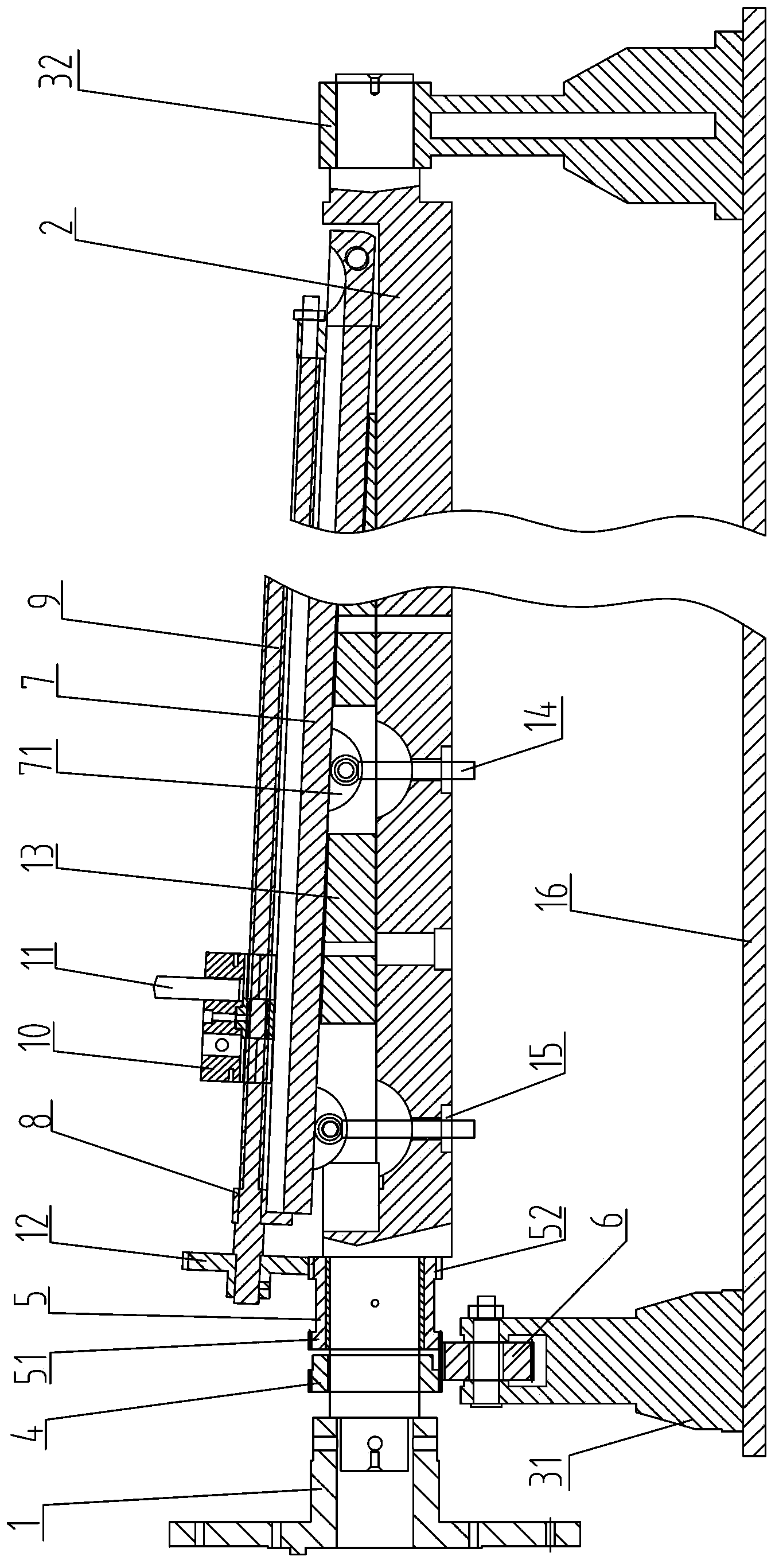

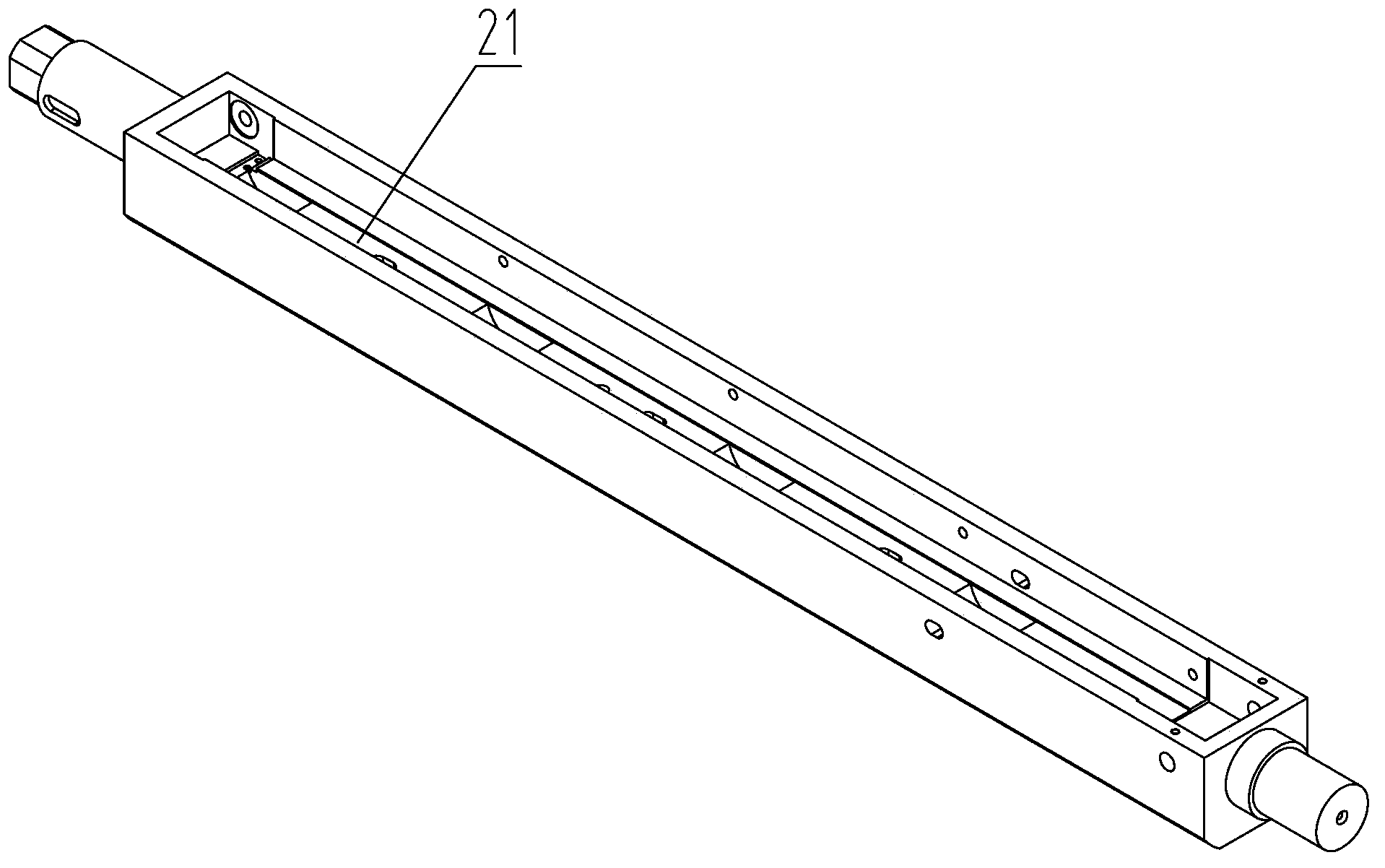

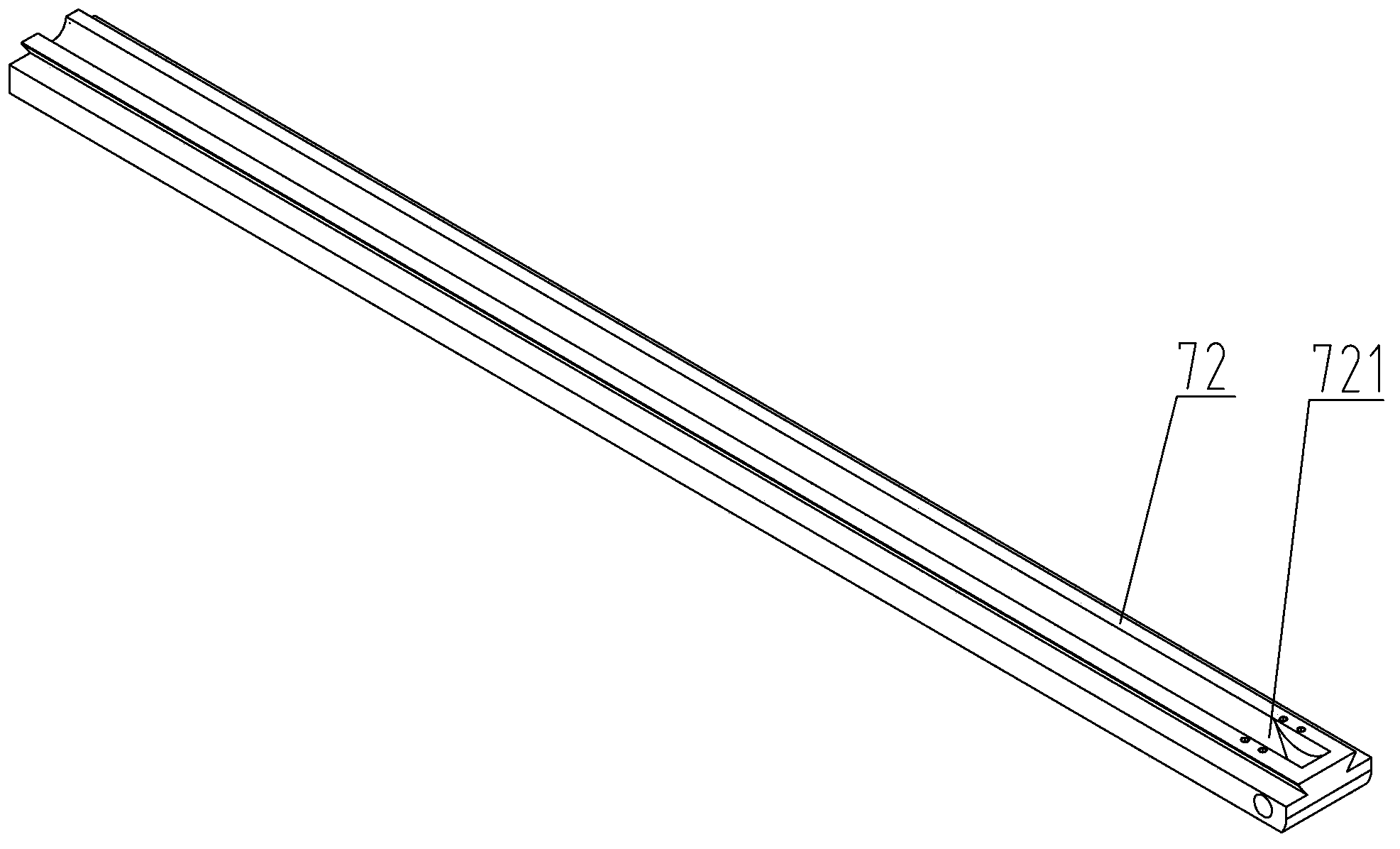

[0012] Such as figure 1 As shown, the device for assisting the boring machine to process long tapered through holes includes a connecting seat 1, a boring bar 2, a first support 31, a second support 32, a driving gear 4, a double gear 5, a transition gear 6, a guide plate 7, Lead screw seat 8, leading screw 9, knife seat 10, cutter 11, driven gear 12, inclined spacer 13, eyebolt 14, nut 15 and boring machine base 16.

[0013] Connecting seat 1 is concentric with the face plate of the boring machine, and is fixed on the face plate of the boring machine with screws. The boring bar 2 is concentric with the faceplate of the boring machine, and is fixedly connected with the connecting seat 1. The journals on both sides of the boring bar 2 are respectively supported by a first support 31 installed on the boring machine base near the faceplate end of the boring machine and a second support 32 away from the faceplate end of the boring machine, so that the boring bar 2 can be supporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com