Method for forming rod part of faucet lifting ring

A faucet and ring rod technology, applied in the direction of the valve device, etc., can solve the problems of high production difficulty and poor dimensional accuracy of the faucet lifting ring rod, and achieve the effect of saving materials and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

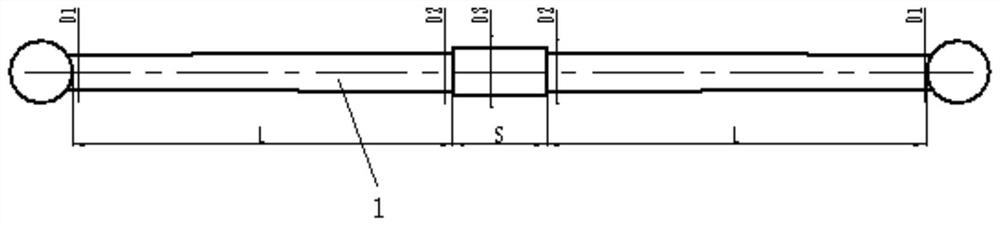

[0031] The present invention is a method for forming the rod part of the handle of the faucet, such as figure 1 As shown, the faucet lifting ring 1 includes a large platform, the two ends of the large platform are symmetrically provided with rods, and the end of the rod away from the large platform is symmetrically provided with a ball head;

[0032] Specifically follow the steps below:

[0033] Step 1, obtain the weight of the raw material according to the size of the faucet lifting ring 1, and cut the material according to the weight, heat it to the initial forging temperature of 1150-1180 °C, and keep it for 3 hours to obtain the blank;

[0034] Step 2, use the ball head forging die to cast the ball heads at both ends, and roughly forge the other remaining blanks to the size of the blank table;

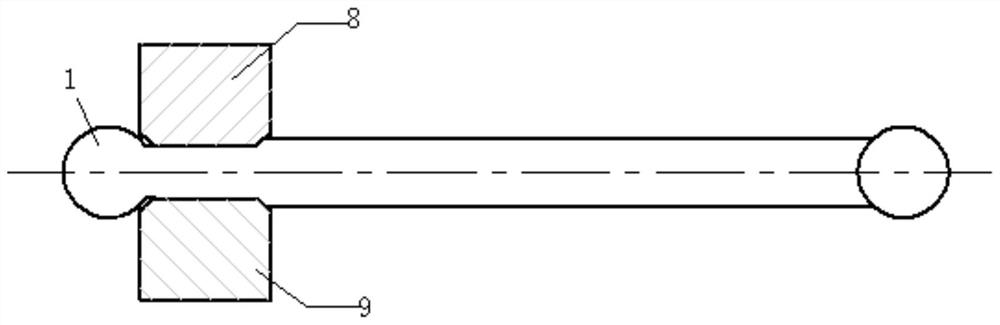

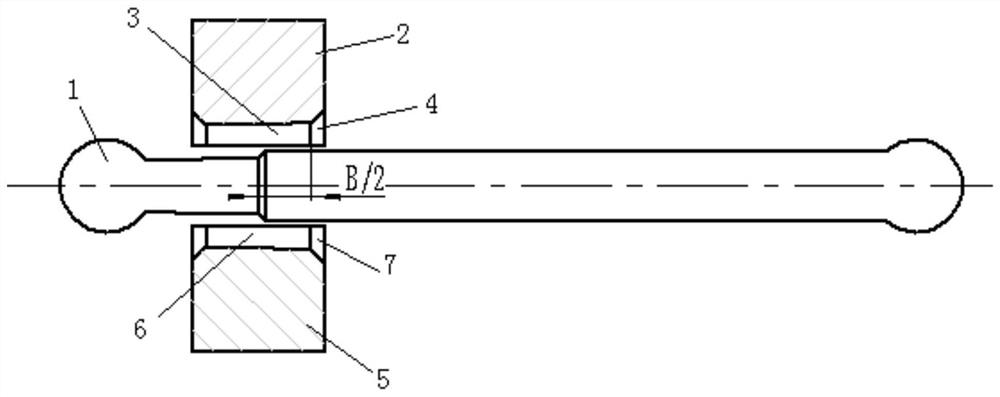

[0035] Such as figure 2 As shown, in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com