Wood plastic pavilion making method and wood plastic pavilion making tool

A technology for making tools and wood-plastic pavilions, which is used in small buildings, engine components, engine lubrication, etc., can solve the problems of inconvenient fixing of columns on the ground, heavy weight, and poor heat insulation effect of columns, and achieve good heat insulation effect. , light weight, easy to make effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

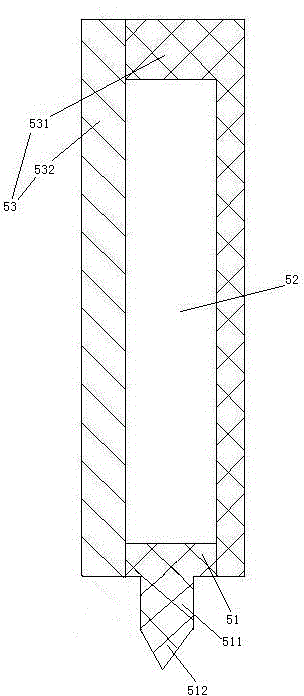

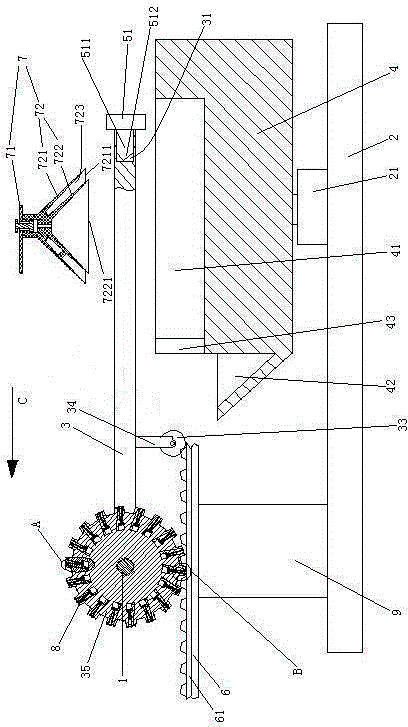

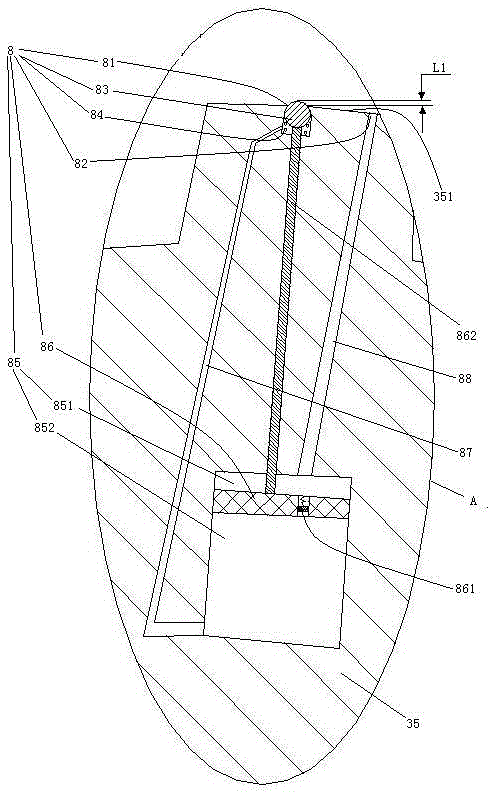

[0033] see figure 2 , a wood-plastic gazebo production tool, including a base 2, a tie rod 3, a core 51, a first workbench 4, a second workbench 6 and a fixed structure 7. The base 2 is provided with a lifting cylinder 21 and a shock absorbing rod 9 . The tie rod 3 extends in the left-right direction. The right end of the pull rod 3 is provided with a threaded hole 31 . The core 51 is provided with a threaded connecting rod 511 . The free end of the threaded connecting rod 511 is provided with a sharp point 512 . The threaded connecting rod 511 is threadedly connected in the threaded hole 31 to fix the core 51 and the tie rod 3 together. The middle part of the pull rod 3 is also provided with a balance roller 33 . The balance roller 33 is connected with the pull rod 3 through a support rod 34 . The balance roller 33 is supported on the second wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com