Numerical control hydraulic spiral vertical broaching machine

A vertical broaching and helical technology, applied in the field of broaching, can solve the problems of low machining accuracy, complicated calculation of gears, poor product coaxiality, etc., and achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

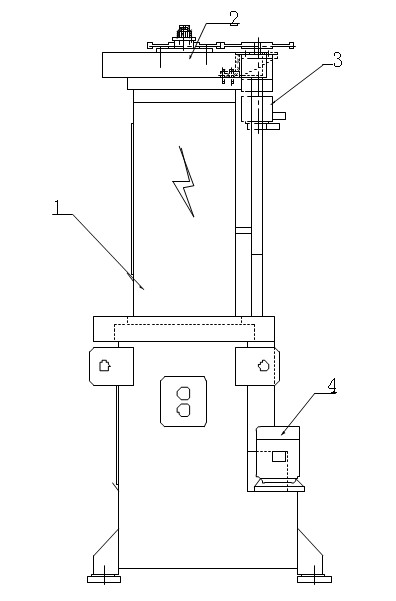

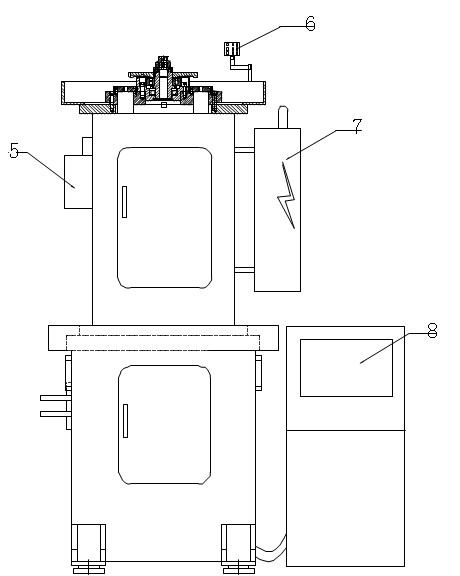

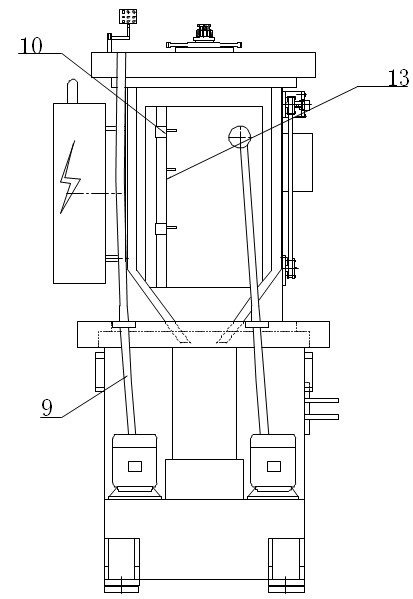

[0014] As shown in the figure, it includes: bed 1, face plate 2, servo motor 3, water pump 4, oil pump 5, control panel 6, electrical box 7, system control box 8, water pipe 9, proximity switch 10, reducer 11, gear 12. Encoder 13.

[0015] The principle of the present invention: the servo motor 3 controls the rotation speed and direction of the workpiece, the workbench uses hydraulic transmission, the broach reciprocates up and down, the encoder 13 monitors the running speed and position of the broach, and the position of the broach is fed back to the servo motor 3, The servo motor 3 adjusts the rotational speed of the workpiece again.

[0016] Due to the requirement of high coaxiality of the helical spline, first of all, the vertical broaching method with high processing quality and stable hydraulic system are used as the basis for the design. Design a fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com