Shaft centrifugal type clamp

A centrifugal, fixture technology, applied in the mechanical field, can solve the problem of time-consuming clamping of workpieces, and achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

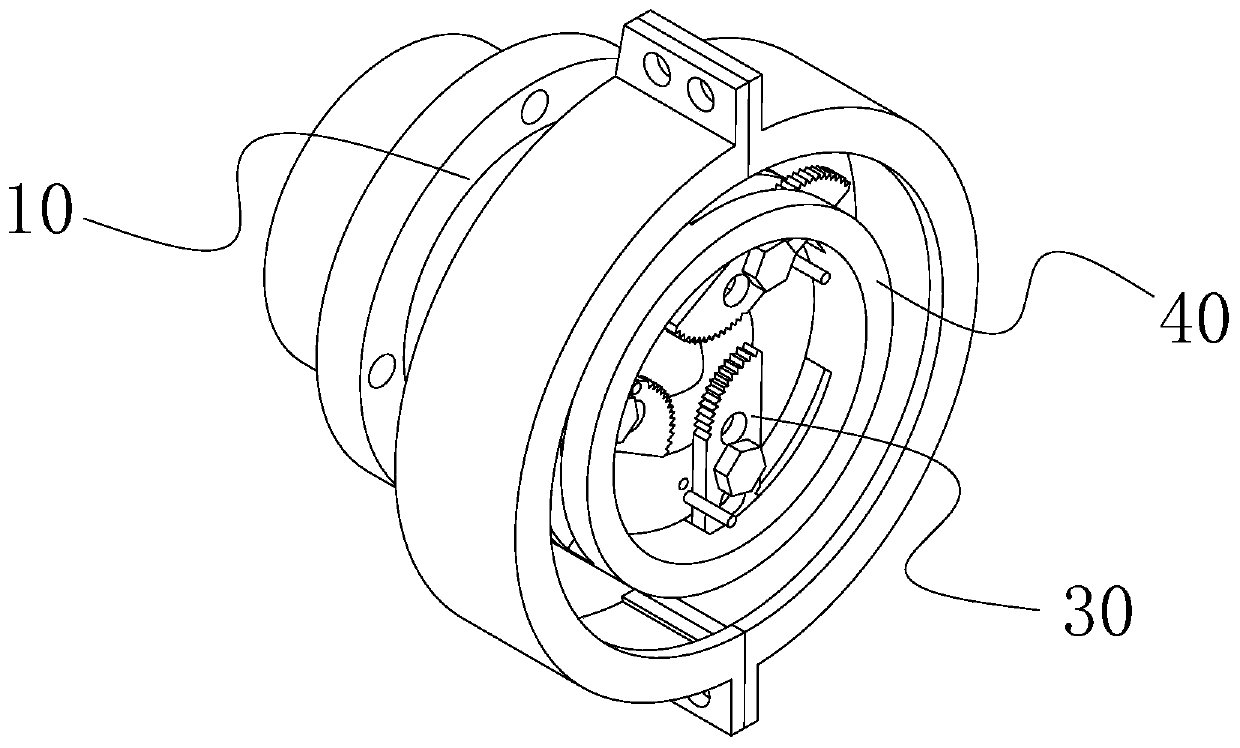

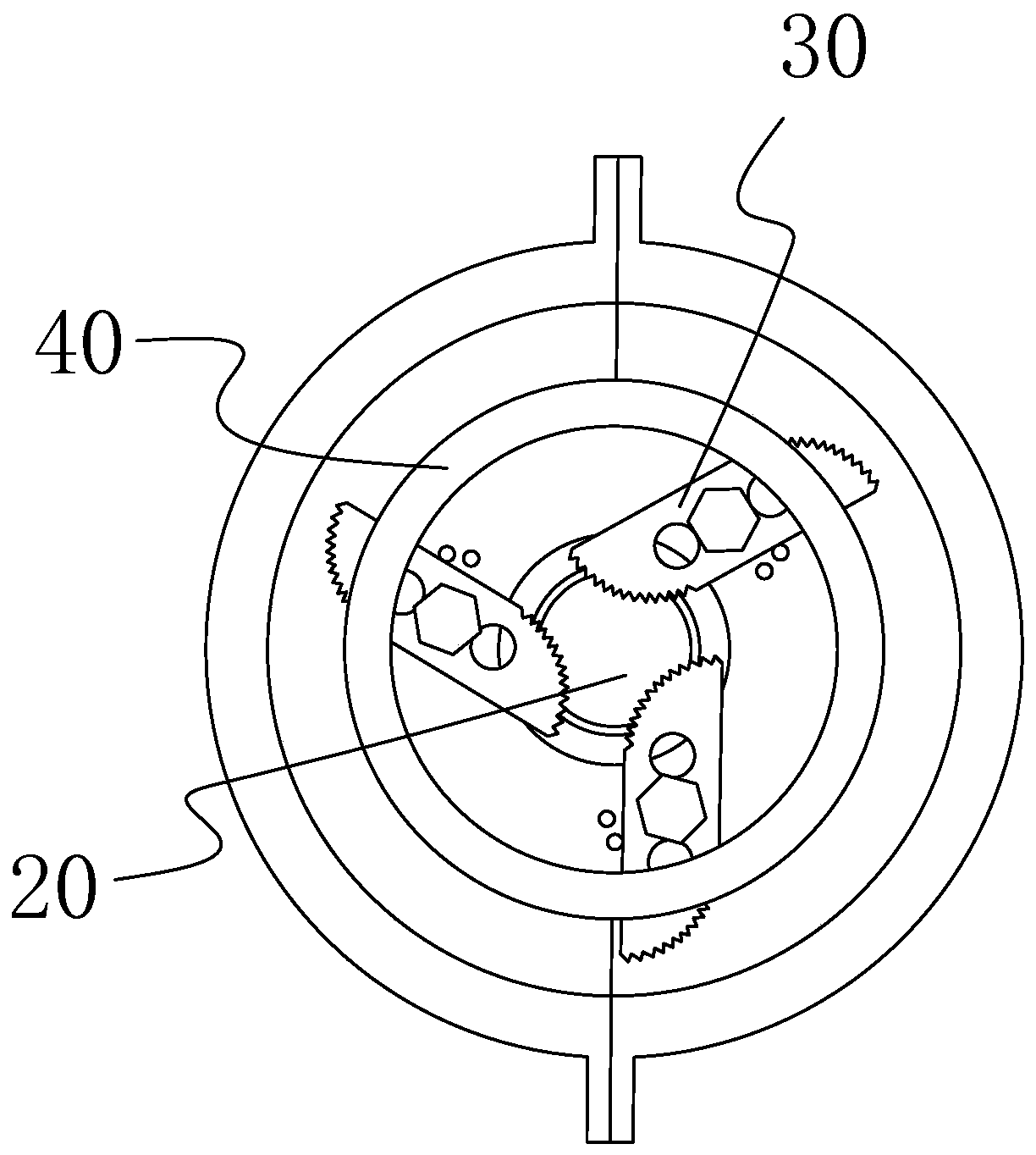

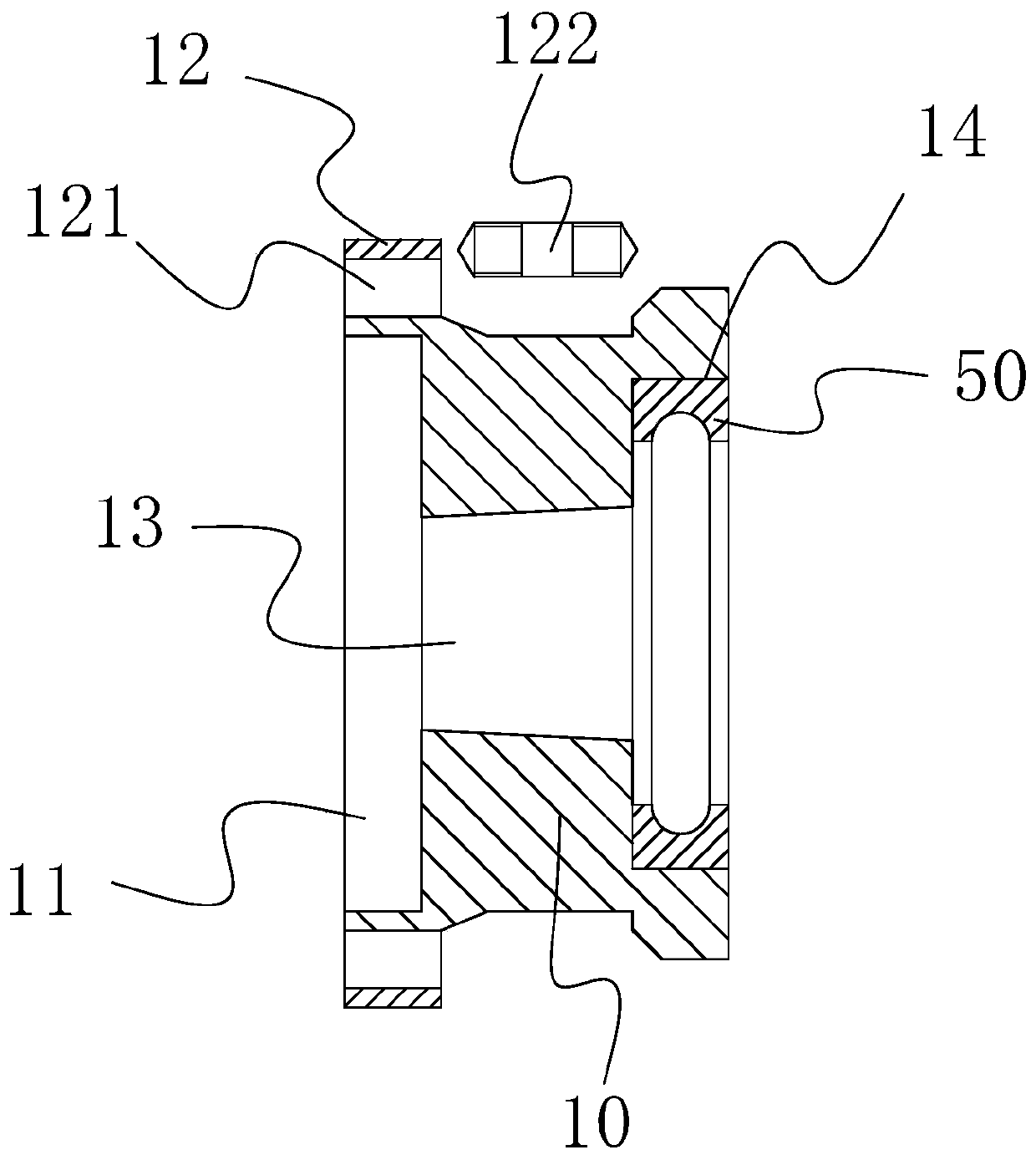

[0031] see Figure 1 to Figure 6 , The present embodiment provides a shaft type centrifugal clamp, including a faceplate 10 , a rotating center 20 , a jaw mechanism 30 , a sliding seat 40 and an annular fixing seat 50 . The faceplate is a hollow structure as a whole, with shoulders at both ends. A connection groove 11 is provided at one end of the faceplate. The connection groove is used for socketing with the spindle of the lathe, and a threaded hole 121 is punched on the shoulder 12 at one end of the connection groove. A plurality of threaded holes are arranged in a circle on the shaft shoulder with one end of the connecting groove, and then the faceplate is locked on the lathe spindle with fixing bolts 122. In this embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com