Lathe bed and disc chuck temporary heating control device for warp knitting machine

A technology of heating device and machine body, which is applied in the direction of auxiliary controller with auxiliary heating device and electric temperature control, etc., which can solve the problems of cumbersome wiring, heavy workload, and bulky main electrical cabinet, etc., and achieve small size , easy to move, high application flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

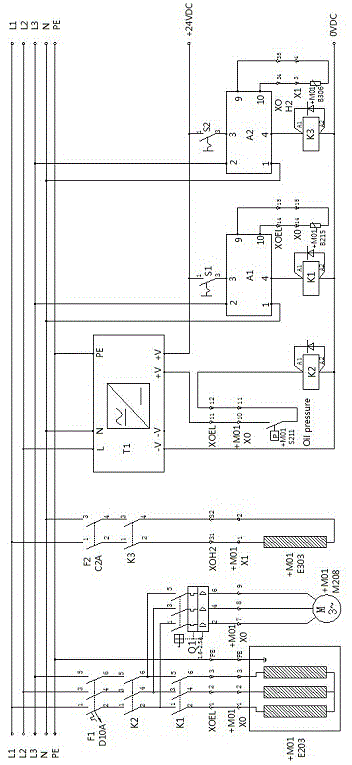

[0014] Such as figure 1 It is a structural schematic diagram of the present invention, a temporary heating control device for warp knitting machine body and faceplate, including three-phase power supply, bed heating device E203, faceplate heating device E303 and circuit control device. The circuit control device includes DC 24V power supply T1, bed Body temperature controller A1 and faceplate temperature controller A2, DC 24V power supply T1 is provided with power interface and output terminal, bed temperature controller A1 is provided with port 1, port 2, port 3, port 4, port 9 and port 10, The flower plate temperature controller A2 is provided with port 1', port 2', port 3', port 4', port 9' and port 10', the bed heating device is connected to the 380V voltage of the three-phase power supply, the bed heating device E203 is connected to all Connect the contactor K1, contactor K2 and 3P miniature circuit breaker in series between the 380V voltage of the three-phase power suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com