Workbench structure of a vertical inner broaching machine

A technology of workbench and internal broaching machine, which is applied in the direction of manufacturing tools, metal processing, planer/slotting machine, etc. It can solve the problems of safety hazards, production efficiency, no additional functions, time-consuming and labor-intensive problems, and achieve saving unloading and cleaning time, The structure is simple and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

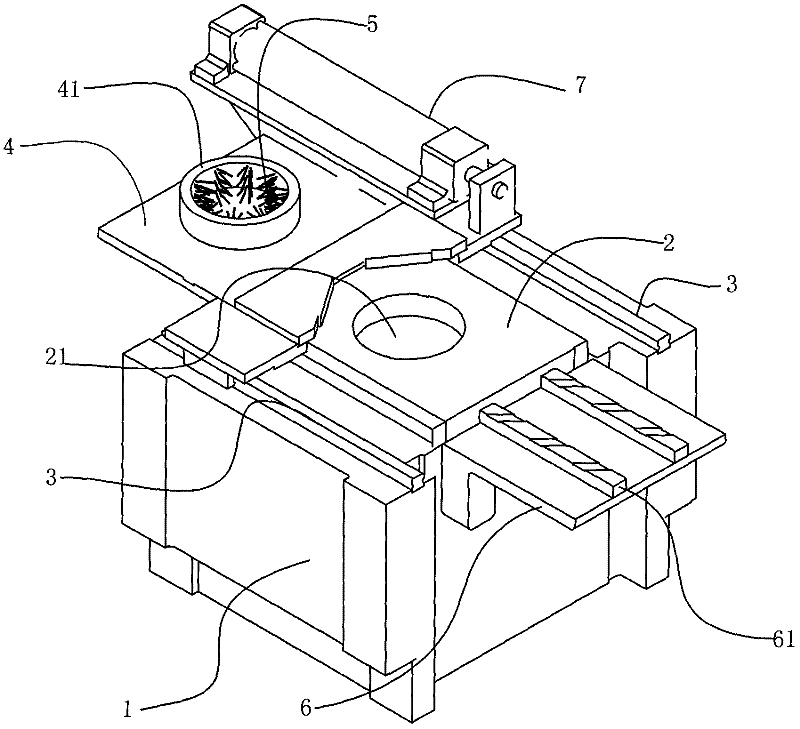

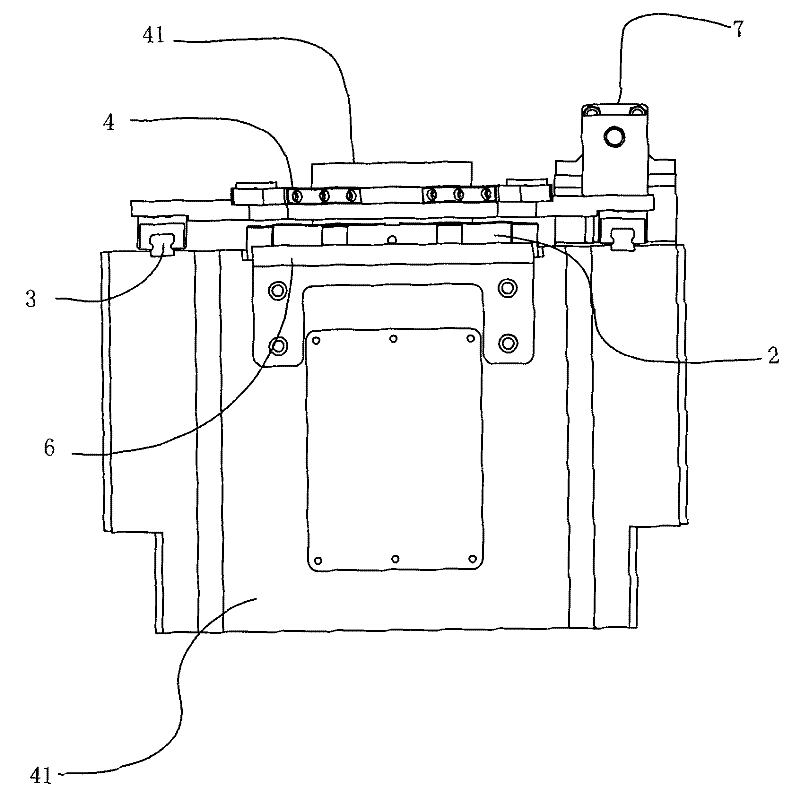

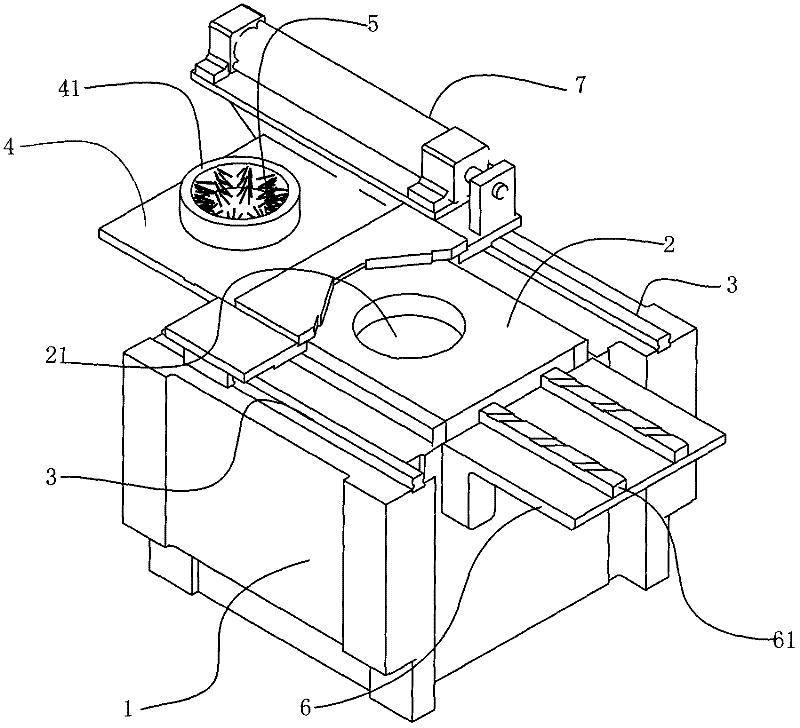

[0012] The workbench structure of vertical inner broaching machine of the present invention, as Figure 1-2 As shown, it includes a workbench body 1 and a faceplate 2 located on the workbench body 1. The faceplate 2 has a through hole 21 for a broach to pass through. The workpiece to be processed is placed on the face plate 2 .

[0013] On the workbench body 1, guide rails 3 are provided on the left and right sides of the faceplate 2, and a pusher plate 4 is provided above the faceplate 2. The pusher plate 4 cooperates with the guide rail 3 to perform horizontal reciprocating movement along the guide rail 3, covering The faceplate 2 may be located at the rear side of the faceplate 2 . The pushing plate 4 also has a hole 41 matching the through hole 21 on the faceplate 2 , and a ring of bristles 5 is arranged on the inner peripheral surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com