Efficient coal cutter

A coal mining machine, high-efficiency technology, applied in the direction of earth drilling, cutting machinery, propulsion, etc., can solve the problem of troublesome replacement of guide shoes, and achieve the effect of prolonging life, prolonging service life and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

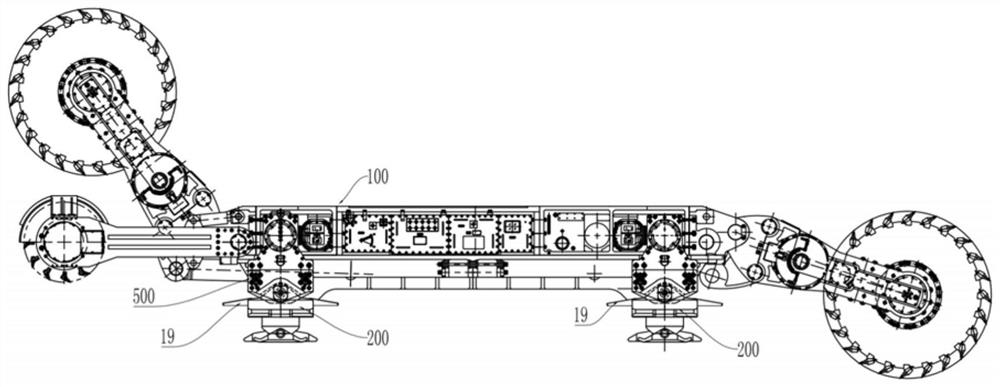

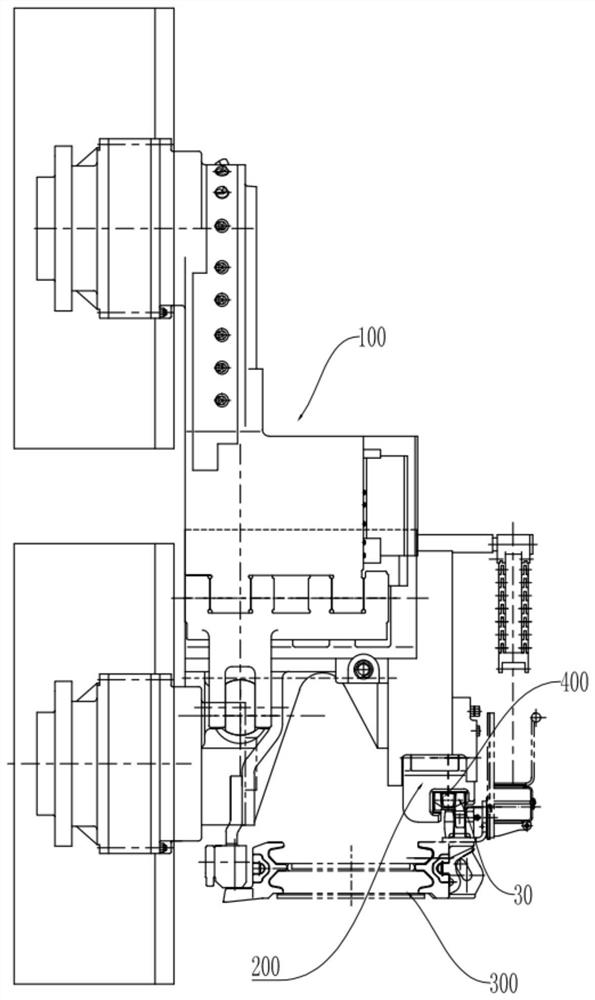

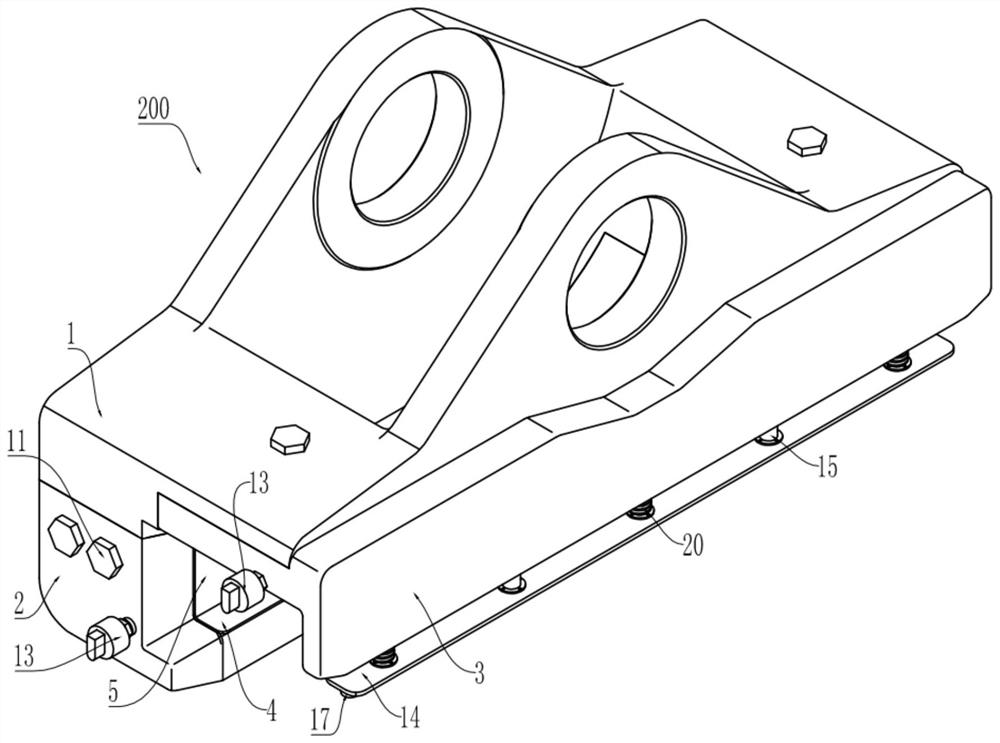

[0047] The embodiment is basically as attached Figure 1 to Figure 11 Shown:

[0048] combine Figure 1 to Figure 5 , a high-efficiency coal mining machine, including a coal mining machine body 100 and a guide shoe 200 supporting the coal mining machine body 100, the guide shoe 200 includes a shoe body 1 and wear parts connected to the shoe body 1 by screws , the wear parts include a first wear block 2 and a second wear block 3, the first wear block 2 and the second wear block 3 enclose the pin row 30, and the first wear block 2 is welded with a bottom resistance Grinding plate 4 and left wear-resistant plate 5, top wear-resistant plate 6 and right wear-resistant plate 7 are welded on the second wear-resistant block 3, bottom wear-resistant plate 4 is positioned at top wear-resistant plate 6 below, left wear-resistant plate 5 and The right wear plate 7 is opposite, and the first wear block 2 is close to the coal transport chain plate of the conveyor 300; the bottom wear plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com