A large-scale rotating body steel casting transport cleaning and displacement tooling

A technology for revolving bodies and steel castings, which is applied in the field of transfer cleaning and displacement tooling for large-scale revolving body steel castings. It can solve problems such as inability to adjust, inability to achieve reasonable width adjustment, and inconvenient cleaning of sliding track residues, etc., to achieve improved The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

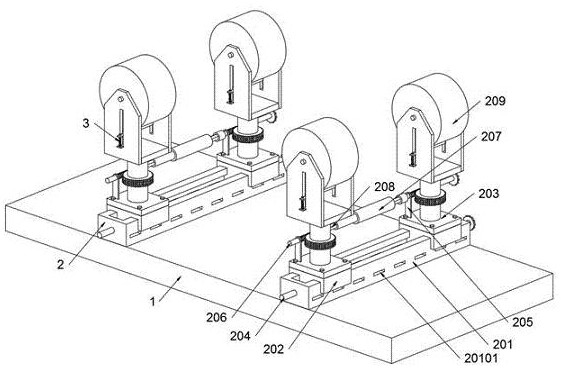

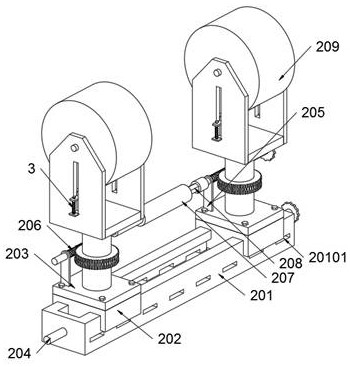

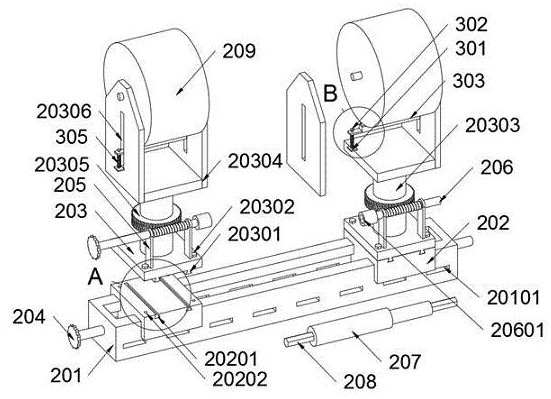

[0032] as attached figure 1 To attach Figure 7 Shown:

[0033] The present invention provides a tooling for cleaning and displacing large-scale revolving steel castings, including a base 1 and a rotating seat 20304; two tooling structures 2 are installed on the base 1, and a cleaning structure 3 is installed on each tooling structure 2 ; referenced as figure 2 and image 3 , the tooling structure 2 includes a connecting seat 20601, an elastic telescopic rod 207 and a connecting head 208. There are two connecting seats 20601, and the two connecting seats 20601 are respectively welded on two adjustment rods 206; the head ends of the elastic telescopic rod 207 and the A connecting head 208 is welded at the tail end, and the connecting head 208 is matched with the connecting seat 20601, and the two connecting heads 208 are plugged and connected with the two connecting seats 20601, so that after the position adjustment of the two sliding seats 202, it can still realize Synchron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com