Valve body shaft hole machining clamping mould

A valve body and shaft hole technology, applied in the field of valve body shaft hole machining molds, can solve the problems of inconvenient positioning, difficult processing and positioning, etc., and achieve the effects of simple structure, convenient processing, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

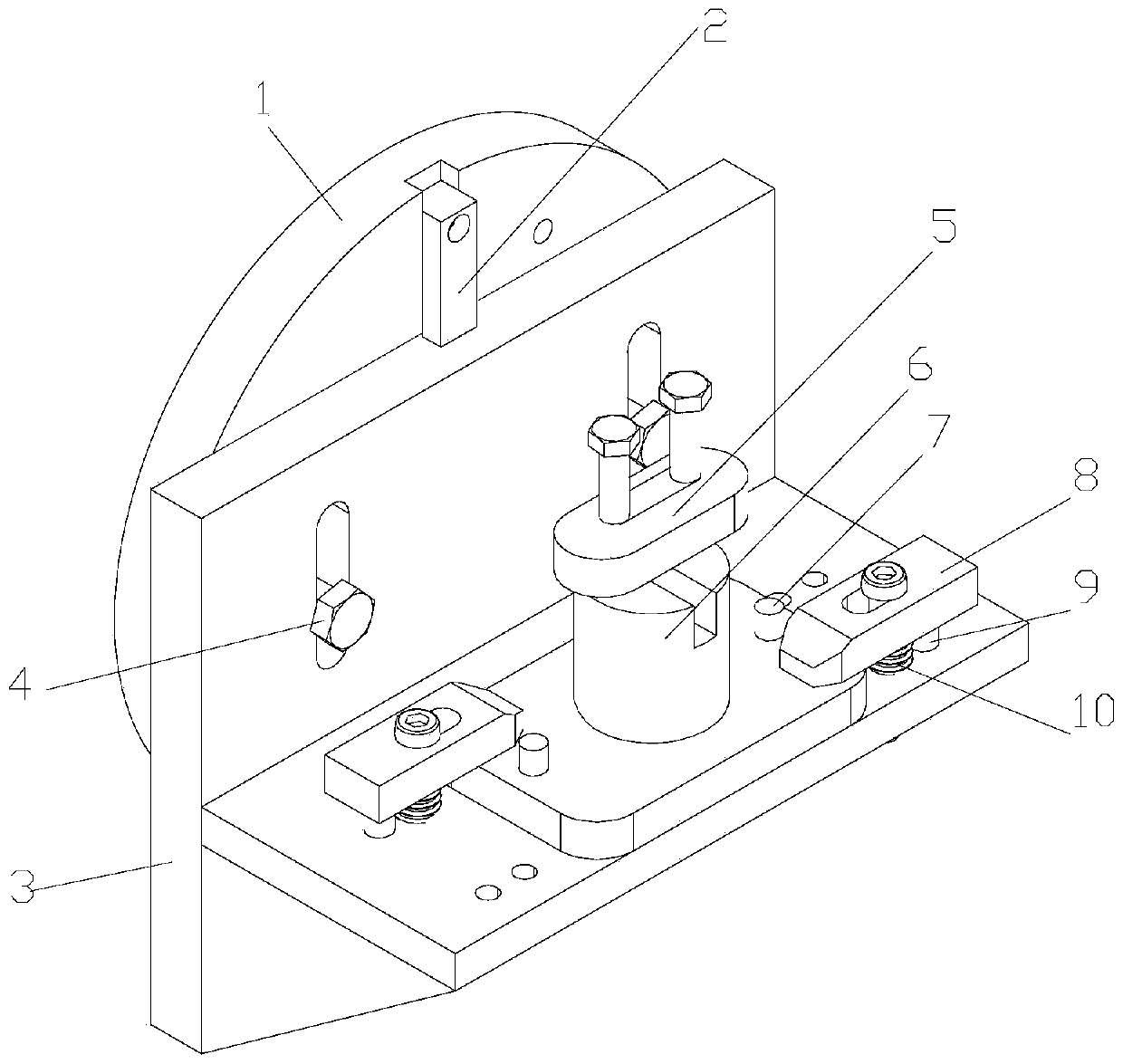

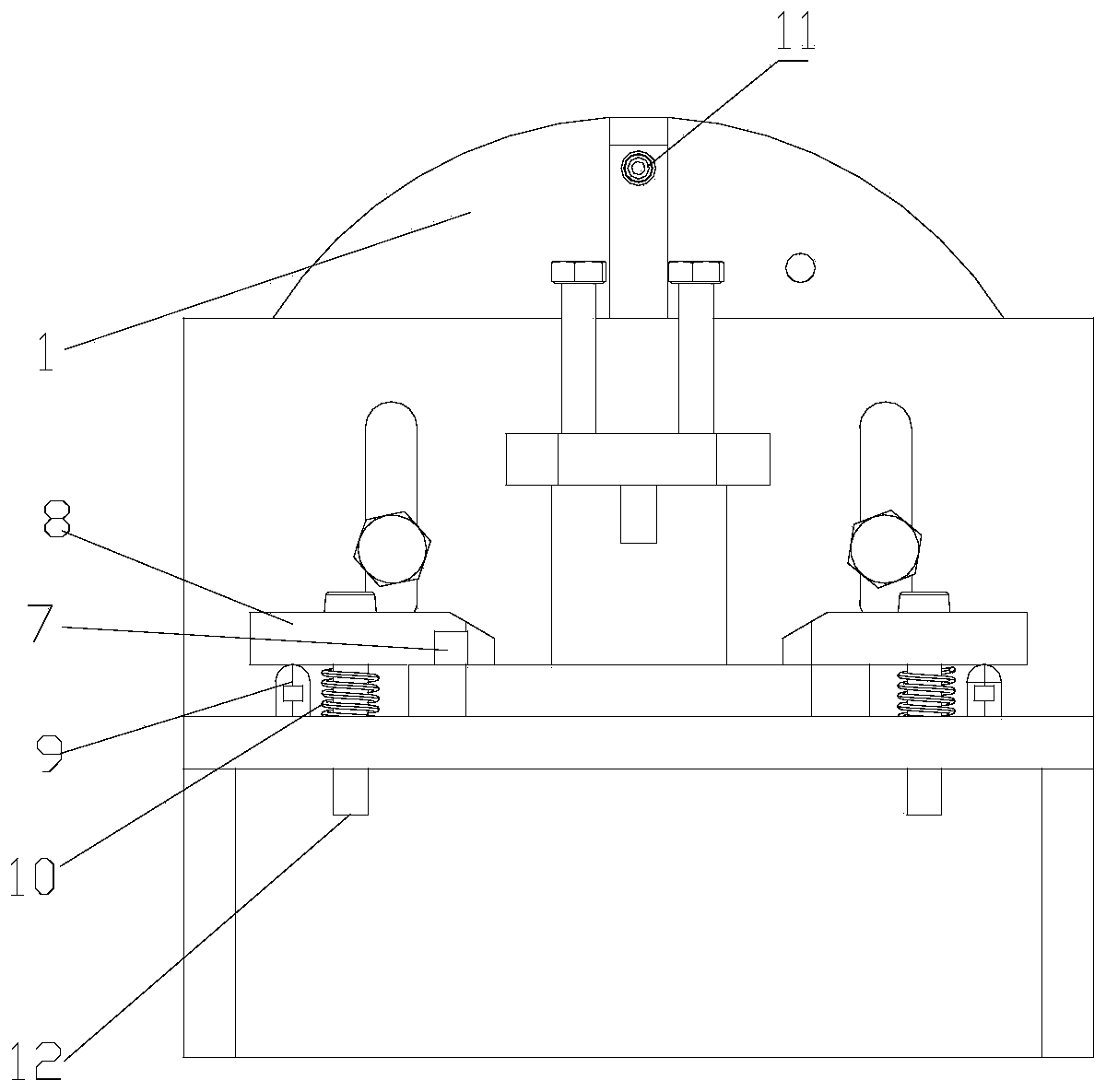

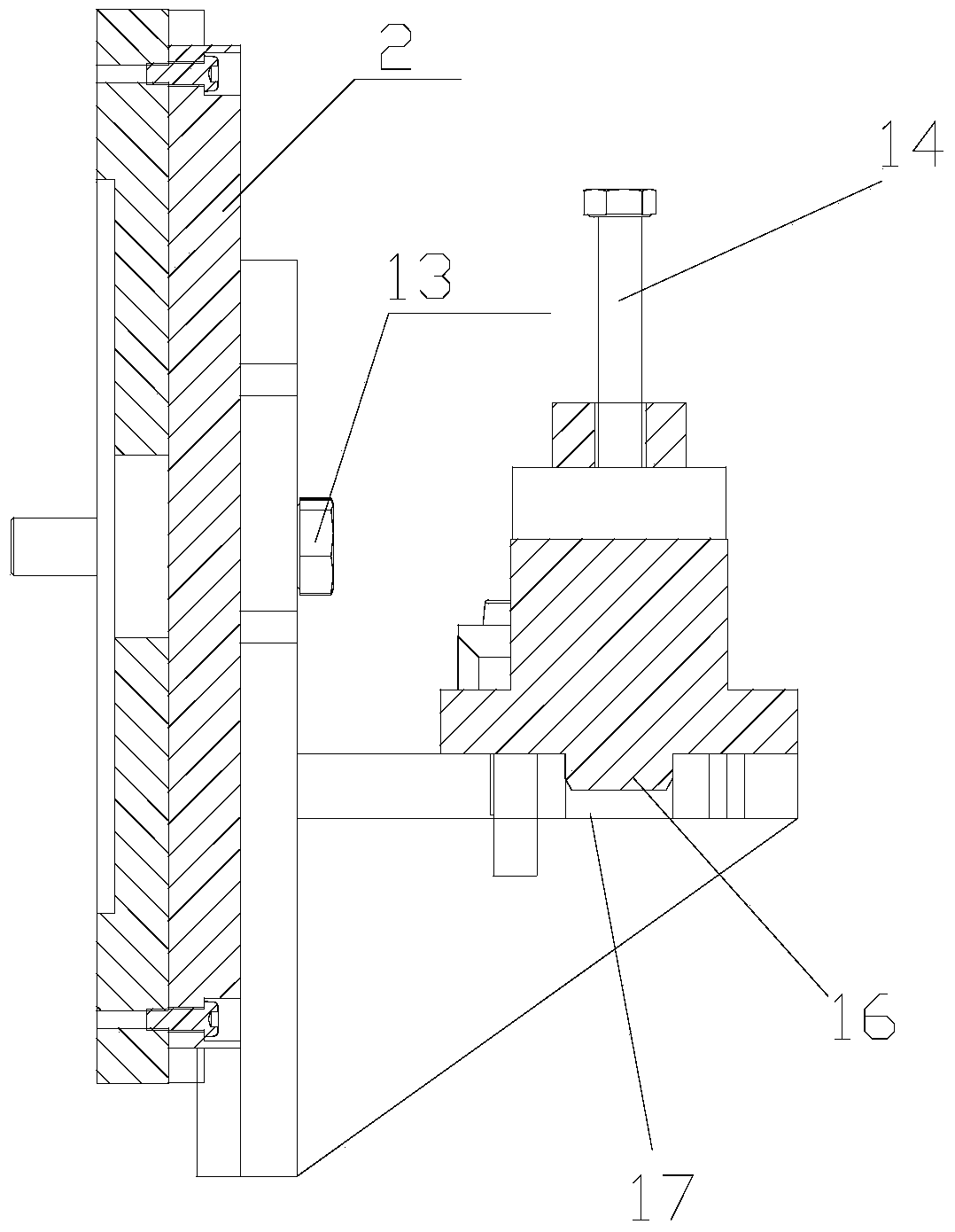

[0016] Such as Figure 1-5 As shown, a valve body shaft hole processing tire of the present invention includes a T-shaped positioning plate 3 assembled with a lathe faceplate 1 through a guide rail 2, and a T-shaped structure is installed on the flat part of the T-shaped positioning plate. The rotating body 6, the rotating body has a cylindrical portion that is matched with the valve body to be processed and a bottom plate connected with the cylindrical portion, the bottom of the bottom plate forms a circular hole 17 on the flat surface that can be rotatably fitted together Bottom boss 16, described plane part is provided with rotating body pressure plate 8, to press described rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com