Roller drive plate clamping tool

A roll and disc clamping technology, which is applied in the field of roll dial fixtures, can solve the problems of laborious hoisting and positioning, troublesome positioning, etc., and achieve the effects of simple structure, convenient manufacture and use, and saving auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

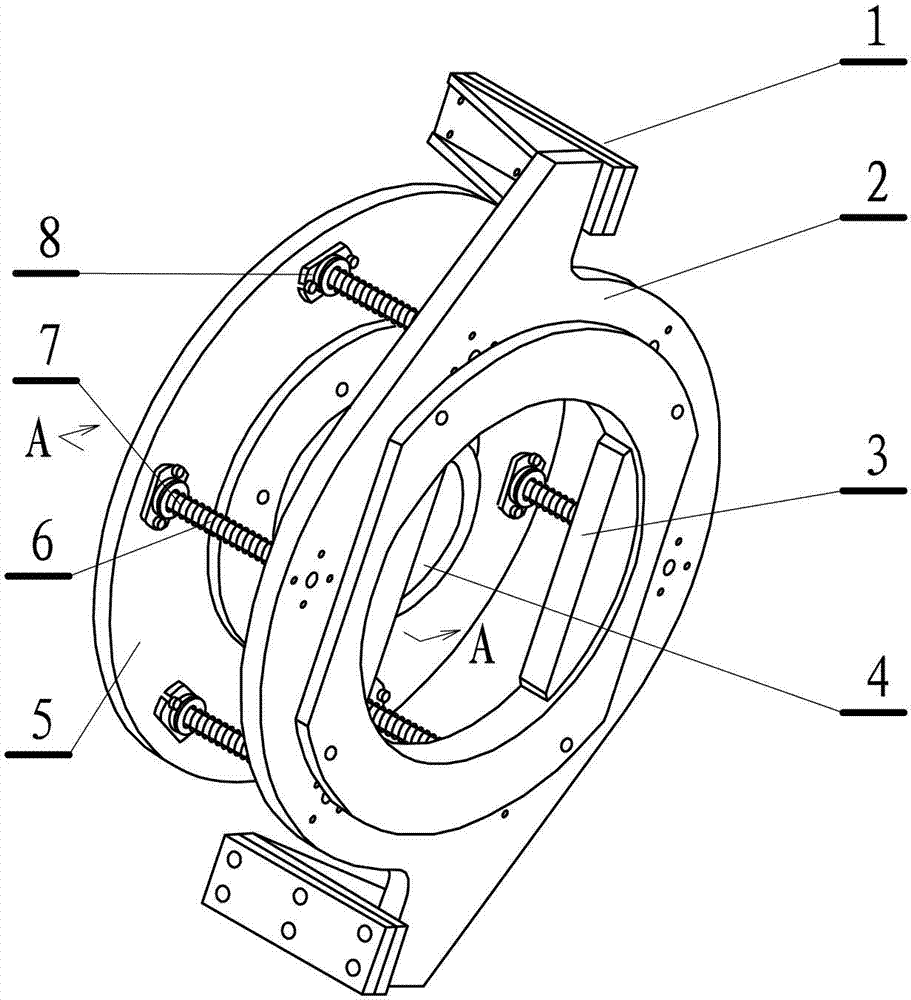

[0010] This embodiment is a roll dial fixture, such as figure 1 shown. This embodiment includes: a disk-shaped sheet-shaped driving disk 2, the outer circumference of the driving disk has a driving claw 1 that matches the shift fork on the main shaft of the roll grinder, and the middle part of the disk is a driving claw that matches the roll driving handle. Holes 3, one end of the driving disc is evenly distributed and fixedly connected to one end of a plurality of support rods 6, and the other end of the support rods passes through the disc-shaped sheet-shaped support disc 5 to set a limit end 9. Springs 7 are sheathed on the support rods, flexible connectors 8 are provided between the support discs and each support rod, and the support discs are connected to the main shaft of the roll grinder through bolts.

[0011] This embodiment is mainly composed of three parts, a support plate fixed on the faceplate of the main shaft of the roll grinder, a drive plate for driving the r...

Embodiment 2

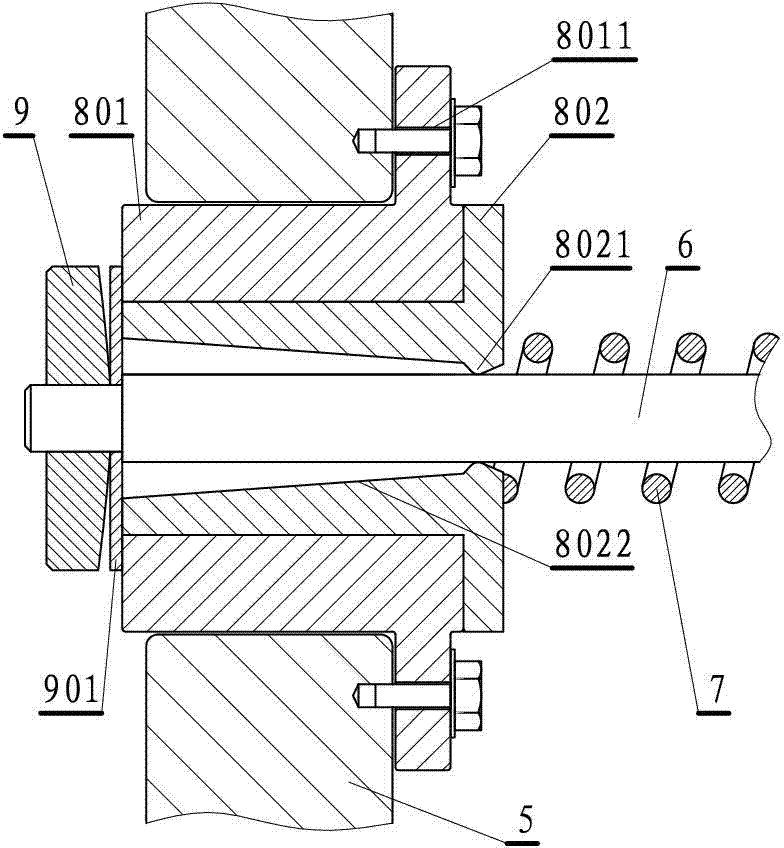

[0021] This embodiment is an improvement of Embodiment 1, and it is a refinement of the embodiment about the flexible connector, such as figure 2 shown. The flexible connector in this embodiment is composed of a fixed sleeve 801 and a guide sleeve 802, the fixed sleeve has a bolt hole 8011 connected with the support plate, the fixed sleeve is fixedly connected with the guide sleeve, The center of the guide sleeve passing through the support rod is a conical hole 8022 with a large port and a small port. The small opening end of the conical hole is provided with a limit ring 8021. The cross-sectional shape of the limit ring is an oblique triangle. The vertices of the oblique triangles are intercepted and replaced by arcs.

[0022] The fixing sleeve described in this embodiment has a mounting claw, and the mounting claw has holes or notches for fixing bolts, and can be fixed on the support plate through the bolts.

[0023] The inner sleeve is the key of the flexible connection...

Embodiment 3

[0026] This implementation is an improvement of the above-mentioned embodiment, and it is a refinement of the above-mentioned embodiment with regard to the limiting end. The contact surface of the limiting end described in this embodiment and the support plate is a circular arc surface, see figure 2 , or a conical surface.

[0027] The arc surface or conical surface limit end described in this embodiment mainly solves the problem of removing the wear between the limit end and the support plate (actually it should be a guide sleeve) due to the swing when the support rod swings. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com