Special clamp of irregular workpieces

A technology for special fixtures and special-shaped workpieces, which is applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems of heavy workload, cumbersome disassembly and assembly process, time-consuming and labor-intensive, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

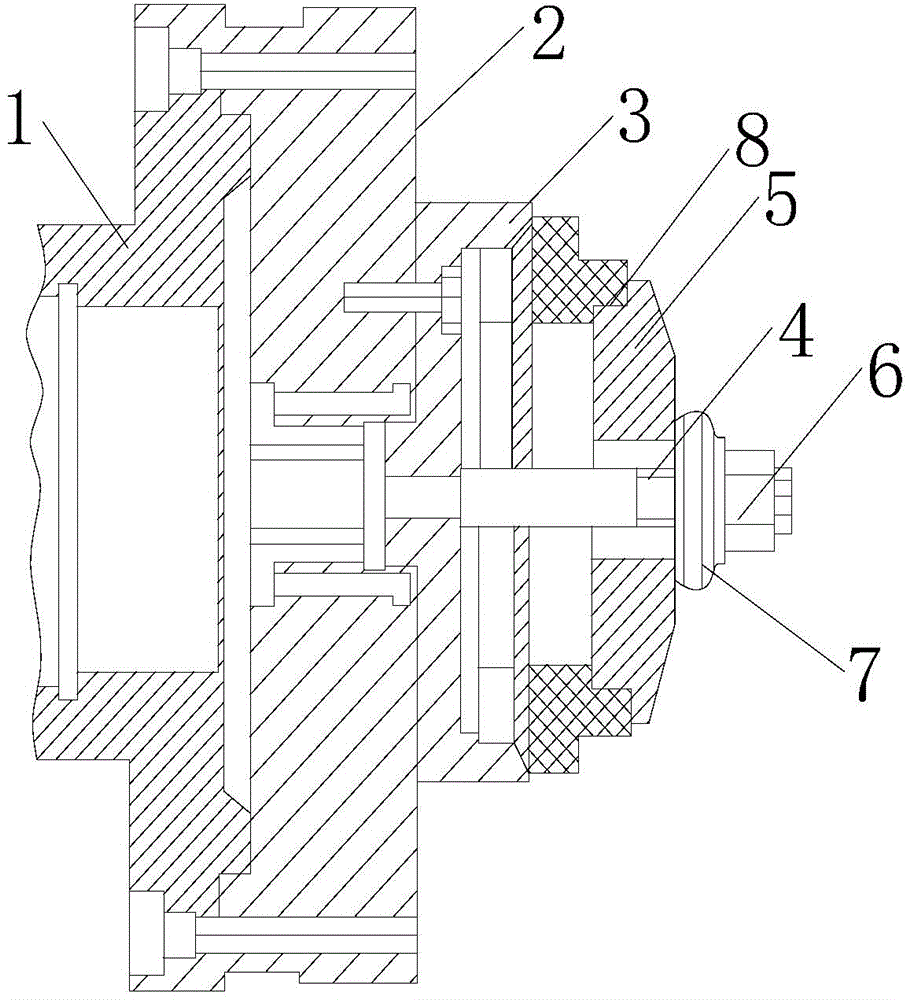

[0010] Such as figure 1 As shown, the special fixture for special-shaped workpieces includes, from left to right, an annular transition plate 1, an annular faceplate 2 connected with the transition plate 1, and a clamping device connected with the faceplate; the clamping device includes a sleeve at the left end The support sleeve 3 in the faceplate, the screw 4 that runs through the support sleeve, the pressure plate 5 that is sleeved on the screw 4, and the washer 7 and the nut 6 that are sleeved on the right end in turn; The compression step part 8.

[0011] When in use, because the screw is installed in the support sleeve, and the support sleeve is installed in the faceplate, the screw is fixed on the faceplate indirectly; and because the pressure plate set on the screw is provided with a compression step, the entire step surface of the workpiece is in line with the pressure plate. The tight step contact not only prevents the workpiece from moving axially, but also prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com