Press-mounting device for rectification window of aviation turbine cooler and press-mounting method

An aviation turbine and press-fitting device technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of easy tearing of the sealing ring installation groove, easy cutting of the sealing ring, uneven force, etc. Achieving good scientificity, ensuring installation quality and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

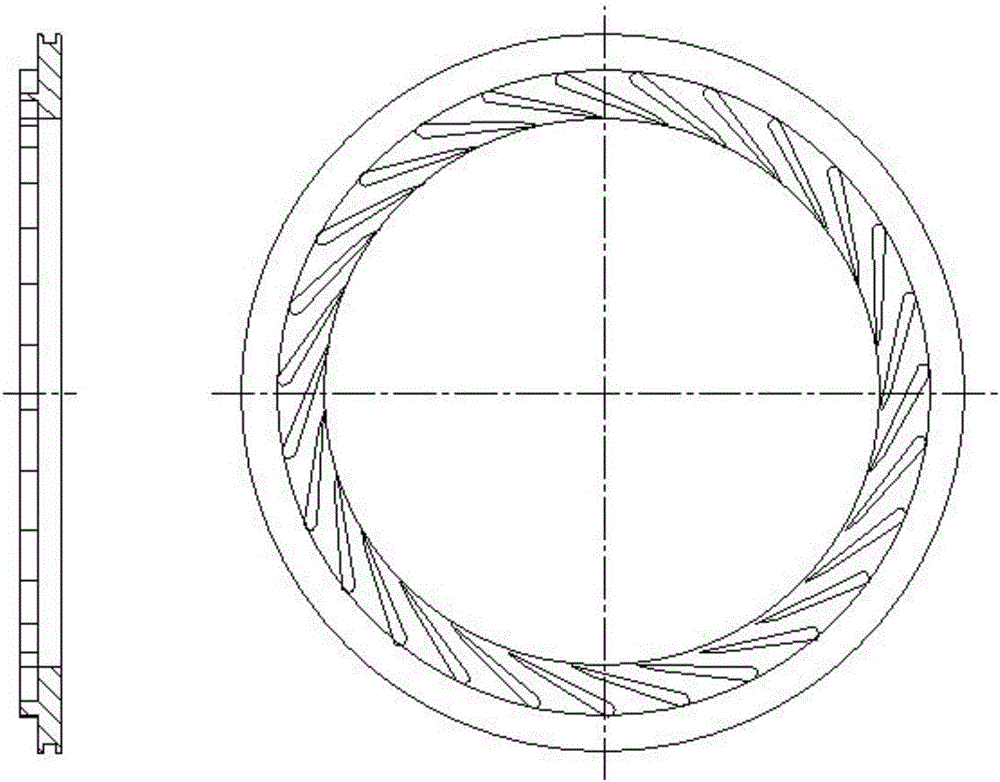

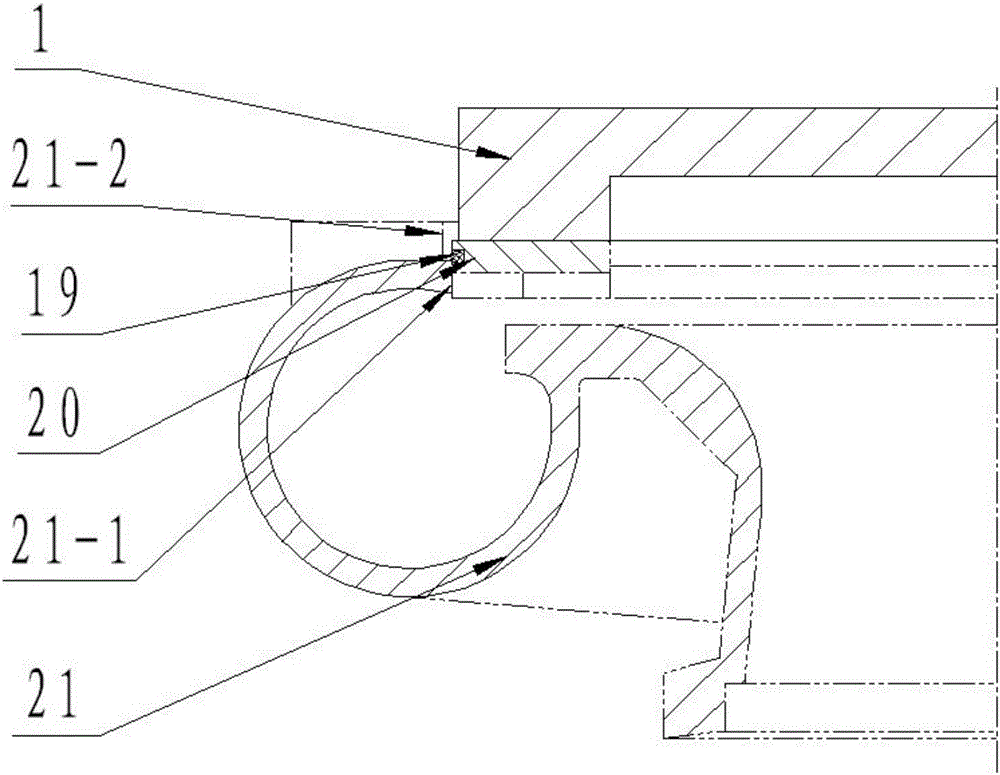

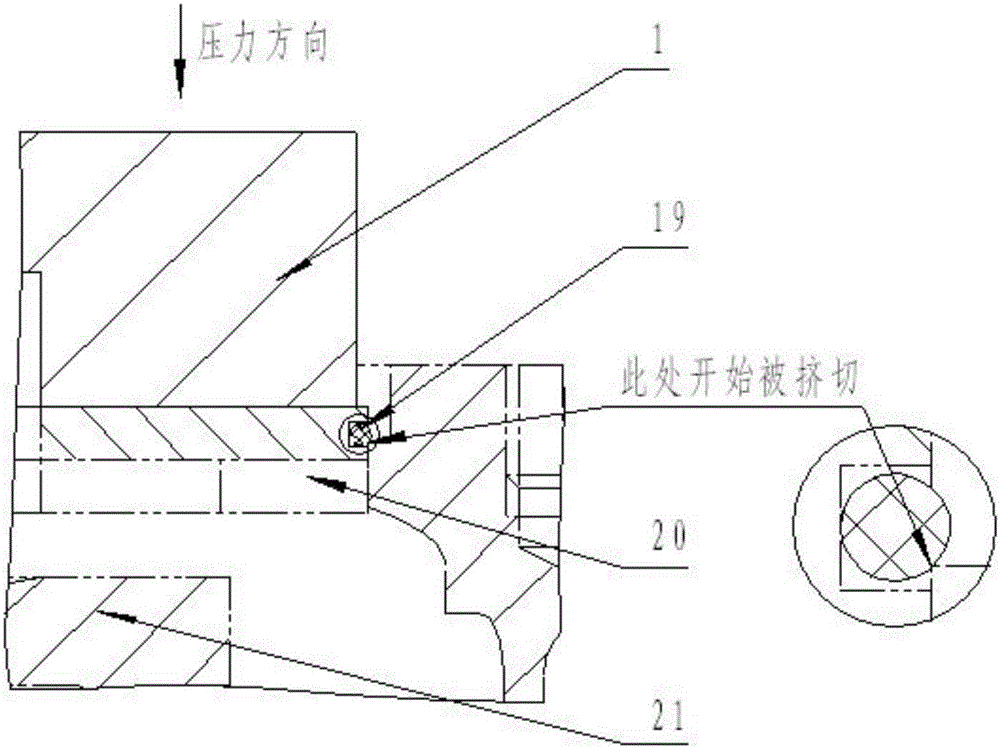

[0054] Example 1: requires an assembly such as Figure 1-2 The rectification window shown is A20 when the

[0055] Select the corresponding guide mechanism 6 according to the figure numbers of the rectifying window A20 and the turbine cover A21, and check whether the surface of the guide mechanism 6 and the sealing ring A19 will be in contact with or not; Enter the screw B18 to make it consistent with the height of the guide 8 and block the guide 8; loosen the nut A10 on the pressure rod 7, and adjust the radial position of the pressure rod 7 according to the size of the rectification window A20, so that the guide mechanism 6 can be set on all On the pressure rod 7, make the pressure rod 7 fit the inner hole A6-4 of the guide mechanism 6, tighten the nut A10 on the pressure rod 7; withdraw the screw B18 to separate it from the guide 8; put the rectifying window A20 Place the assembly parts with the seal ring A19 in the guide mechanism 6, and place the guide mechanism 6 on the...

Embodiment 2

[0056] Example 2: requires an assembly such as Figure 11-12 The rectification window shown is B23 when the

[0057] (1) The nozzle on the rectifying window B23 is fully open along the circumference ( Figure 11 ), so it is installed with the turbine cover B24 ( Figure 12 ) when there is no angular positioning requirement;

[0058] (2) The turbine cover B24 has a 24-1 inner hole for installing the rectifying window B23, and another group of 24-2 threaded holes related to the axial position of the 24-1 inner hole, providing a guide mechanism B ( Figure 13 ) positioning benchmark.

[0059] (3) Guide mechanism B ( Figure 13 ) consists of a positioning piece B25, a guide B26, and a screw 27. The angle of the guide B26 taking the conical surface 26-2 bell mouth is 30°, and the radius of the 26-1R profile is 4 of the cross-sectional diameter of the seal ring 22 φ2.5 The times are R10, the 26-3 inner hole is consistent with the size and precision of the 24-1 inner hole where ...

Embodiment 3

[0063] needs to be assembled as Figure 15-16 When the rectification window C30 is shown:

[0064] (1) The nozzle on the rectification window C29 is divided along the circumference ( Figure 15 ), so there is an angular positioning requirement when it is installed with the turbine cover C30;

[0065] (2) The turbine cover C30 has a 30-1 inner hole for installing the rectifying window C29, and another group of 30-2 threaded holes related to the axial position of the 30-1 inner hole, providing a guide mechanism C ( Figure 17 ) positioning benchmark.

[0066] (3) The guide mechanism C is composed of a positioning piece C31, a guide C32, a screw 33, a positioning block 34, a positioning screw 35, a nut 36, a positioning screw pile 37, a nut 38, and a positioning pin 39. The guide C32 takes a conical surface 32- 2 The angle of the bell mouth is 30°, 32-1, the radius of the R-shaped surface is 5 times of the cross-sectional diameter φ2 of the sealing ring 28 is R10, and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com