Stirrer

A technology of stirrer and stirring plate, which is applied in the direction of mixers with rotating stirring devices, chemical instruments and methods, dissolution, etc., can solve the problems of long stirring time, reduced stirring effect, and failure to achieve stirring, etc., to achieve increased stirring The effect of increasing the number of times, stirring efficiency, and improving the stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

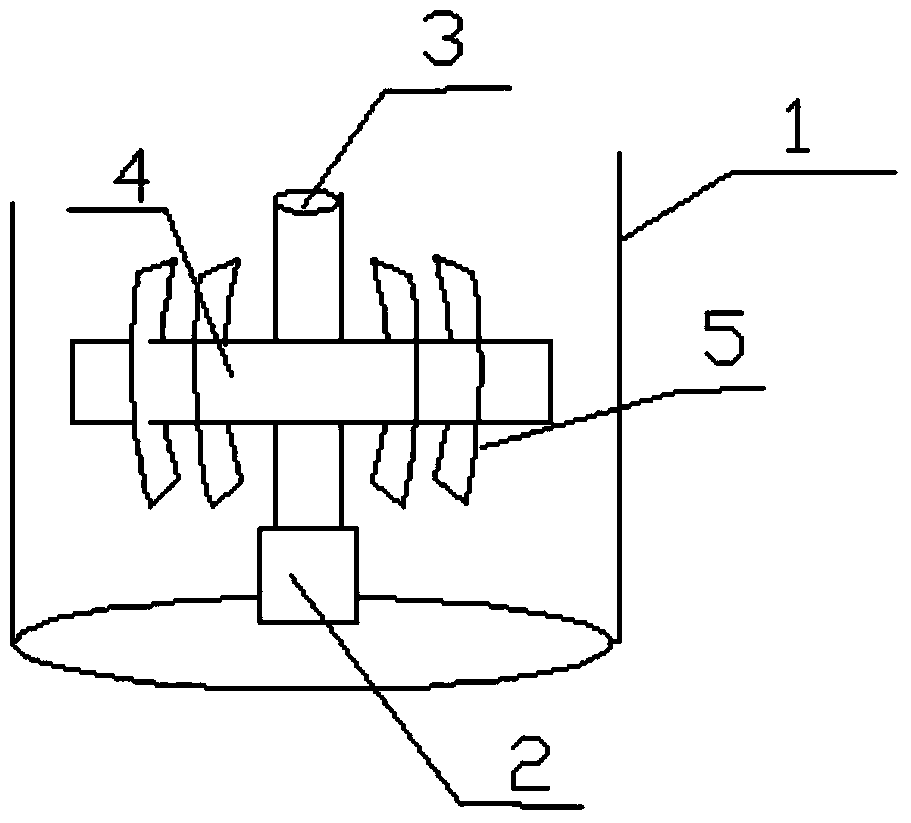

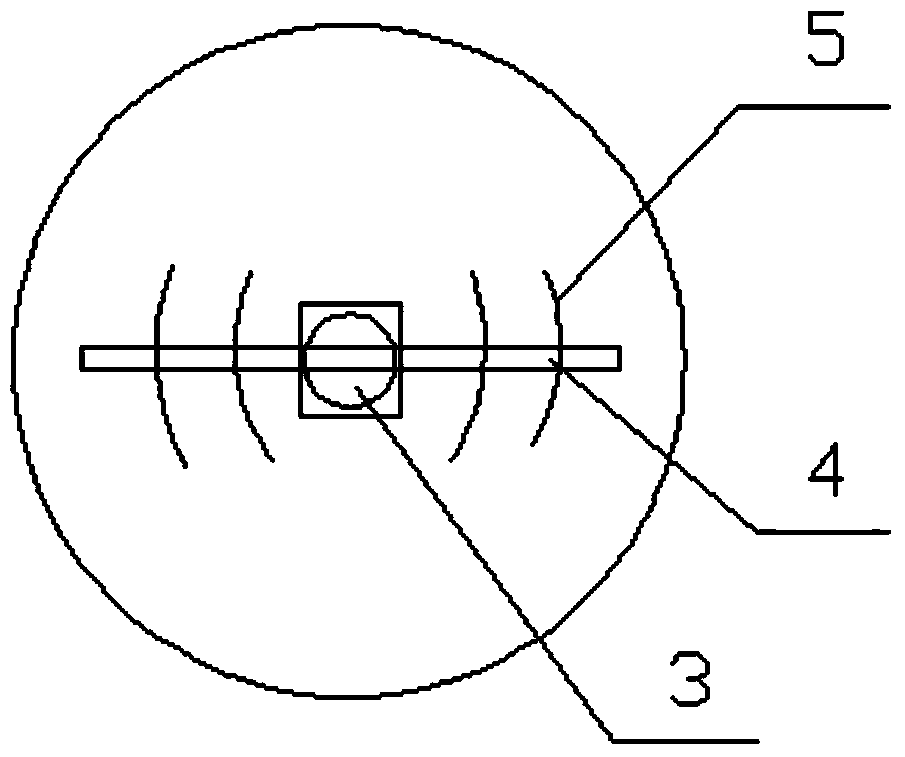

[0036] Such as figure 1 , 2 As shown, a stirrer includes a housing 1, a motor 2 installed at the center of the bottom of the housing 1, a stirring shaft 3 vertically installed above the motor 2, and a stirring beam 4 vertically fixed to the stirring shaft 3; it also includes an arc-shaped stirring Plate 5; two arc-shaped stirring plates 5 are respectively arranged on both sides of the stirring shaft 3, and the arc-shaped stirring plates are fixed on the stirring beam; the distance between the bottom end of the arc-shaped stirring plate and the bottom of the housing 1 is 5 mm; the stirring plate The two ends of the stirring beam are vertically fixed; the stirring plate is arc-shaped and relatively symmetrically arranged at the two ends of the stirring beam. The stirring beam passes through the center of the arc-shaped stirring plate, and a stirring member is added. Stirring plate 5 stirs at the same time, which increases the number of stirring times and improves the stirring e...

Embodiment 2

[0038] Referring to Example 1, further, the agitator includes a housing 1, a motor 2 installed at the center of the bottom of the housing 1, a stirring shaft 3 vertically installed above the motor 2, and a stirring beam 4 vertically fixed to the stirring shaft 3 ; It also includes an arc-shaped stirring plate 5; there are 4 arc-shaped stirring plates at one end of the beam, and they are arranged in the same arc direction.

Embodiment 3

[0040] Further, the agitator includes a housing 1, a motor 2 installed at the center of the bottom of the housing 1, a stirring shaft 3 vertically installed above the motor 2, and a stirring beam 4 vertically fixed to the stirring shaft 3; it also includes an arc Stirring plate 5; the arc-shaped stirring plate is viewed from the outside of the stirring shaft, and the cross-sectional shapes are respectively 1 / 6 arc, 1 / 5 arc, and 1 / 4 arc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com