An industrial liquid stirring device

A stirring device and liquid technology, which is applied to mixers, dissolvers, and mixers with rotating stirring devices, can solve the problems of long stirring time, increased resistance, and reduced stirring effect, so as to increase the number of stirring times and increase the Improvement of contact area and stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

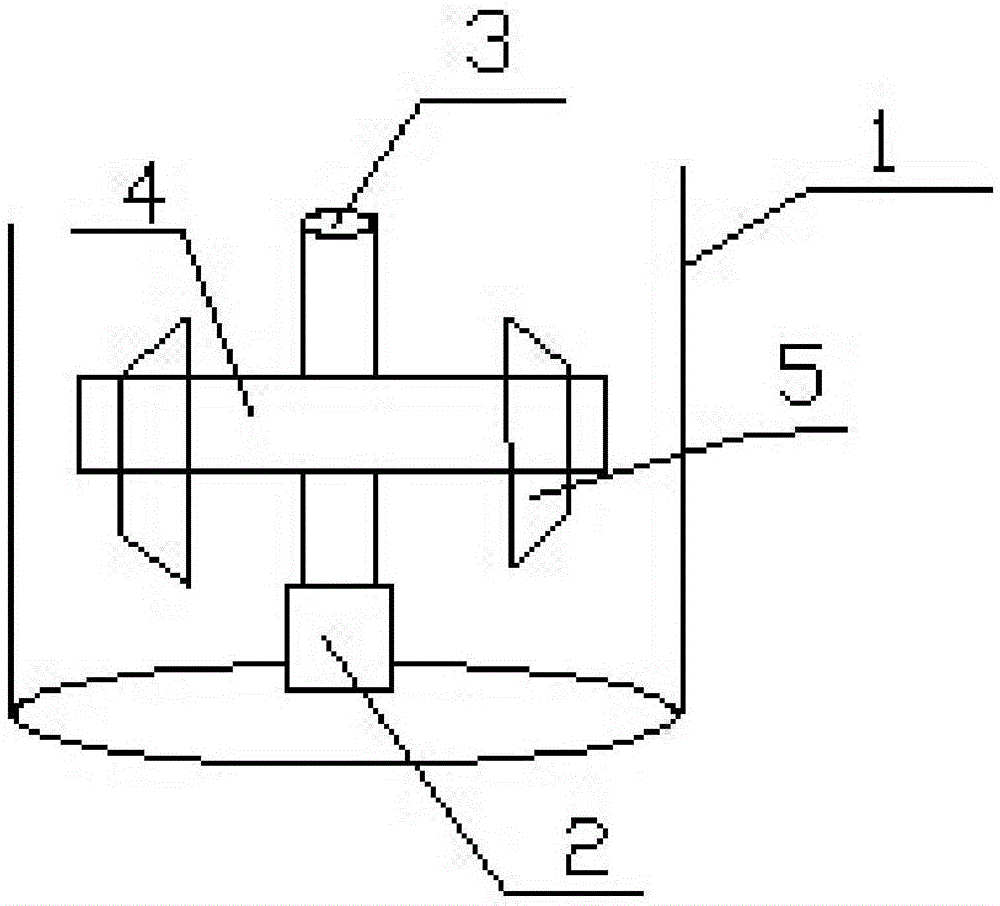

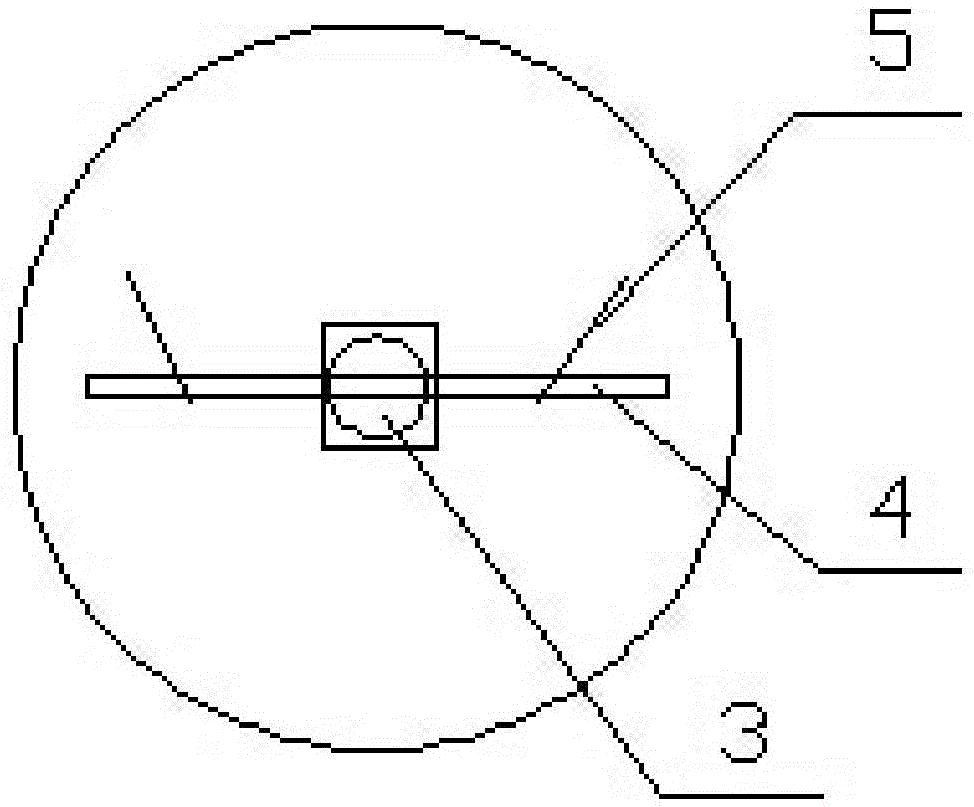

[0034] Such as figure 1 , 2 As shown, the industrial liquid stirring device includes a housing 1, a motor 2 installed at the center of the bottom of the housing 1, a stirring shaft 3 vertically installed above the motor 2, and a stirring beam 4 vertically fixed to the stirring shaft 3; it also includes a stirring plate 5 A stirring plate 5 is arranged on both sides of the stirring shaft 3, the stirring plate 5 is vertically arranged, and the central part is fixedly embedded on the beam; the stirring plate is located on the same side of the vertical plane where the stirring beam is located; The stirring plate 5 is arranged on the same side of the stirring beam 4; the distance between the bottom end of the stirring plate 5 and the bottom of the housing 1 is 5mm; by setting the stirring plate 5 on the stirring beam 4, the stirring parts are added, and the stirring beam 4 Simultaneous stirring with the stirring plate 5 increases the number of stirring times and improves the stirr...

Embodiment 2

[0036] Referring to Embodiment 1, it includes a housing 1, a motor 2 installed at the center of the bottom of the housing 1, a stirring shaft 3 vertically installed above the motor 2, and a stirring beam 4 vertically fixed to the stirring shaft 3; a stirring plate 5 is also included. Further, At least two stirring plates 5 are arranged on both sides of the stirring shaft 3, and the stirring plates 5 on the same side of the stirring shaft are arranged in parallel.

Embodiment 3

[0038] Further, the industrial liquid stirring device of the present invention includes a housing 1, a motor 2 installed at the bottom center of the housing 1, a stirring shaft 3 vertically installed above the motor 2, and a stirring beam 4 vertically fixed to the stirring shaft 3; Stirring plate 5 is also included as a trapezoidal steel plate, and the long side of the trapezoid is a part embedded and fixed on the cross-section of the stirring beam. The trapezoidal setting makes the convection of the upper and lower stirring liquids smoother and the stirring effect is enhanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com