A step-by-step continuous stirring device and stirring method

A mixing device and secondary mixing technology, applied in cement mixing devices, unloading devices, clay preparation devices, etc., can solve the problem of reducing the workability and hardening strength of finished materials, affecting the shear damage of powdery aggregates, and affecting Binder hydration, aggregate coating and other problems, to increase the retention and mixing time, reduce the barrier effect, and reduce the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

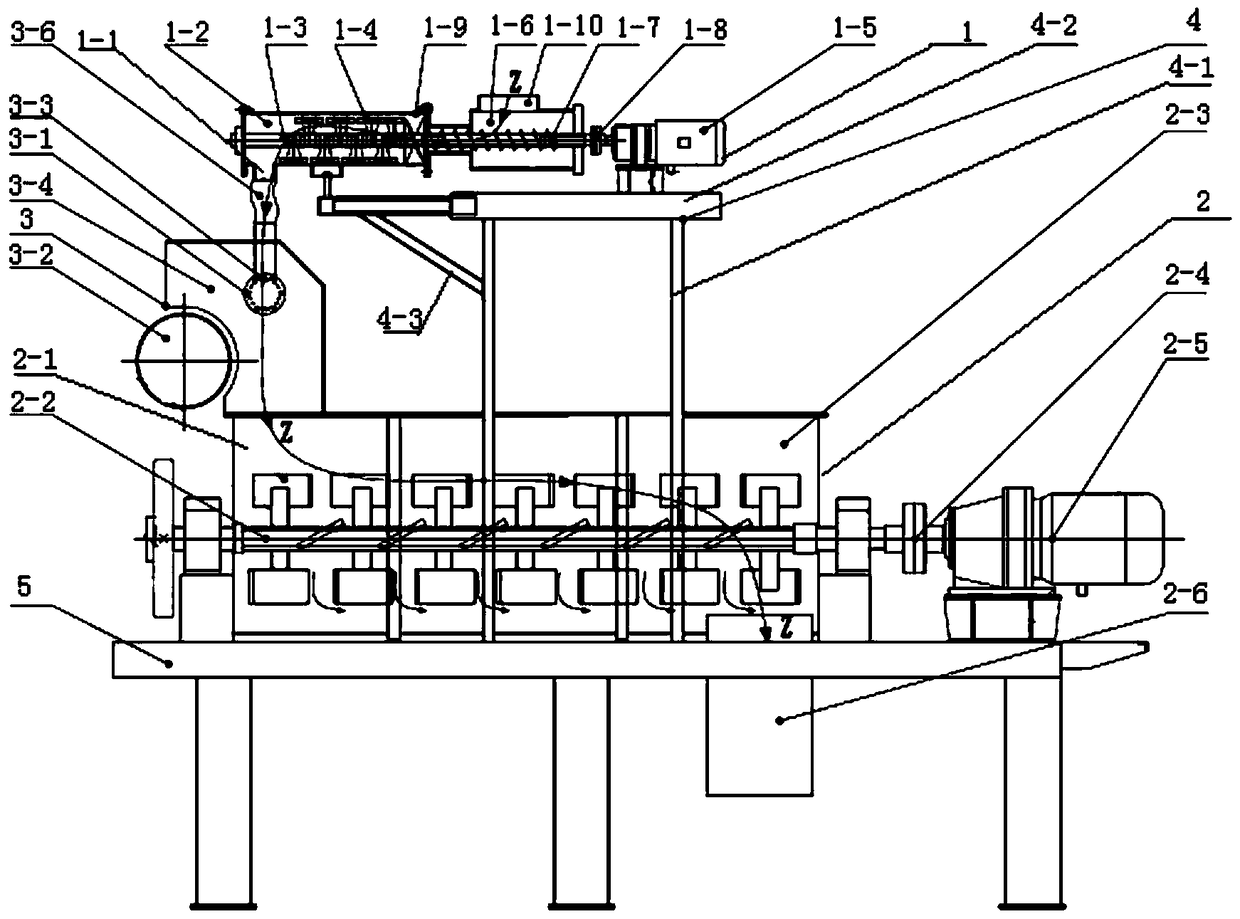

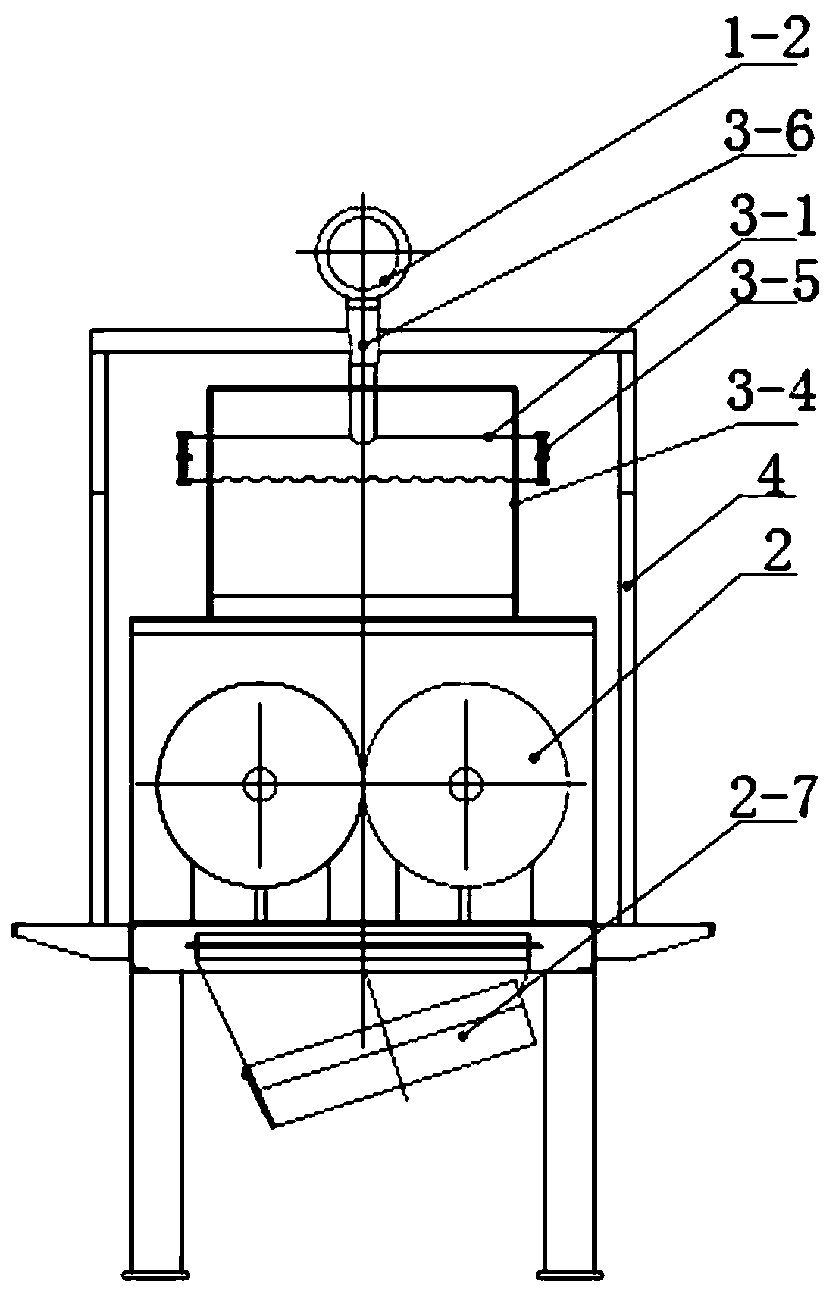

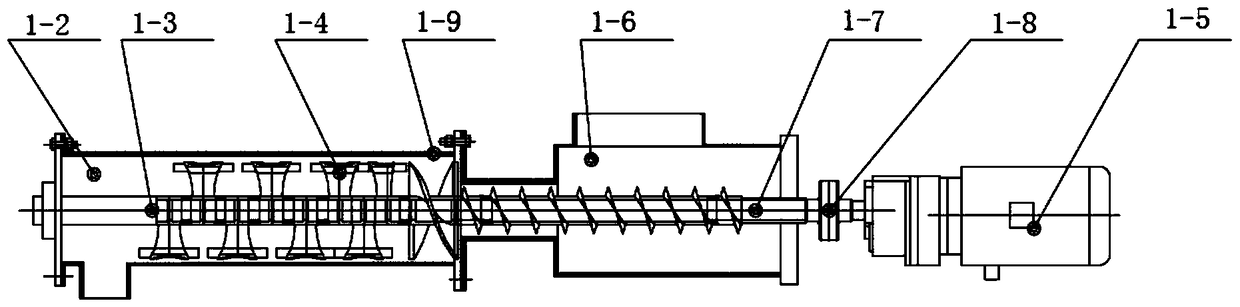

[0034] Comply with the above-mentioned technical scheme, see Figure 1-2 , the graded continuous stirring device of the present invention comprises a continuous single-shaft mixer 1 and a continuous double-shaft mixer 2, the continuous single-shaft mixer 1 is provided with a first-stage stirring outlet 1-1, and the continuous double-horizontal mixer The shaft mixer 2 is provided with a secondary stirring feed inlet 2-1, and the continuous single-horizontal shaft mixer 1 includes a primary mixing drum 1-2, and the primary mixing drum 1-2 is provided with a primary stirring shaft 1-3 , the primary stirring shaft 1-3 is distributed with primary stirring blades 1-4; the continuous twin-shaft mixer 2 is provided with a secondary stirring shaft 2-2; the continuous single-shaft mixer 1 and the continuous double-horizontal The shaft mixer 2 is connected through a conduction mechanism 3, which includes a blanking horizontal tube 3-1 and a feed pulley 3-2; 1-1 output, falling into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com