Fire preventing and extinguishing pulping device

A fire prevention and pulping technology, which is applied to mixers with rotating stirring devices, dissolving, mixers, etc., can solve the problems of slow mixing, easy to appear dead angles, and affect the use of slurry, so as to increase the speed, facilitate full mixing, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

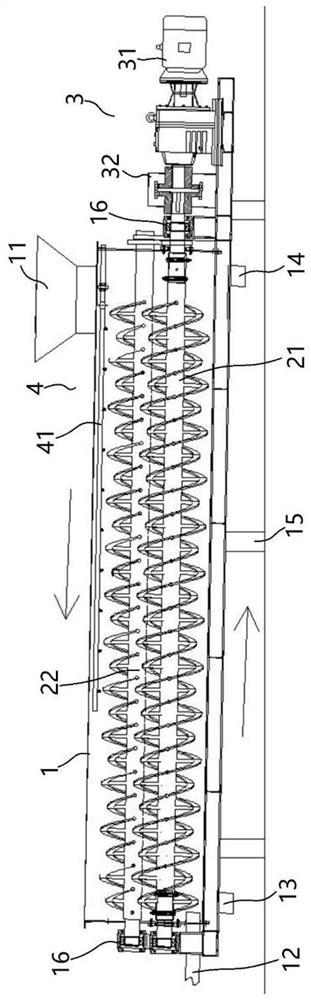

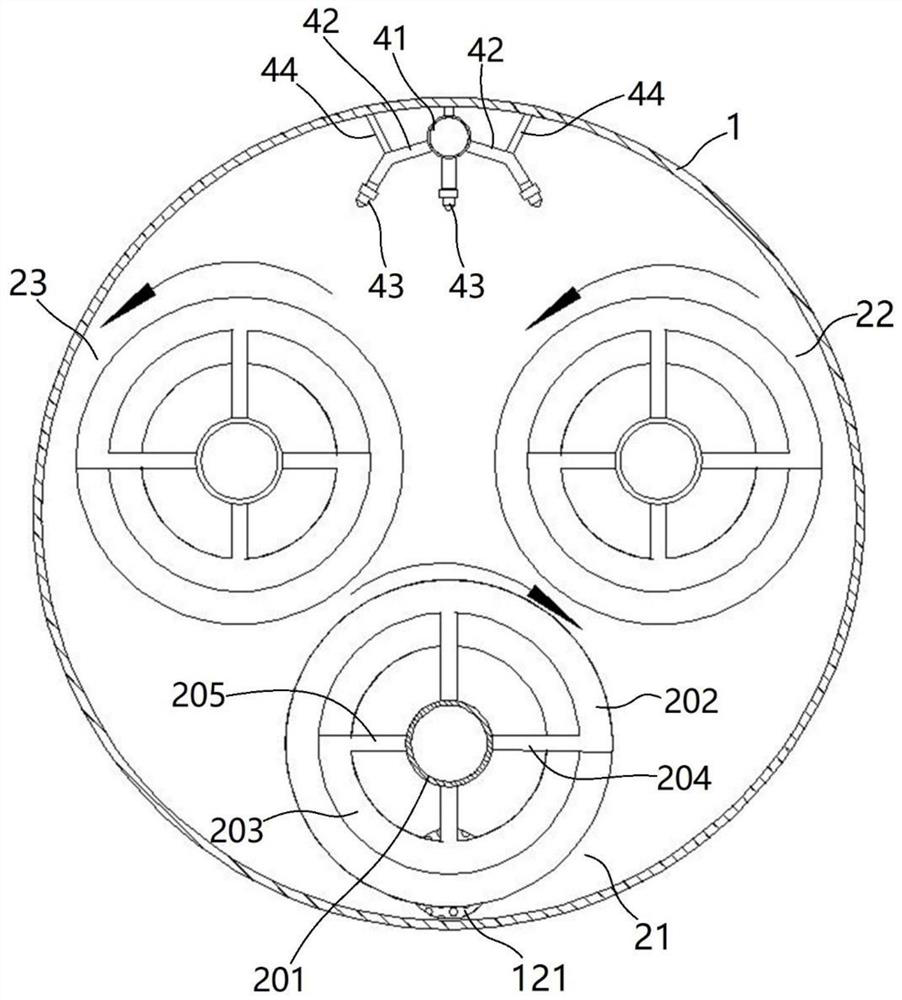

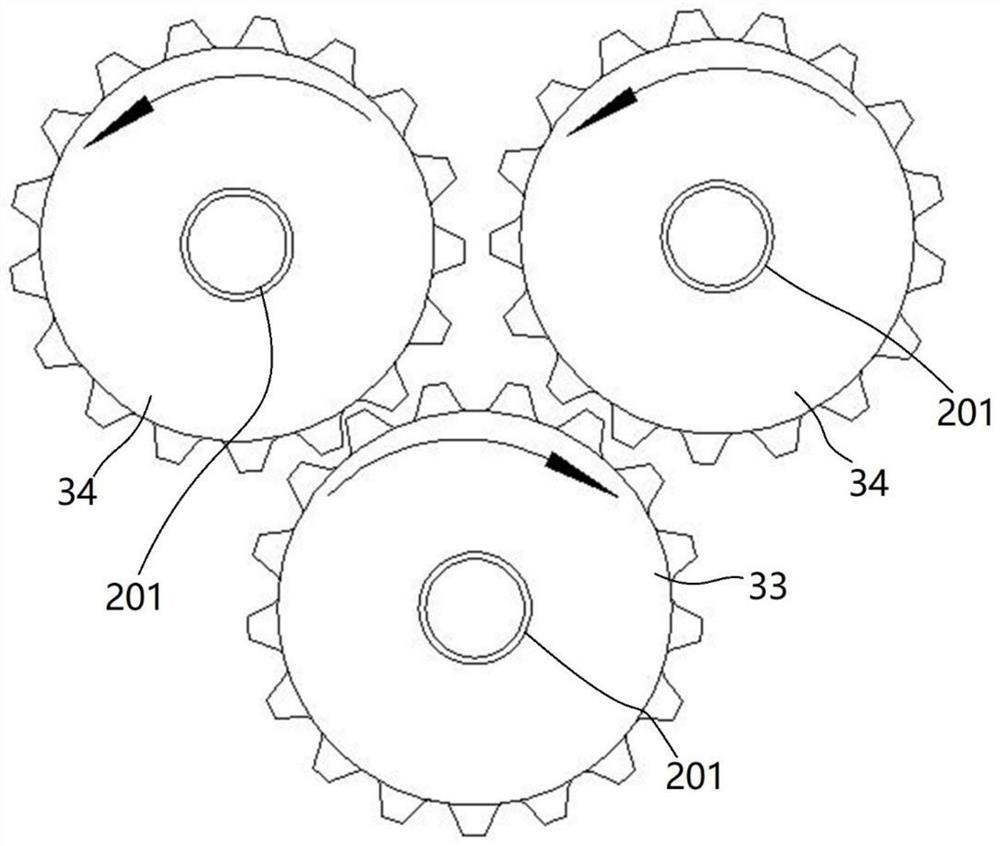

[0043] An embodiment of the anti-fire extinguishing pulping device of the present invention: as figure 1 As shown, the fire-proof pulping device includes a mixing drum 1 , a stirring and conveying mechanism, a driving mechanism 31 , a feeding mechanism, and a spraying device 4 . in:

[0044] The mixing drum 1 is a hollow cylindrical shell with a cylindrical mixing chamber, and the best choice is galvanized steel. The upper part of one end of the mixing drum 1 has a feed port 11, and the lower part of the other end is provided with a slurry outlet 12 and a first slag outlet 13. , the feed inlet 11 is provided with a material-receiving funnel, and the mixing cylinder 1 is inclined so that one end where the feed inlet 11 is set is lower than the other end where the slurry outlet 12 is set, and the inclination angle is 5-15°. The mixing cylinder 1 is set A second slag outlet 14 is provided at the lower part of one end of the feed inlet 11 . On-off valves are provided at the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com