Construction method of cement mixing pile in saline-alkaline silt soft foundation

A technology of cement mixing piles and construction methods, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as large cement resources, high engineering cost, and complexity, and achieve saving construction materials, ensuring pile quality, and operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

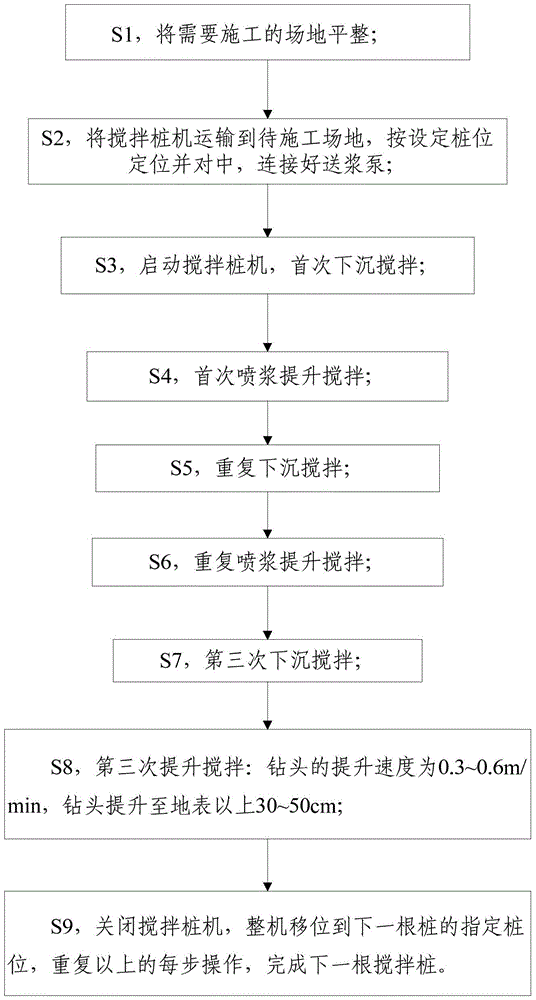

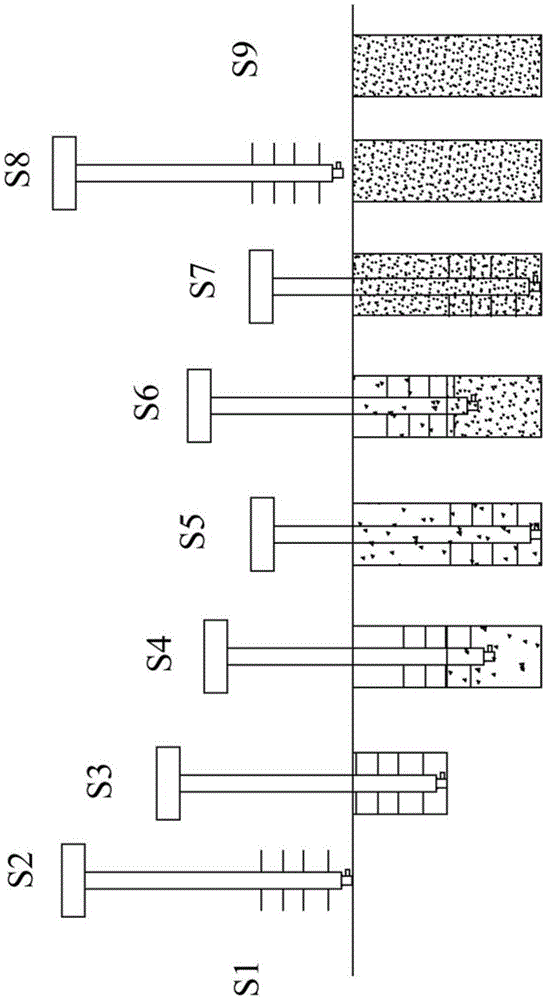

[0026] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

[0027] Reference figure 1 with 2 As shown, the construction method of the salt-alkaline silt soft foundation cement mixing pile of the present invention uses the SP-5 mixing pile machine to operate (not limited to the use of this kind of mixing pile machine), including the following steps:

[0028] Step S1, level the site to be constructed.

[0029] Step S2, transport the SP-5 pile mixer to the construction site, position and center the pile position according to the set, and connect the slurry pump.

[0030] Step S3, start the main motor of the pile mixer, and sink and stir for the first time: the sinking speed of the drill bit is 0.2~0.5m / min. When the operator feels the body begins to shake, the drill bit sinks si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com