Electric stirring cup capable of being operated manually

A technology of electric stirring and electric motor, which is applied in the direction of mixer accessories, mixers with rotating stirring devices, dissolving, etc. It can solve the problems of blocking, destructive samples, low efficiency, time-consuming and laborious, etc., and achieves convenient use and good stirring effect , Improve the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

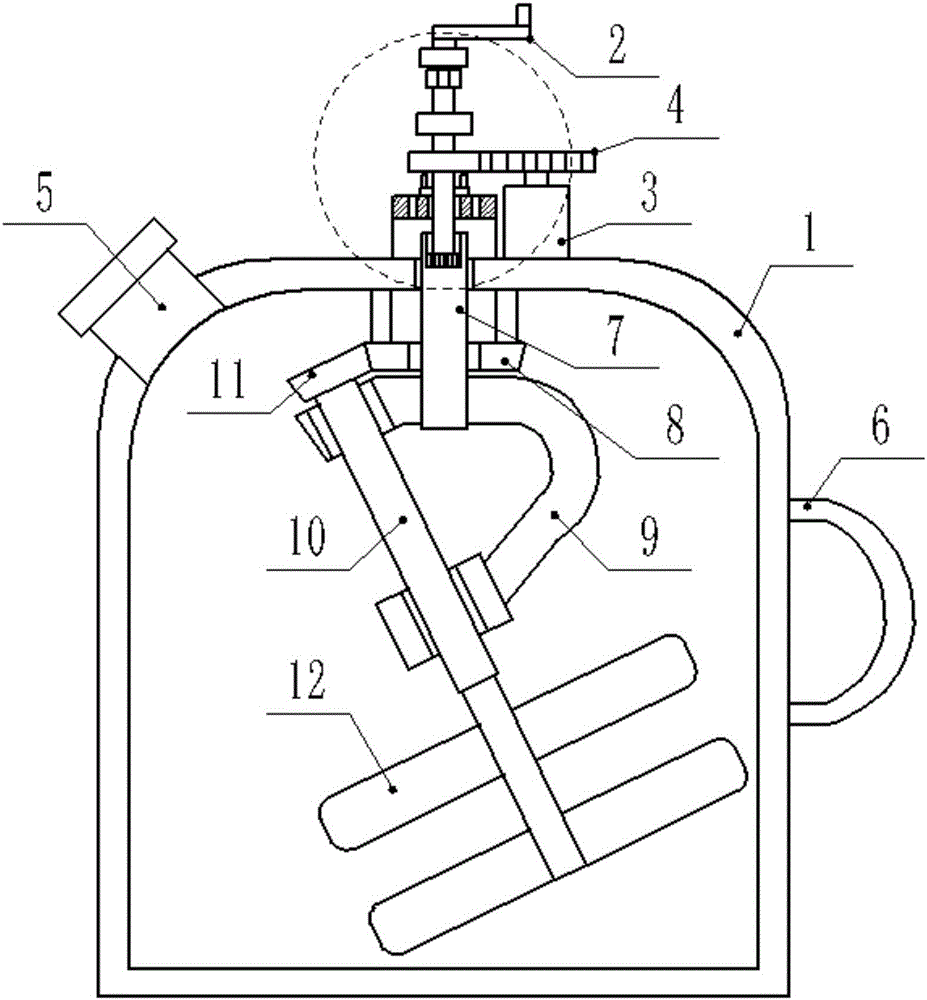

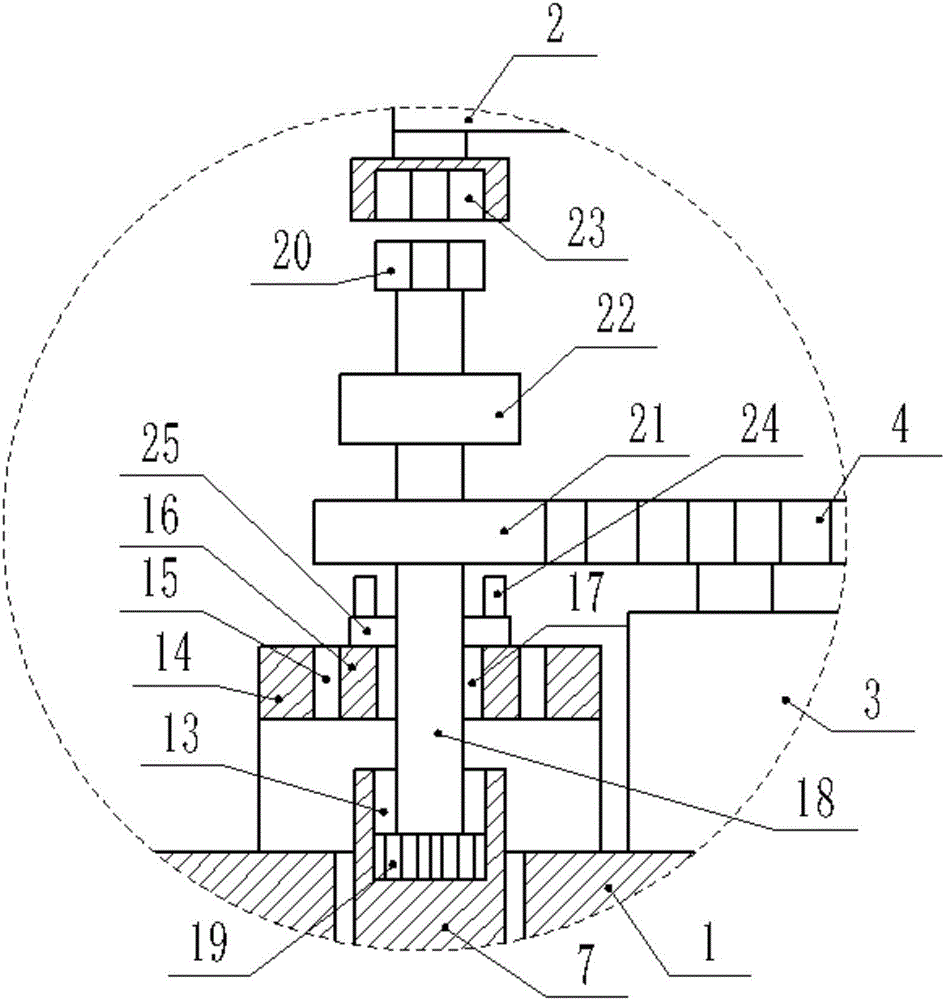

[0016] see Figure 1-2 , a manual electric stirring cup, including a cup body 1, a hand wheel 2 and an electric motor 3, the electric motor 3 is fixedly connected to the upper end of the cup body 1, and the output shaft of the electric motor 3 is fixedly connected to a driving gear 4 The upper end of the cup body 1 is fixedly connected with a feed port 5, the side wall of the cup body 1 is also fixedly connected with a handle 6, the center of the top plate of the cup body 1 is connected with a transmission shaft 7 in rotation, and the lower end of the top plate of the cup body 1 is fixedly connected with an umbrella Gear Ⅰ8, the drive shaft 7 passes through the inner hole of the bevel gear Ⅰ8 and leads to the bottom of the bevel gear Ⅰ8, the lower end of the drive shaft 7 is fixedly connected with a 'V'-shaped transfer shaft 9, and the two shaft ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com