Patents

Literature

79results about How to "Meet mixing requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

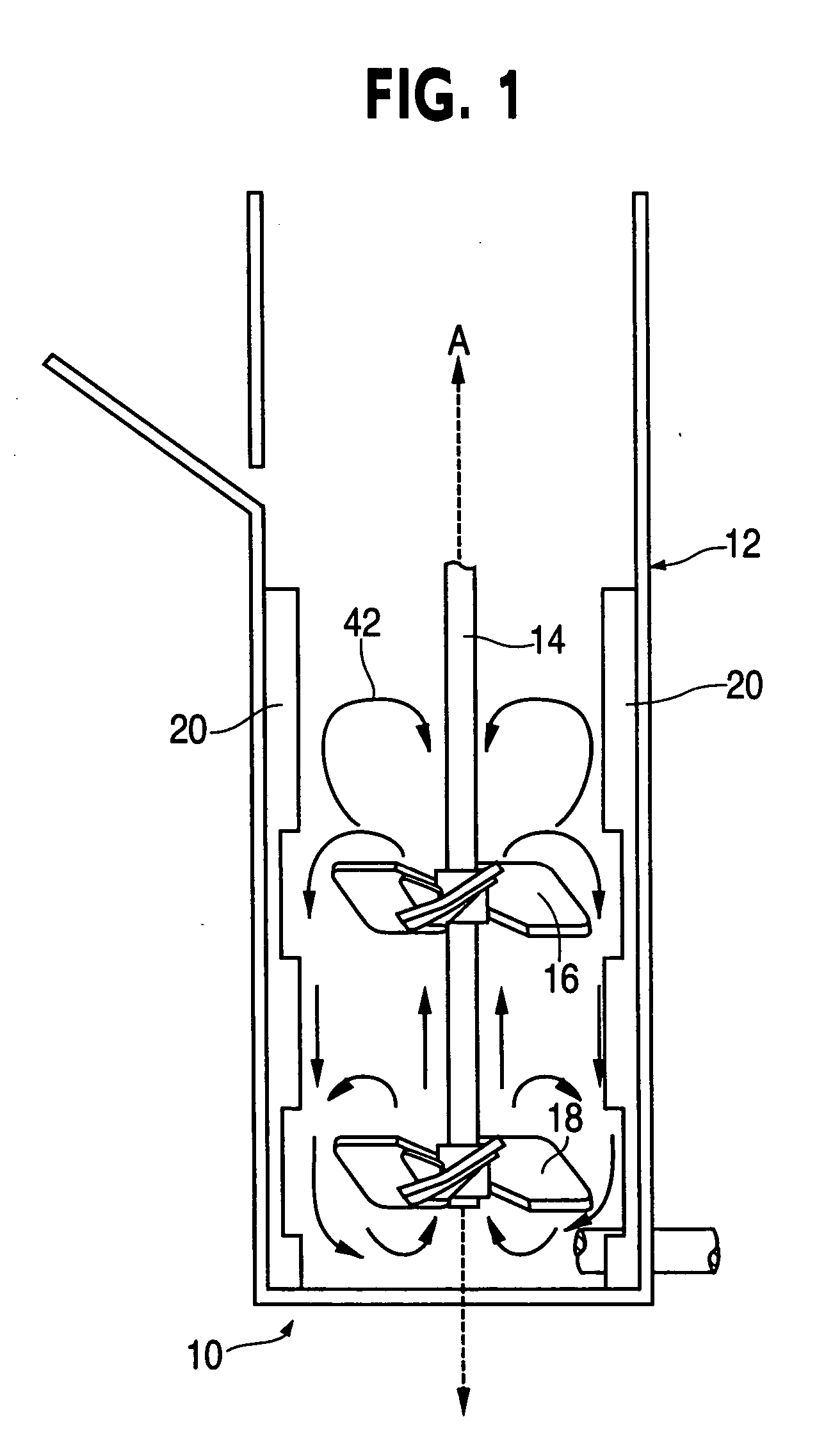

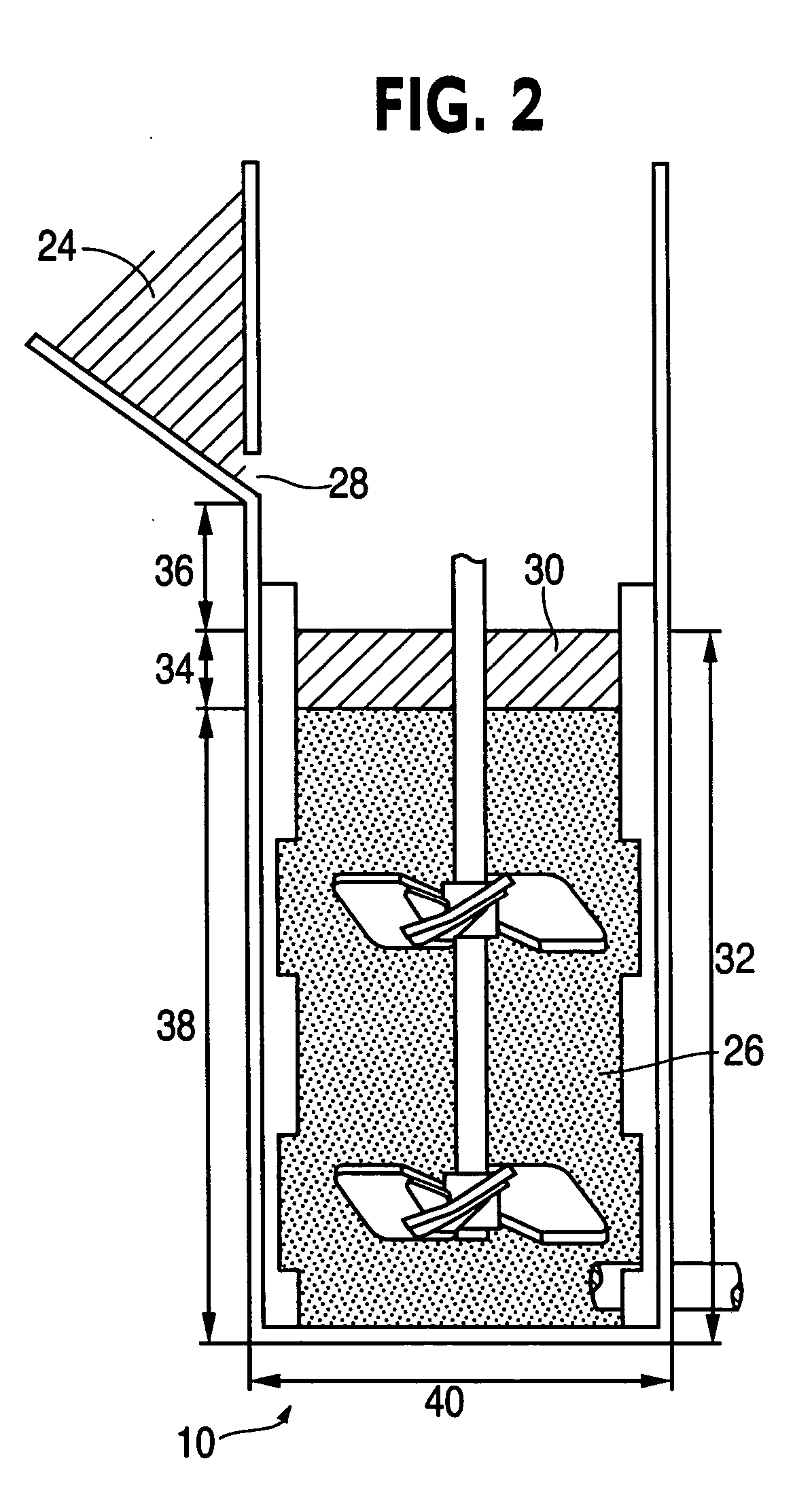

Agitation system and method for dry solids addition to fluid

ActiveUS20060176771A1Meet mixing requirementsFlow mixersTransportation and packagingProcess engineeringScrubber

Owner:SPX FLOW INC

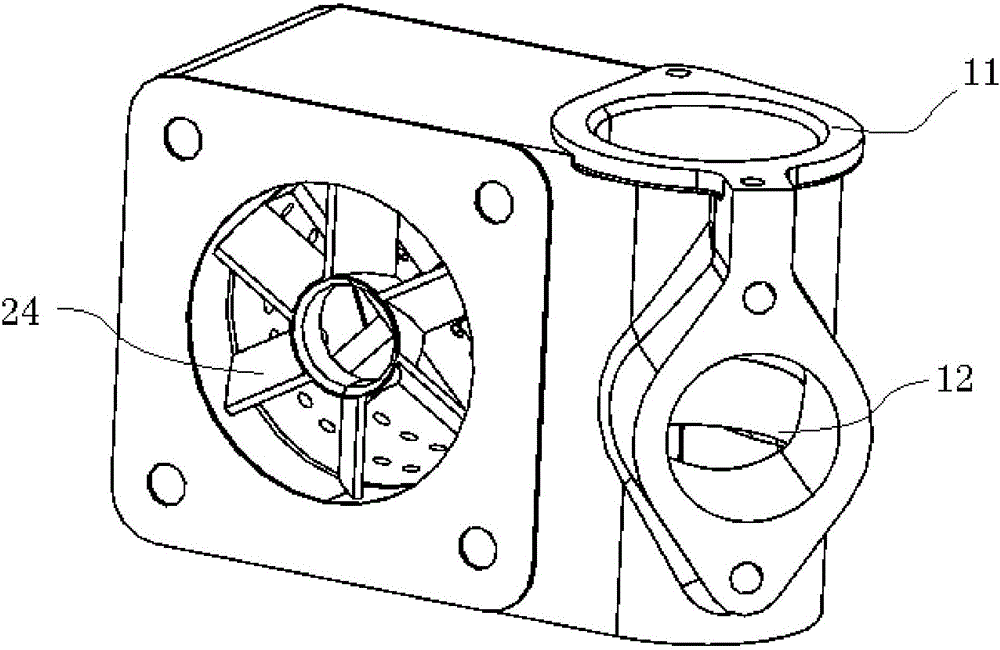

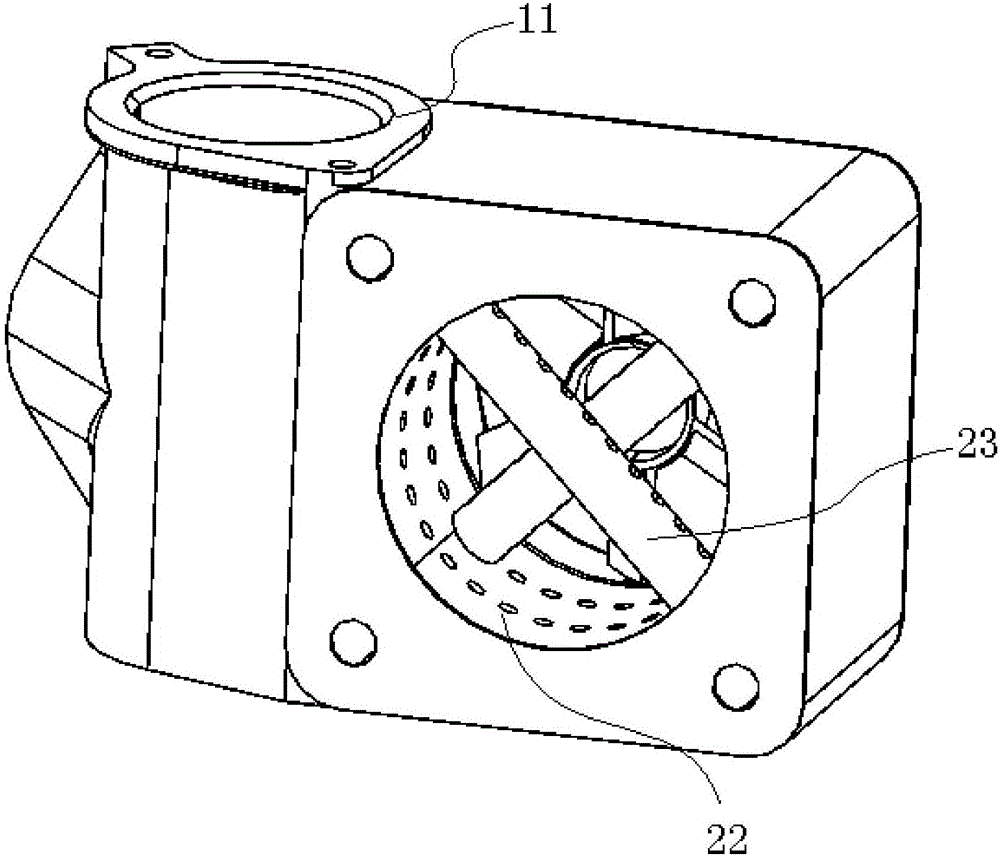

Integrated EGR (exhaust gas recirculation) mixer

InactiveCN105003361AReduce volumeReduce the risk of breakageInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringExhaust gas recirculation

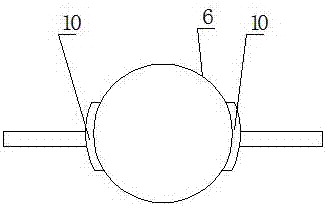

The invention discloses an integrated EGR (exhaust gas recirculation) mixer. The integrated EGR mixer comprises an EGR valve seat part as well as a mixing and turbulence part, wherein an EGR valve mounting flange is arranged at the top end of the EGR valve seat part, and an exhaust gas inlet is formed in one side wall of the EGR valve seat part; the mixing and turbulence part and the EGR valve seat part are integrally formed, one side of the mixing and turbulence part is a gas mixer gas inlet side, and the other side of the mixing and turbulence part is an engine gas inlet connection pipe gas outlet side; a mixing and turbulence cavity is formed between the gas mixer gas inlet side and the engine gas inlet connection pipe gas outlet side, a mixing cavity is located in the upstream position of the mixing and turbulence cavity, and a mixing core is arranged in the mixing cavity, and a circular exhaust gas groove is formed in the peripheral side of the mixing core and communicated with the exhaust gas inlet of the EGR valve seat part through an exhaust gas runner; a turbulence cavity is formed in the downstream position of the mixing and turbulence cavity. The integrated EGR mixer integrates an EGR mixer, an EGR valve seat and a turbulator and is convenient to mount and small in system vibration, so that the hidden danger of pipeline breakage is reduced.

Owner:GUANGXI YUCHAI MASCH CO LTD

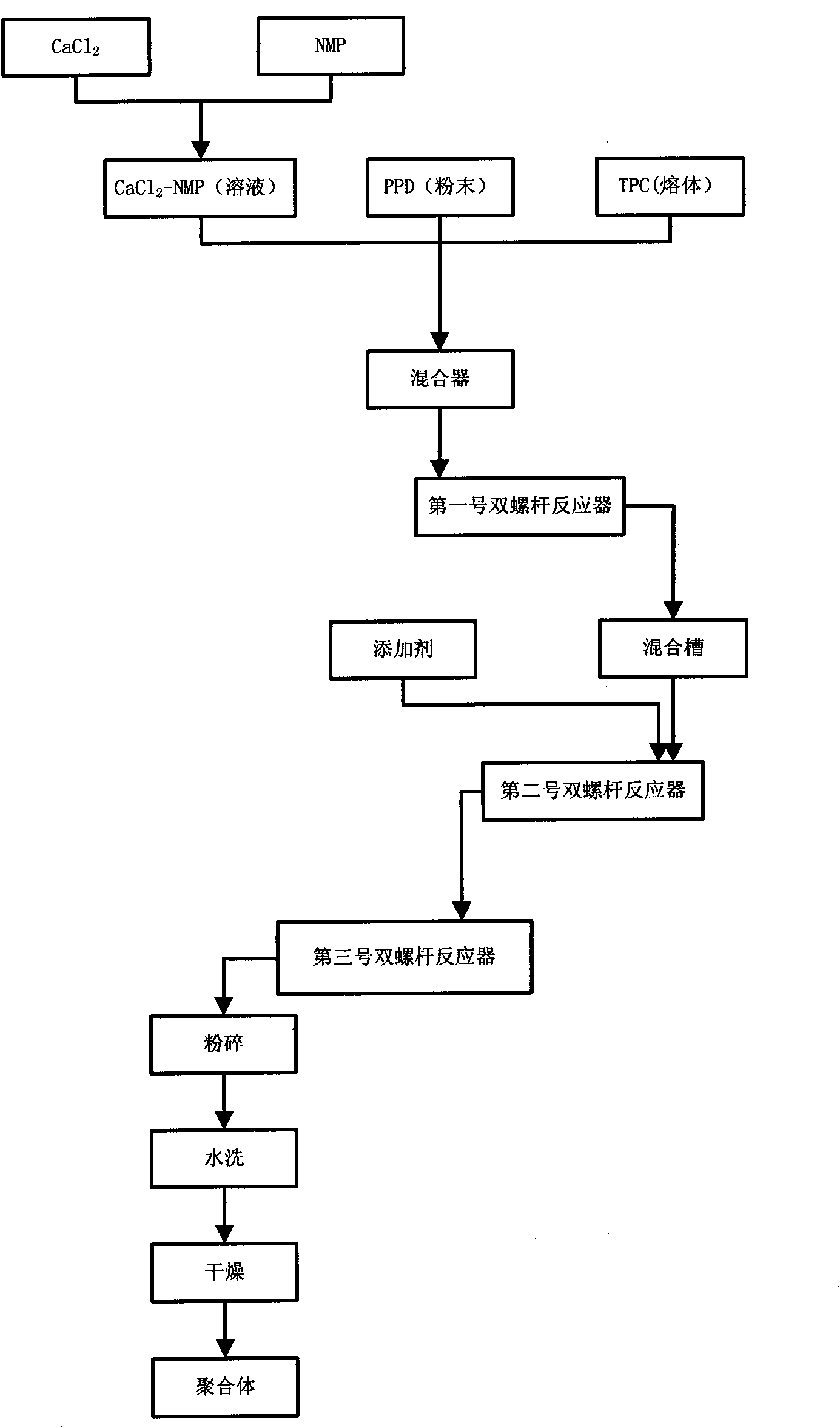

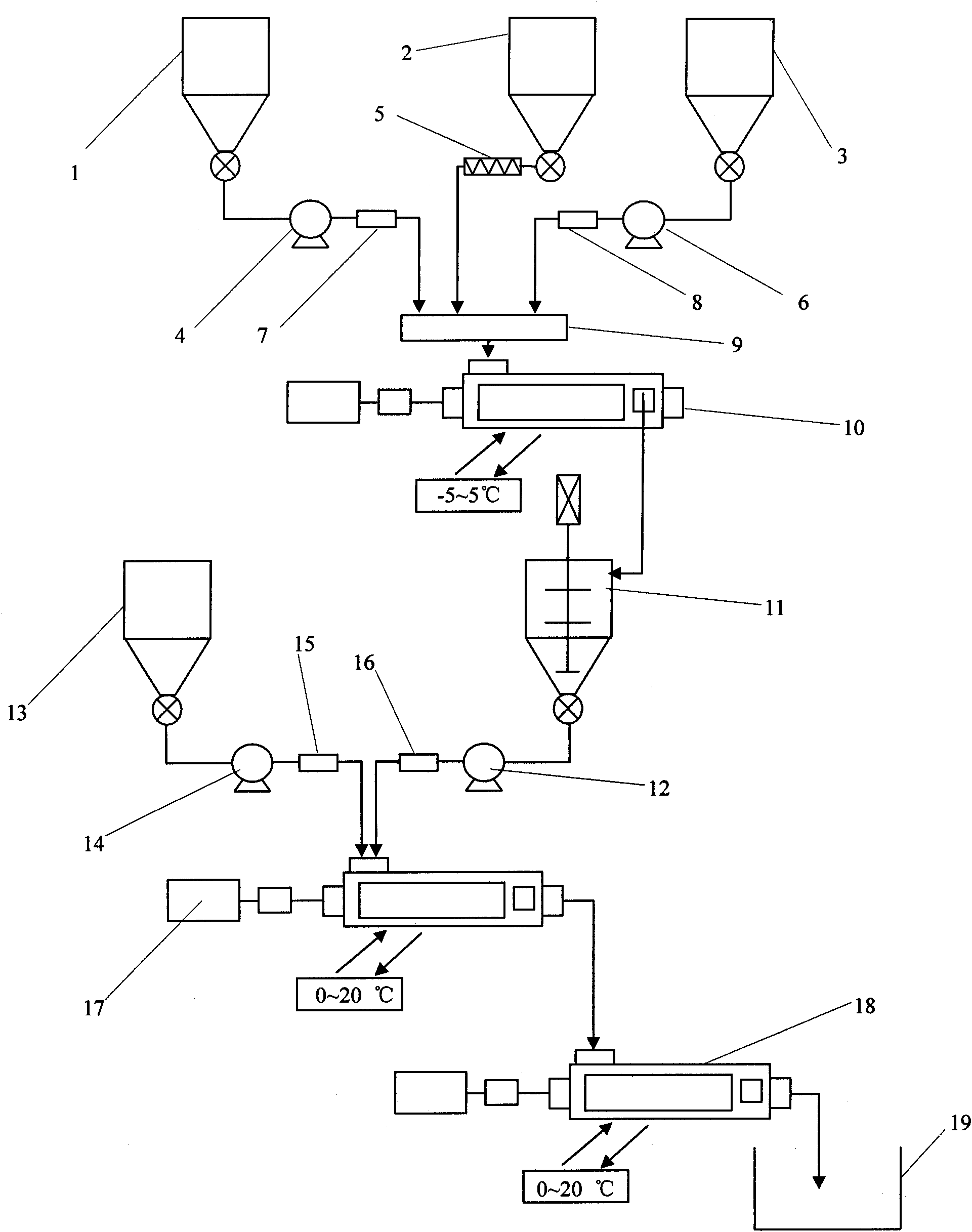

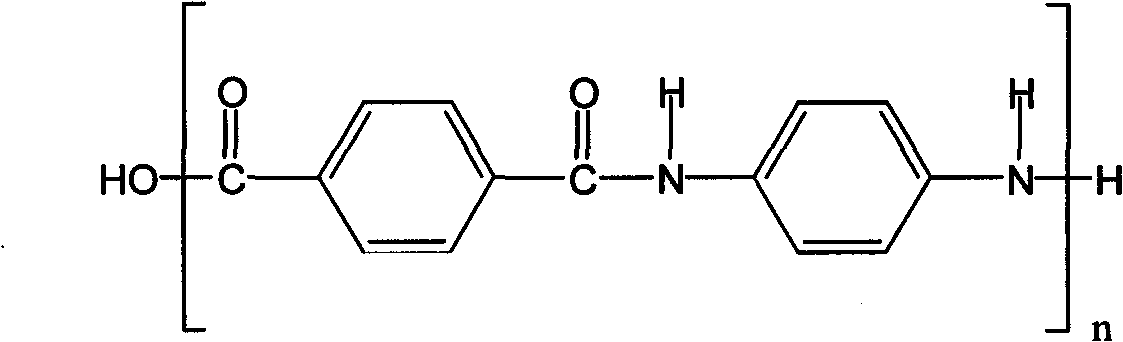

Device for continuous preparation of poly(p-phenylene terephthalamide) polymer and preparation method

ActiveCN102206339AMeet continuous and stable spinningContinuous and accurate meteringMonocomponent polyamides artificial filamentP-PhenylenediaminePhenylene

A device for continuous preparation of poly(p-phenylene terephthalamide) polymer and a preparation method belong to the field of polymer materials, and relate to the polymer material manufacturing technology. The invention is characterized in that: the poly(p-phenylene terephthalamide) polymer is prepared by using the preparation device and through the following steps: preparing a cosolvent-solvent system; proportionally and simultaneously adding the cosolvent-solvent, p-phenylenediamine and terephthaloyl chloride into a No.1 mixer, mixing and allowing the mixture to flow into a twin screw reactor; successively allowing the mixture to flow into a subsequent mixer and a No.2 twin screw reactor till a light-yellow breadcrumb-like mixture is extruded from a No.3 twin screw reactor, pulverizing the mixture, washing by water, and drying to obtain the poly(p-phenylene terephthalamide) polymer. The method of the invention can solve the problems of deepened color and decreased reactivity of p-phenylenediamine caused by long-term storage in a cosolvent-containing solvent; the combination of a plurality of twin screw reactors meets the mixing requirements of the polycondensation reaction at different stages and provides a logarithmic viscosity of above 6.5 dl / g; the performance requirements for industrial continuous preparation are met.

Owner:上海舟汉纤维材料科技股份有限公司

Electric stirring cup capable of being operated manually

InactiveCN106582384AImprove mixing effectReduce damageRotary stirring mixersTransportation and packagingAgricultural engineeringBevel gear

The invention discloses an electric stirring cup capable of being operated manually. The electric stirring cup comprises a cup body, a hand wheel and an electric motor, wherein a top plate of the cup body is rotationally connected with a transmission shaft, the lower end of the top plate of the cup body is fixedly connected with a bevel gear I, the lower end of the transmission shaft is fixedly connected with a coupling shaft, a stirring shaft is rotationally connected to the coupling shaft, the upper end of the stirring shaft is fixedly connected with a bevel gear II, and the lower part of the stirring shaft is fixedly connected with a stirring blade; and the upper end of the transmission shaft is provided with a gear groove, the upper end of the top plate of the cup body is fixedly connected with a support plate, a middle rotating shaft is rotationally connected with the center of the support plate through a rolling bearing, a driving shaft is in slip connection with the center of the middle rotating shaft through a linear bearing, the lower end of the driving shaft is fixedly connected with a driving gear, the upper end of the driving shaft is fixedly connected with a fixture block, and a transmission gear is fixedly connected to the driving shaft. The electric stirring cup disclosed by the invention is good in rotation effect and small in damage to a sample, can be switched between manual operation and electric operation conveniently, is convenient and flexible in use, and is labor-saving and efficient.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

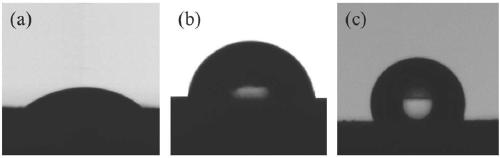

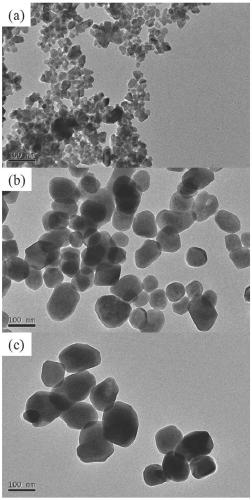

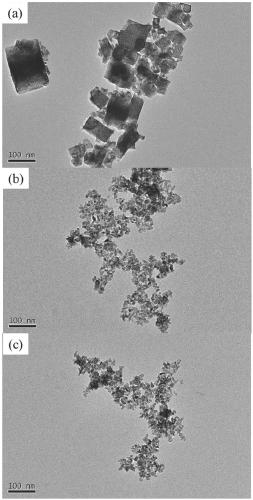

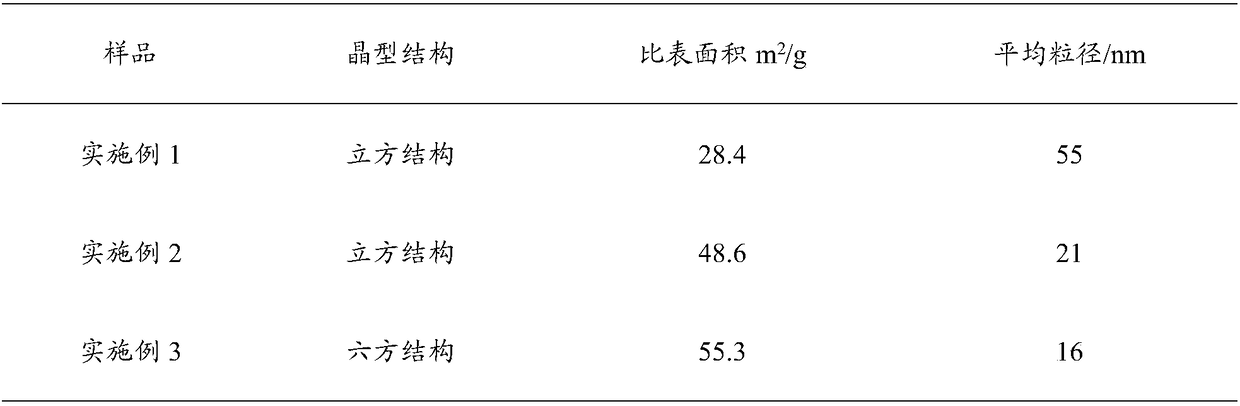

Barium sulfate material and preparation method thereof

ActiveCN109279640AImprove mass transfer efficiencyMeet mixing requirementsMaterial nanotechnologyCalcium/strontium/barium sulfatesChemistryControllability

The invention provides a barium sulfate material and a preparation method thereof, and belongs to the technical field of inorganic material preparation. The method comprises the following steps: mixing a continuous phase and a dispersed phase in a membrane dispersion micro-reactor to obtain a mixed solution; carrying out a precipitation reaction on the mixed solution to obtain a barium sulfate suspension; and carrying out an aging reaction on the suspension to obtain the barium sulfate material, wherein the continuous phase is a barium chloride water solution, and the dispersed phase is a mixed solution of a sodium sulfate water solution and a surfactant-containing ethanol solution. According to the invention, rapid mixing of barium chloride, sodium sulfate and a surface modifier solutioncan be realized in the membrane dispersion micro-reactor, mass transfer efficiency of the system is effectively improved, and mixing requirements of a precipitation process are met. Meanwhile, uniformnesting of the surfactant on the surface of the barium sulfate is realized in situ, and realization of surface hydrophobic modification and particle size controllability of the barium sulfate material is facilitated. According to the embodiment, the contact angle of the barium sulfate material provided by the invention is 80-110 degrees, and the particle size is in a range of 30-80 nm.

Owner:TSINGHUA UNIV +1

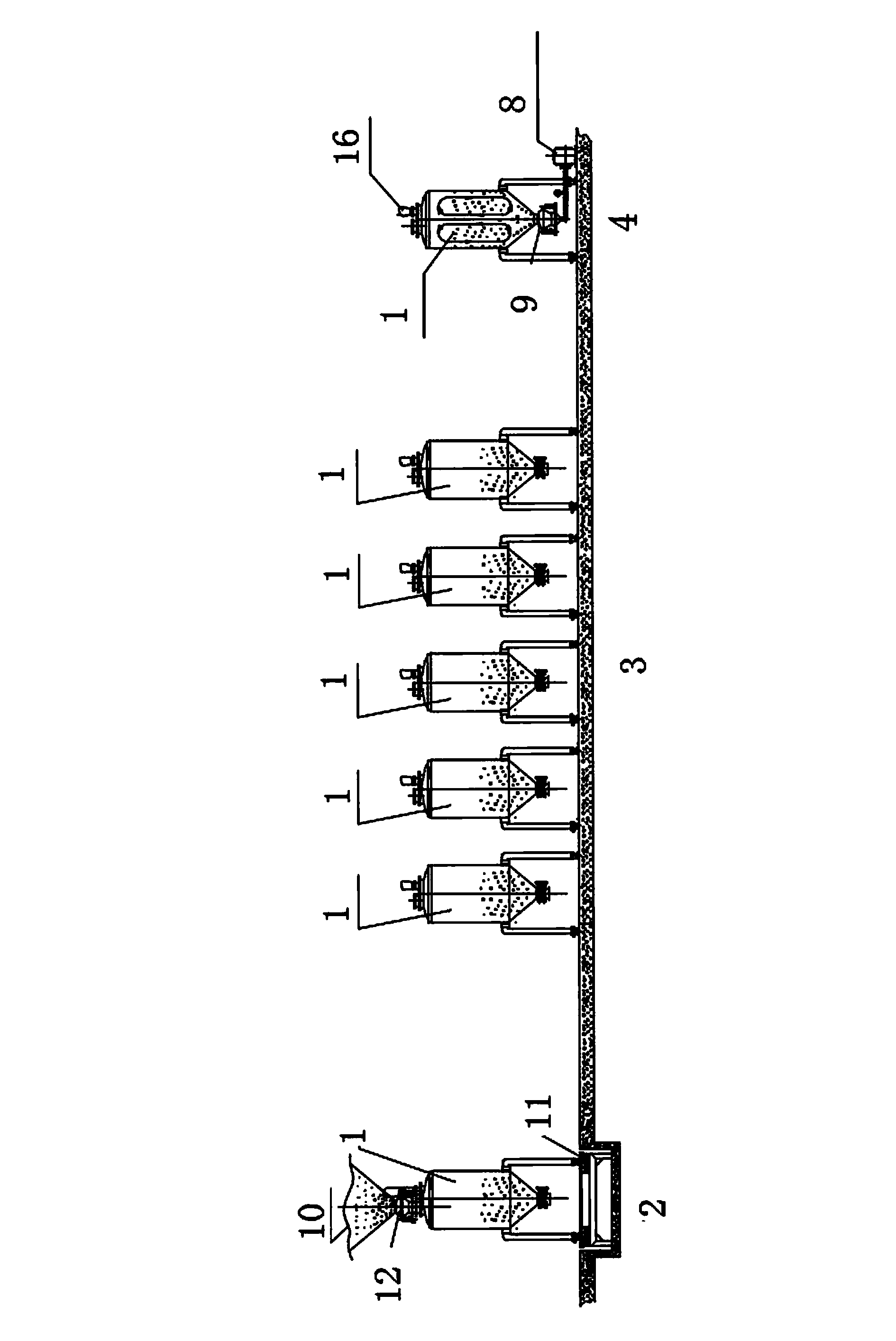

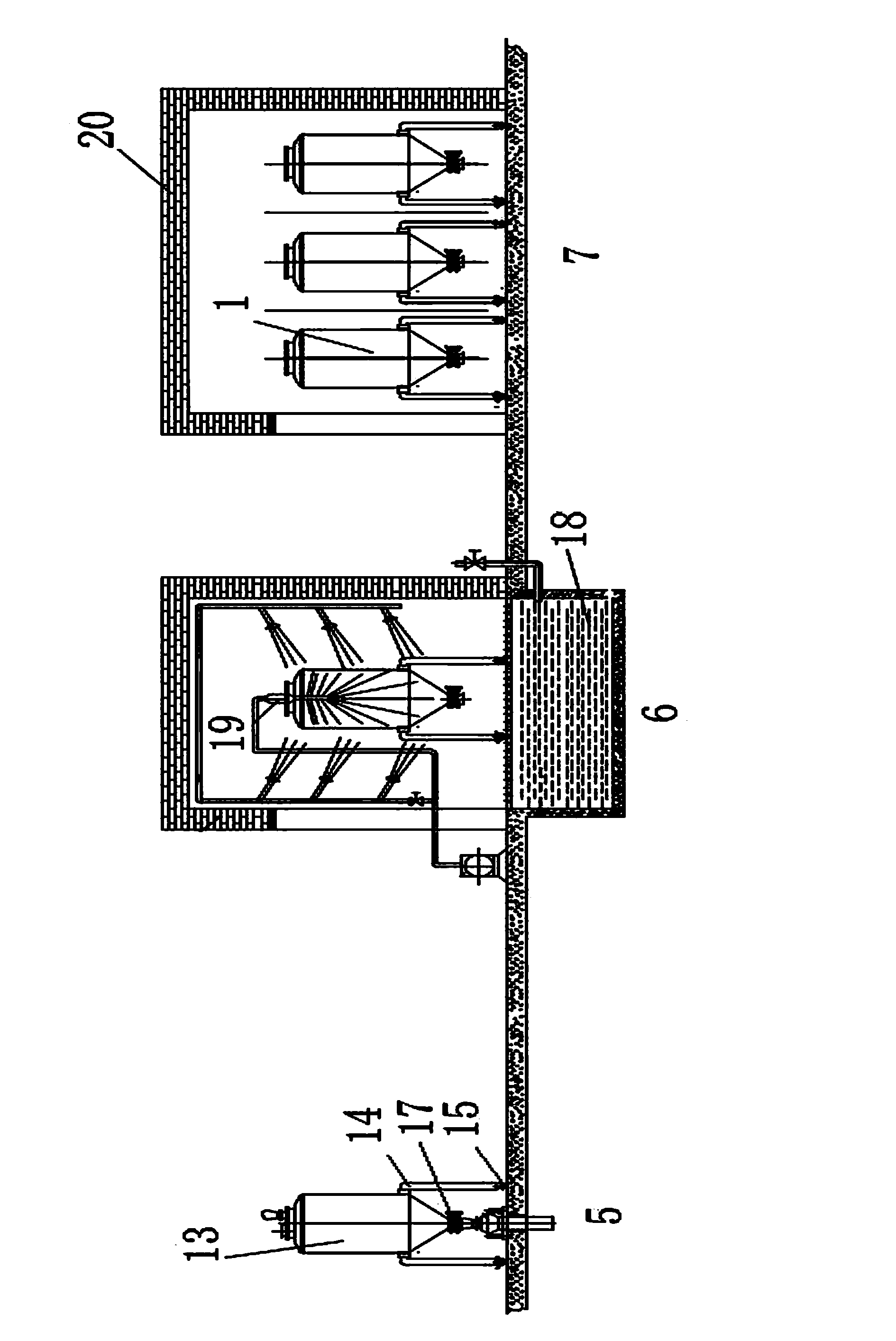

Temporary storage and mixing system used for material, and application method thereof

InactiveCN103386274AReduce cleaning and disinfection workReduce pollution sourcesTransportation and packagingMixer accessoriesHybrid systemEngineering

The invention relates to a temporary storage and mixing system used for materials, and an application method thereof. The system is characterized in that: the material temporary storage and mixing system is provided with a feeding station and a mixing station which are respectively provided with a feeding device and a mixing device matching a material temporary storage container. When in use, functions such as feeding, storing, and mixing can be completed in a same material temporary storage container. During mixing, the system is directly connected with a high-pressure air machine through an air injection structure on the bottom of the material temporary storage container; clean high-pressure air is injected into the material temporary storage container; the material is lifted and turned under the driving of air, such that a purpose of uniform mixing is achieved. Also, secondary pollution during material temporary storage and mixing is reduced. The operation of the entire mixing process is convenient and less error-prone.

Owner:上海博正名荣包装机有限公司

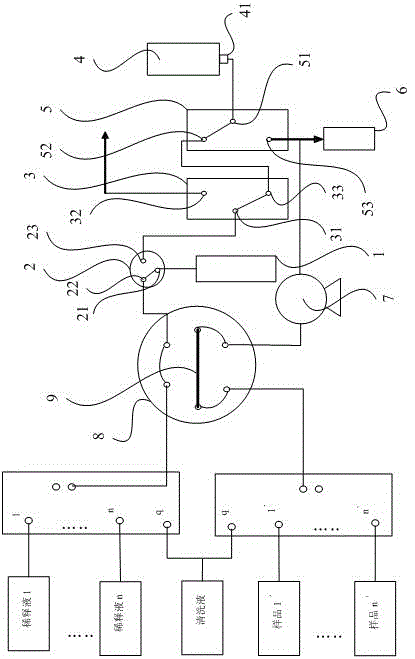

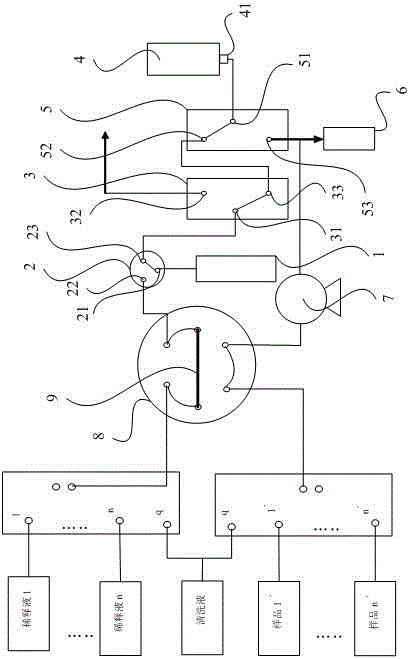

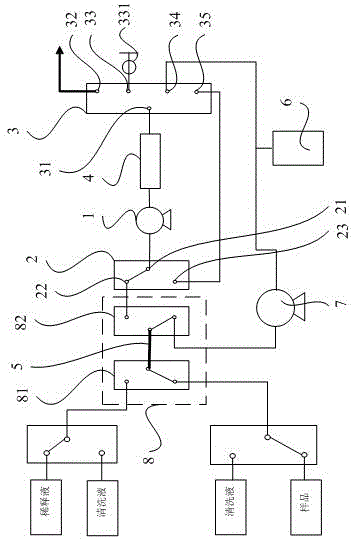

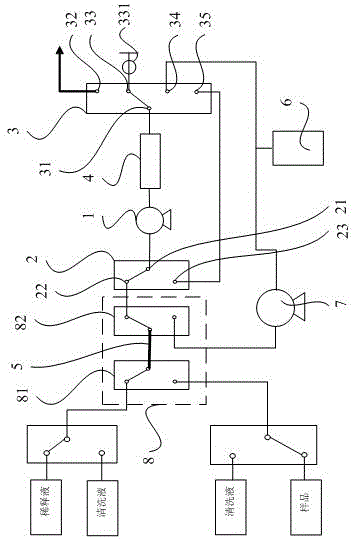

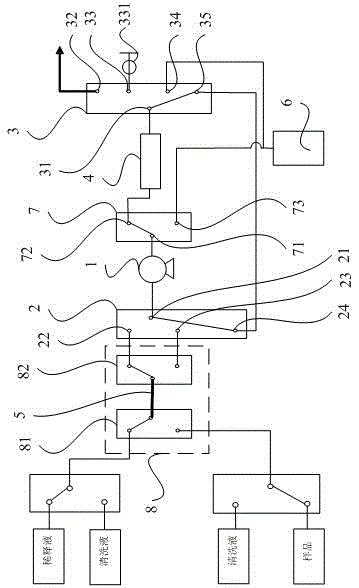

Automatic online micro-scale sample dilution and mixing system and mixing method

ActiveCN104062170AAccurate dilutionMeet mixing requirementsComponent separationPreparing sample for investigationHybrid systemSample dilution

The invention provides an automatic online micro-scale sample dilution and mixing system and a mixing method. The device includes a syringe pump, a first multi-position switching valve, a second multi-position switching valve, a third multi-position switching valve, a mixer, a six-way valve, a quantitative tube and a sample introduction pump. The first multi-position switching valve comprises a first main port and two first switch ports; the second multi-position switching valve comprises a second main port and two second switch ports; the third multi-position switching valve comprises a third main port and two third switch ports; the mixer is provided with a liquid inlet and outlet port; the quantitative tube and sample introduction pump are connected to the six-way valve; the syringe pump is connected with the first main port; one first switch port is connected with the second main port, and the other first switch port is connected with the six-way valve; one second switch port is connected with one third switch port; and the third main port is connected with the liquid inlet and outlet port. The invention improves versatility of the automatic on-line micro-scale sample dilution mixing system, and meets the requirements of automatic on-line sample dilution and mixing.

Owner:QINGDAO PUREN INSTR

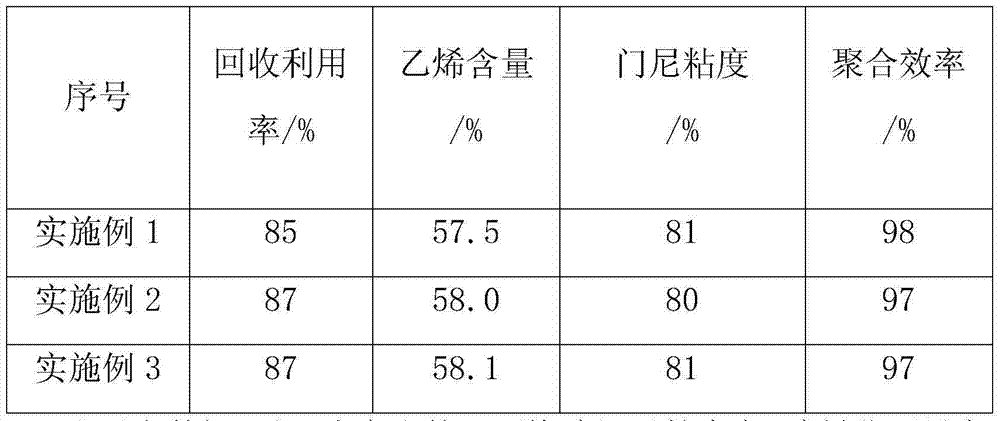

Production technology of ethylene propylene rubber

InactiveCN103539882AIncrease concentrationHigh reuse rateChemical recyclingPolymer scienceThermal insulation

The invention discloses a production technology of ethylene propylene rubber and relates to the field of rubbers. The production technology of the ethylene propylene rubber comprises five technological processes, namely polymerization, removal of a catalyst, recycling of a monomer and a solvent, coagulation as well as dehydration and drying. According to the production technology of the ethylene propylene rubber, a catalyst (described in the specification) is adopted in the polymerization process, a reaction speed is greatly increased, a full liquid phase thermal insulation reaction is adopted in the polymerization process, namely reaction heat is used for warming a polymerization kettle in a thermal insulation manner, optimal design of the polymerization kettle can meet reactant mixing requirement, a liquid-liquid filling reaction system can accurately control parameters of the polymerization technological process and product quality, concentration of a polymer glue solution is high, quantity of a cycle solvent is low, efficiency of recycled steam and recycling rate of the solvent are high, the polymerization kettle is small in volume but high in production intensity, conversion per pass is high, raw materials and a cycle monomer do not need to be refined, content of residual catalyst in the product is low, qualified rate of a product is high, consumption of the raw materials and the catalyst is low, and content of a vanadium catalyst in sewage is low. The production technology of the ethylene propylene rubber is good, high in production elasticity and low in investment.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

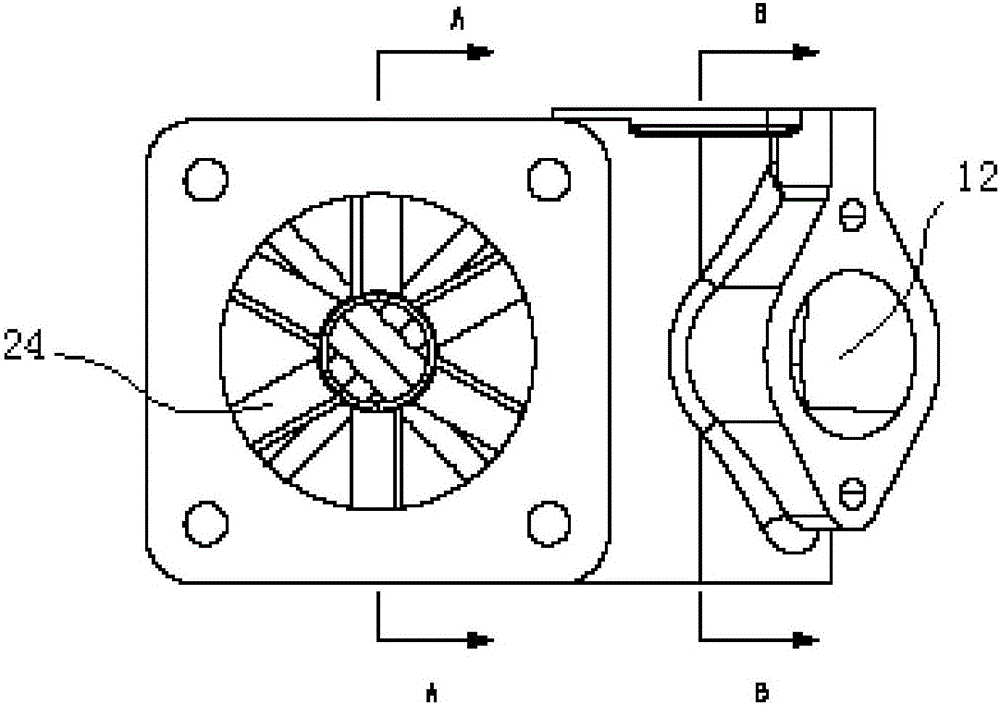

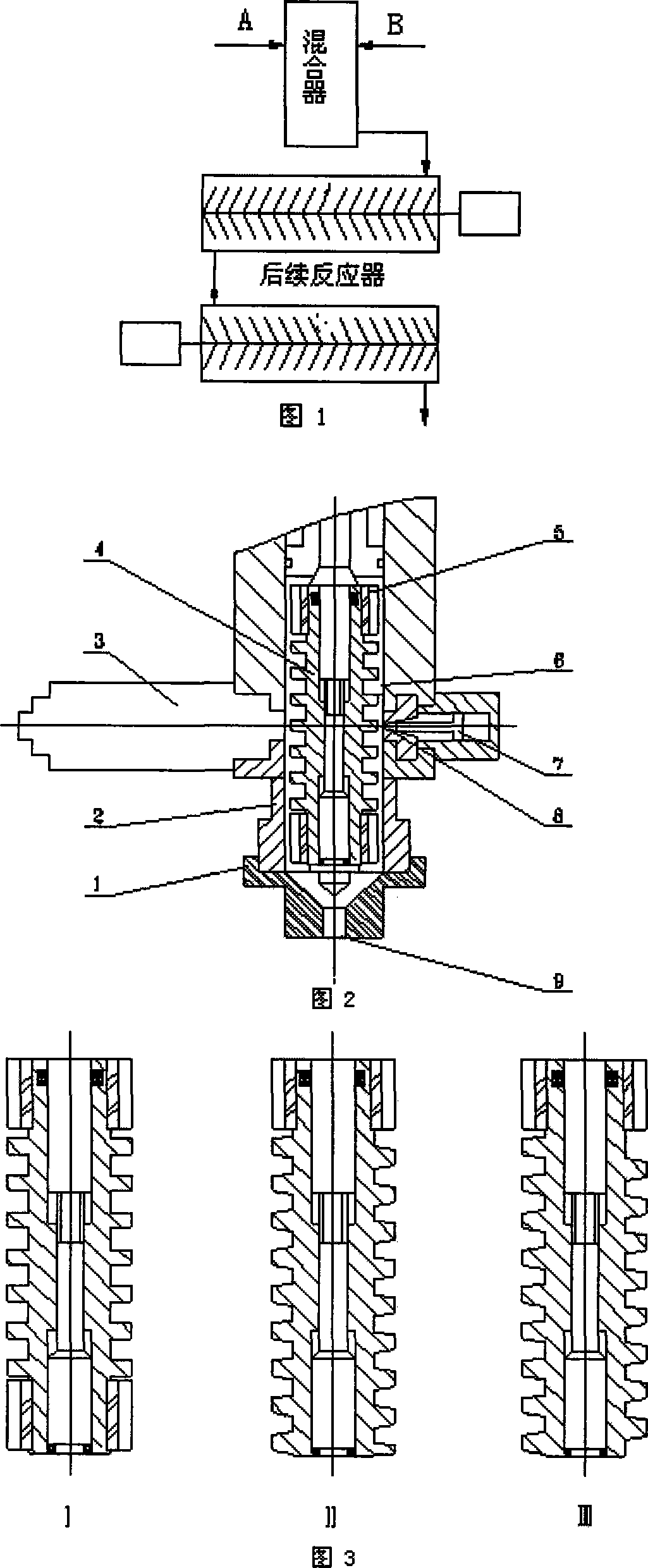

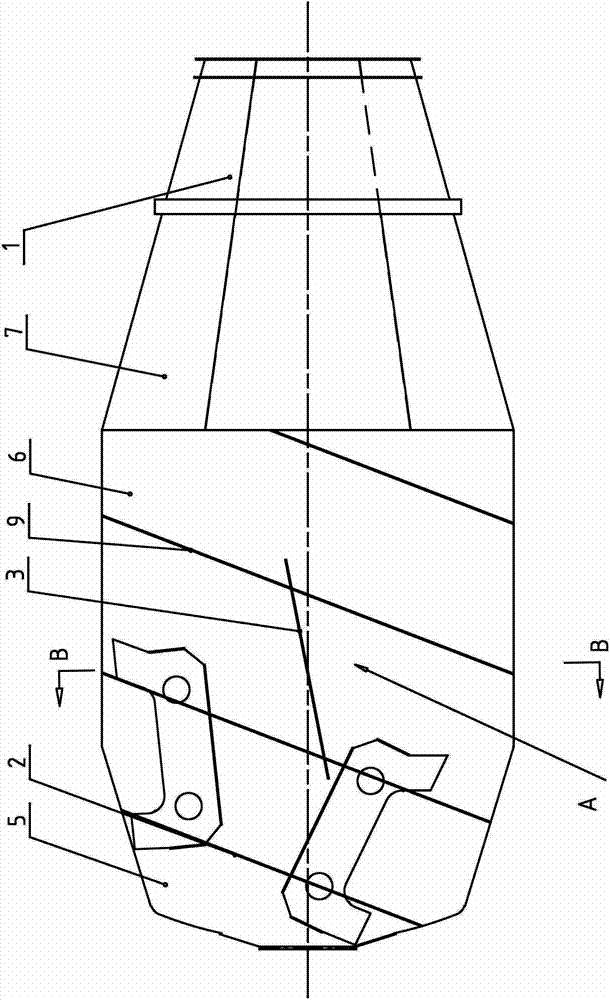

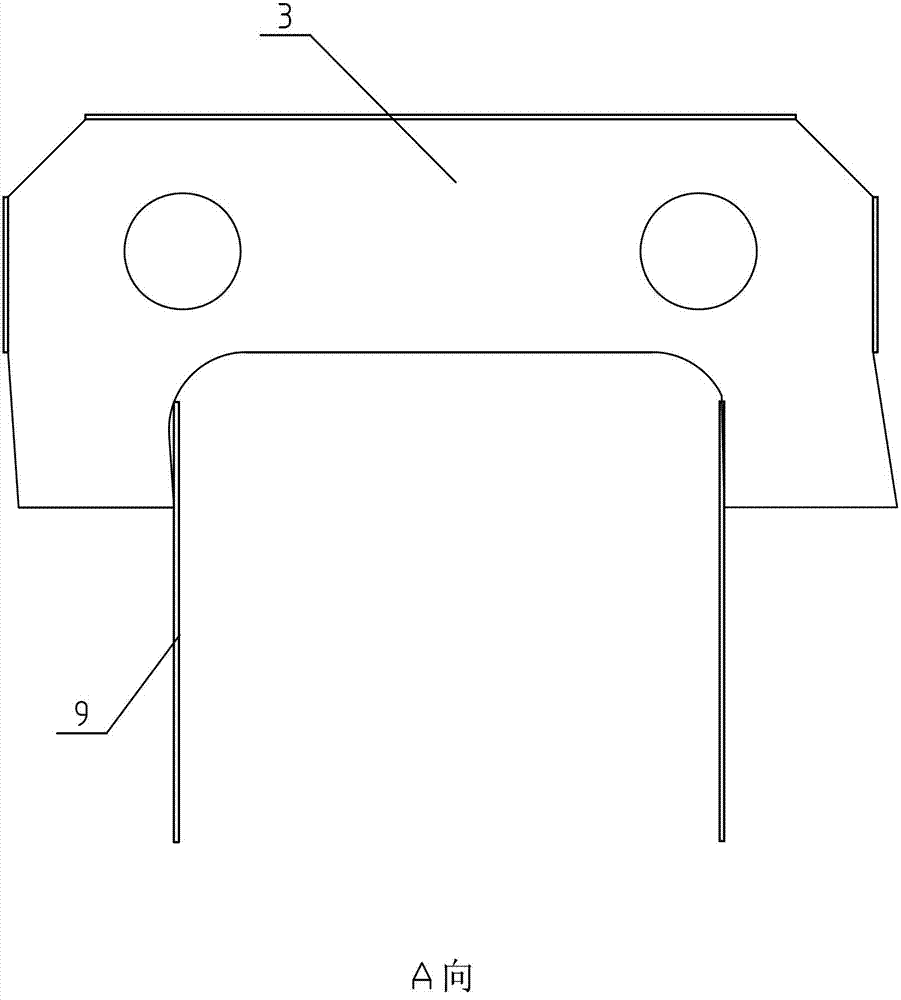

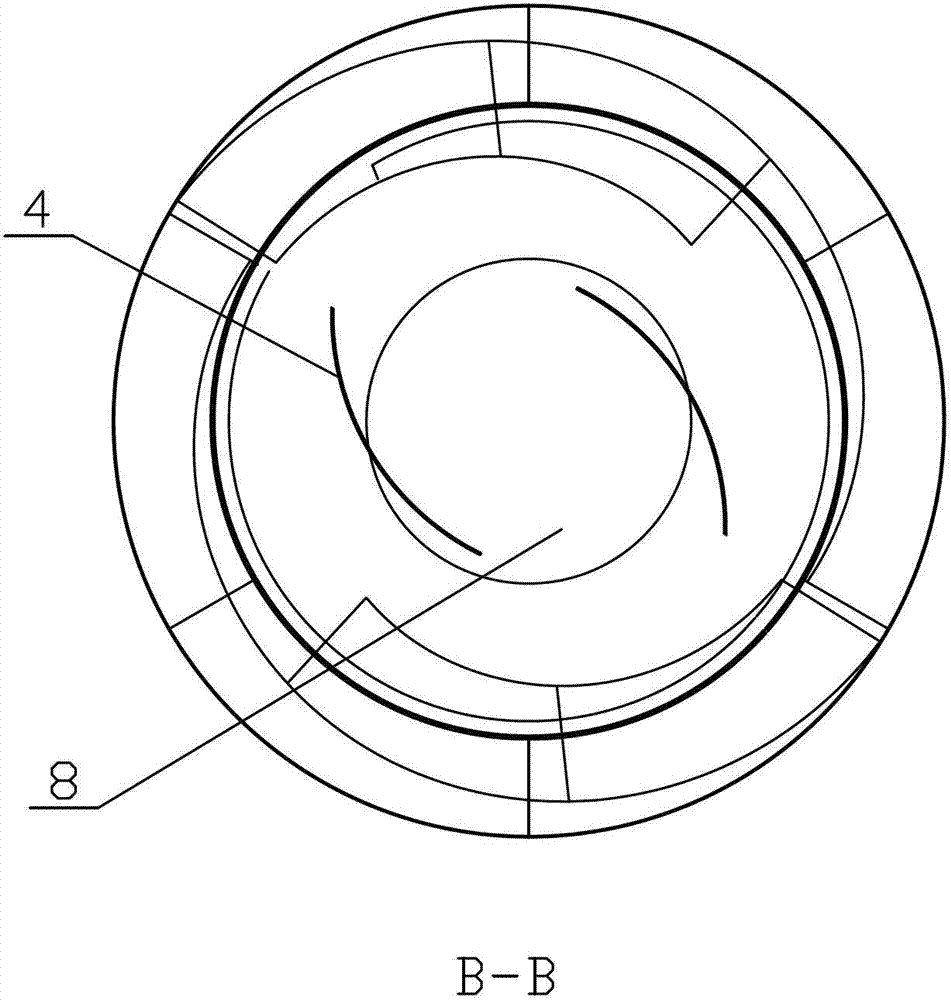

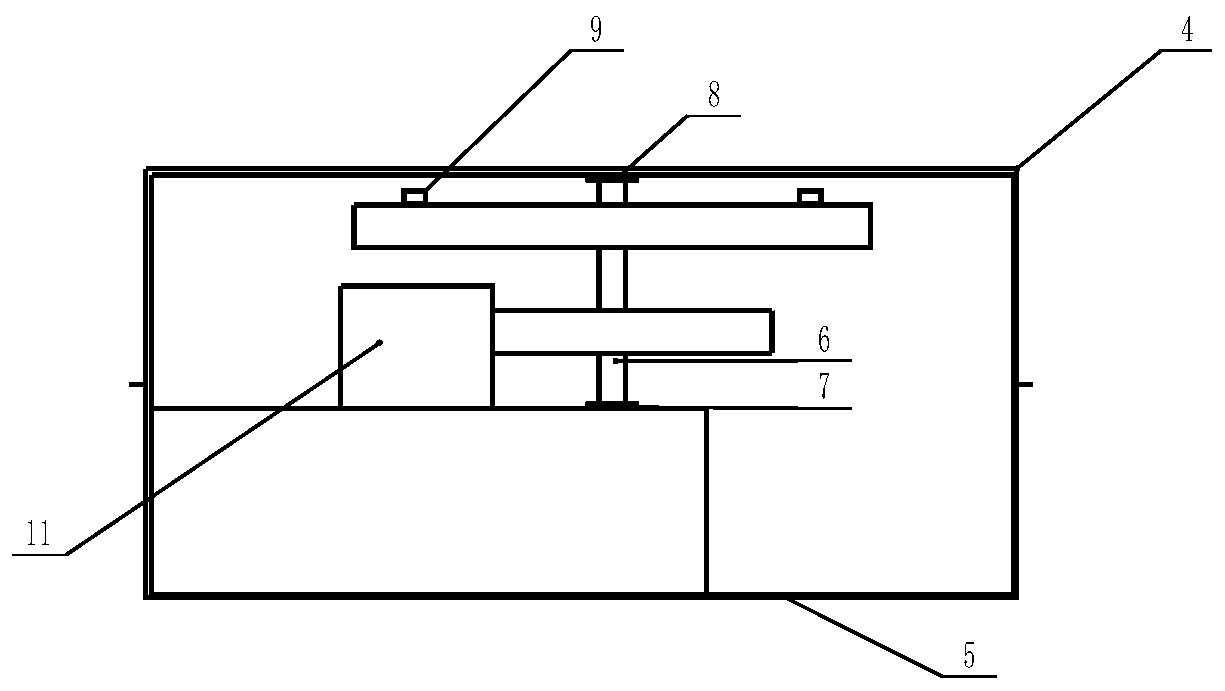

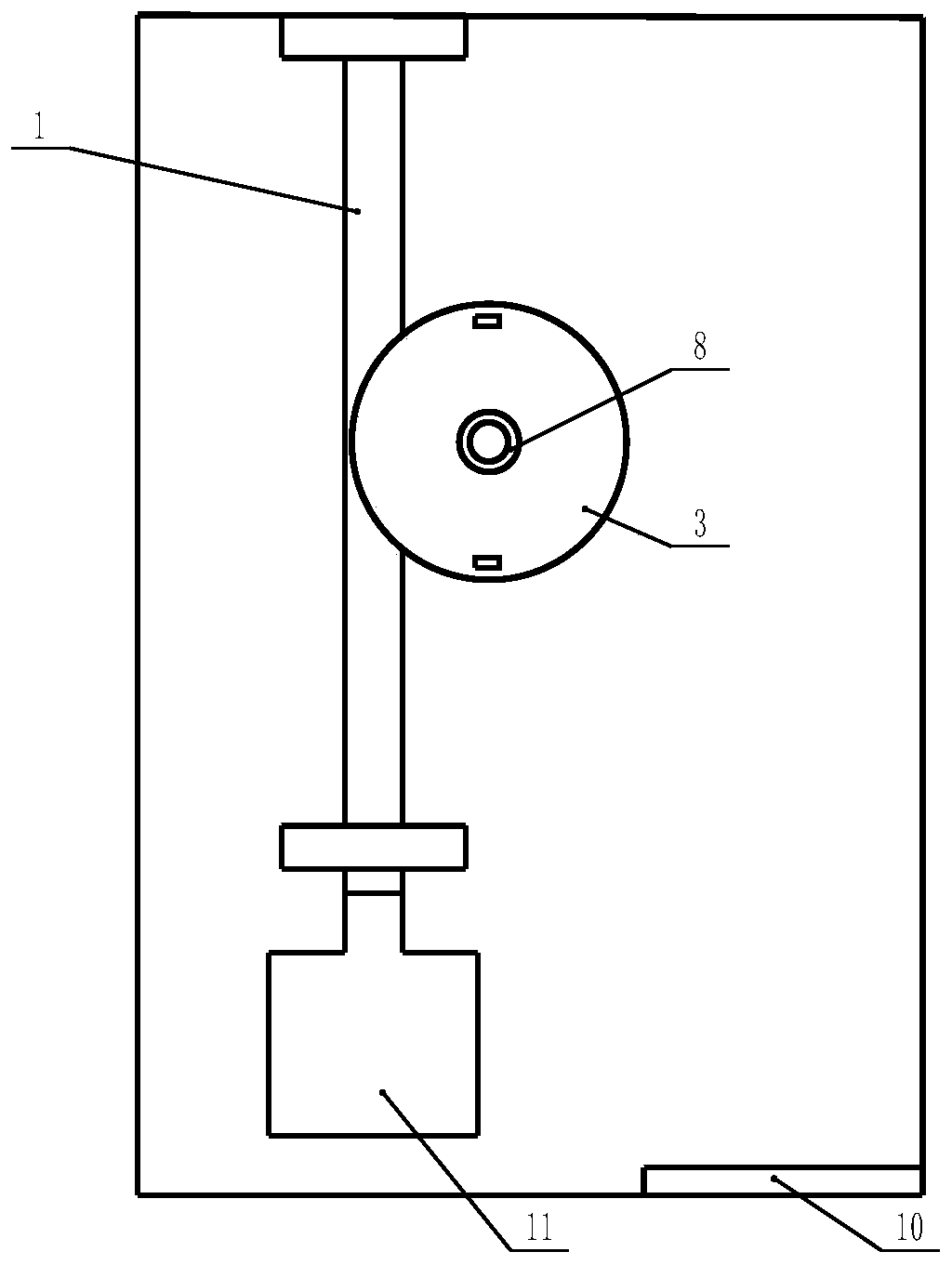

Mixer for aramid II polymerization

ActiveCN101195681AContinuous mixingMeet mixing requirementsMonocomponent polyamides artificial filamentTemperature differenceEngineering

The invention discloses a mixture for mixing materials with high temperature difference to polymerize aramid fiber II, which comprises a shell and a mixing chamber in the shell. The invention is characterized in that the mixing chamber is arranged with an internal mixing rod which top is connected with a mixing head, the shell is connected with two fluid channels communicated with the mixing chamber and an injection hole, and the lower end of the mixing shell is provided with an outlet. The invention can be used to continuously mix components at the ratio of stoichiometric coefficient, to meet different mixing demands of different materials. The invention can be used in the production of aramid fiber II, to continuously and stably produce poly-(p-phenyleneterephthalamide) resin.

Owner:中蓝晨光化工有限公司

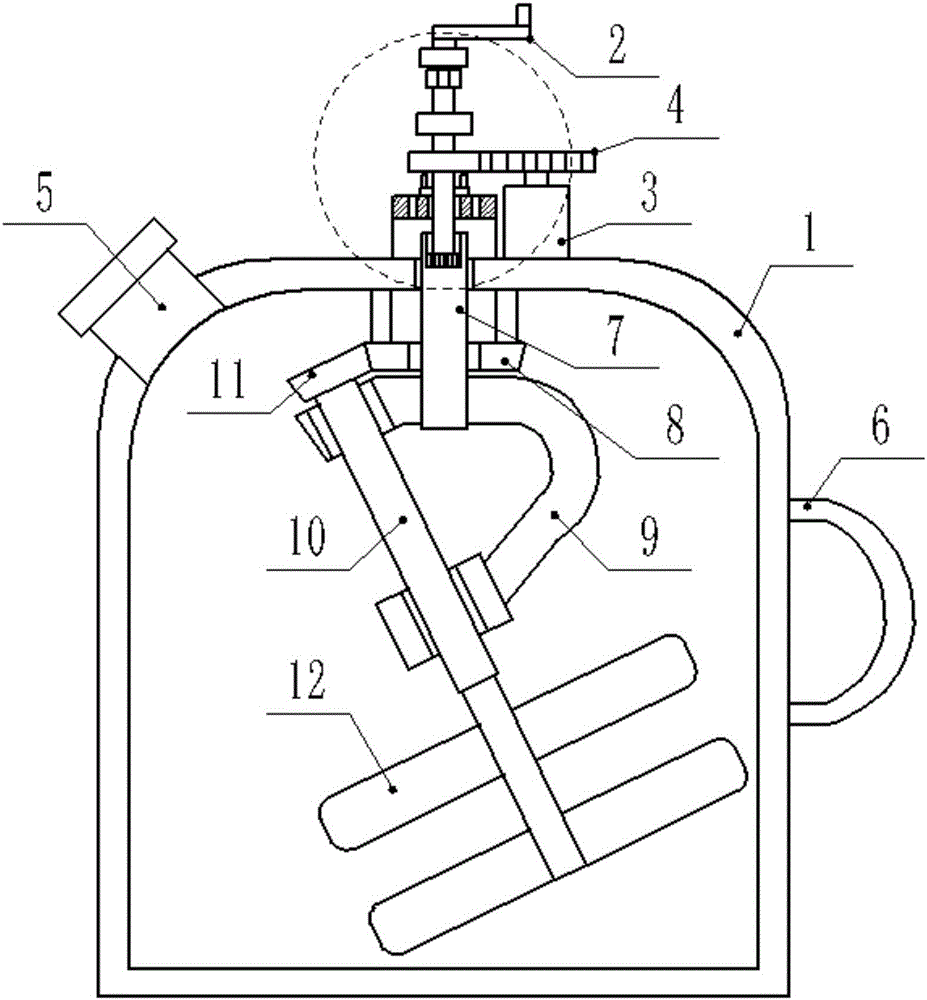

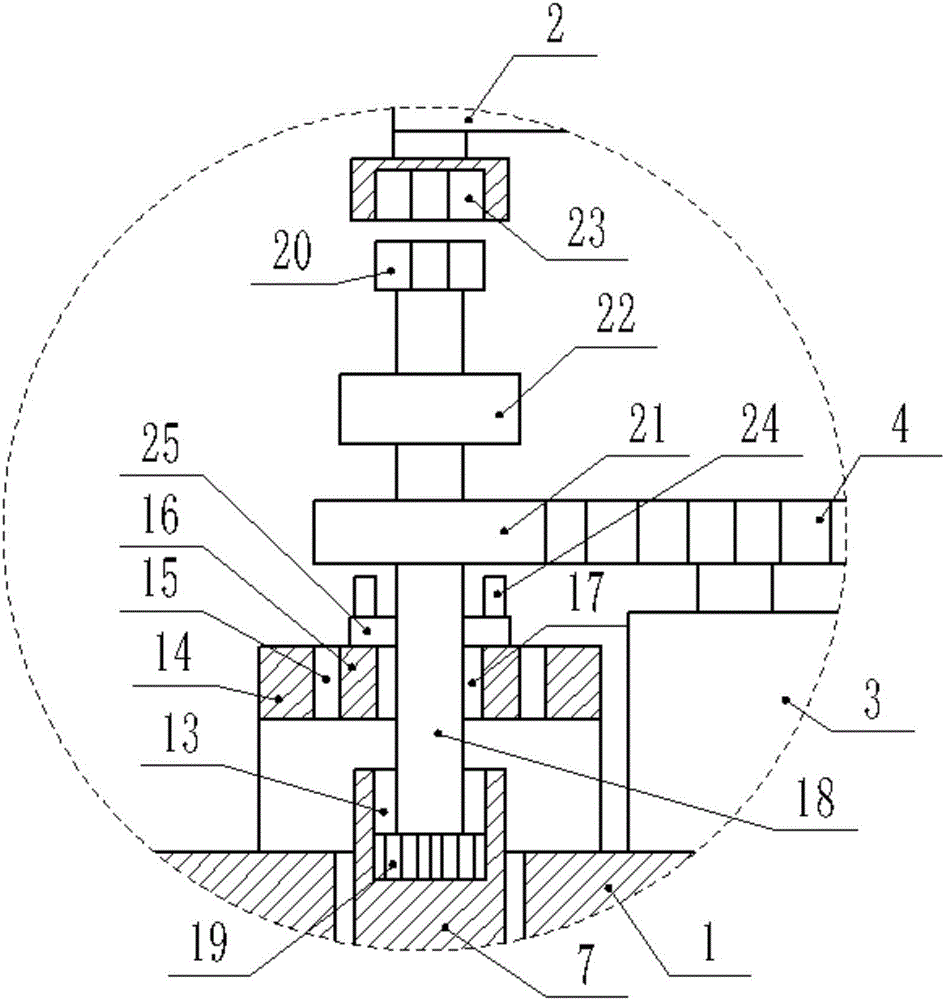

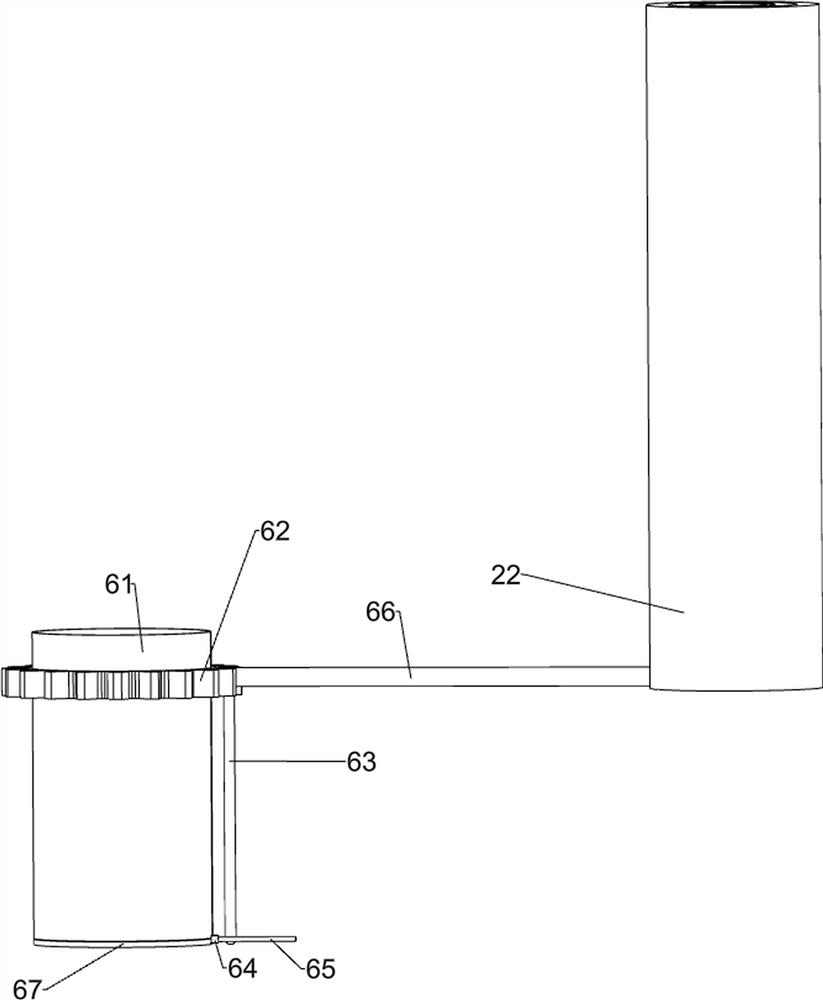

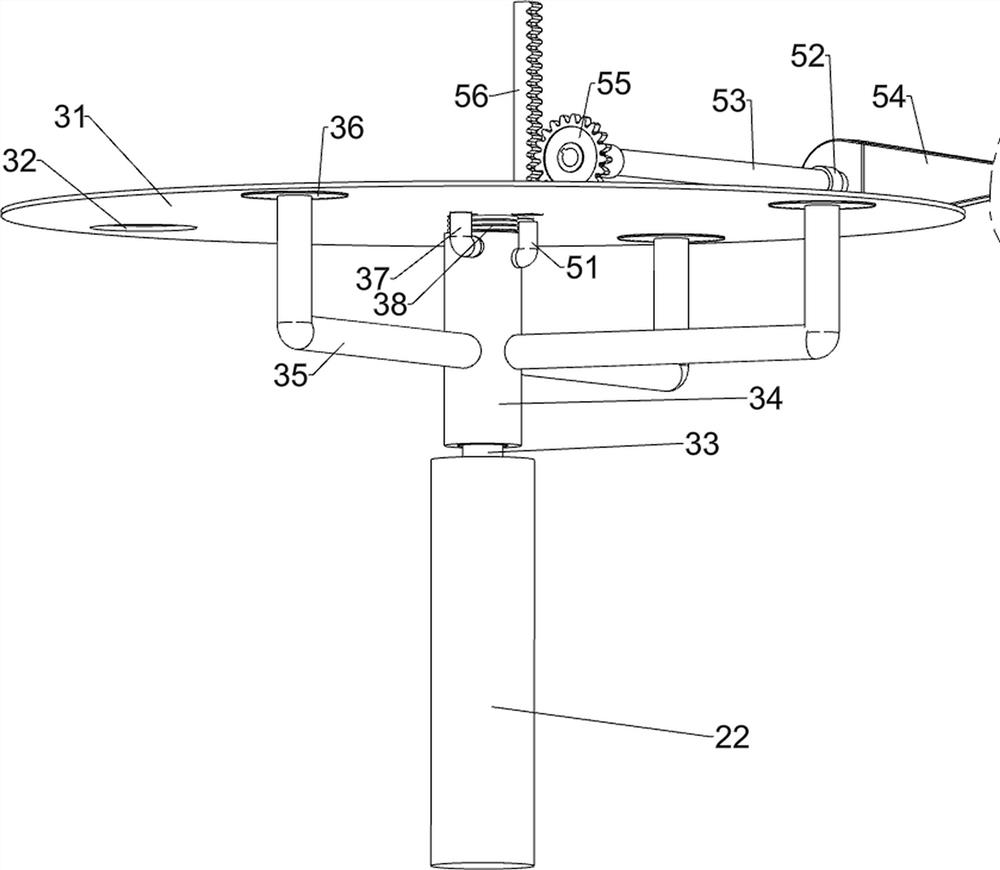

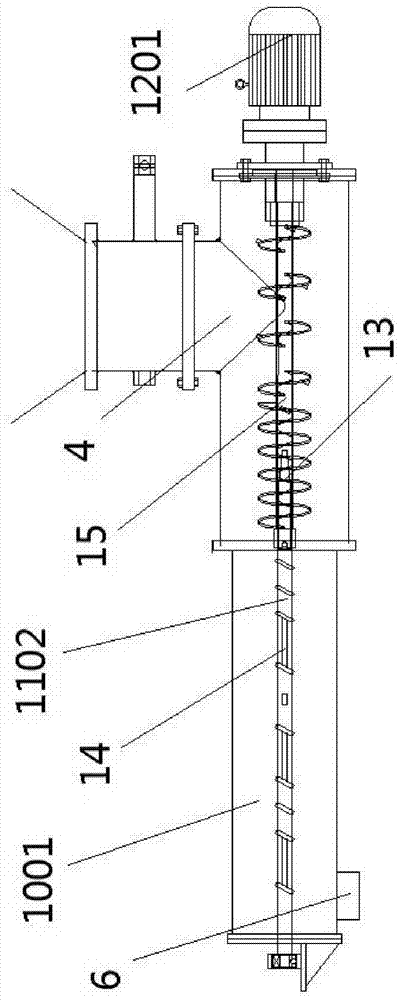

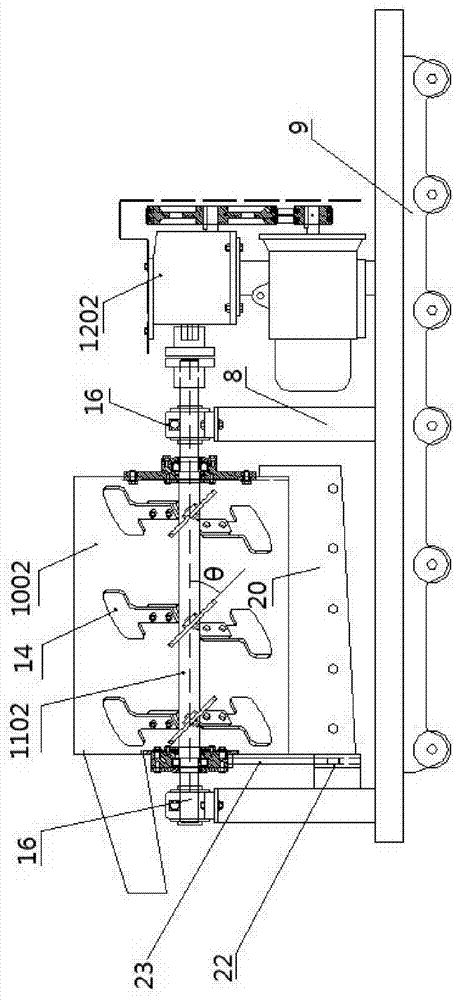

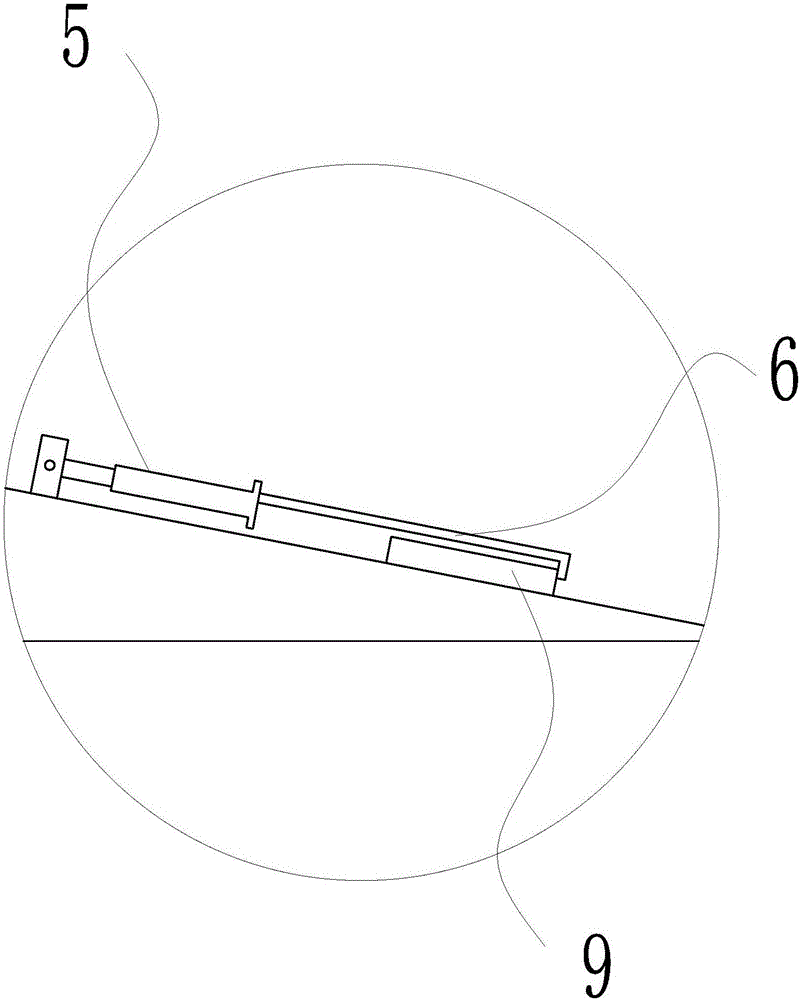

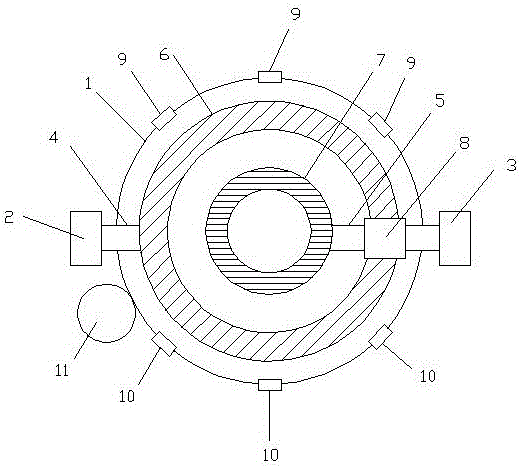

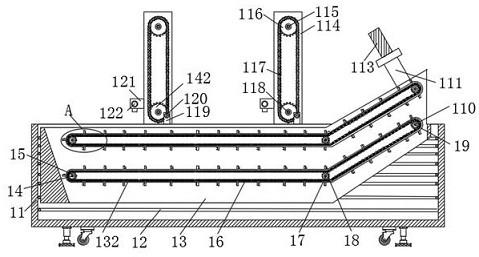

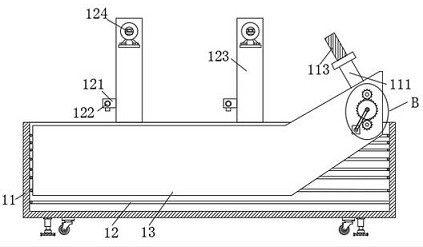

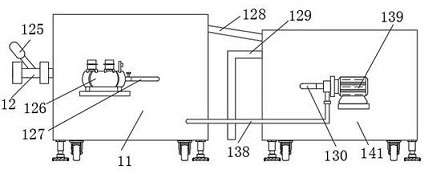

Automatic rare earth ore feeding mixer

InactiveCN112058126AAutomatic releaseMeet mixing requirementsTransportation and packagingRotary stirring mixersMining engineeringMechanical engineering

The invention relates to a rare earth ore mixer, in particular to an automatic rare earth ore feeding mixer. The invention provides an automatic rare earth ore feeding mixer which can automatically feed rare earth ore and improve the rare earth mixing efficiency. The automatic rare earth ore feeding mixer comprises a sedimentation tank; a stirring assembly mounted on the sedimentation tank and used for stirring and mixing in a rotating manner; a stirring barrel mounted on the sedimentation tank; a material control assembly mounted in the stirring barrel; a storage hopper mounted on the sedimentation tank; and an adjusting assembly mounted between the material control assembly and the stirring barrel and carrying out adjustment in a rotating manner. According to the invention, through cooperation of the stirring assembly, the material control assembly and the adjusting assembly, rare earth can be automatically put down and mixed, discharging of the rare earth can be controlled accordingto needs, the requirement for rare earth mixing is better met, the mixed rare earth can be automatically discharged through a discharging assembly, and the equipment is more convenient to use.

Owner:袁启进

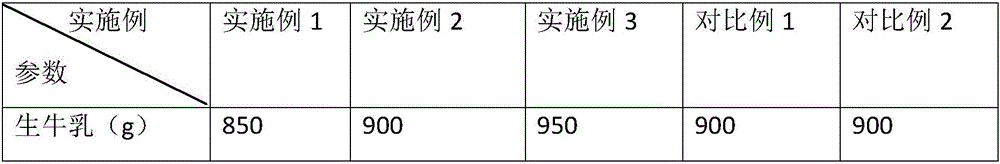

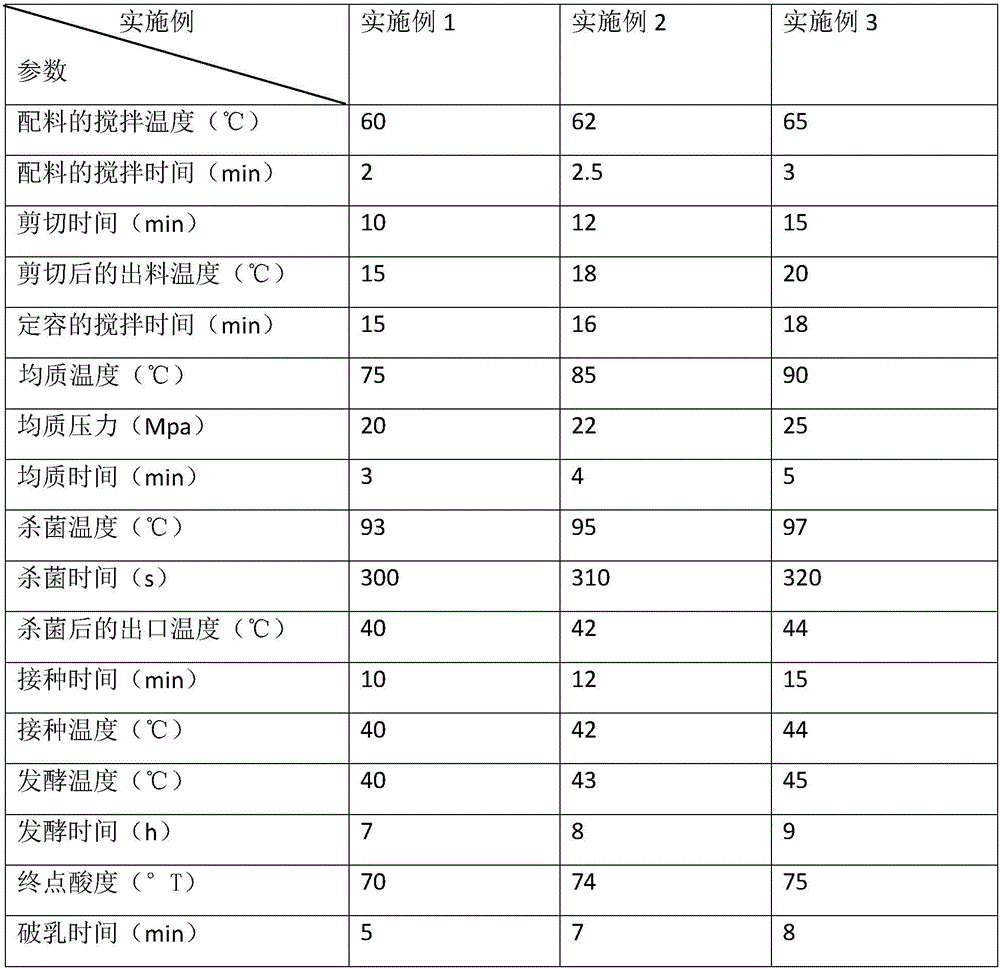

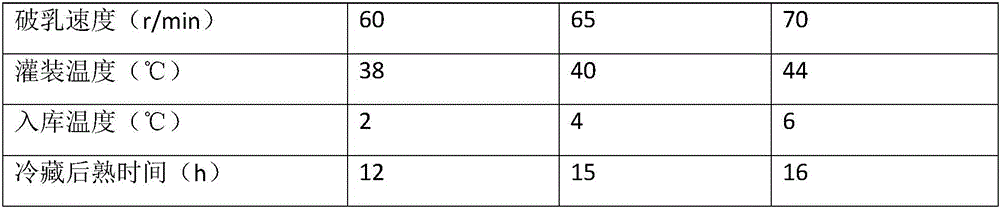

Preparation method of fermented milk

InactiveCN106615129AAvoid clearing outAvoid potential risksMilk preparationLactobacillusFermentationSweet food

The invention belongs to the technical filed of frozen desserts, and especially relates to a preparation method of fermented milk. The preparation method of the fermented milk comprises the following steps: (1), taking materials; (2), blending the materials; (3), fixing volume; (4), carrying out homogenizing and sterilizing; (5) carrying out inoculating; (6) carrying out fermentation; (7) carrying out demulsification; (8) carrying out filling; and (9) carrying out warehousing. The fermented milk prepared by the preparation method is pure in taste and stable in structure.

Owner:重庆光大集团乳业股份有限公司

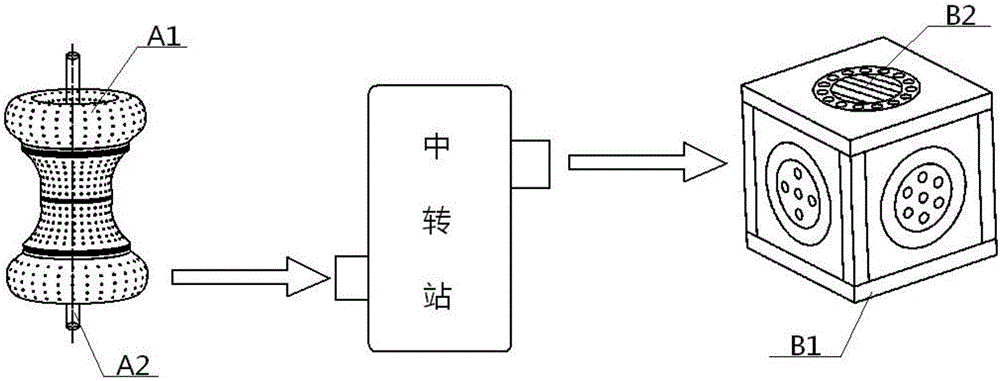

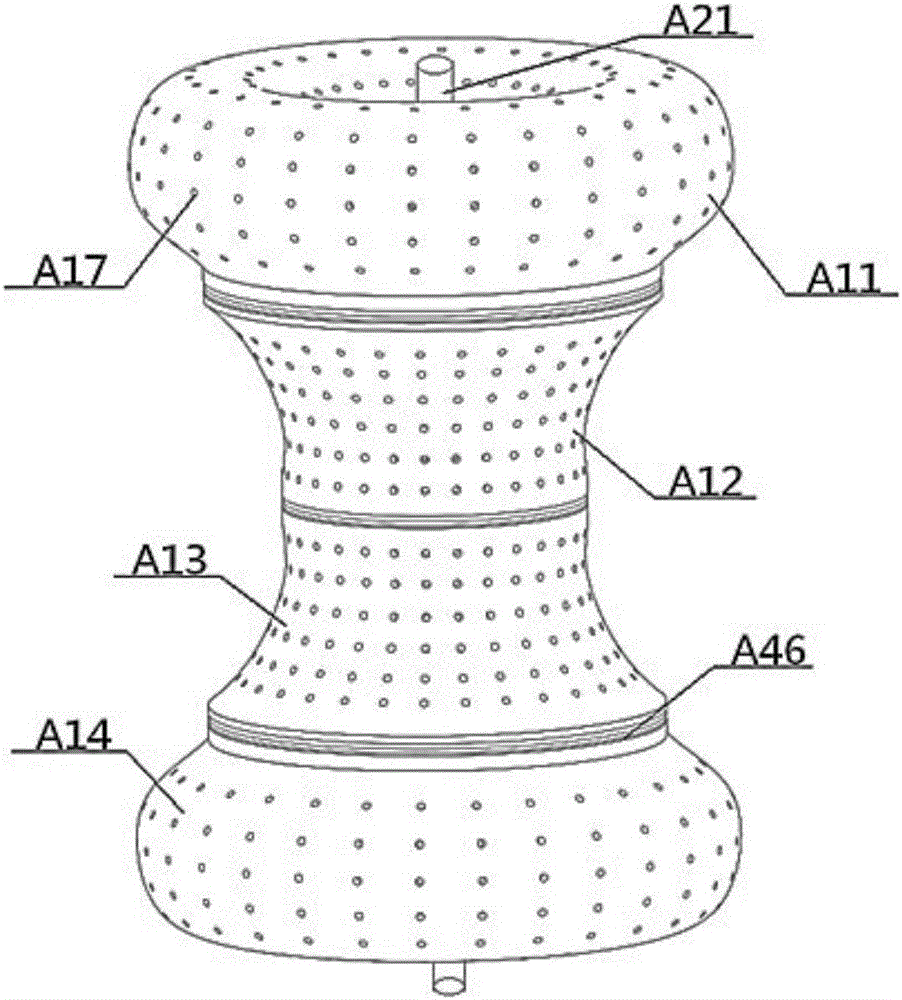

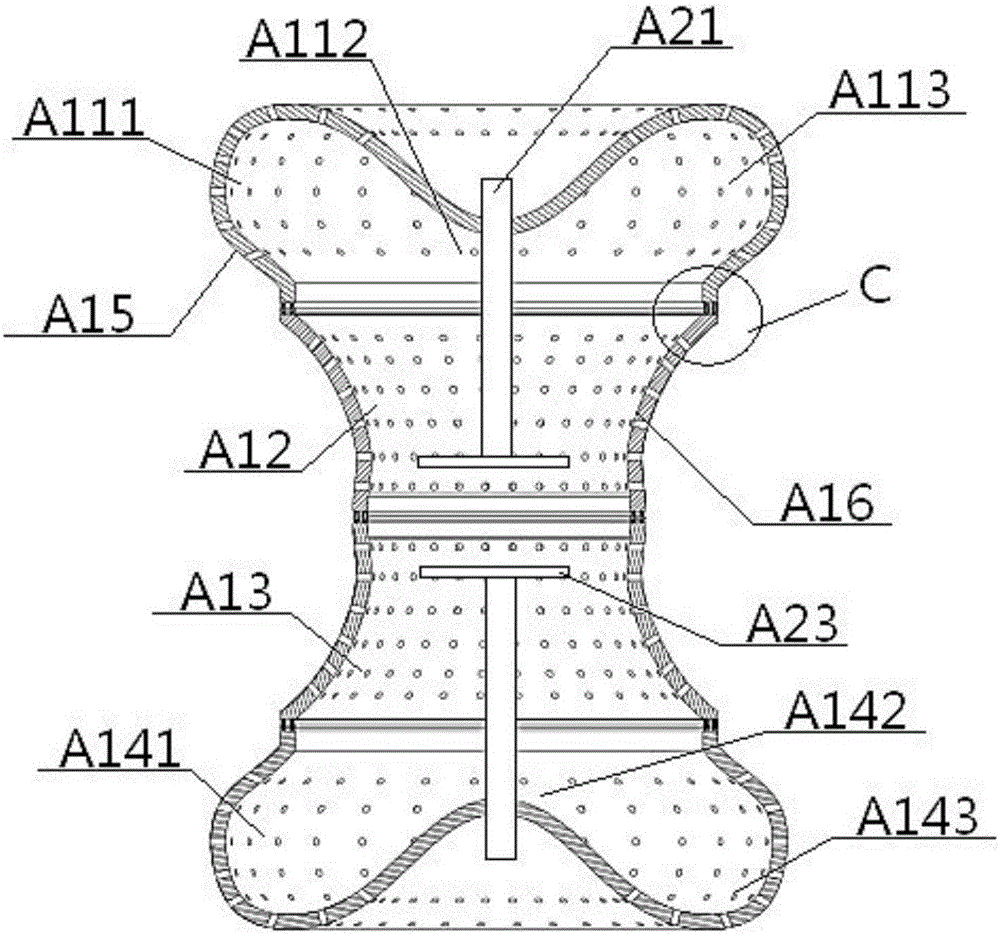

Refining and mixing system adopted in wet-process phosphoric acid refining process by solvent extraction method

ActiveCN106379879AImprove uniformityImprove stirring effectPhosphorus compoundsPhosphoric acidLubrication

A refining and mixing system adopted in a wet-process phosphoric acid refining process by a solvent extraction method is used for liquid-liquid mixing or liquid-powder mixing and comprises an A type mixing device, a transfer station and a B type mixing device which communicate with each other successively, wherein the A type mixing device has functions including that an external containing body can rotate, a heating body can be arranged and a rotating airflow can be generated, and a stirrer has three functions of body stirring, airflow stirring and enhanced stirring; the B type mixing device has functions including that an external containing body can generate a rotating airflow, a heating body can be arranged and a module can be replaced, and a stirrer has four functions of body stirring, airflow stirring, enhanced stirring, and midway addition of raw materials. The system can eliminate a fluid stagnation zone, can heat a mixed object, has the advantages of good mixing performance and high uniformity, can achieve rotation of an external container, strong lubrication effect, various stirring functions and midway addition, and has a wide range of application.

Owner:HUAZHONG NORMAL UNIV

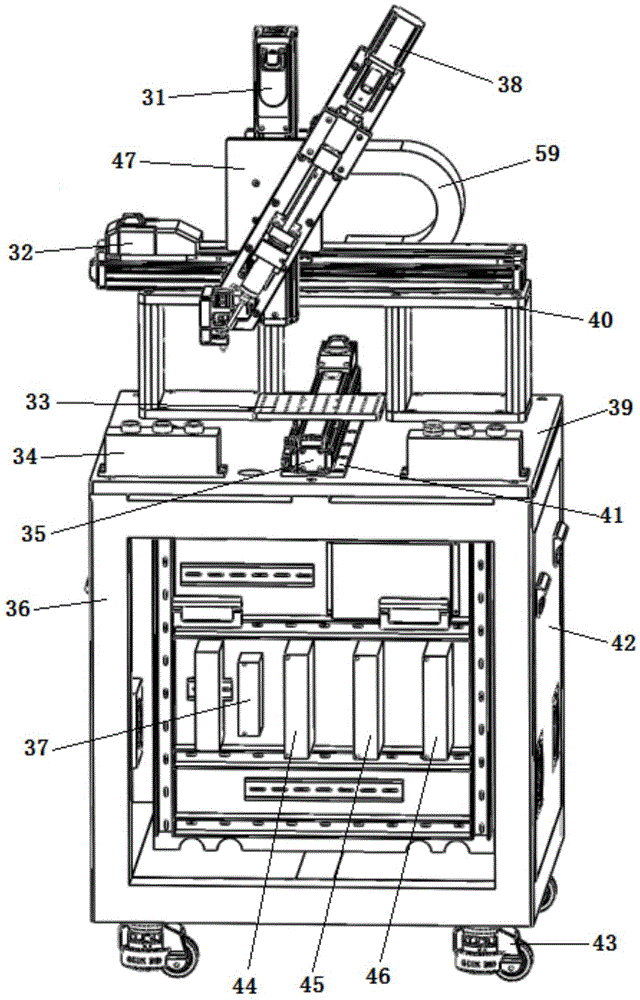

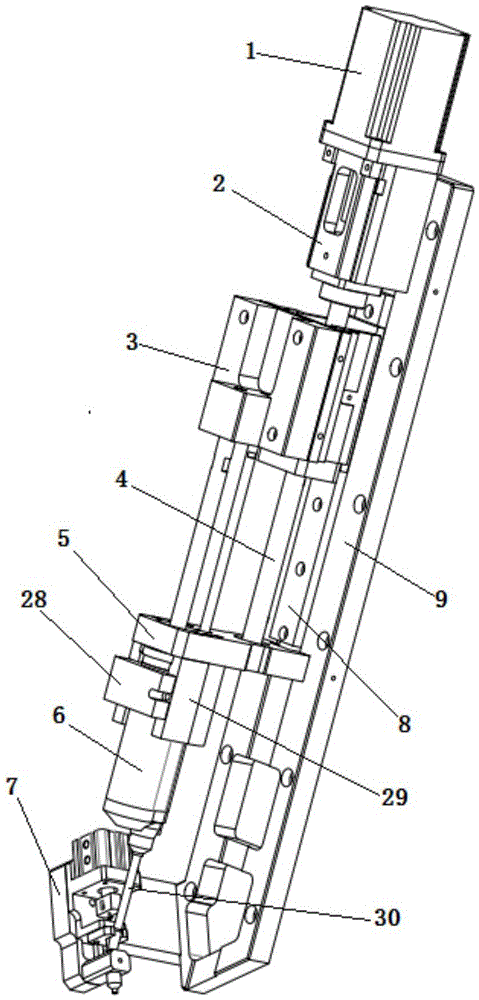

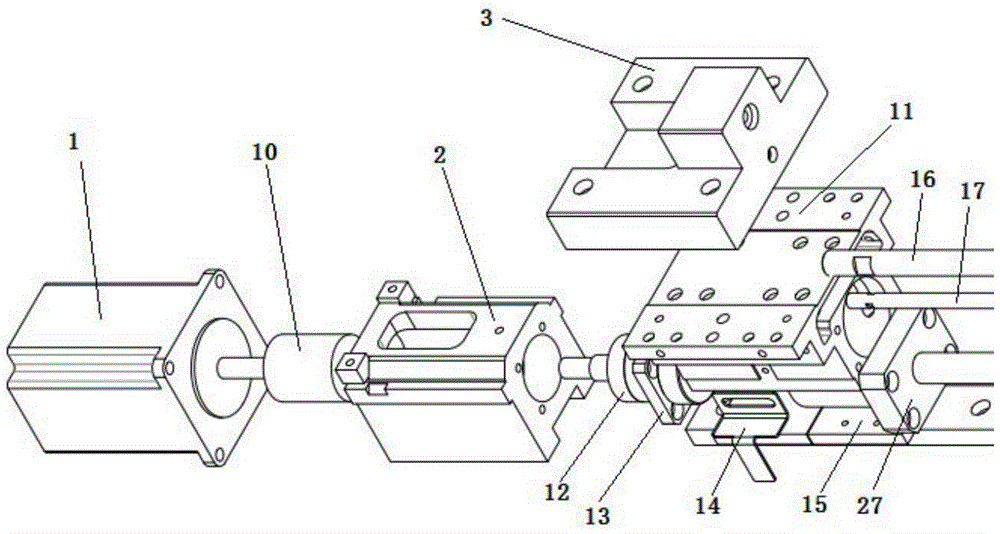

Three-axis orthogonal coordinate dispensing machine

InactiveCN105618330AHigh efficiency and stabilityPush glue evenlyLiquid surface applicatorsCoatingsOrthogonal coordinatesControl system

The invention discloses a three-axis orthogonal coordinate dispensing machine. The three-axis orthogonal coordinate dispensing machine comprises a dispensing machine rack, an orthogonal coordinate control system and a stepping glue pushing mechanism. The rack comprises an outer frame, a substrate, an electric control unit, side door plates and rolling wheel supporting feet. The substrate is horizontally fixed to a table frame, and the electric control unit is disposed in the outer frame and comprises an X-axis servo driver, a Y-axis servo driver, a Z-axis servo driver and a stepping motor driver. The side door plates are arranged on the periphery of the outer frame, and the rolling wheel supporting feet used for adjusting levelness are arranged at the four corners of the lower side of the outer frame. The orthogonal coordinate control system comprises an X axis, a Y axis and a Z axis, and the stepping glue pushing mechanism is fixed to the Z axis. The three-axis orthogonal coordinate dispensing machine is reasonable in structural design, more precise in glue pushing amount, higher in efficiency and more stable, and particularly solves the quick dispensing problem of mixed glue fundamentally.

Owner:SUZHOU TERUITE ROBOT CO LTD

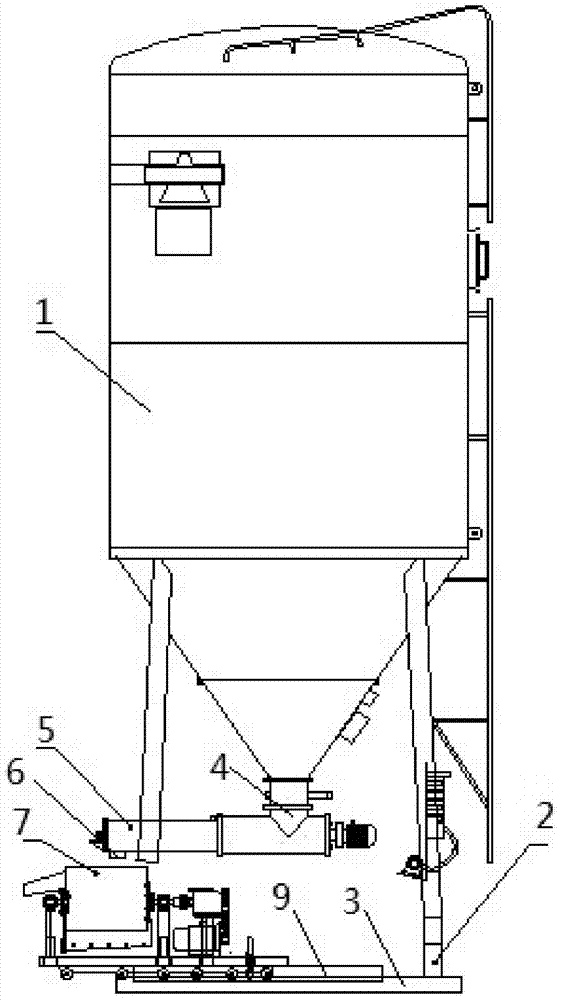

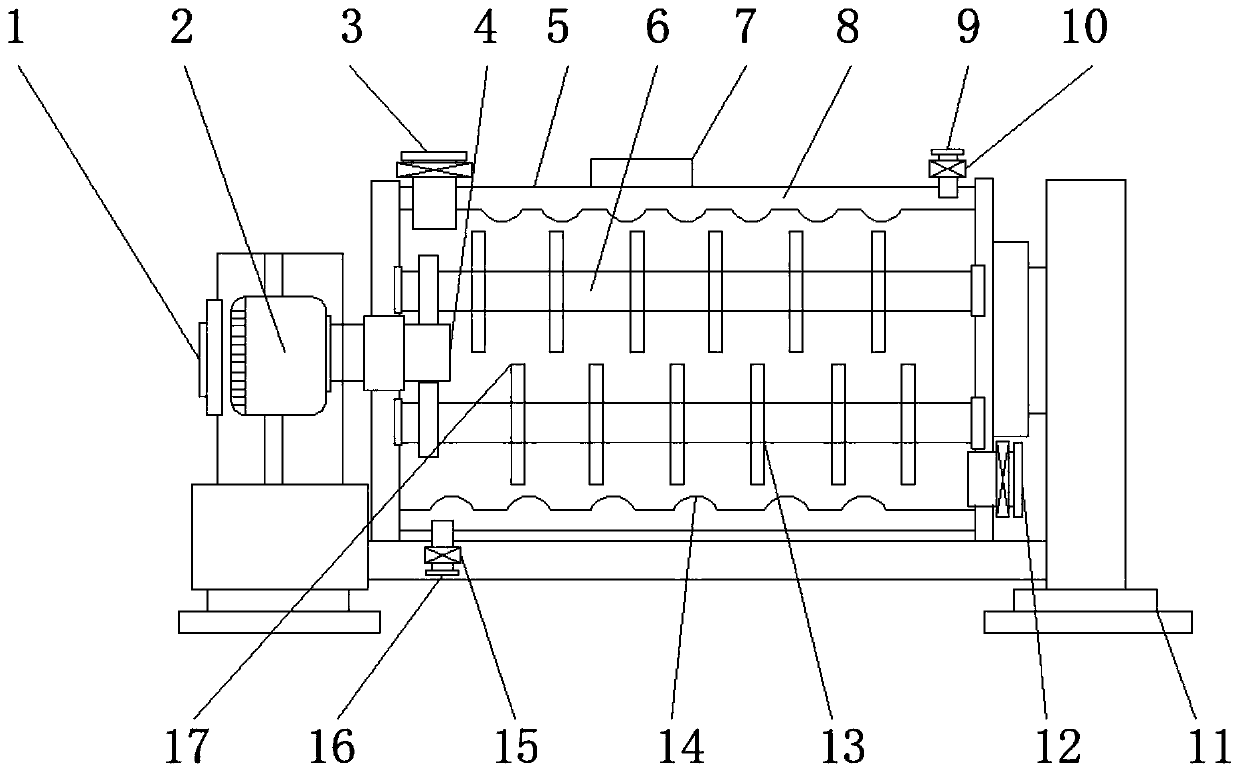

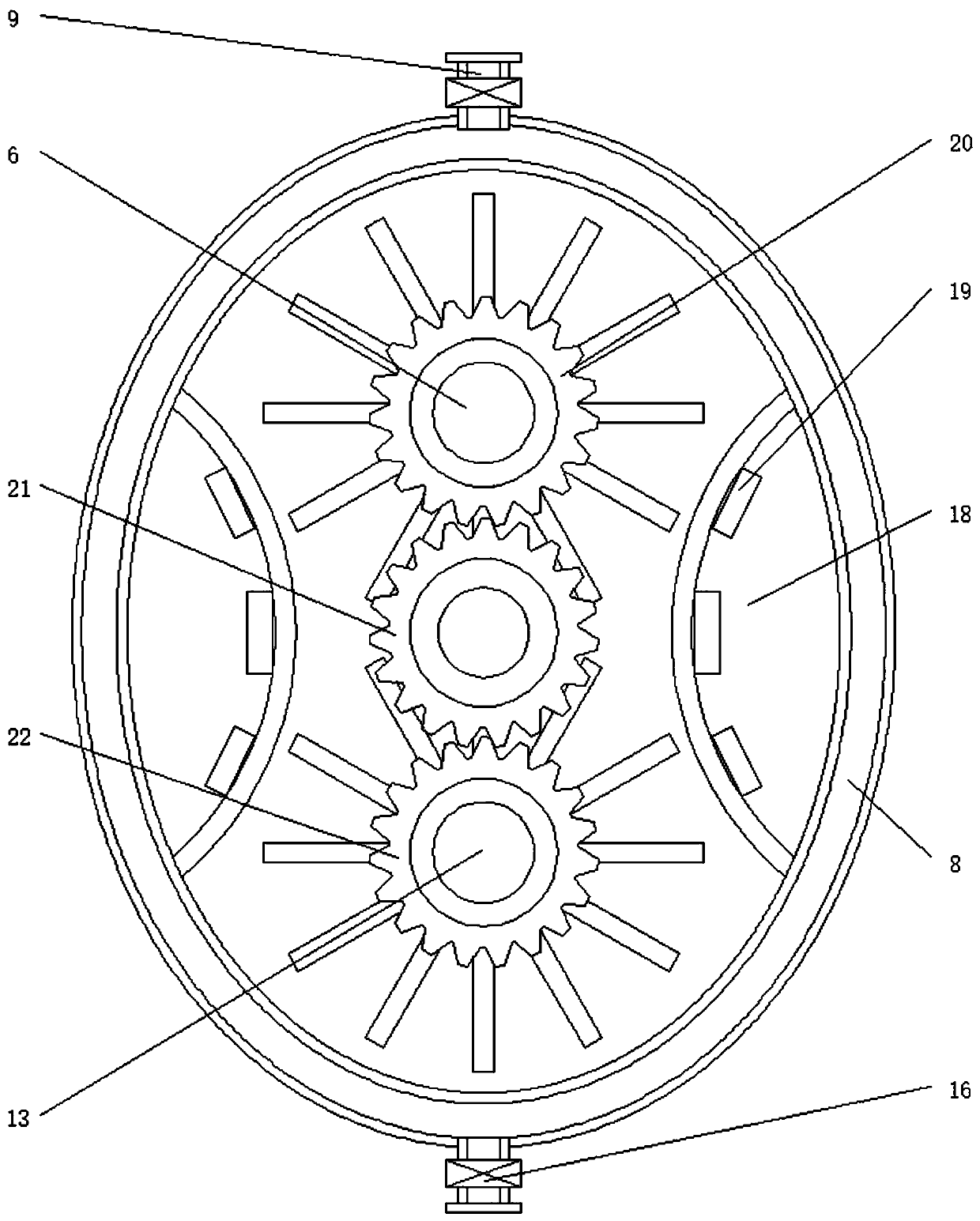

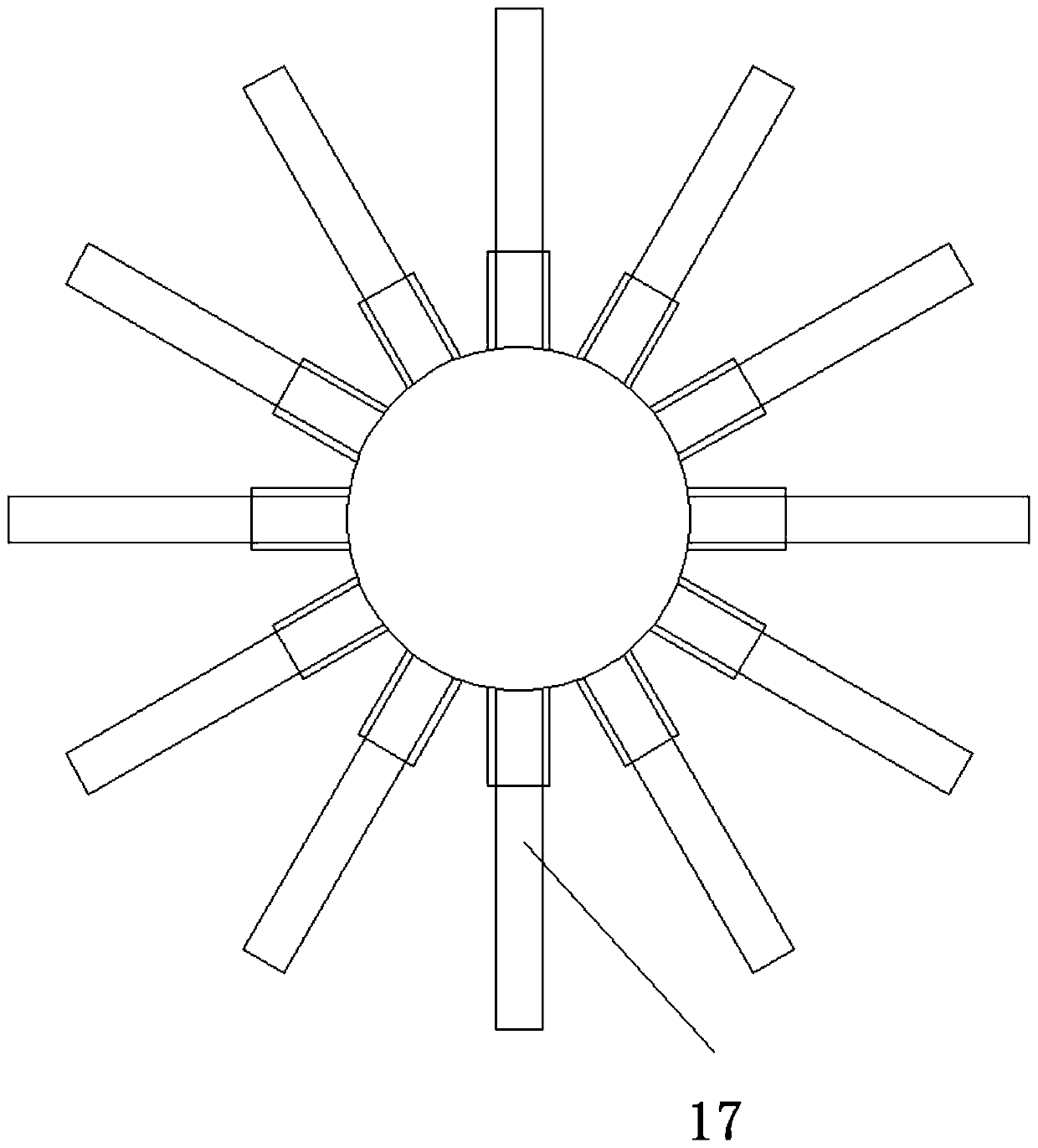

Horizontal dry-mixed mortar stirrer

ActiveCN103934902AMeet mixing requirementsReduce processing costsCement mixing apparatusMixing operation plantPulp and paper industryProcessing cost

The invention relates to the field of mortar storing and stirring devices and in particular relates to a horizontal dry-mixed mortar stirrer. The horizontal dry-mixed mortar stirrer comprises a storage tank, wherein the storage tank is fixed on a base through a bracket; a discharging opening of a discharging tank is downward; a discharging opening of the storage tank is communicated with a first stirring assembly; a first discharging opening is formed in the first stirring assembly; a second stirring assembly is arranged under the first discharging opening; the second stirring assembly is fixed on the bracket; the bottom of the bracket is arranged on a movable device; the first stirring assembly comprises a first shell with the hollow inside; a first stirring shaft is mounted in the first shell; one end of the first stirring shaft is connected with a first motor in a transmission manner; the second stirring assembly comprises a second shell with the hollow inside; a second stirring shaft is mounted in the second shell; one end of the second stirring shaft is connected with a second motor in the transmission manner. The horizontal dry-mixed mortar stirrer is capable of meeting the stirring requirements of materials, enlarging the application range and saving the processing cost.

Owner:JIANGSU WOLVES MACHINERY

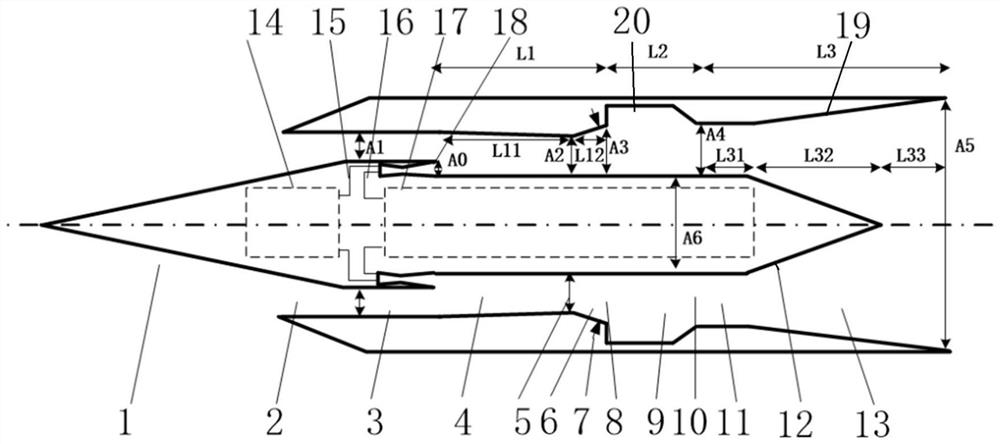

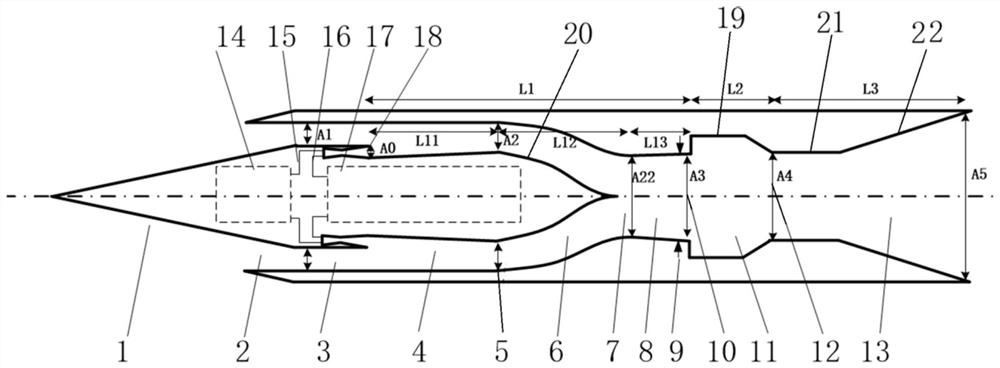

Rocket ramjet wide-speed-range engine based on annular pressurization center body tail confluence

ActiveCN112682219AImprove thrust performanceReduce nozzle exit areaRam jet enginesComposite engine plantsRamjetCombustion chamber

The invention discloses a rocket ramjet wide-speed-range engine based on annular pressurization center body tail confluence. The engine comprises a center body, an air inlet channel, a combustion chamber with a concave cavity and a spray pipe. An embedded rocket in a conventional rocket ramjet engine is arranged on the outer side of the center body, the rocket gas and air are mixed in an annular mixing channel, and the contact area of rocket jet flow and the air is increased, so that the mixing distance of two air flows can be effectively shortened. Meanwhile, annular airflow is converted into central pipe flow through a central body contraction section at the spray pipe, the outlet area of the engine spray pipe can be reduced, and therefore the structural size of the engine is reduced, and the overall thrust performance of the rocket ramjet engine can be effectively improved by adopting the scheme.

Owner:NAT UNIV OF DEFENSE TECH

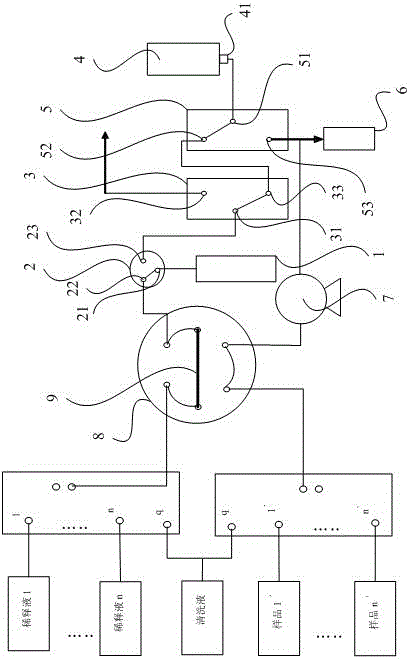

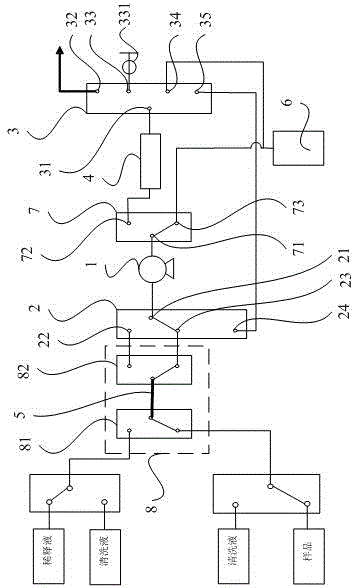

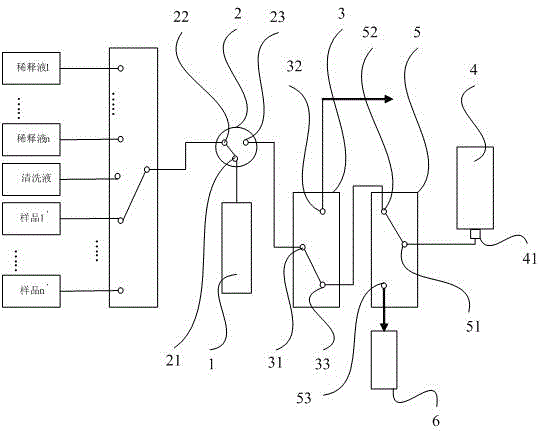

Automatic online micro-scale sample dilution and mixing system and mixing method

ActiveCN104062168AWell mixedEffect of substance contentPreparing sample for investigationHybrid systemEngineering

The invention provides an automatic online micro-scale sample dilution and mixing system and a mixing method. The system includes a constant flow pump, a first multi-position switching valve, a second multi-position switching valve, a mixer, a six-way valve, a quantitative tube and a sampling pump. The first multi-position switching valve comprises a first main port and two first switch ports in selective connection with the first main port; the second multi-position switching valve comprises a second main port and four second switch ports in selective connection with the second main port; two ports of the quantitative tube and the inlet of the sampling pump are connected to the six-way valve, constant flow pump and the mixer are successively connected between the first main port and the second main port; and one first switch port are connected with the six-way valve, the other first switch port is connected with one of the second switch ports, and the other second switch port is provided with a plug. The invention improves versatility of the automatic on-line micro-scale sample dilution mixing system, and meets the requirements of automatic on-line sample dilution and mixing.

Owner:QINGDAO PUREN INSTR

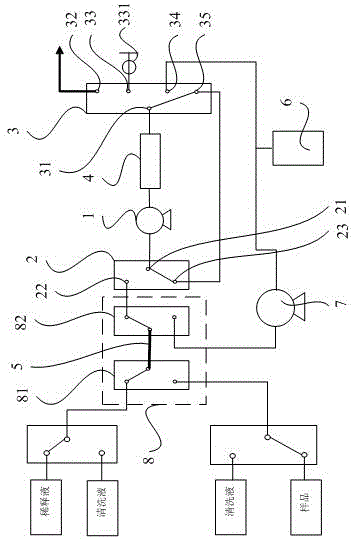

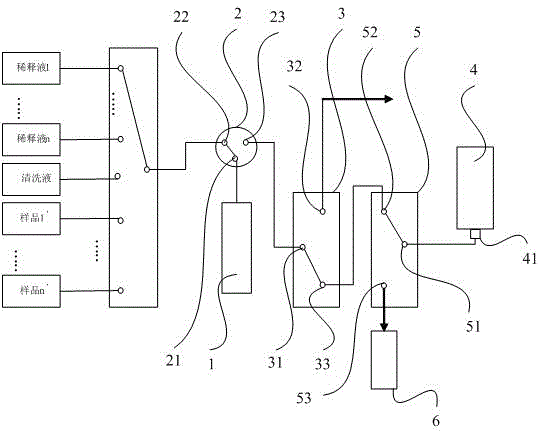

Automatic online micro-scale sample dilution and mixing device and mixing method

ActiveCN104062169AAccurate dilutionDilute and mix accuratelyPreparing sample for investigationSample dilutionElectrical and Electronics engineering

The invention provides an automatic online micro-scale sample dilution and mixing device and a mixing method. The device includes a constant flow pump, a first multi-position switching valve, a second multi-position switching valve, a third multi-position switching valve, a mixer, a six-way valve, and a quantitative tube. The first multi-position switching valve comprises a first main port and three first switch ports; the second multi-position switching valve comprises a second main port and four second switch ports; the third multi-position switching valve comprises a third main port and two third switch ports; the quantitative tube and two first switch ports are respectively connected to the six-way valve, a constant flow pump is connected between the first main port and the second main port; the mixer is connected between the third switch ports and the second main port; the reaming first switch ports are connected with one of the second switch ports, and the other second switch port is provided with a plug. The invention improves versatility of the automatic on-line micro-scale sample dilution mixing system, and meets the requirements of automatic on-line sample dilution and mixing.

Owner:QINGDAO PUREN INSTR

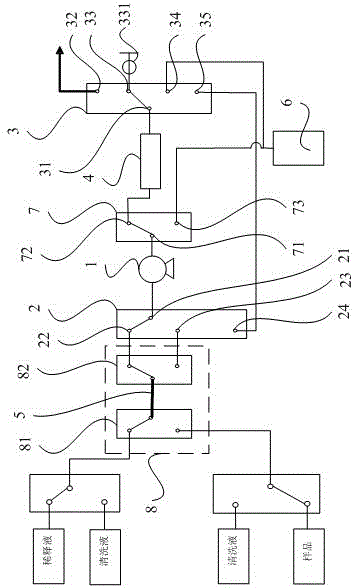

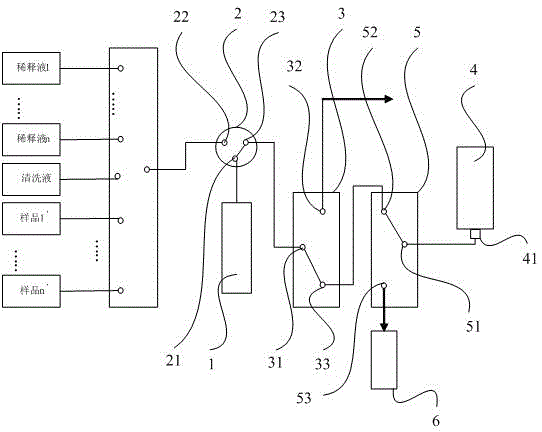

Automatic online sample dilution and mixing device and mixing method

InactiveCN104062167AImprove versatilitySatisfy dilute mixing requirementsPreparing sample for investigationSample dilutionElectrical and Electronics engineering

The invention provides an automatic online sample dilution and mixing system and a mixing method. The device includes a syringe pump, a first multi-position switching valve, a second multi-position switching valve, a third multi-position switching valve and a mixer. The first multi-position switching valve comprises a first main port and two first switch ports in selective communication with the first main port; the second multi-position switching valve comprises a second main port and two second switch ports in selective communication with the second main port; the third multi-position switching valve comprises a third main port and two third switch ports in selective communication with the third main port; the mixer is provided with a liquid inlet and outlet port; the syringe pump is connected with the first main port; one first switch port is connected with the second main port; one second switch port is connected with one third switch port; and the third main port is connected with the liquid inlet and outlet port. The invention improves versatility of the automatic on-line micro-scale sample dilution mixing system, and meets the requirements of automatic on-line sample dilution and mixing.

Owner:QINGDAO PUREN INSTR

Plastic bag raw material mixer

The invention discloses a plastic bag raw material mixer. The plastic bag raw material mixer comprises a heat dissipation fan, a motor device, a barrel body and a thermometer, wherein the left side ofthe motor device is equipped with the heat dissipation fan; the right side of the motor device is fixedly connected with a drive shaft; the right side of the drive shaft is arranged inside the barrelbody; the upper side of the drive shaft is equipped with a first transmission shaft; a discharge hole is formed in the middle of the right side of the barrel body; the barrel body is fixedly arrangedon the bracket; the left lower side of the barrel body is equipped with a steam outlet; and an outlet regulating valve is arranged on the steam outlet. The plastic bag raw material mixer disclosed bythe invention adopts dual transmission shafts, and dispersing discs are uniformly arranged on the transmission shafts in a spaced mode, so that raw materials do not form fixed rotating vortex duringrotation, raw material mixing is more uniform, mixing time is shortened, working efficiency is improved, mixing work of plastic bag raw materials can be performed better, and development of the plastic bag processing industry is promoted.

Owner:颍上县浩楠塑料包装有限公司

Mobile stirring device for rubber compound production

The invention discloses a mobile stirring device for rubber compound production. The mobile stirring device for rubber compound production comprises a bin, a stirring shaft arranged in the bin, a speed reducer connected with the stirring shaft, and a motor for driving the speed reducer to operate; a feed port is formed above the bin; a cover plate is movably arranged above the feed port; meanwhile, a first cylinder is provided; the first cylinder can drive the cover plate to move to realize opening and closing of the feed port; four stand columns are arranged at the lower part of the bin; one wheel is arranged below each stand column; a discharge port is formed in the lower end of the bin; and a baffle plate capable of moving is provided, and is driven by a second cylinder to realize opening and closing of the discharge port. The mobile stirring device for rubber compound production is simple in structure, can satisfy general stirring requirements, can randomly move, improves the production efficiency, can automatically open and close the feed port and the discharge port through designing the first cylinder and the second cylinder, and saves the loading time.

Owner:马弗橡塑(镇江)有限公司

Vibrational multifunctional stirring device and stirring method thereof

InactiveCN106076143AAvoid damageExtended service lifeRotary stirring mixersTransportation and packagingEngineeringMotor drive

The invention discloses a vibrational multifunctional stirring device and a stirring method thereof. The vibrational multifunctional stirring device comprises a spherical mixing bin, a driving component and a stirring component, the stirring component is installed in the mixing bin, the driving component provides power to the stirring component and comprises a first motor and a second motor, the stirring component comprises a first stirring shaft, a second stirring shaft, a first stirring blade and a second stirring blade, the first motor drives the first stirring shaft, the second motor drives the second stirring shaft, atomizing nozzles and air nozzles are arranged on the mixing bin, a periodical pendulum bob is arranged on the outer wall of the mixing bin, and all the periodical pendulum bob, the atomizing nozzles and the air nozzles are connected with a controller. Compared with the prior art, the vibrational multifunctional stirring device has the advantages that the first motor and the second motor can rotate clockwise or anticlockwise simultaneously, or one rotates clockwise while the other rotates anticlockwise, or one rotates while the other does not rotate, various mixing requirements can be met, stirring is more sufficient, and better stirring effect is achieved.

Owner:WUXI LEHUA AUTOMATION TECH

Movable stirring device

InactiveCN107970810AMeet the needs of large-scale productionEasy to moveTransportation and packagingRotary stirring mixersEngineeringMechanical engineering

Owner:CHANGGE DAYANG PAPER CO LTD

Metal fibre chopping process

InactiveCN103668562AIncrease friction forceIncrease the deformation processTows to slivers/yarnsFiberPolyester

The invention discloses a metal fibre chopping process, which relates to the textile technical field of a metal fibre chopping process used for synthetic processing for metal fibres and cotton polyester fibres. According to the metal fibre chopping process, the long-time technical problem of non-uniform blending proportion of metal fibres and cotton polyester fibres under the traditional process conditions is solved by the steps of metal fibre bundle change, metal fibre deformation, friction force adjustment and metal fibre chopping, thus improving the finished product quality; meanwhile, the mixing time is reduced, thus increasing the processing efficiency; moreover, the condition of metal raise dust in the subsequent mixing procedures can be greatly improved, thus achieving an environment-friendly effect.

Owner:吴建华

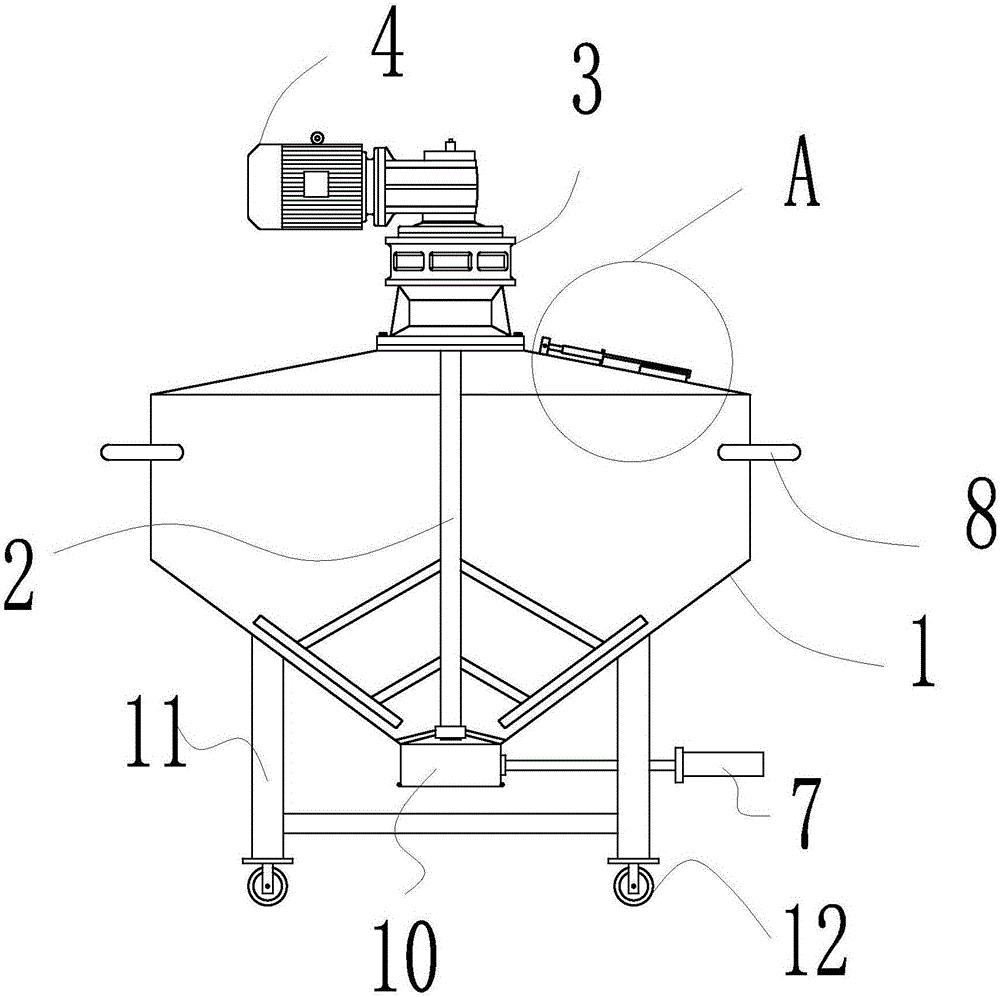

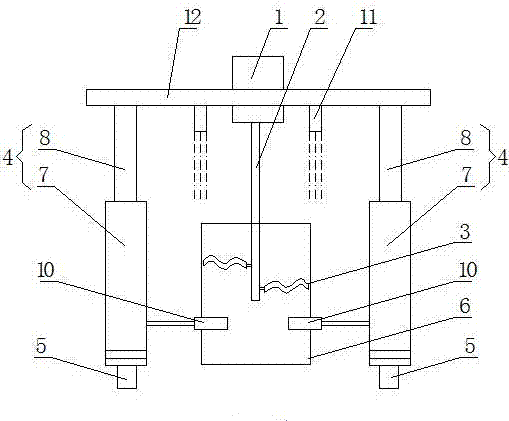

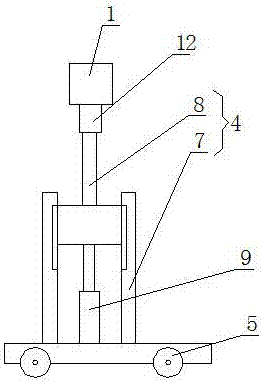

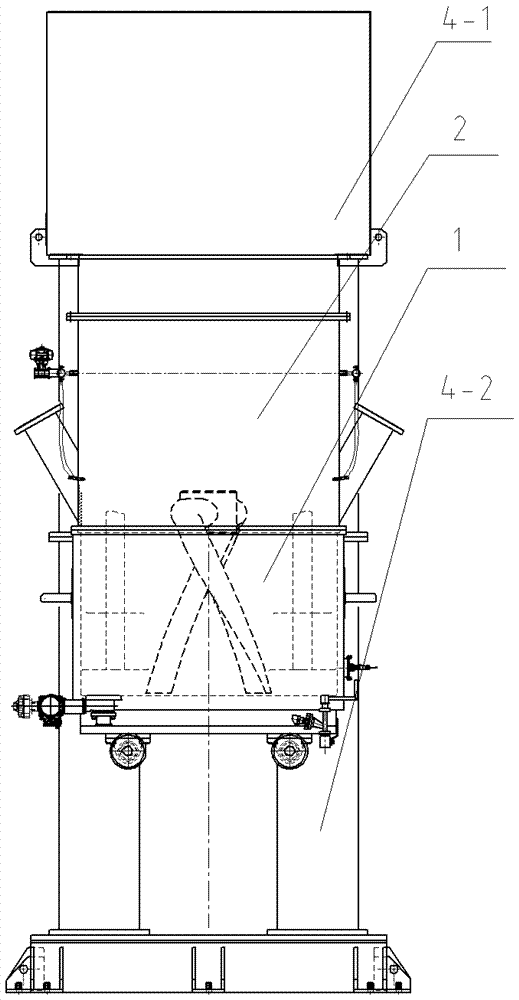

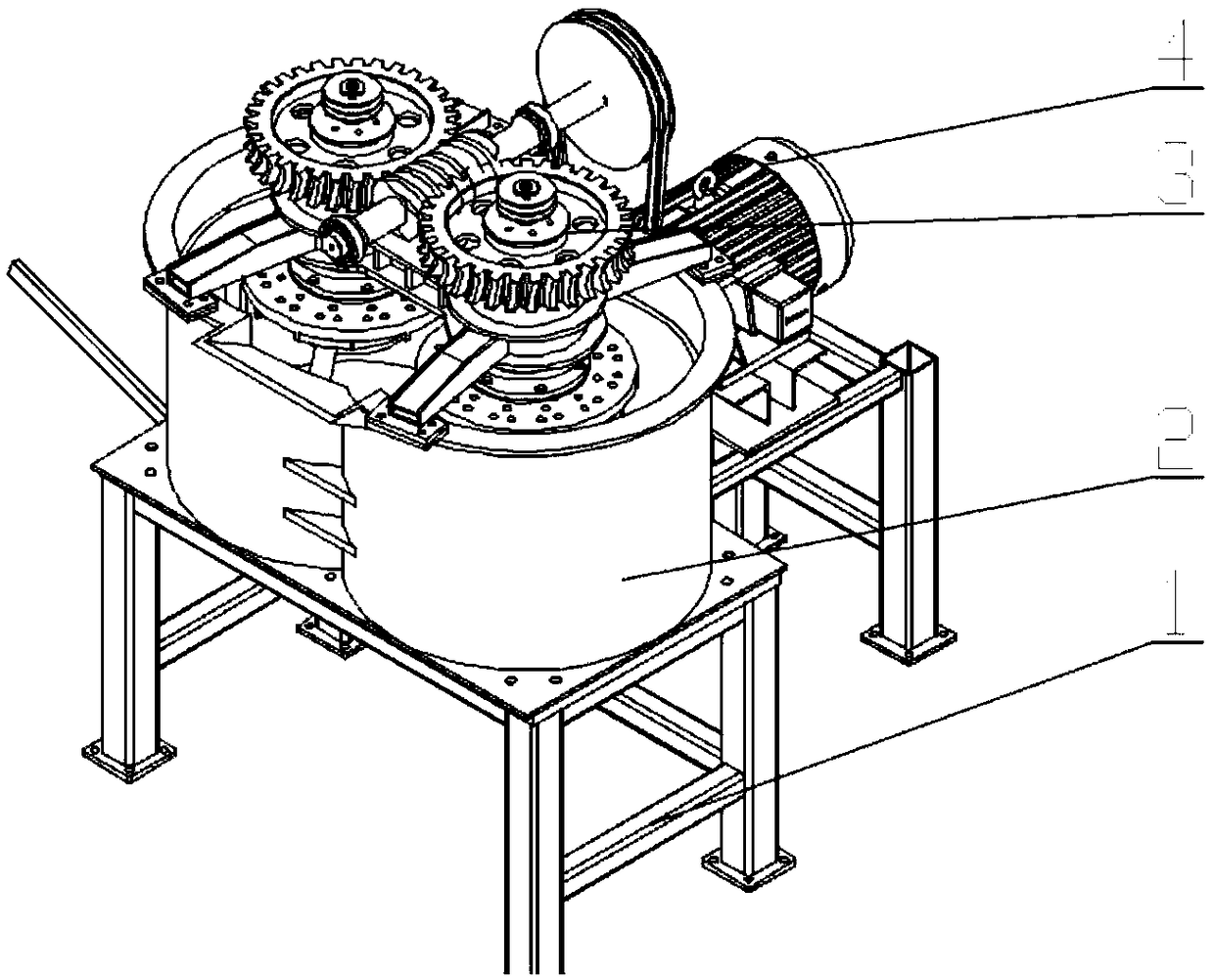

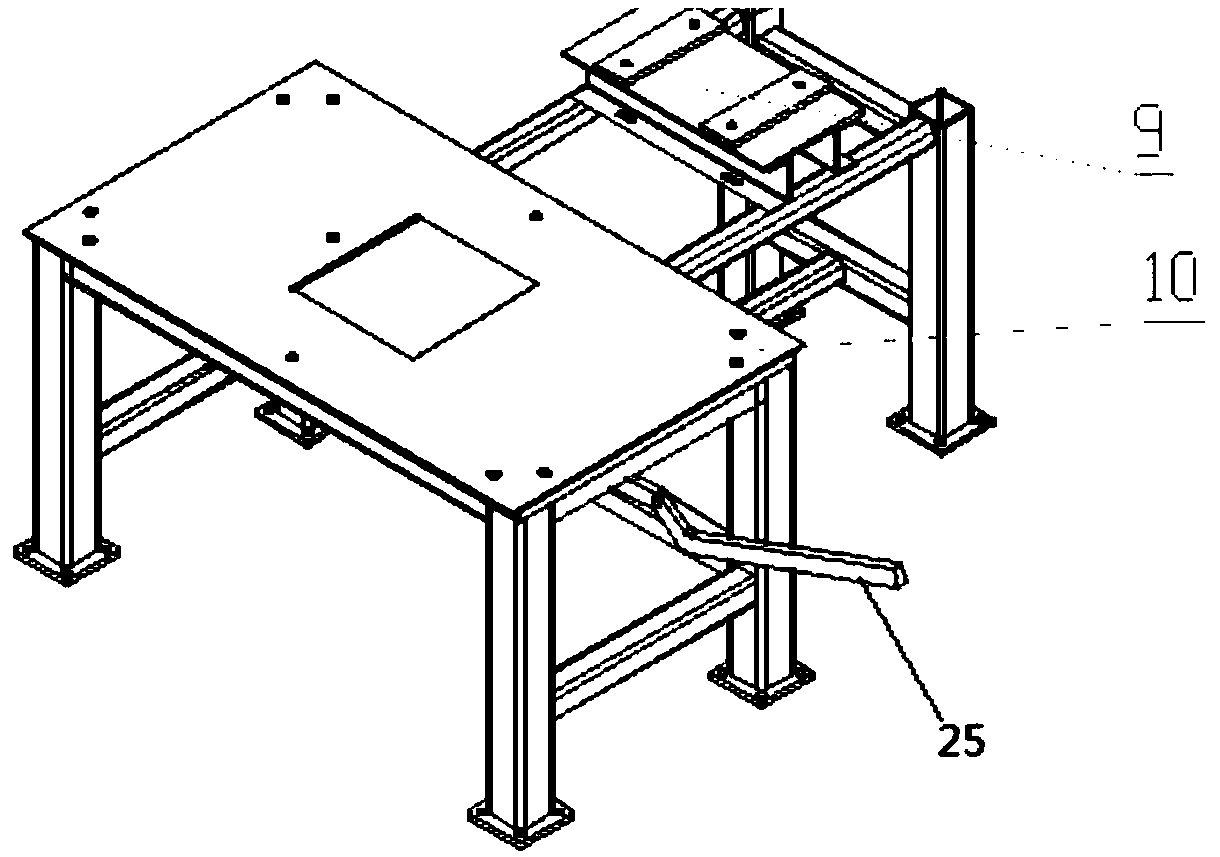

Large-scale stirring equipment

PendingCN107213819AMeet the mixing requirementsReduce volumeTransportation and packagingRotary stirring mixersBiochemical engineeringPortal frame

The invention relates to the field of stirring equipment and particularly relates to large-scale stirring equipment. The large-scale stirring equipment can be conveniently carried and transported and can meet the stirring requirements of large-scale containers. The large-scale stirring equipment comprises a stirring kettle and a stirring mechanism, wherein the stirring mechanism is connected to a driving mechanism. The large-scale stirring equipment is characterized in that the stirring mechanism and the driving mechanism are mounted on a portal frame, the portal frame is formed by splicing a lower-end support part and an upper-end inverse U-shaped bracket, and the stirring kettle is movably arranged at the lower-end support part.

Owner:ROSS WUXI EQUIP COMPANY

Confluence rocket ramjet wide-speed-range engine based on annular pressurization center body mixing section

ActiveCN112682218AImprove thrust performanceShorten the mixing distanceRam jet enginesComposite engine plantsRamjetCombustion chamber

The invention discloses a confluence rocket ramjet wide-speed-range engine based on an annular pressurization center body mixing section. The confluence rocket ramjet wide-speed-range engine based on the annular pressurization center body mixing section comprises a center body, an air inlet channel, a combustion chamber with a concave cavity and a spray pipe. An embedded rocket in a conventional rocket ramjet engine is arranged on the outer side of the center body in a front-arranged mode, mixed pressurization of the rocket gas and air is conducted in an annular mixing channel, and then central pipe flow is formed through confluence. Due to the fact that the contact area of rocket jet flow and air is increased, the mixing distance of two air flows can be effectively shortened. By the adoption of the scheme, the overall thrust performance of the rocket ramjet engine can be effectively improved.

Owner:NAT UNIV OF DEFENSE TECH

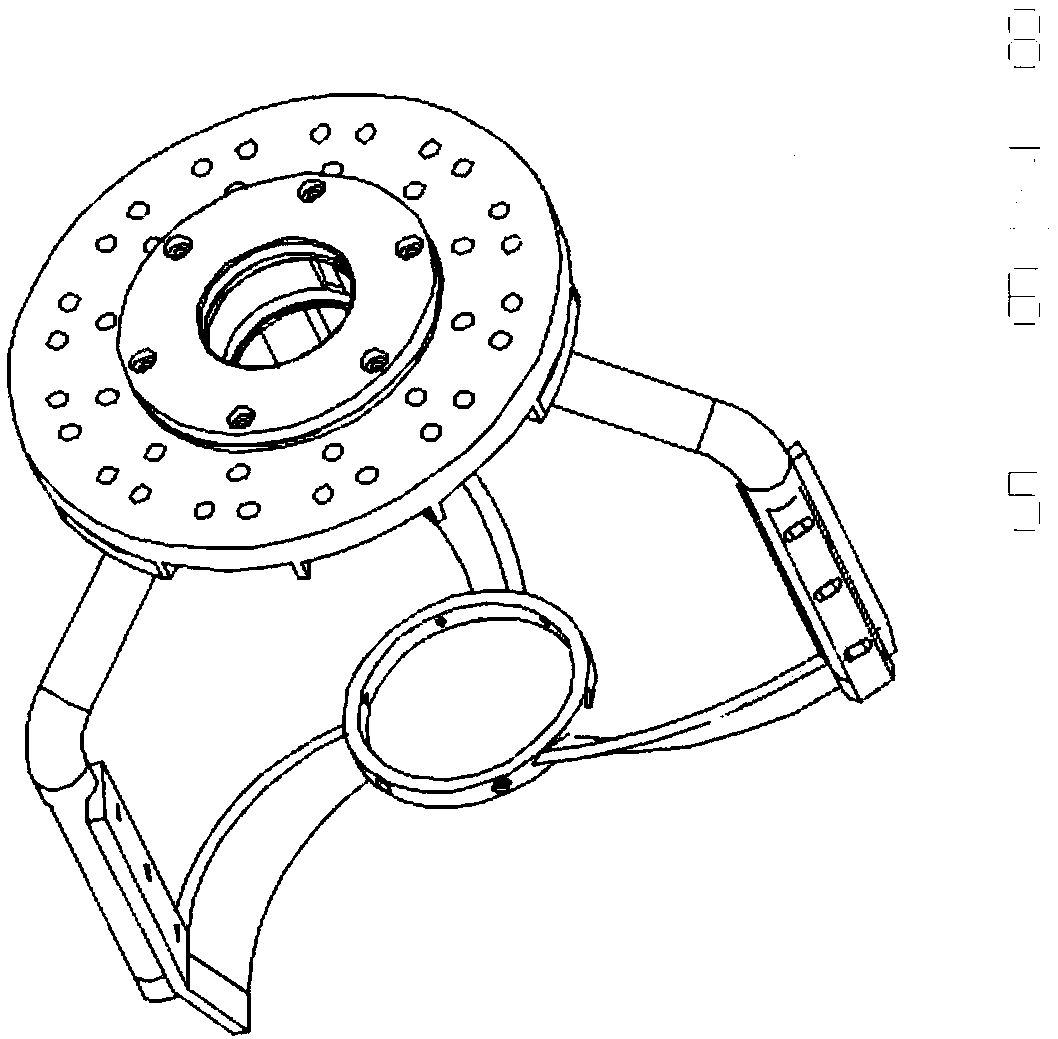

Integrated barrel type vertical-shaft stirring machine adopting dual-wormwheel and single-worm transmission

PendingCN109159297AImprove stabilitySimple structureCement mixing apparatusPulp and paper industryWorm drive

An integrated barrel type vertical-shaft stirring machine adopting dual-wormwheel and single-worm transmission comprises a supporting underframe, a stirring barrel, a dual-wormwheel and single-worm transmission device, a driving device, and stirring devices, wherein the stirring barrel and the driving device are both arranged on the supporting underframe; the stirring devices are arranged in the stirring barrel; the dual-wormwheel and single-worm transmission device is arranged on the stirring devices; and the driving device is connected with the dual-wormwheel and single-worm transmission device, and drives the stirring devices to rotate through the dual-wormwheel and single-worm transmission device. The stirring machine provided by the invention has the advantages that the stirring machine comprises the stirring barrel, the dual-wormwheel and single-worm transmission device, the driving device and the stirring devices, and a stirring barrel part is separated from a driving part; concrete raw materials are added into the stirring barrel, and the driving device is started to drive the stirring devices to rotate synchronously and in opposite directions through the dual-wormwheel andsingle-worm transmission device, so that forced stirring of the mixed concrete materials is achieved; the materials are discharged after the stirring; and the overall structure is simple, and high stability and high operating reliability are achieved during the whole process.

Owner:CHANGAN UNIV

Truck-mixed concrete stirring drum

InactiveCN103072205AMeet the mixing requirementsImprove quality and efficiencyCement mixing apparatusHelical lineHelical blade

The invention discloses a truck-mixed concrete stirring drum, and belongs to stirring drums. The stirring drum provided by the invention structurally comprises a cylinder body and helical blades around the inner surface of the cylinder body, wherein the cylinder body is divided into a front cone, a middle section, a rear cone and a sealing head; the helical blade comprises two logarithmic helical belts arranged symmetrically at an angle of 180 degrees, compulsory stirring blades and reverse pushing blades; each spiral belt is formed in a way that a plurality of small helical blades in the same helical direction are overlapped one by one and are subjected to assembly welding along pre-marked logarithmic helical lines along the inner wall of the cylinder body; the four compulsory stirring blades are welded in pairs on the front cone and the middle section of the cylinder body; and the two reverse pushing blades are welded on the front cone and the sealing head. According to the stirring drum provided by the invention, the material stirring is uniform, material adhesion is avoided, the stirring requirement of a mixer truck on the transit mixed concrete is met, the truck-mixed concrete quality is improved, the stirring efficiency is also improved, and the problem that a current general stirring drum can not meet the stirring requirement of the transit mixed concrete is solved.

Owner:SHANTUI JANEOO MACHINERY

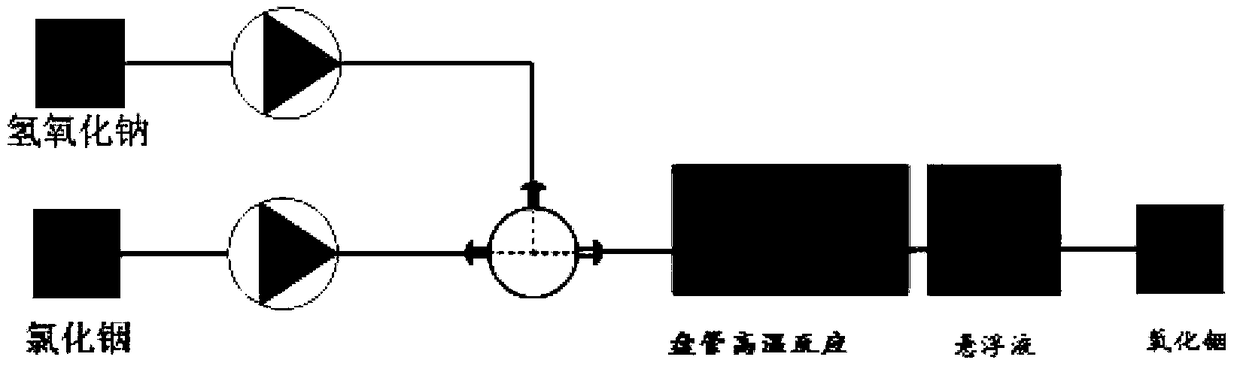

Preparation method of indium oxide with controllable crystal form

ActiveCN109205659AGrow fastImprove mass transfer efficiencyGallium/indium/thallium compoundsInorganic materialsSodium hydroxide

The invention provides a preparation method of indium oxide with controllable crystal forms, and belongs to the field of inorganic material preparation. In a microreactor, fluid cross-flow shearing isused for realizing fast mixing of indium chloride solution and sodium hydroxide solution; the mass transfer efficiency of the system is effectively improved; the mixing requirements in the fast precipitation process are met; meanwhile, a continuous coil pipe is continuously introduced for high-temperature reaction; fast growth of particles in indium oxide precursor suspension is realized; temperature regulation is utilized; the crystal formation transition is realized in the growth process; indium oxide of different crystal form structures is finally prepared.

Owner:TSINGHUA UNIV

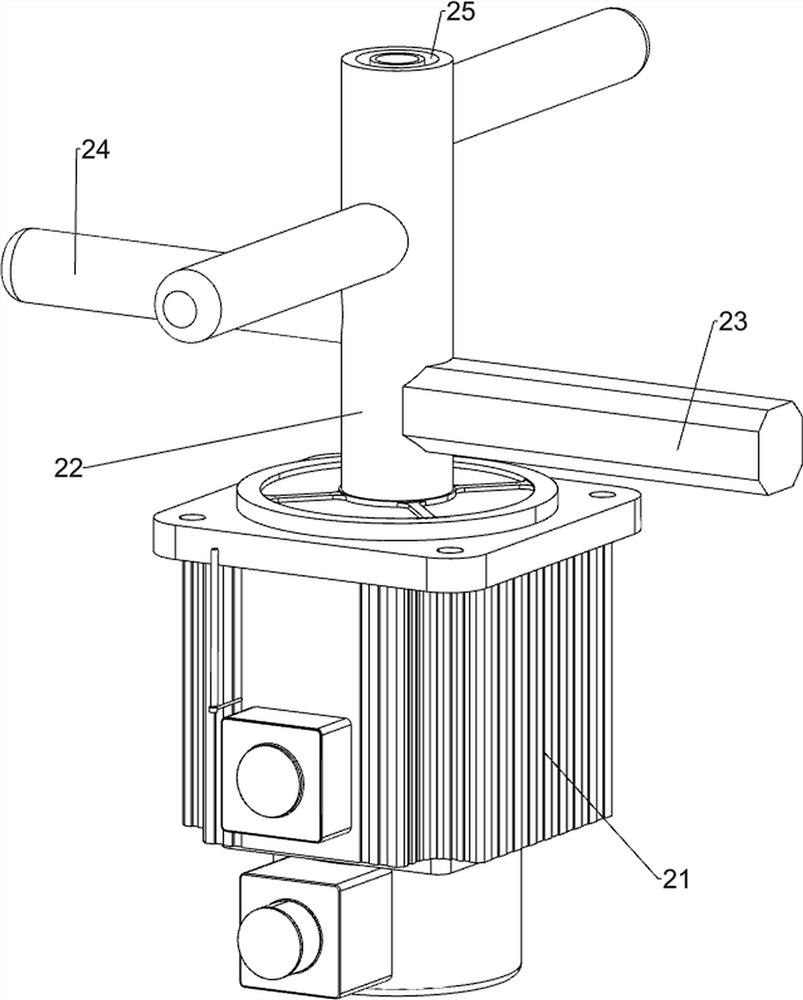

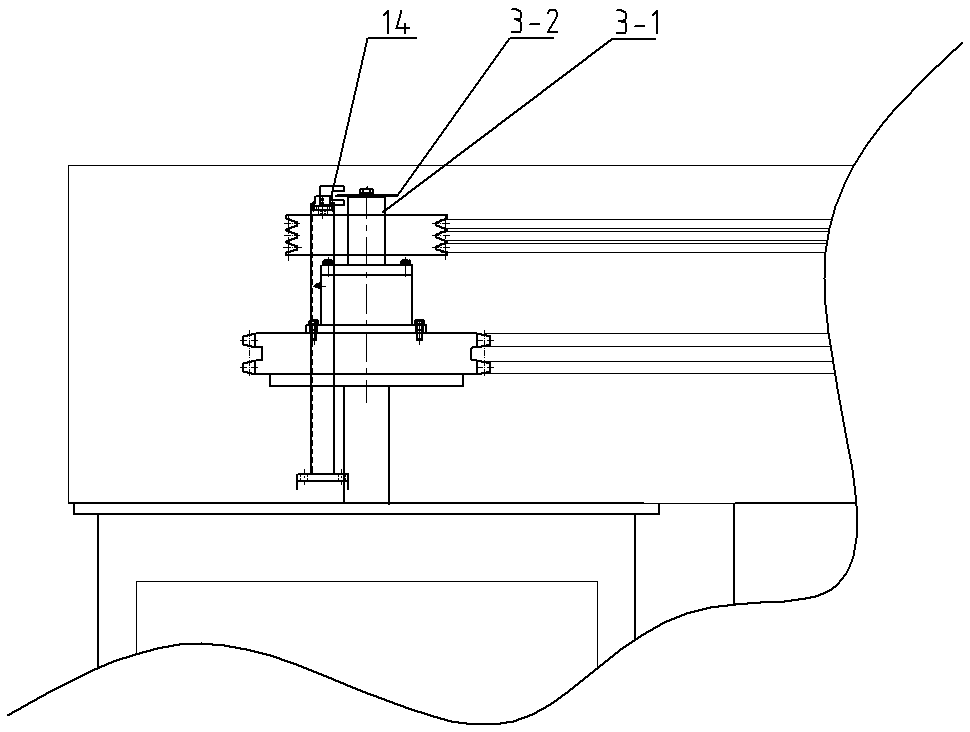

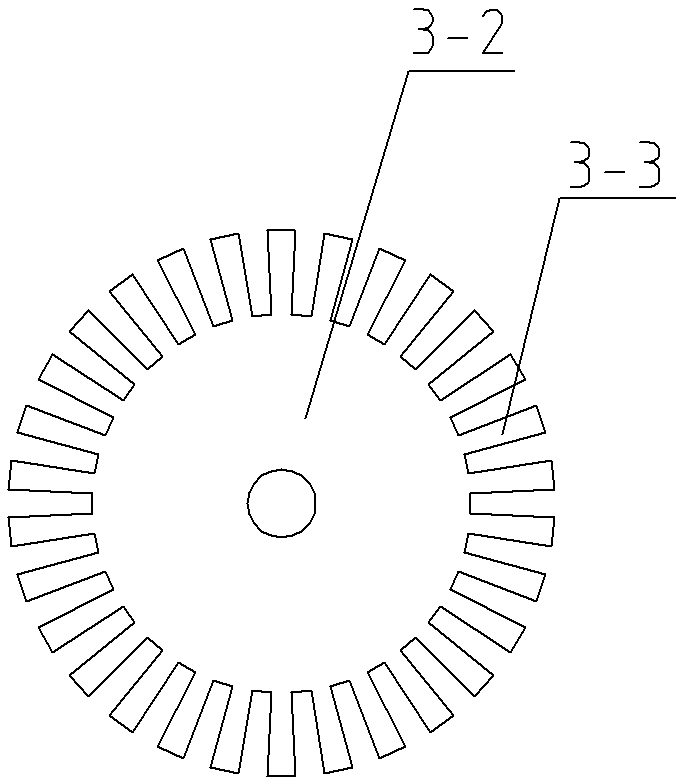

Novel microextraction high-throughput magnetic stirring system

PendingCN110860108AAchieving stirringStir wellPreparing sample for investigationLiquid solutions solvent extractionElectric machineControl engineering

The invention discloses a novel microextraction high-throughput magnetic stirring system. The system comprises an extractor and a magnetic stirring system, the stirring system utilizes a motor to drive a worm to rotate, through turbine-worm transmission, the power of the motor is transmitted from the worm to turbines to drive the turbines to move, finally, rotary tables on turbine shafts are driven to rotate, thus providing corresponding power for stirring, the number of the turbines can be set according to the number of solutions needing stirring, thus better meeting the stirring requirement.The magnetic stirring system can achieve stirring of multiple groups of samples and stirring of multiple samples in a group of samples, realizes the purpose of stirring in high-throughput detection,the stirring system is provided with a plurality of rotary tables, and each rotary table is equipped with a pair of magnetic bodies, so that power is provided for each solution needing stirring, and each group of samples are stirred more uniformly.

Owner:CHINA JILIANG UNIV +1

Instant convenient product production line of sheep by-products

PendingCN112914046AEasy to cleanAvoid hurtingSievingRotating receptacle mixersProcess engineeringBy-product

The invention discloses an instant convenient product production line of sheep by-products. The production line comprises an unfreezing slow melting line, a cleaning line, a trimming line, a pre-cooking impurity removal line, a marinating impurity removal line, a lifting line, a vibration shredding line, an air cooling line, a material mixing line, a split charging line, a packaging line, a high-temperature sterilization line, a belt conveying line and a cooling line, a discharging port of the unfreezing slow melting line is located above a feeding port of the cleaning line, a discharging port of the cleaning line is located above a feeding port of the trimming line, and a discharging port of the trimming line is located above a feeding port of the precooking impurity removal line. The production line is compact in structure and high in unfreezing speed, and has the functions of sterilizing and grabbing frozen sheep by-products and water circulation, the cleaning speed is high, circulating cleaning can be achieved, impurity removal is conducted in a mechanical manner, manual participation is reduced, the impurity removal efficiency is high, marinating and boiling are sufficient, the marinating and boiling impurity removal efficiency is high, the function of supplementing soup to a marinating and boiling impurity removal box is achieved, the mixing efficiency is high, mixing is uniform, and using is convenient.

Owner:锡林郭勒盟羊羊牧业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com