Large-scale stirring equipment

A kind of mixing equipment and large-scale technology, which is applied in the direction of mixer accessories, mixers with rotating mixing devices, mixers, etc., can solve the problems of difficult transportation and handling, small volume, large volume, etc., to achieve convenient transportation and transportation, meet mixing requirements, The effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

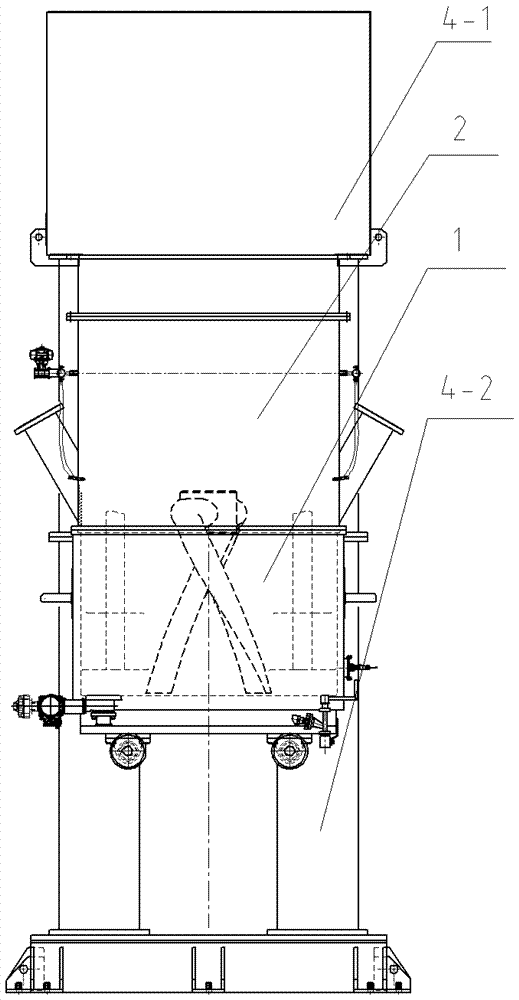

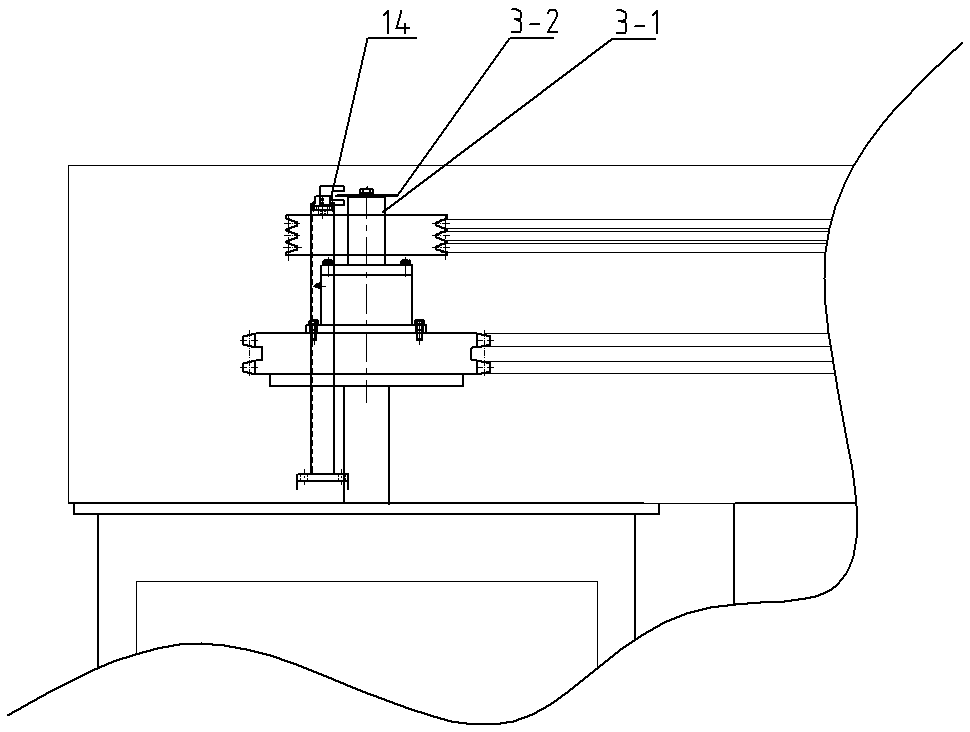

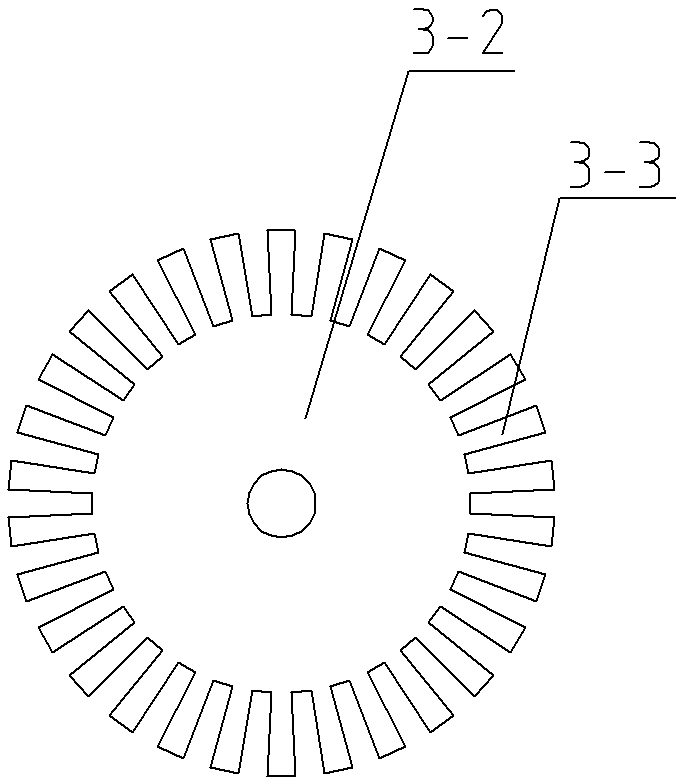

[0029] See Figure 1 to Figure 12 As shown, a large-scale stirring equipment includes a stirring tank 1 and a stirring mechanism 2. The stirring mechanism 2 is connected to a driving mechanism 3. Both the stirring mechanism 2 and the driving mechanism 3 are installed on a gantry 4, and the gantry 4 is supported by a lower end support portion 4- 1 and the upper inverted U-shaped bracket 4-2 are combined, and the stirring tank 1 is movably arranged on the lower support part 4-1.

[0030] The connection between the lower support part 4-1 and the upper inverted U-shaped bracket 4-2 is connected by a flange 5 and bolts 6; a guide rail 7 is arranged on the lower support part 4-1, and a guide rail 7 Cooperating guide wheels 8 can be conveniently pushed into place and unloaded manually.

[0031] The lower end support part 4-1 is provided with a jacking bracket 9, and V-shaped bumps 10 are respectively installed on both sides of the jacking bracket 9, and the bottom of the stirring ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com