Horizontal dry-mixed mortar stirrer

A technology of horizontal mixer and dry-mixed mortar, which is applied in mixing plants, cement mixing devices, mixing operation control, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

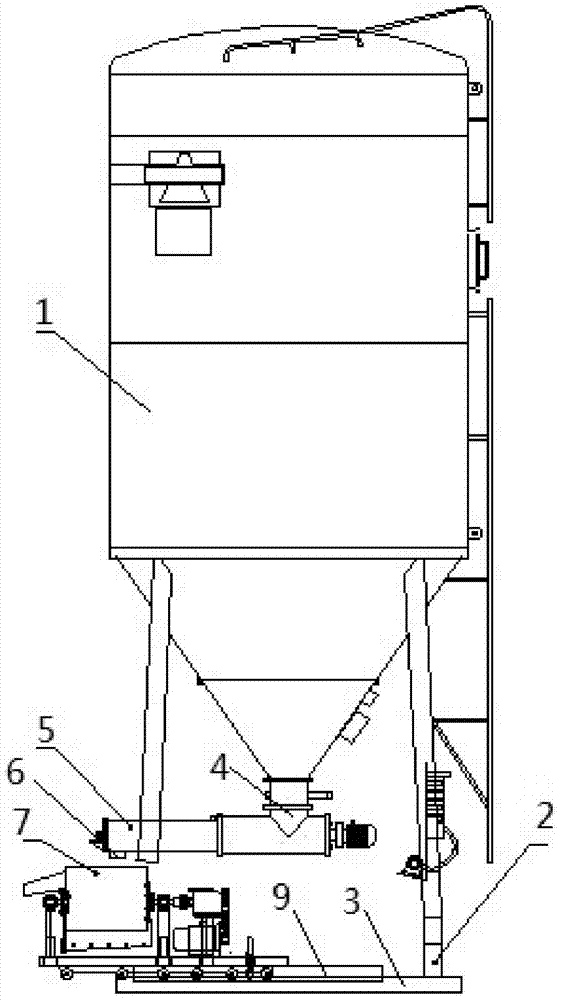

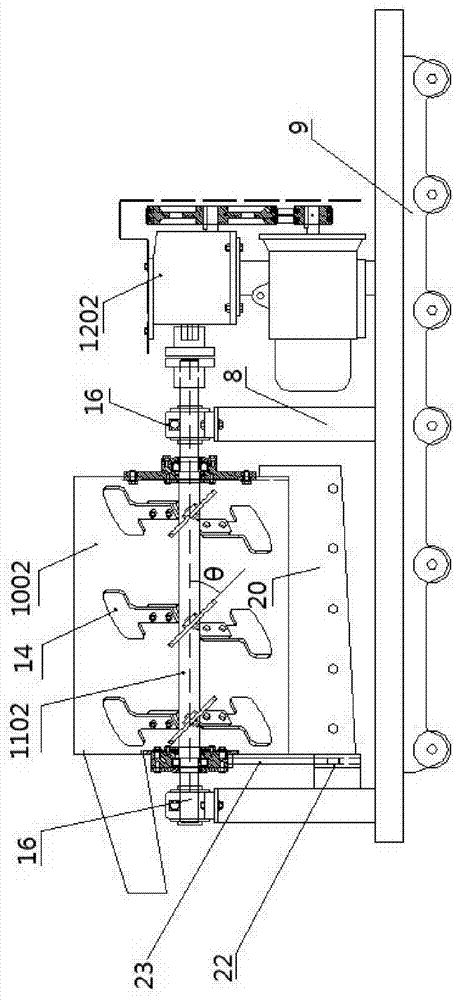

[0026] Such as figure 1 As shown, a dry-mixed mortar horizontal mixer of the present invention includes a storage tank 1, the storage tank 1 is fixed on the base 3 through a bracket 2, and the discharge port 4 of the storage tank 1 is downward; The discharge port 4 of the storage tank 1 is connected to the first stirring assembly 5, the first stirring assembly 5 is provided with a first discharge port 6, and the first discharge port 6 is provided with a second stirring assembly 7; The second stirring assembly 7 is fixed on the support 8, and the bottom of the support 8 is arranged on the mobile device. In this embodiment, the moving device includes a guide rail 9 and a slider installed in cooperation with the guide rail 9, the bracket 8 is arranged on the slider, and the number of the guide rail 9 and the slider is two, which are fixed on the bottom of the bracket 8 in parallel .

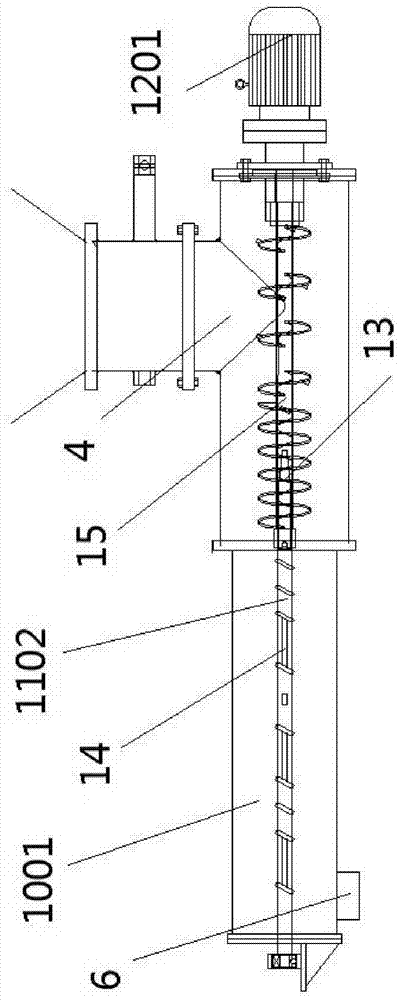

[0027] Such as figure 2 As shown, the first stirring assembly 5 includes a hollow first hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com