Instant convenient product production line of sheep by-products

A by-product and production line technology, applied in the production line of ready-to-eat sheep by-products, can solve problems affecting the quality of stewed sheep by-products, complex operation of stewed and impurity removal equipment, and waste of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

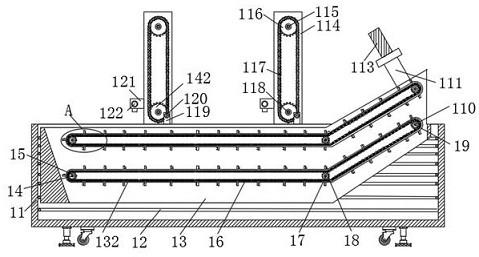

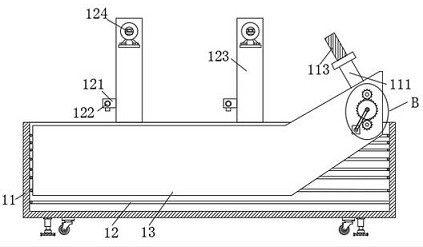

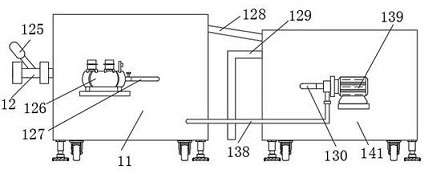

[0054] Embodiment one: if Figure 1-32 As shown, a sheep by-product ready-to-eat convenience product production line includes a thawing and softening line 1, a cleaning line 2, a trimming line 3, a pre-cooking line 4, a brine-cooking line 5, a lifting line 6, a vibrating shredding line 7, Air-cooling line 8, mixing line 9, sub-packing line 101, packaging line 102, high-temperature sterilization line 103, belt conveyor line 104 and cooling line 105, the outlet of thawing and softening line 1 is located at the inlet of cleaning line 2 The outlet of the cleaning line 2 is located above the inlet of the trimming line 3, the outlet of the trimming line 3 is located above the inlet of the precooking and removing impurities line 4, and the outlet of the precooking and removing impurities line 4 The feed port is located above the feed port of the stewed and decontaminated line 5, the discharge port of the stewed decontaminated line 5 is located above the feed port of the lifting line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com