Integrated barrel type vertical-shaft stirring machine adopting dual-wormwheel and single-worm transmission

A technology of worm drive and double worm gear, which is applied in the direction of cement mixing equipment, clay preparation equipment, chemical instruments and methods, etc., can solve the problem of inability to meet the rigidity requirements of mixing large-volume mixture, the shaft end seal cannot be effectively solved, and the discharge port The problem of sticking and clogging can be solved, and the effect of simple structure, increased rigidity and increased mixing area can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further described below in conjunction with accompanying drawing:

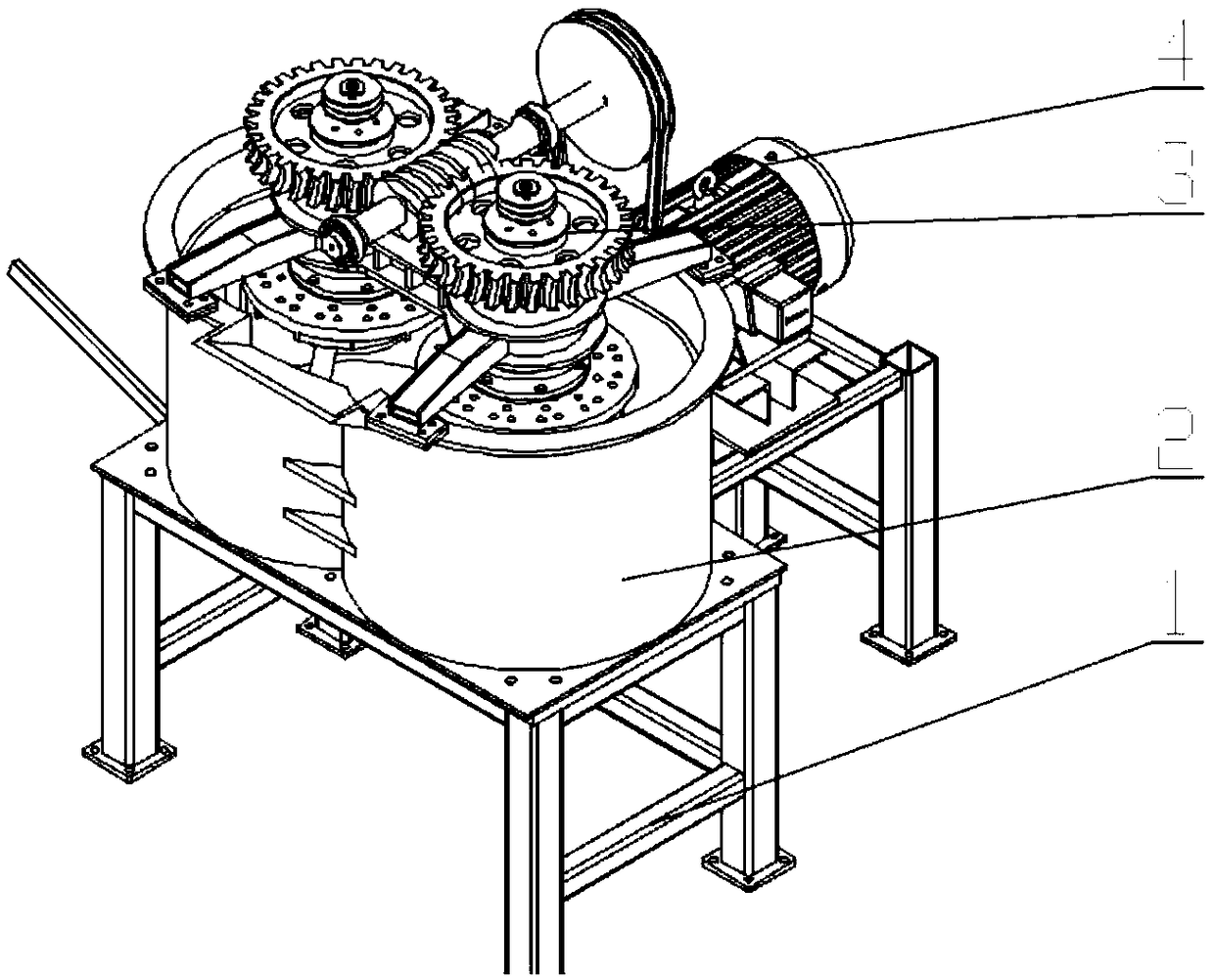

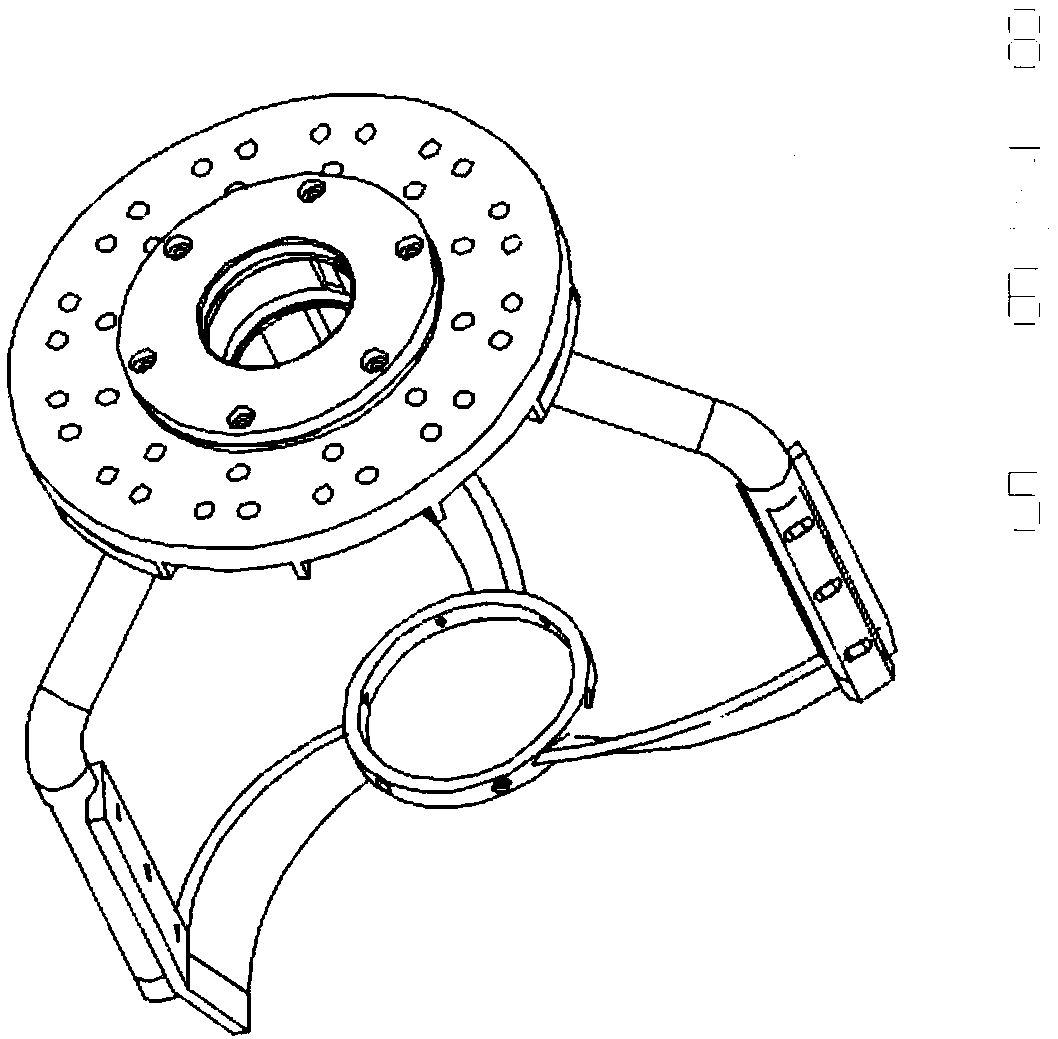

[0037] see Figure 1-Figure 4 , a dual-worm gear and single-worm drive conjoined cylinder vertical shaft mixer, comprising a supporting base 1, a conjoined mixing drum 2 is connected to the supporting base 1, and two reversely rotating stirring devices are arranged in the conjoined mixing drum 2 , also includes a driving device 4 and a double worm gear single worm transmission device connecting the driving device 4 and the stirring device;

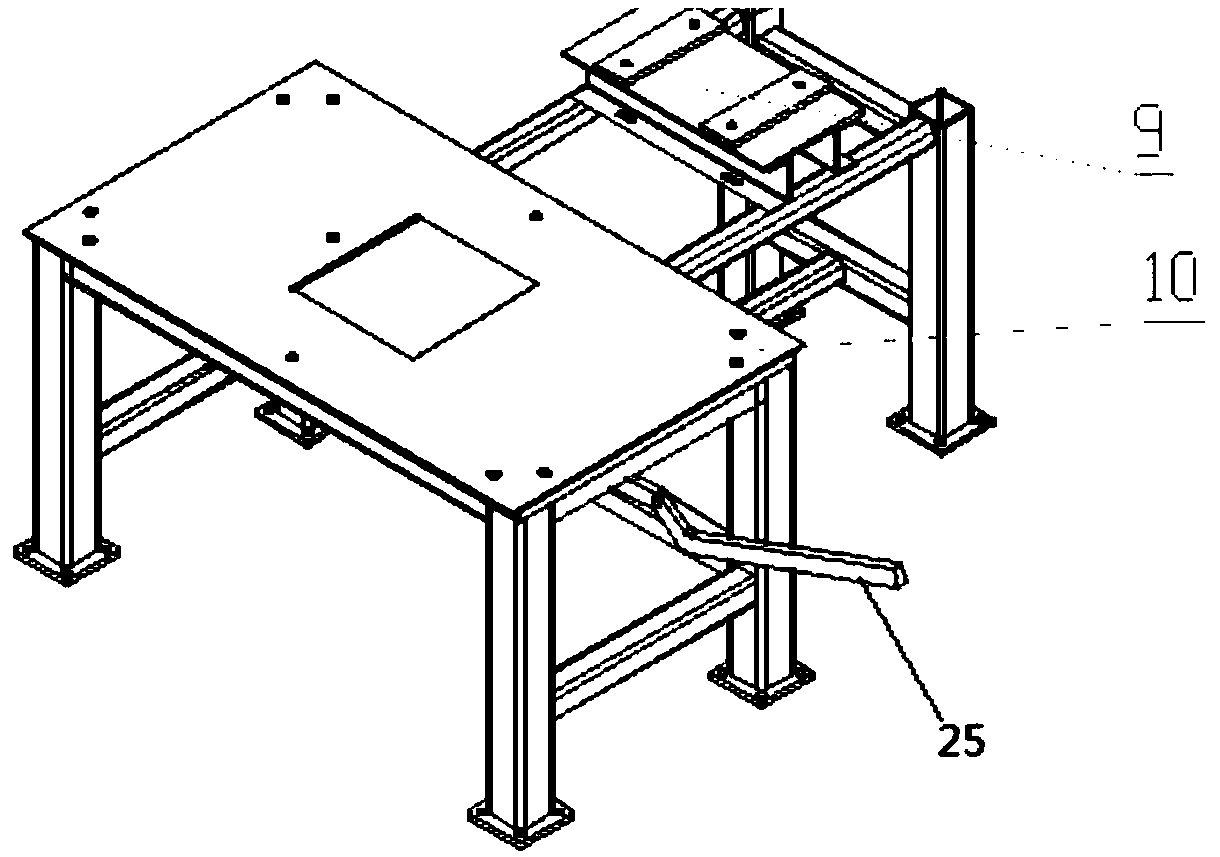

[0038] Several rubber shock-absorbing gaskets are installed at the bottom of each support leg of the support chassis 1, and a shock-absorbing rubber frame is placed above the front part of the support chassis 1 so as to be connected with the bottom plate 10 of the conjoined mixing drum 2, and the rear part of the support chassis 1 The driving motor seat 9 is fixed on the top, and the driving motor seat 9 is formed by tailor-welding of horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com