Preparation method of indium oxide with controllable crystal form

An indium oxide, crystal form technology, applied in chemical instruments and methods, inorganic chemistry, gallium/indium/thallium compounds, etc., can solve the problems of difficult industrial application, difficult adjustment, discontinuous reaction process, etc. The effect of mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

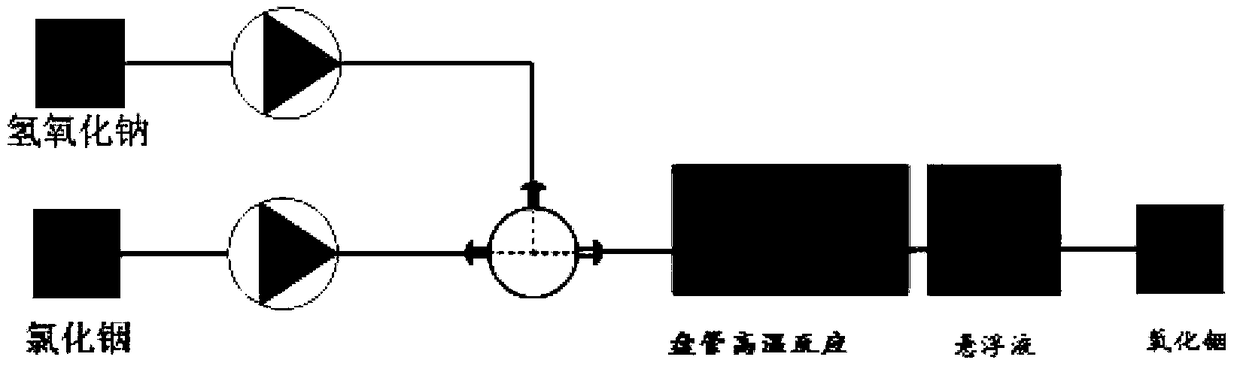

[0020] The invention provides a method for preparing indium oxide with controllable crystal form, comprising the following steps:

[0021] In the microreactor, the indium chloride solution and the sodium hydroxide solution are mixed for a precipitation reaction to obtain a precipitated product, and the precipitated product is subjected to a high-temperature reaction in a coil to obtain an indium oxide precursor suspension;

[0022] The indium oxide precursor suspension is sequentially separated, washed, dried, and high-temperature roasted to obtain indium oxide; when the temperature of the high-temperature reaction is [100,140]°C, the obtained indium oxide has a cubic structure, and when the high-temperature reaction When the reaction temperature is [160,180]°C, the obtained indium oxide has a hexagonal structure.

[0023] In the present invention, in a microreactor, an indium chloride solution and a sodium hydroxide solution are mixed for a precipitation reaction to obtain a ...

Embodiment 1

[0035] 1) Prepare an indium chloride solution with a concentration of 1g / L, and make it flow into the microreactor at a flow rate of 5mL / min.

[0036] 2) Prepare a sodium hydroxide aqueous solution with a concentration of 2mol / L, and make it flow into the microreactor at a flow rate of 5mL / min, realize rapid mixing of the two phases by shearing the dispersed phase, and pass it into the subsequent coil.

[0037] 3) Pass the mixed solution through a 16-meter-long coil pipe to continue the reaction at 140° C., and the reacted mixed solution is collected in a stirred tank after being cooled.

[0038] 4) Centrifuge the mixed liquid in the stirred tank, wash the obtained solid twice with deionized water and ethanol, and then dry to obtain the precursor powder.

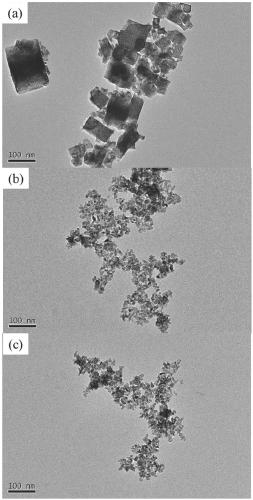

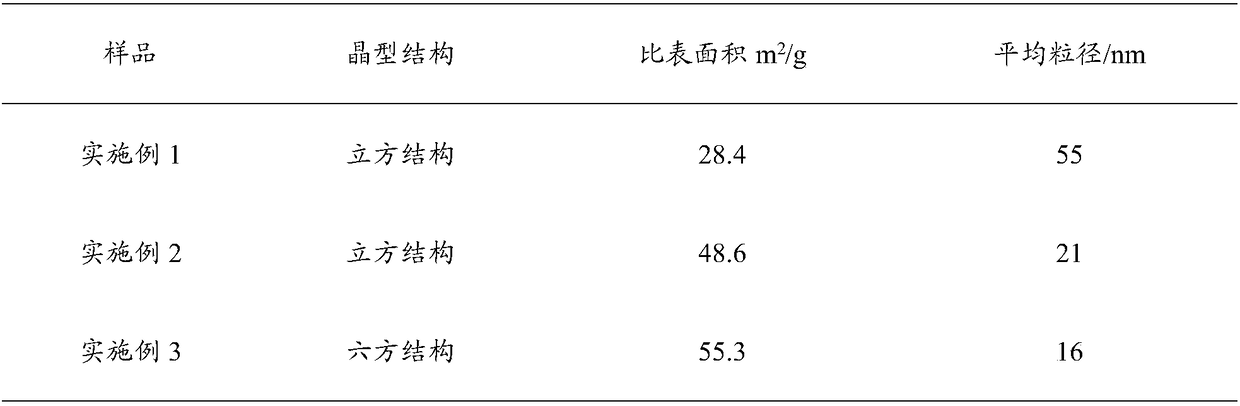

[0039] 5) Put the precursor powder in a muffle furnace and bake it at 400°C to obtain a yellow indium oxide powder, denoted as a.

Embodiment 2

[0041] 1) Prepare an indium chloride solution with a concentration of 1g / L, and make it flow into the microreactor at a flow rate of 10mL / min.

[0042] 2) Prepare a sodium hydroxide aqueous solution with a concentration of 1mol / L, and make it flow into the microreactor at a flow rate of 10mL / min, realize rapid mixing of the two phases by shearing the dispersed phase, and pass it into the subsequent coil.

[0043] 3) Pass the mixed solution through an 8-meter-long coil pipe to continue the reaction at 100° C., and the reacted mixed solution is collected in a stirred tank after being cooled.

[0044] 4) Centrifuge the mixed liquid in the stirred tank, wash the obtained solid twice with deionized water and ethanol, and then dry to obtain the precursor powder.

[0045] 5) Put the precursor powder in a muffle furnace and bake it at 400°C to obtain a yellow indium oxide powder, denoted as b.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com