Truck-mixed concrete stirring drum

A concrete and mixing drum technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of inability to meet the requirements of vehicle-mixing concrete mixing, improve mixing quality and mixing efficiency, and shorten mixing time. , the effect of low residual rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

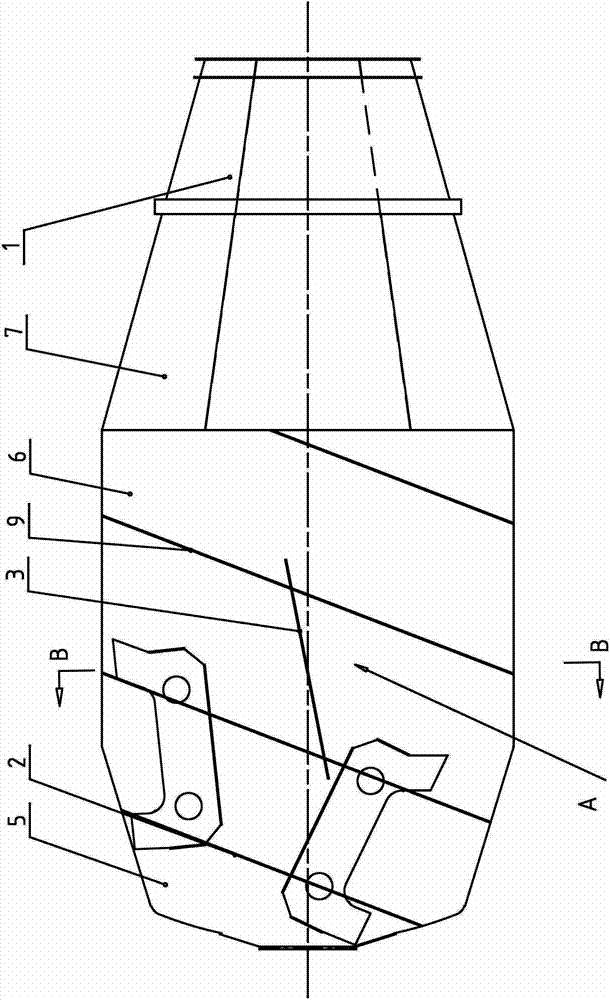

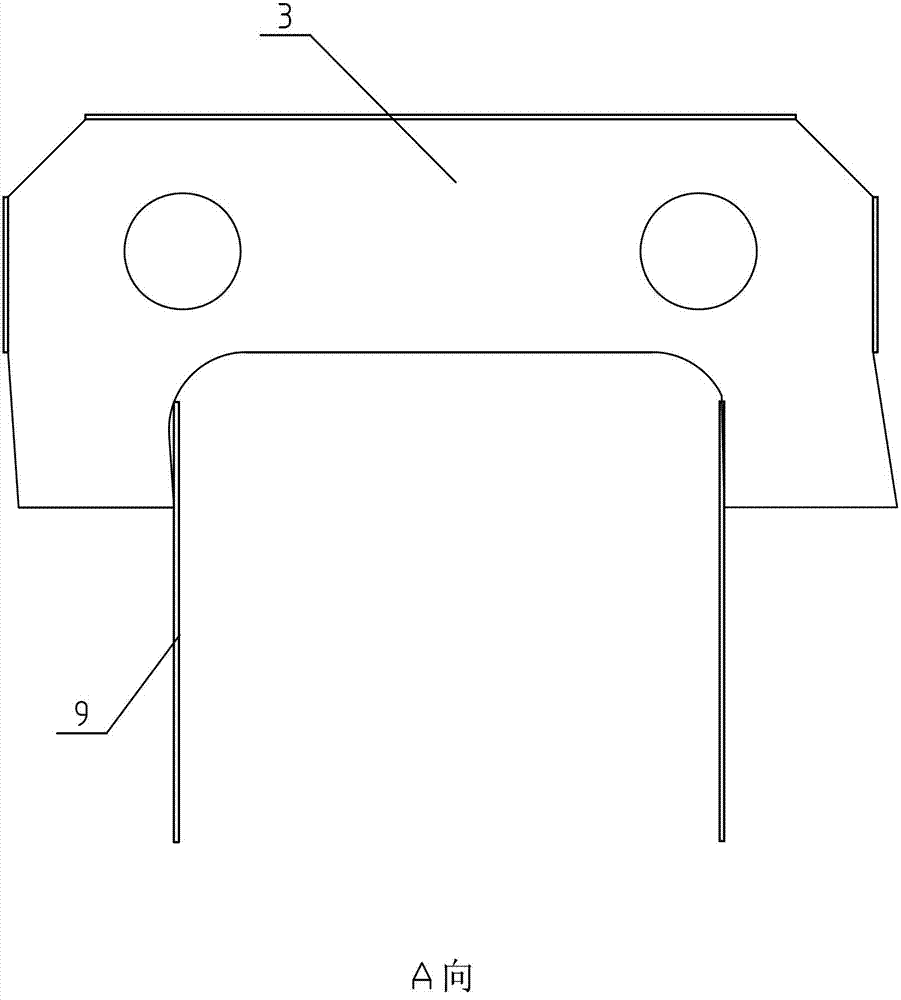

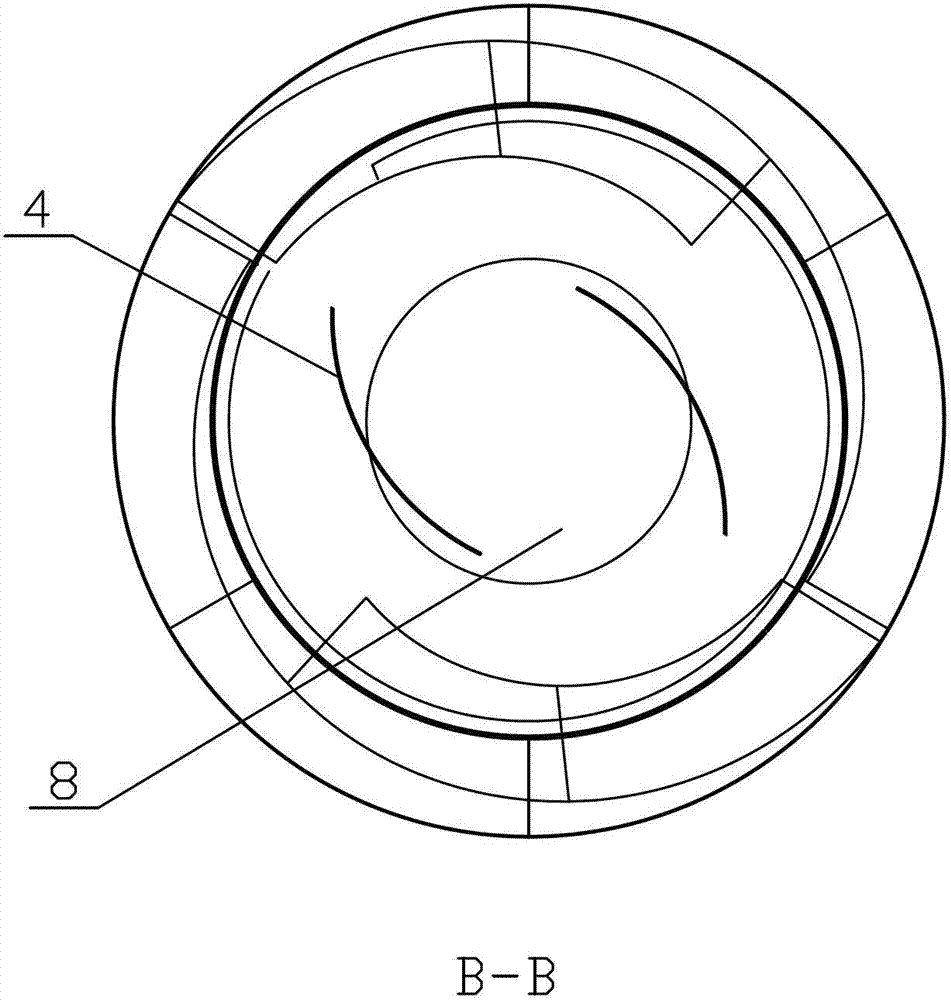

[0014] Refer to the attached figure 1 to attach Figure 4 The truck-mixed concrete mixing drum of the present invention will be described in detail below.

[0015] The truck-mixed concrete mixing drum of the present invention is composed of a cylinder body 1 and spiral blades surrounding the inner surface of the cylinder body 1. The cylinder body 1 includes a front cone 5, a middle section 6, a rear cone 7 and a head 8. , the helical blades include two logarithmic helical belts 2 arranged symmetrically at 180°, forced stirring blades 3 and reverse thrust blades 4, and each helical belt 2 is overlapped one by one by several small helical blades 9 with the same direction of rotation along the cylinder. The internal wall is pre-drawn logarithmic spiral and welded. There are four forced stirring blades 3 welded in pairs to the front cone 5 and the middle section 6 of the cylinder, and two reverse thrust blades 4 are welded to the front cone 5 and the middle section 6 respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com