Barium sulfate material and preparation method thereof

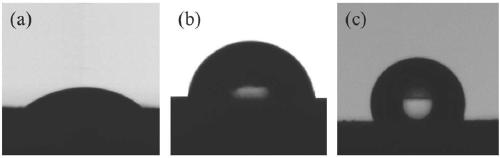

A barium sulfate, sodium sulfate aqueous solution technology, applied in chemical instruments and methods, calcium/strontium/barium sulfate, nanotechnology for materials and surface science, etc. Poor effect, poor hydrophobicity and dispersibility of barium sulfate, etc., to achieve excellent hydrophobicity and particle size controllability, ensure hydrophobicity, and meet mixing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a kind of preparation method of barium sulfate material, comprises the following steps:

[0024] (1) In the film dispersion microreactor, the continuous phase and the dispersed phase are mixed to obtain a mixed solution; the continuous phase is an aqueous barium chloride solution, and the dispersed phase is a mixture of an aqueous sodium sulfate solution and an ethanol solution containing a surfactant mixture;

[0025] (2) carrying out the precipitation reaction to the mixed solution obtained in the step (1) to obtain a barium sulfate suspension;

[0026] (3) The barium sulfate suspension obtained in the step (2) is subjected to an aging reaction to obtain a barium sulfate material.

[0027] In the present invention, the continuous phase and the dispersed phase are preferably prepared first.

[0028] In the present invention, the continuous phase is an aqueous solution of barium chloride. In the present invention, the concentration of the bariu...

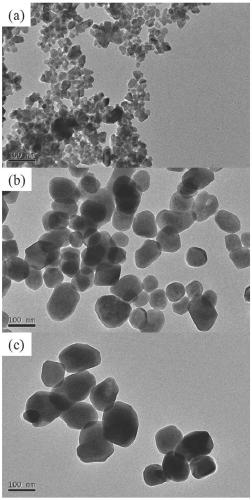

Embodiment 1

[0044] (1) In the membrane dispersion microreactor, pass the dispersed phase through the microporous membrane at a flow rate of 20mL / min, and quickly mix with the continuous phase flowing at a flow rate of 20mL / min to obtain a mixed solution; the continuous phase is the concentration Be the barium chloride aqueous solution of 0.2mol / L, the dispersed phase is the mixed solution that concentration is the sodium sulfate aqueous solution of 0.4mol / L, the ethanol solution of the sodium stearate of 0.5mmol / L according to volume ratio 1:1 mixing; The microporous equivalent diameter of the microporous membrane in the membrane dispersion reactor is 5 μm;

[0045] (2) passing the mixed solution through a coil pipe with an outer diameter of 3 cm and a length of 1.5 meters and carrying out a precipitation reaction, the temperature of the precipitation reaction is 50° C., and the precipitation reaction product flows into a stirred tank to continue stirring to obtain a barium sulfate suspens...

Embodiment 2

[0049] (1) In the membrane dispersion microreactor, pass the dispersed phase through the microporous membrane at a flow rate of 20mL / min, and quickly mix with the continuous phase flowing at a flow rate of 20mL / min to obtain a mixed solution; the continuous phase is the concentration It is a 0.1mol / L barium chloride aqueous solution, and the dispersed phase is a mixed solution in which a concentration of 0.2mol / L sodium sulfate aqueous solution and 1mmol / L sodium stearate ethanol solution are mixed according to a volume ratio of 1:1; the film The microporous equivalent diameter of the microporous membrane in the dispersion reactor is 2 μm;

[0050] (2) passing the mixed solution through a coil pipe with an outer diameter of 3 cm and a length of 1.5 meters and carrying out a precipitation reaction, the temperature of the precipitation reaction is 50° C.; the precipitation reaction product flows into the stirred tank and continues to stir to obtain a barium sulfate suspension;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com