Automatic rare earth ore feeding mixer

A technology of automatic feeding and mixing machine, which is applied to mixers, mixers with rotary mixing devices, mixer accessories, etc., can solve the problems of automatic feeding and other problems, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

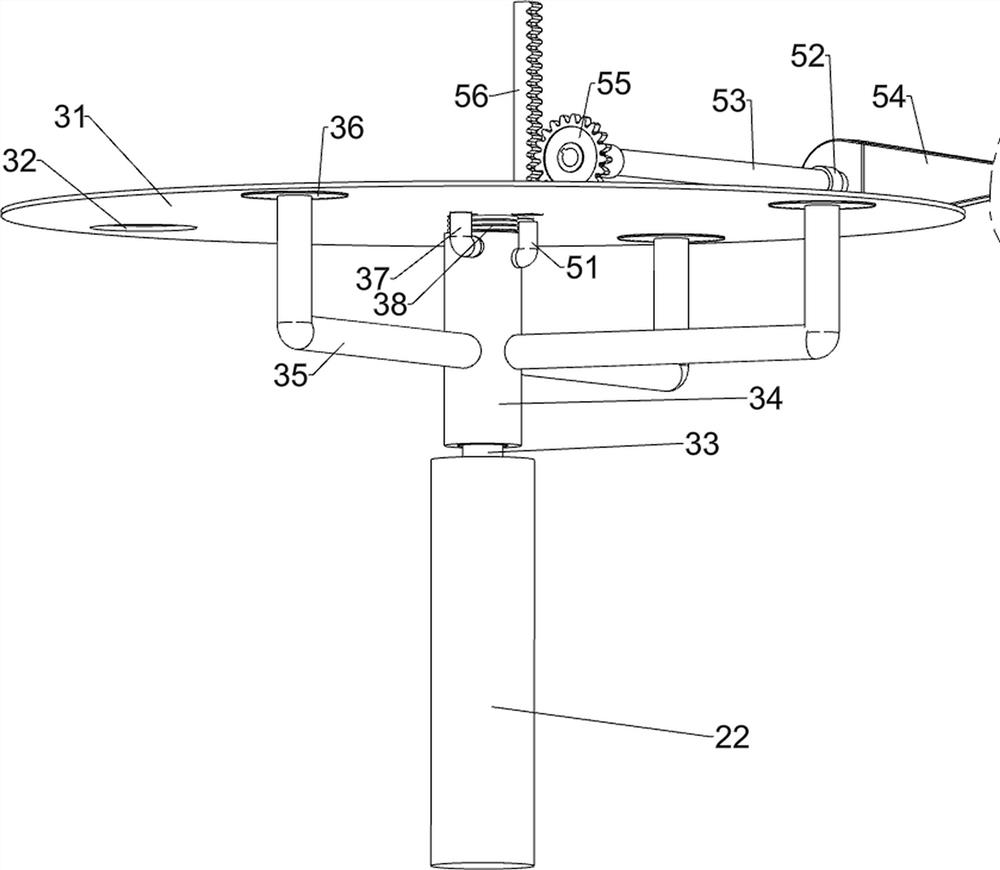

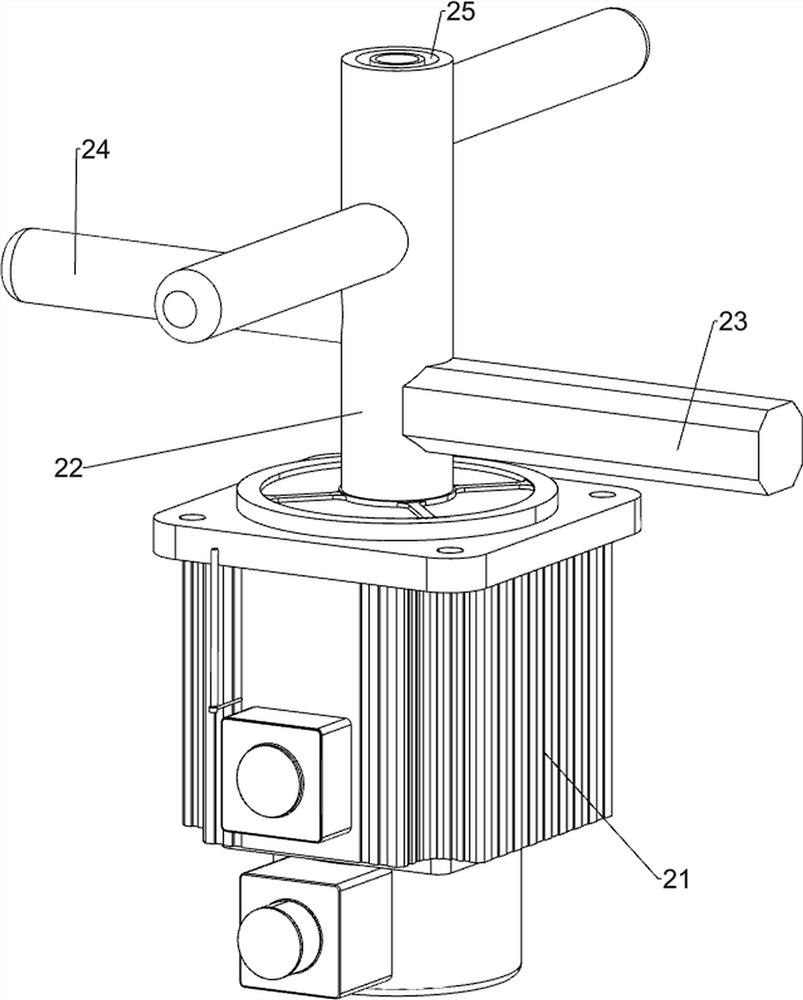

[0020] A rare earth ore automatic feeding mixer, such as Figure 1-4 As shown, it includes a sedimentation tank 1, a stirring assembly 2, a mixing tank 3, a material control assembly, a storage hopper 4 and an adjustment assembly 5. The rear side of the sedimentation tank 1 is equipped with a stirring assembly 2 for stirring and mixing by rotation. The sedimentation tank 1 The middle part of the rear side is fixed with a mixing tank 3 by bolts, and a material control component is installed in the mixing tank 3, and four storage hoppers 4 are fixed on the top of the rear side of the sedimentation tank 1 through bolts. Adjustment assembly 5 for adjustment by means of rotation.

[0021] When it is necessary to use the device to mix rare earth metals, the rare earth metals to be mixed are first placed in the storage hopper 4, and then the stirring assembly 2 is controlled to start working, and the stirring assembly 2 triggers the material control assembly to start working, so that...

Embodiment 2

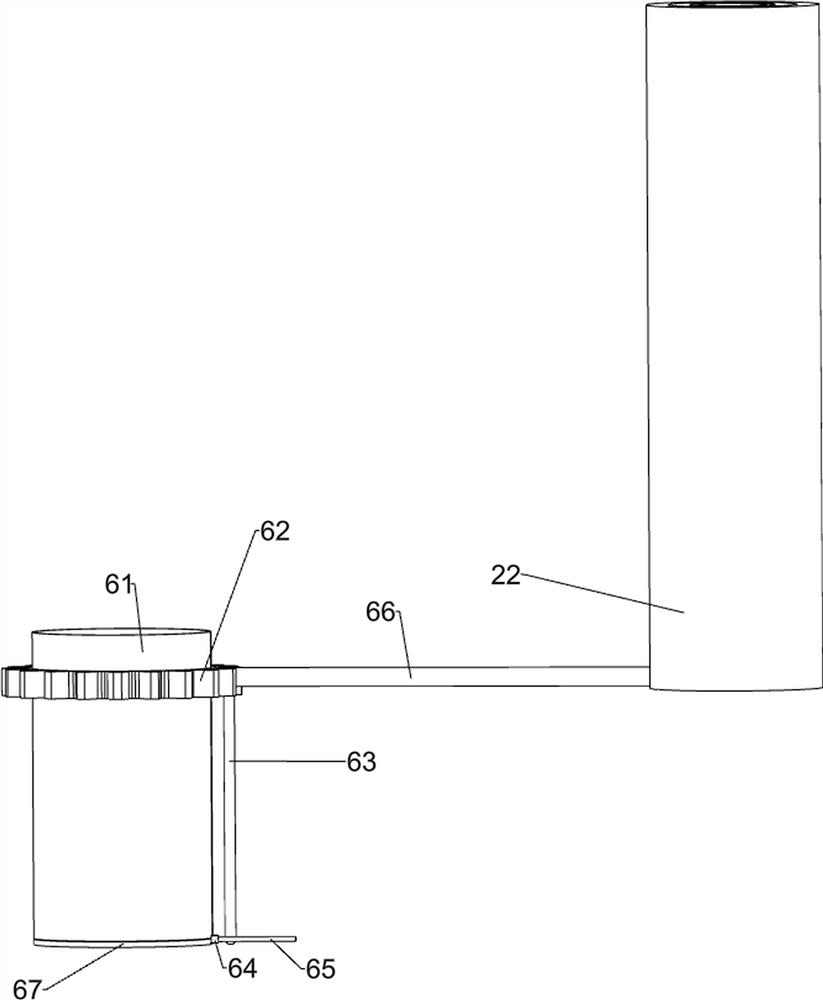

[0029] On the basis of Example 1, such as figure 1 and 5 As shown, a discharge assembly 6 is also included, and the front side of the bottom of the mixing bucket 3 is equipped with a discharge assembly 6 that is discharged by rotating. The discharge assembly 6 includes a discharge pipe 61, a ring gear 62, a connecting rod 63, Rotating plate 64, swing rod 65, telescopic push rod 66 and discharge plate 67, the front side of the bottom of the mixing bucket 3 is provided with a discharge pipe 61, the upper part of the discharge pipe 61 is keyed with a gear ring 62, and the rear side of the bottom of the gear ring 62 is welded There is a connecting rod 63, the bottom of the discharge pipe 61 is rotated by a torsion spring 38 and is provided with a rotating plate 64, the front side of the rotating plate 64 is welded with a discharge plate 67, and the rear side of the rotating plate 64 is welded with a swing bar 65, and the connecting rod 63 is connected to the swinging plate 64. Ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com