Automatic online micro-scale sample dilution and mixing system and mixing method

A mixing system and sample technology, applied in the field of chromatographic analysis devices, can solve the problem that the mixer cannot meet the requirements of automatic online sample dilution and mixing, and achieve the effect of improving the mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

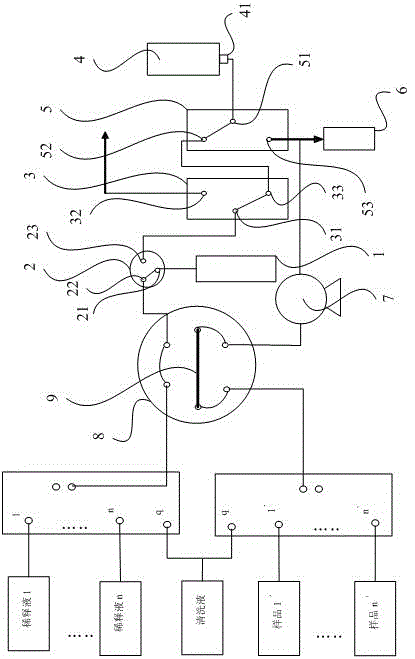

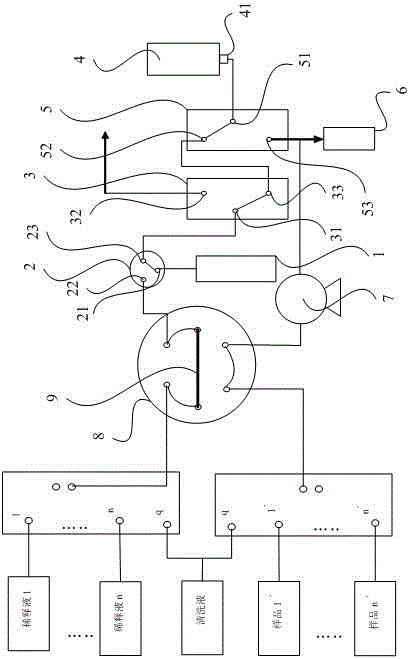

[0025] Such as figure 1 As shown, the automatic online micro-sample dilution mixing system in this embodiment includes a syringe pump 1, a first multi-position switching valve 2, a second multi-position switching valve 3, a third multi-position switching valve 5, a mixer 4, and a six-way valve 8. Quantitative tube 9 and sampling pump 7; the first multi-position switching valve includes a first main port 21 and two first switching ports 22, 23 selectively communicated with the first main port 21, and the second multi-position switching valve 3 Including the second main port 31 and two second switching ports 32, 33 selectively communicating with the second main port 31, the third multi-position switching valve 5 includes a third main port 51 and two switching ports selectively communicating with the third main port 51 The third switching port 52, 53 of the mixer 4 has a liquid inlet and outlet hole 41; the two ports of the metering tube 9 and the inlet of the sampling pump 7 are...

Embodiment 2

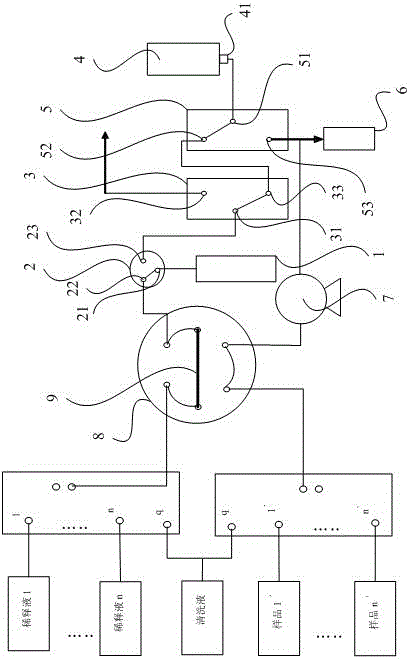

[0030] Such as Figure 4 As shown, the automatic online micro-sample dilution mixing system in this embodiment includes a syringe pump 1, a first multi-position switching valve 2, a second multi-position switching valve 3, a mixer 4, a six-way valve 8, a quantitative tube 9 and a sample injection Pump 7; the first multi-position switching valve 1 includes a first main port 21 and two first switching ports 22, 23 selectively communicated with the first main port 21, and the second multi-position switching valve 3 includes a second main port 31 and Three second switching ports 32, 33, 34 selectively communicated with the second main port 31, the mixer 4 has a liquid inlet and outlet hole; the two ports of the quantitative tube 9 and the inlet of the sampling pump 7 are connected to the six-way valve 8 , the syringe pump 1 is connected to the first main port 21, one of the first switching ports 23 is connected to the second main port 31, the other first switching port 22 is conne...

Embodiment 3

[0033] The automatic online micro-sample dilution and mixing system in this embodiment is based on the above-mentioned embodiment 1 or embodiment 2, the difference is that: Figure 5 As shown, the mixer 4 includes a mixing tube 40 and a waterproof and breathable membrane 42. The mixing tube 40 is provided with a liquid inlet and outlet hole 41 and an inlet and outlet air hole (not shown), and the inlet and outlet air hole is provided with a waterproof and breathable membrane 42. Specifically, the waterproof and breathable membrane 42 has the functions of ventilation and waterproof. During the mixing process of the syringe pump 1, the waterproof and breathable membrane 42 can balance the pressure in the mixing tube 40 to ensure the smooth operation of the syringe pump 1. At the same time, the waterproof and breathable The membrane 42 can effectively filter the pollutants contained in the gas entering the mixing tube 40 to ensure the measurement accuracy of the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com