Mobile stirring device for rubber compound production

A stirring device and a technology for mixing rubber, applied in the field of movable stirring devices, can solve the problems of inability to move, high quality of the cover and high cost, and achieve the effects of improving production efficiency, simple structure and saving feeding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

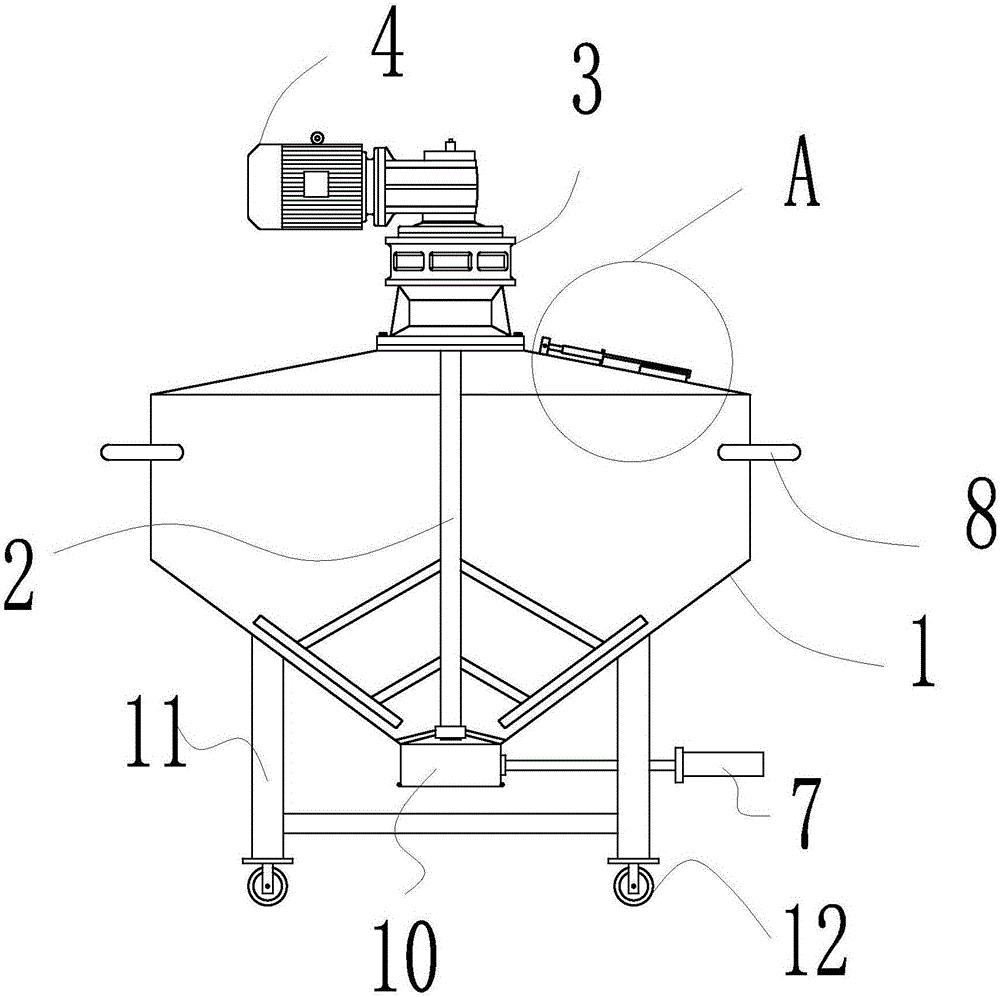

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

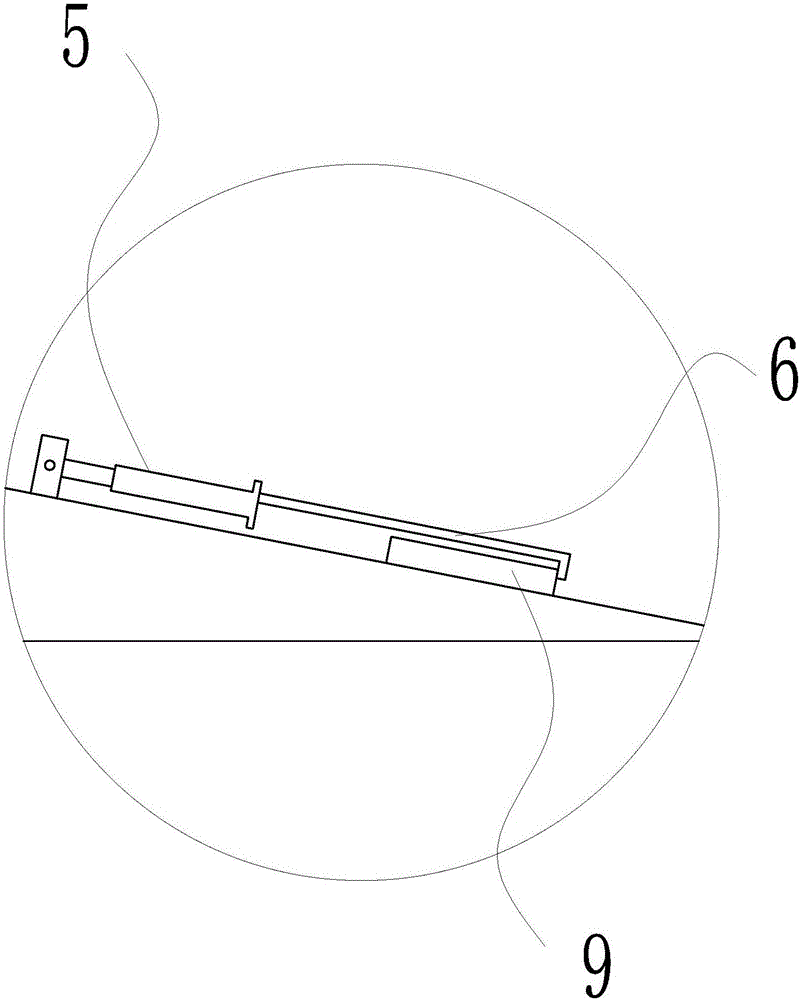

[0019] figure 1 and 2 As shown, a movable stirring device for the production of mixed rubber includes a silo 1, an agitating shaft 2 arranged in the silo 1, a reducer 3 connected to the agitating shaft 2, and a drive for the reducer 3 Running motor 4, the top of the feed bin 1 is provided with a feed port, a cover plate 9 is movable above the feed port, and a first cylinder 5 is provided at the same time, and the end of the first cylinder 5 is connected to a L-shaped block 6, the first cylinder 5 pulls the cover plate 9 to translate through the L-shaped block 6, and the first cylinder 5 can drive the cover plate 9 to move to realize the opening and closing of the feed port ;

[0020] The lower part of the silo 1 is provided with four uprights 11, and a wheel 12 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com