Crushing machine for salt

A technology of pulverizers and racks, which is applied in the direction of grain processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

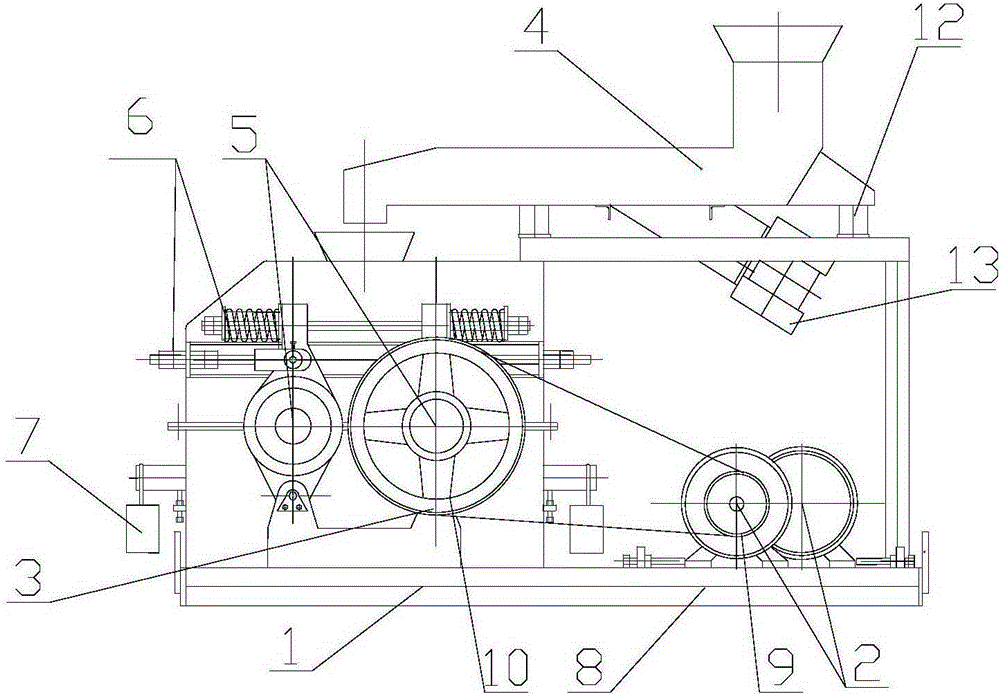

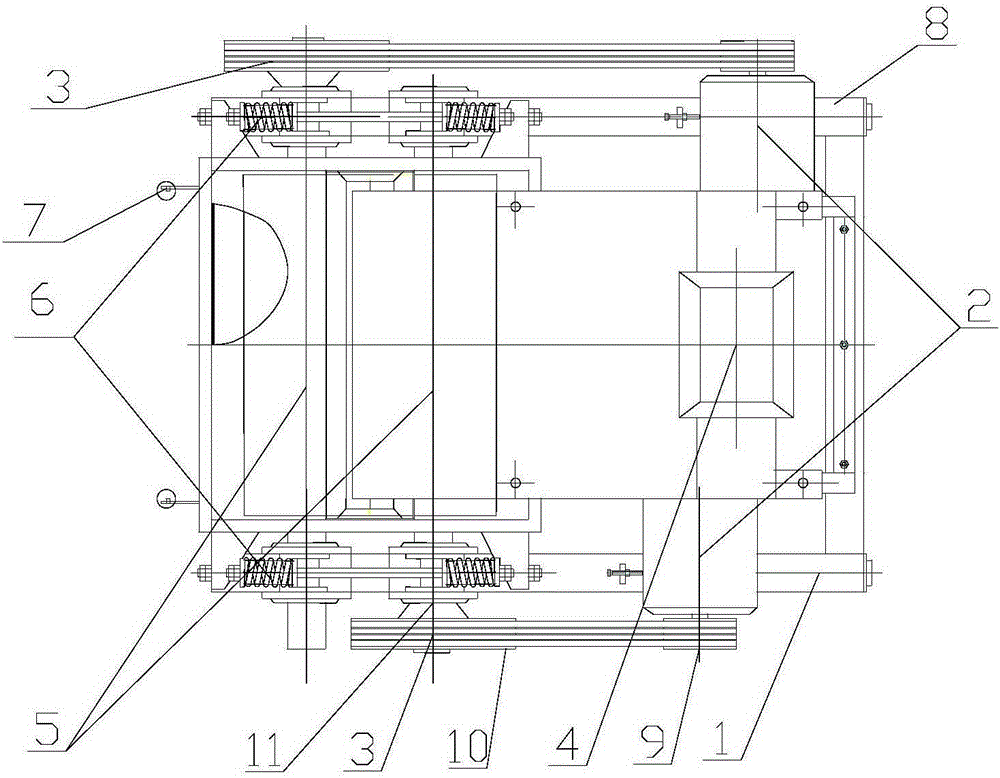

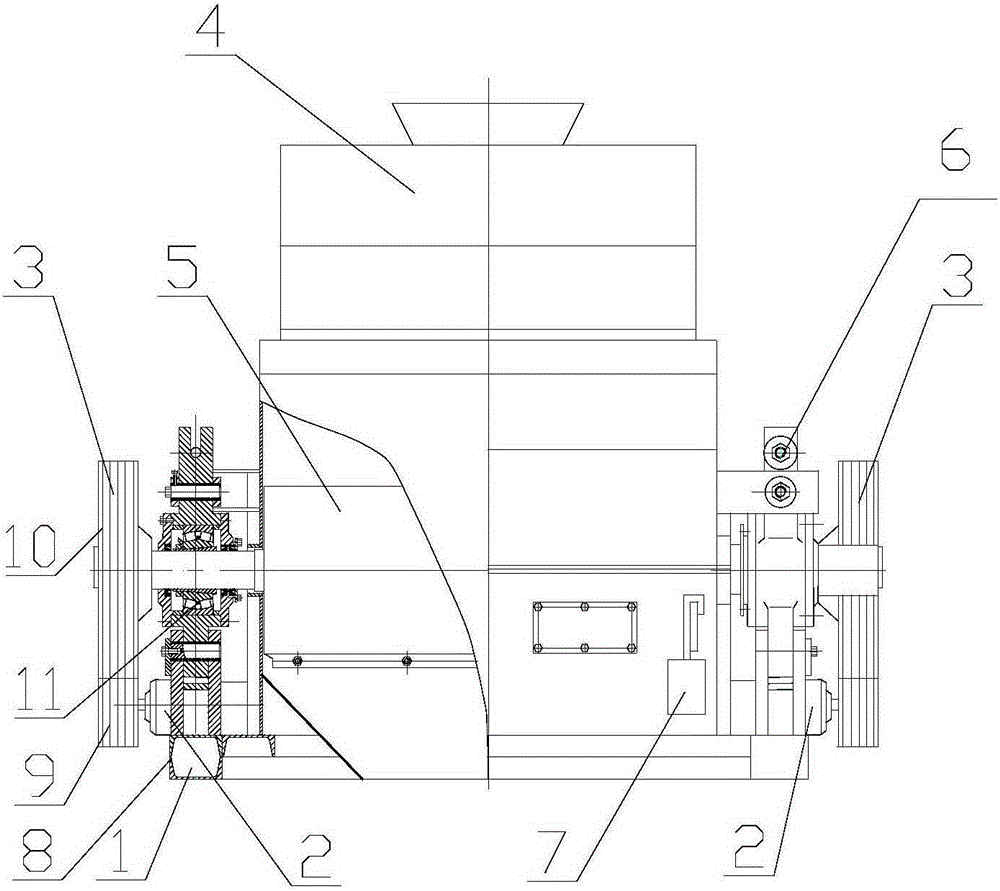

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0017] Such as figure 1 , 2 , 3, the uniform material distribution device 4 is placed on the upper part of the base frame 1, the motor 2, the transmission mechanism 3 and the crushing roller 5 are fixed on the lower platform of the base frame 1, the adjustment mechanism 6 is located at the upper end of the crushing roller 5, and the cleaning device 7 is set In the lower part of the crushing roller 5, the main mechanism and components are arranged and fixed in this way.

[0018] The frame 1 is made of steel welded into a three-dimensional hexagonal frame, the motor 2 and the crushing roller 5 are fixed on the steel inside the frame, and the shaft heads of the two motors are fixed with small sheaves 9 protruding out of the frame respectively, and connected by a triangle belt. On the large sheave 10 fixed on the 5 shaft heads of two crushing rollers, a transmission sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com