Patents

Literature

51results about How to "Has self-lubricating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for laser cladding soft and hard composite coating self-lubricating cutter

InactiveCN103522652AImprove toughnessHigh surface hardnessMetallic material coating processesMetal layered productsNano al2o3Hardness

The invention belongs to the field of machinery cutting cutter manufacturing, and relates to a preparation method for a laser cladding soft and hard composite coating self-lubricating cutter. A rake face coating of the cutter is a multi-layer structure. Firstly, a hard coating of nano Al2O3 ceramic or an ultrafine cemented carbide, etc. is clad on the rake face of the cutter by utilization of a CO2 laser synchronous feeding manner, and then a self-lubricating soft coating is clad by utilization of nickel-covered MoS2 powder or nickel-covered WS2 powder. The cutter has characteristics of good toughness, high hardness, a self-lubrication function, and the like. During a drying cutting process, the hard coating bears loads and the rake face self-lubricating soft coating has low shearing strength, thus reducing friction between the cutter and chips, reducing the cutting temperature and the cutting force, and therefore cutter abrasion is reduced. The cutter can be widely used for dry cutting and cutting machining of difficult-to-machine materials.

Owner:SHANDONG UNIV

Bionic cleaning water-based paint and preparation method thereof

InactiveCN105733385AAchieve sustained releaseThe effect of long-term lubrication and cleaningAntifouling/underwater paintsPaints with biocidesRough surfaceWater based

The invention discloses cleaning water-based paint with a bionic self-lubricating effect, and a preparation method thereof. By utilizing the characteristic that the surface is self-lubricated through a common nepenthes imitating effect, and adopting a mode of loading silicone oil on aerogel, a silicone oil lubricating fluid with the lubricating effect is sealed into a water-based resin paint base material; by combining adsorption of an aerogel porous structure and transfer behaviors, on a water-based resin surface, of silicone oil, the controlled release effect, on the surface of the water-based paint base material, of the silicone oil lubricating oil is achieved, and long-time self-lubricating cleaning effect is achieved. According to the preparation method, a super-hydrophobic rough surface is not needed to be constructed; the prepared paint has self-cleaning effect, good stability, environmental protection and no pollution; the preparation method is simple, is innovative, is high in implementation, and is more beneficial to industrial application.

Owner:宁夏金石通新材料有限公司

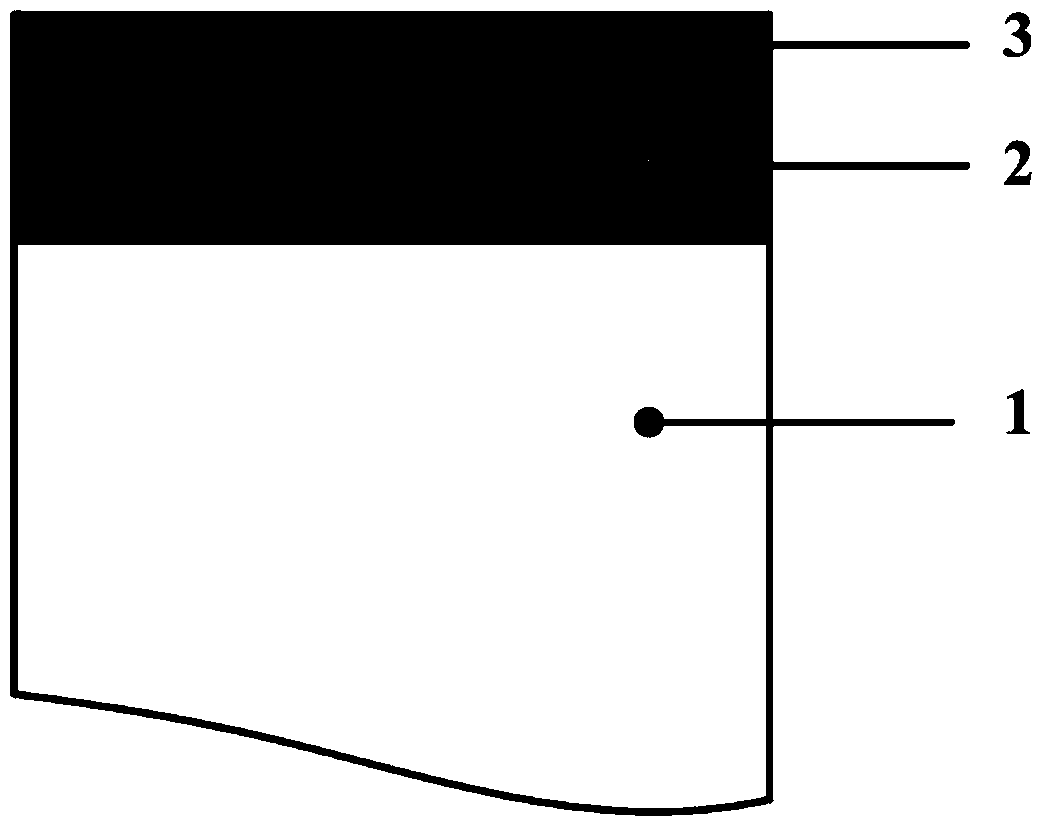

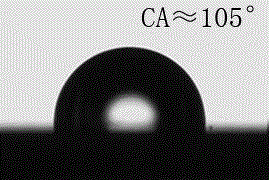

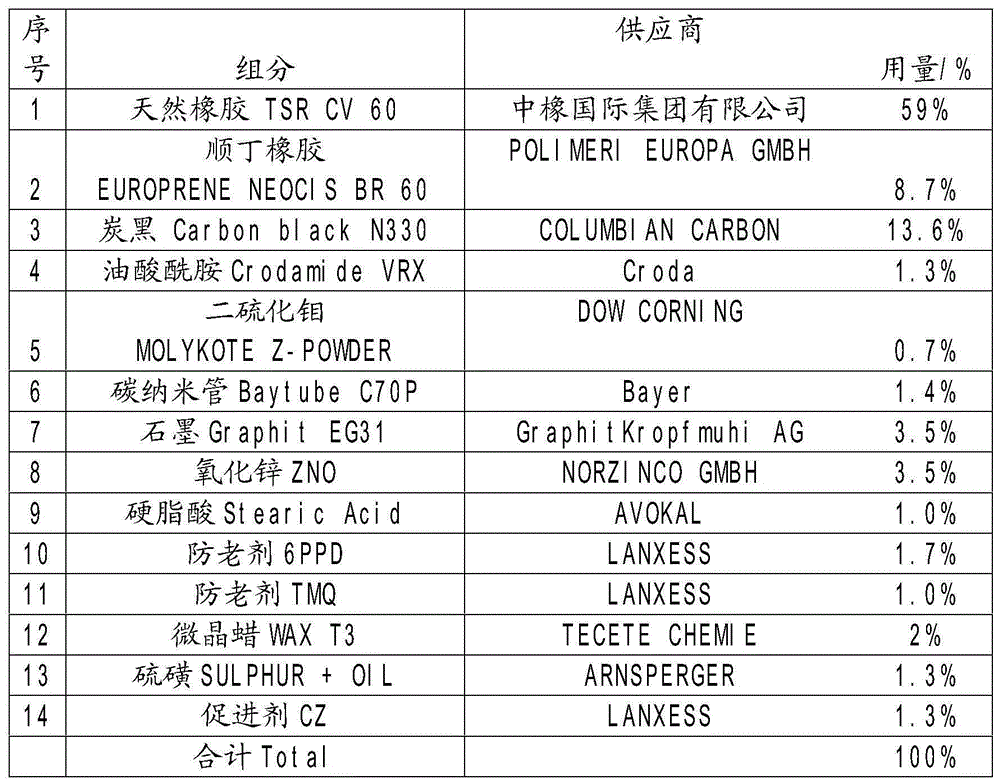

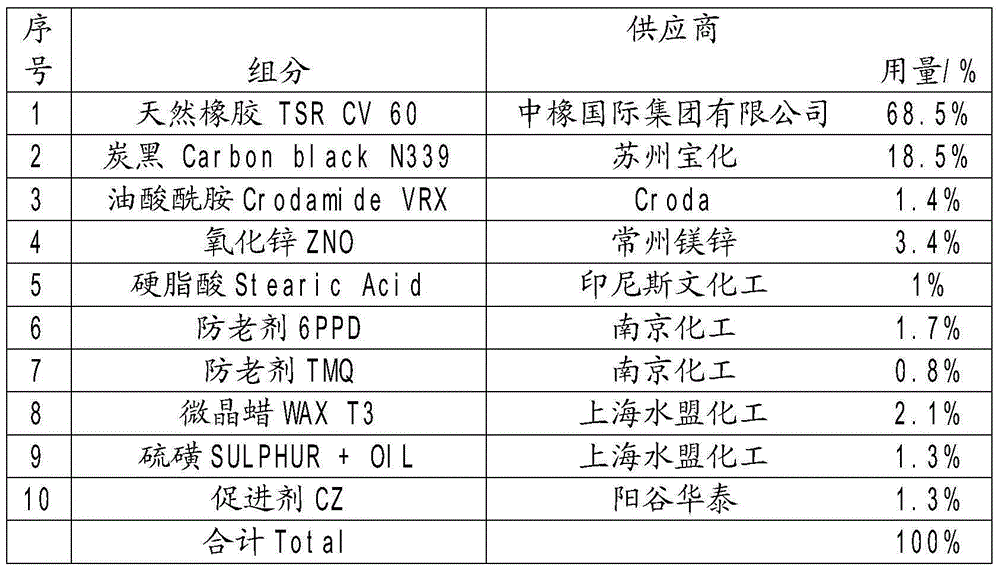

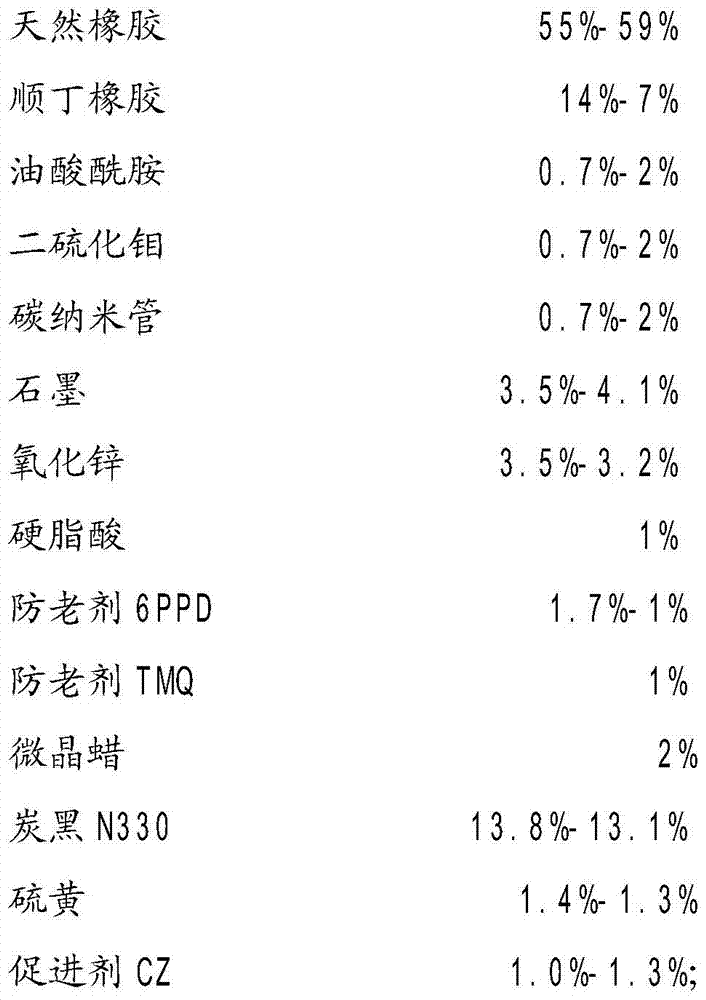

Rubber with self-lubricating effect for lining and preparation method of rubber

ActiveCN105295120AExcellent abrasion resistancePlay a lubricating effectVegetable oilMicrocrystalline wax

The invention discloses rubber with a self-lubricating effect for a lining. The rubber is prepared from the following components in percentage by weight: 55 to 59 percent of natural rubber, 7 to 14 percent of butadiene rubber, 0.7 to 2 percent of refined vegetable oil oleamide, 0.7 to 2 percent of molybdenum disulfide, 0.7 to 2 percent of carbon nano tubes, 3.5 to 4.1 percent of graphite, 3.2 to 3.5 percent of zinc oxide, 1 percent of stearic acid, 1 to 1.7 percent of antioxidant 6PPD, 1 percent of antioxidant TMQ, 2 percent of microcrystalline wax, 13.1 to 13.8 percent of carbon black N 330, 1.3 to 1.4 percent of sulfur grundum and 1.0 to 1.3 percent of accelerant CZ. The rubber for the lining, disclosed by the invention, has quadruple sustained releasing functions and is suitable for the lining of a self-lubricating high-end car; the problem that common self-lubricating rubber easily fails in lubricating can be solved, and the abrasion resistance of the rubber is increased; by combining specific situations of rubber abrasion at different stages, the service life of rubber and lining products can be prolonged. Meanwhile, the invention provides a preparation method of the rubber with the self-lubricating effect for the lining.

Owner:BOGE ELASTMETALL SHANGHAI CO LTD

Environmental self-lubricating wear-resistant copper alloy and preparation method thereof

The invention discloses environmental self-lubricating wear-resistant copper alloy, comprising the following components by mass percent: 5-13% of Sn, 2-9% of Ni and / or Co, 2-11% of Bi, 0.05-0.3% of Zr, 0.05-0.5% of RE, the balance of Cu and inevitable impurities, wherein the content of the impurity is smaller than or equal to 0.3%, the RE is Ce-La misch metal. Meanwhile, the preparation method of the environmental self-lubricating wear-resistant copper alloy is disclosed. The environmental self-lubricating wear-resistant copper alloy has the advantages that the conventional wear-resistant copper alloy containing lead is replaced, and the environmental self-lubricating wear-resistant copper alloy is the wear-resistant copper alloy material with environment-friendly and self-lubricating effects. The alloy solidification molding process is interfered by adopting a strong pulsed electromagnetic physical field in the manufacturing process, the as-cast segregation and loosening of the obtained environmental self-lubricating wear-resistant copper alloy are significantly reduced, the alloy is fine and even in as-cast structure, and high in density, the hardness of the molded casting is greater than 70HB, the tensile strength is greater than 230MPa, and the alloy density is greater than 8.7g / cm<3>. The environmental self-lubricating wear-resistant copper alloy has good overall performance, the preparation method is good in stability, and low in cost, the preparation process is green and free of pollution, and industrialization is easily achieved.

Owner:镇江金鑫有色合金有限公司 +2

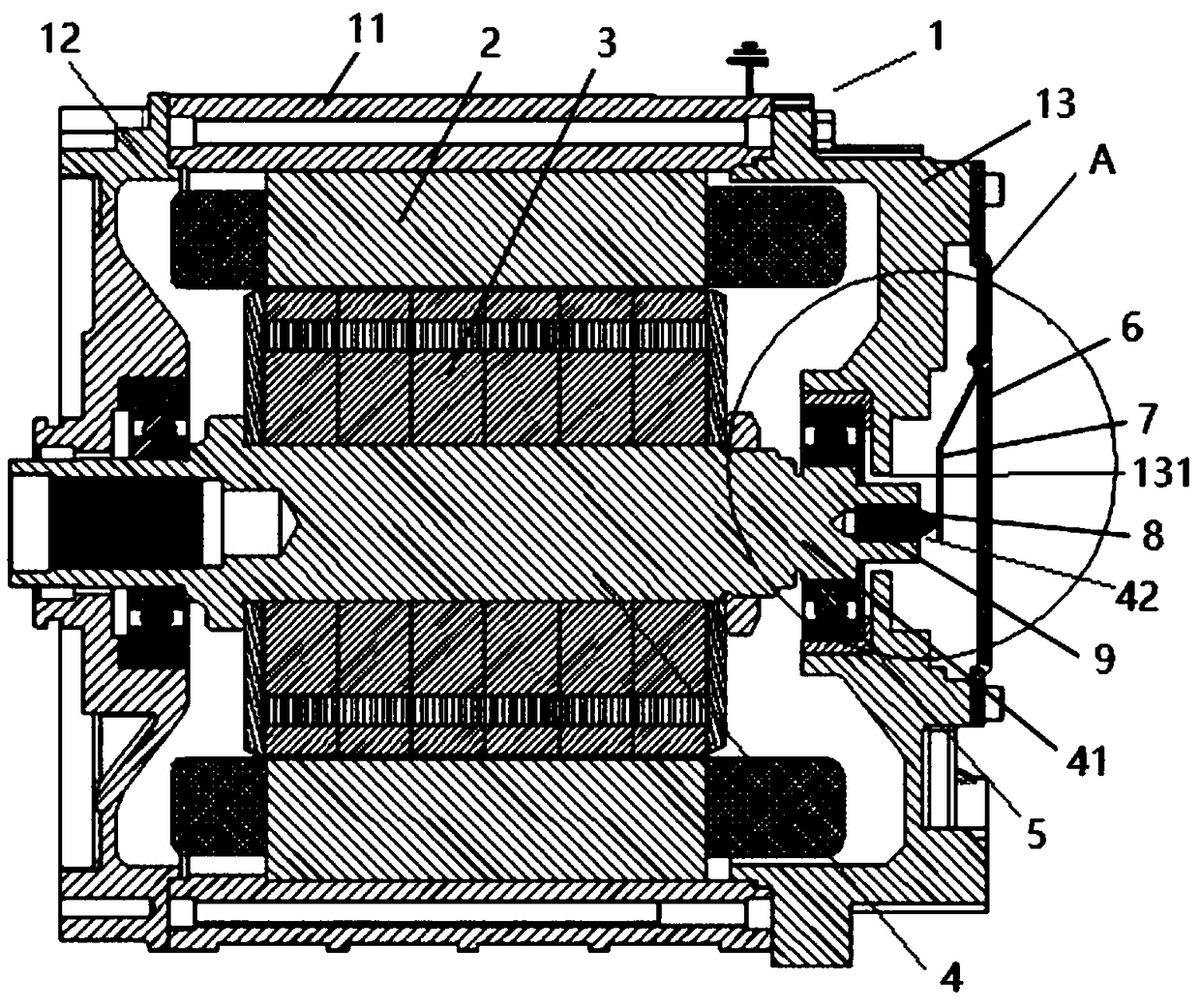

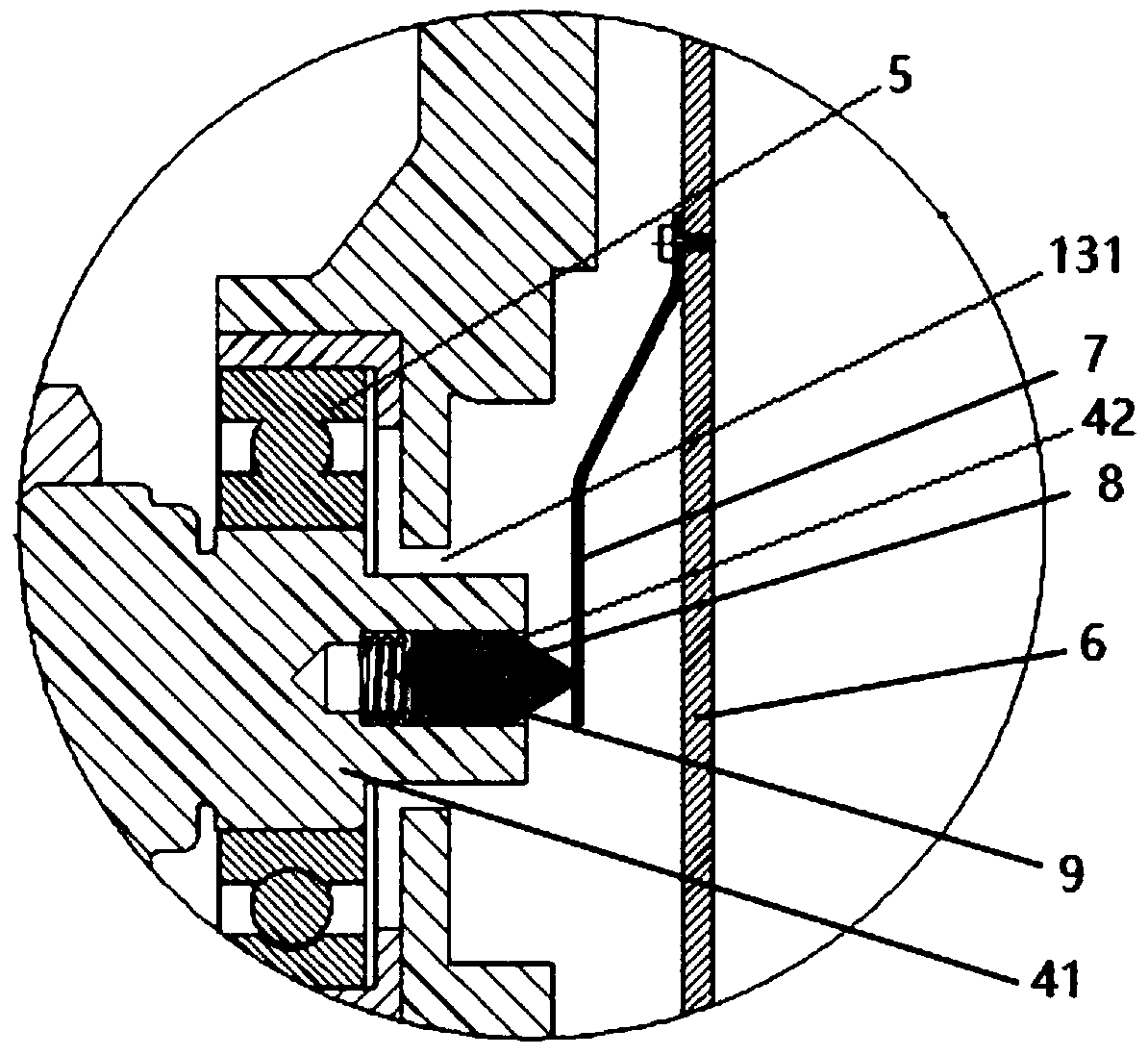

A motor shaft current eliminating structure and motor

PendingCN109194039ACompact structureSimple structureStructural associationSupports/enclosures/casingsPower flowGraphite

The invention relates to a motor shaft current eliminating structure and a motor. The motor shaft current eliminating structure comprises a rear cover plate, a graphite rod and at least one electrically conductive elastic member, the rear cover plate can be electrically connected to the housing of the motor. The graphite rod can be placed in a graphite rod mounting hole of a motor rotating shaft,and the conductive elastic member is an electrically conductive spring and / or an electrically conductive elastic piece; the graphite rod is electrically connected with the rear cover plate directly orthrough the electrically conductive elastic piece; and the graphite rod can be electrically connected with the motor rotating shaft directly or through the electrically conductive spring. The embodiment of the invention has the advantages of compact structure, simplicity and low cost. The graphite rod and the conductive elastic parts are all inside the motor, which are not affected by the external environment, and do not produce noise when running, so the conductive parts are reliable.

Owner:GUANGZHOU XIAOPENG MOTORS TECH CO LTD

Preparation method of self-lubricating insulated iron powder for motor magnetic core

InactiveCN101658932AHigh resistivityImprove the lubrication effectMetallic material coating processesMagnetic circuit characterised by insulating materialsElectrical resistance and conductanceIron powder

A preparation method of a self-lubricating insulated iron powder for a motor magnetic core belongs to the technical fields of magnetic functional material and powder metallurgy. The preparation methodcomprises the steps of adding water-atomized iron powder or reduced iron powder that is produced industrially in phosphorated fluid, stirring for 10-90 minutes at temperature of 20-90 DEG C, filtering, washing and then adding the mixture in saponified fluid, stirring for 10-90 minutes at temperature of 20-90 DEG C, filtering, and at last conducting drying at temperature of 20-150 DRG C to obtainthe insulated iron powder which is coated with phosphate and zinc stearate on the surface and has lubricating function. The preparation method has the advantages of simple technology, low cost, easy formation of industrialized scale and capability of directly obtaining powder with high resistivity, good lubricating property and good compression property; and during forming, without adding any lubricants, the preparation method can obtain an iron powder magnetic core with high performance, thus being applicable to novel, variable-frequency and high-frequency motor magnetic cores.

Owner:UNIV OF SCI & TECH BEIJING +1

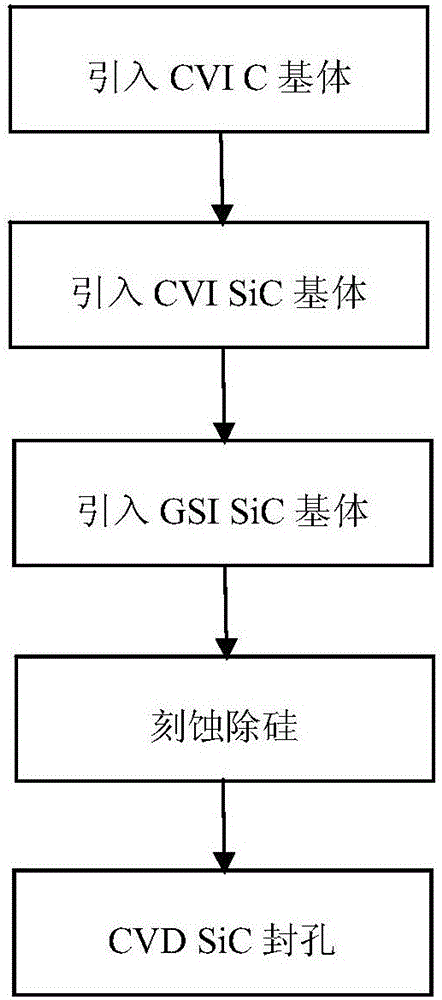

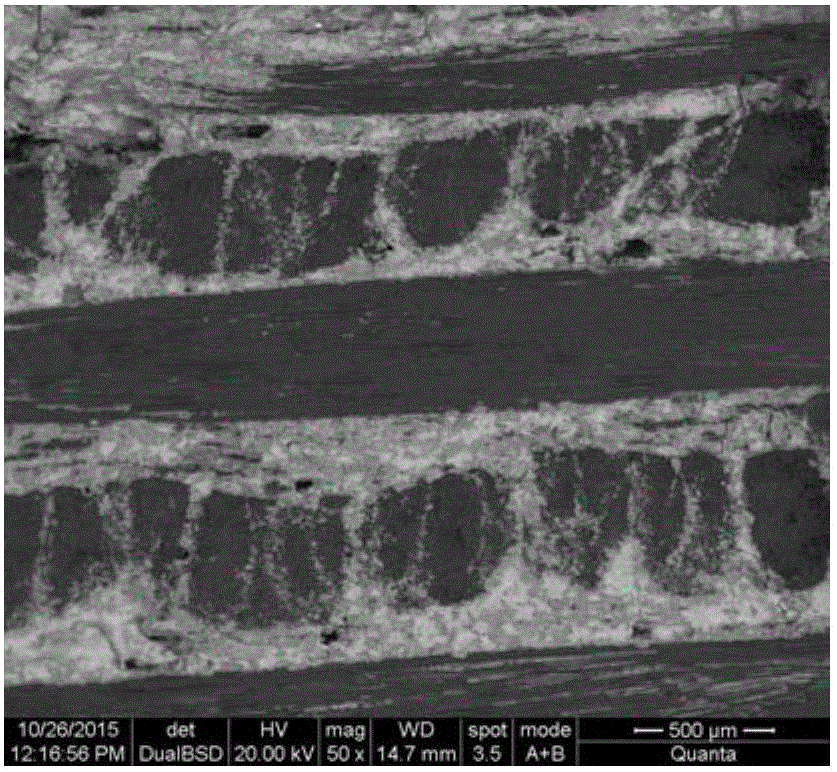

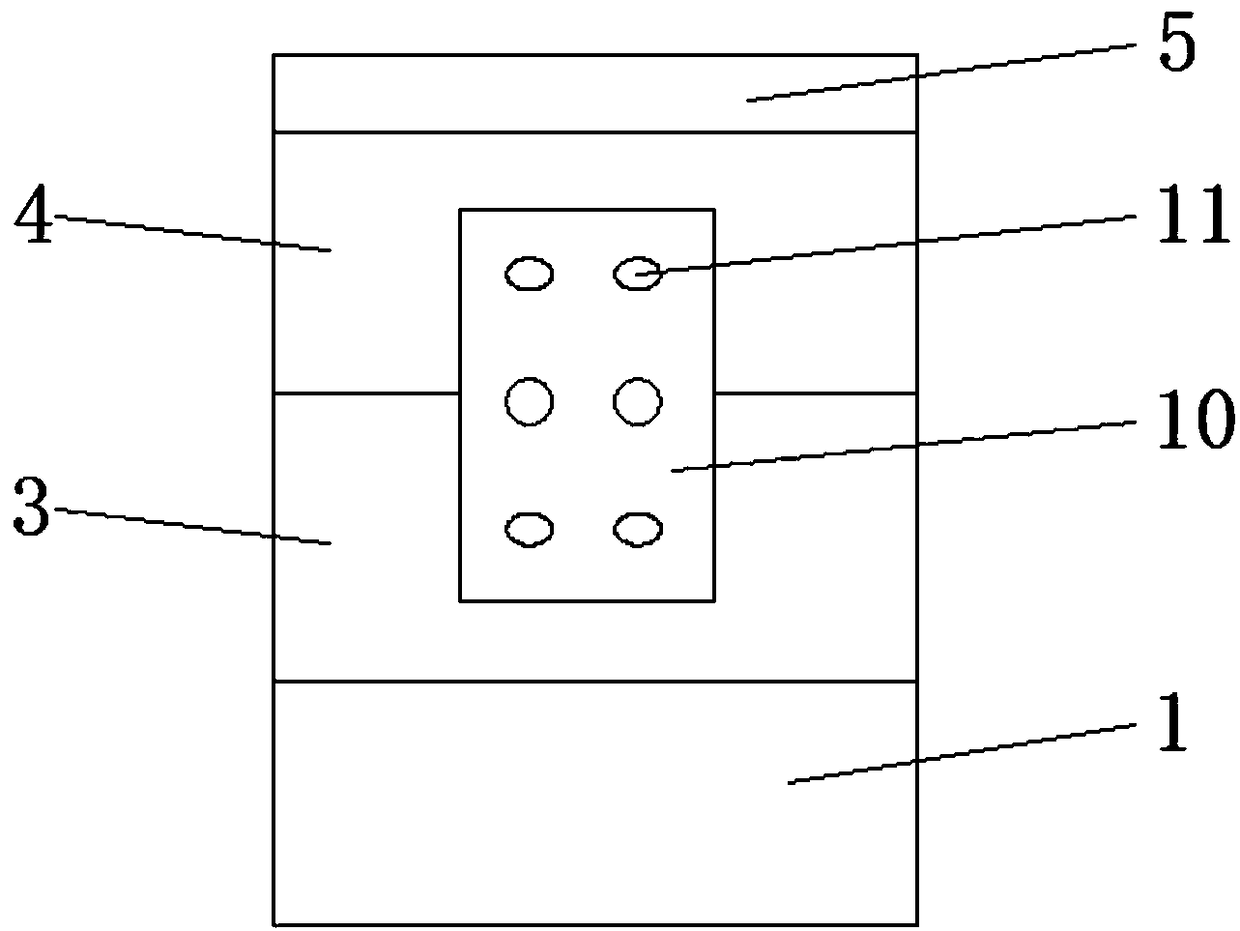

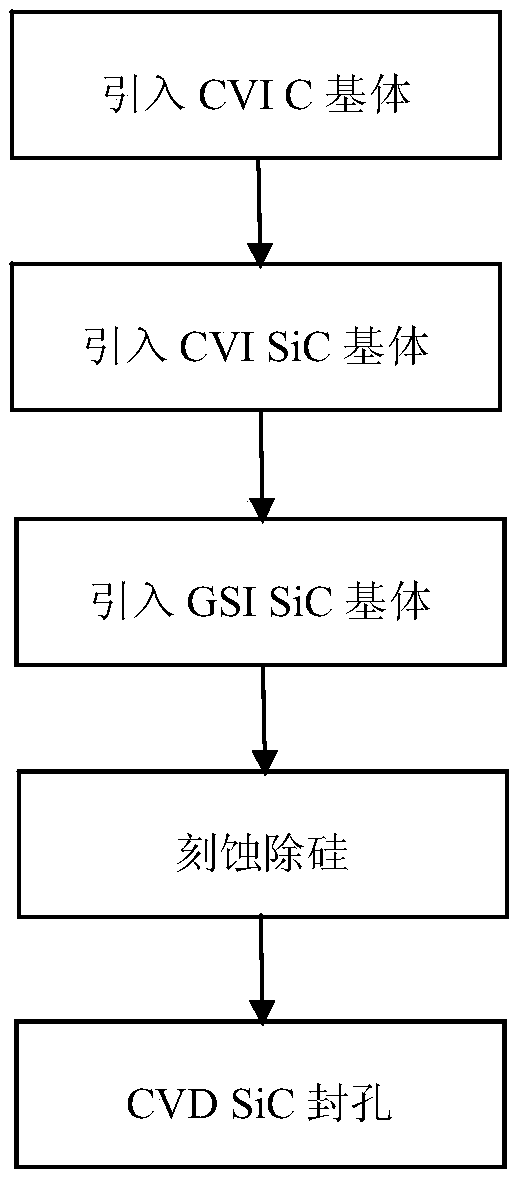

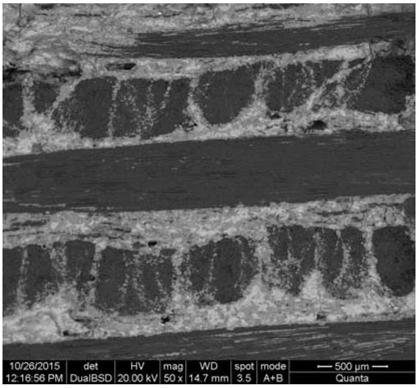

C/C-SiC composite material, and preparation method and application thereof

ActiveCN106064951AHigh densityImprove thermal conductivity and mechanical propertiesOther chemical processesCarbon matrixFiber

The invention discloses a C / C-SiC composite material, and a preparation method and an application thereof. The C / C-SiC composite material comprises a carbon fiber prefabricated part, a carbon matrix and a silicon carbide matrix, aperatures of the carbon fiber prefabricated part are filled with the carbon matrix and the silicon carbide matrix, the silicon carbide matrix comprises a first silicon carbide matrix and a second silicon carbide matrix, and the second silicon carbide matrix is introduced through a vapor silicon infiltration sintering technology. The preparation method comprises the following steps: 1, introducing the carbon matrix; and 2, respectively introducing the first silicon carbide matrix and the second silicon carbide matrix. The C / C-SiC composite material has the advantages of uniform components, high density, fine matrix particles, high friction stability, high heat conductivity and excellent mechanical performances. The preparation method is simple, and the composite material has excellent performances.

Owner:NAT UNIV OF DEFENSE TECH

Strengthened and toughened in-site reaction-type micro-structure self-lubricating bearing and preparation method thereof

ActiveCN110318017AImprove toughnessHigh hardnessMolten spray coatingBearing componentsMicro structureCarbon nanotube

The invention discloses a strengthened and toughened in-site reaction-type micro-structure self-lubricating bearing and a preparation method thereof. A matrix of the bearing is made from chromium-containing alloy steel, a cubic boron nitride coating containing PbO, Mo, TiB2, BNNTs, CNTs and graphene is arranged on the surface of the matrix, and the surface of the coating is of a micro-structure; and the coating is prepared through a plasma vacuum spaying method. The self-lubricating bearing prepared through the method has good toughness on the whole, the binding force between the matrix and the coating is high, and boron nitride nanotubes (BNNTs) and carbon nanotubes (CNTs) are added, so that the cubic boron nitride coating on the surface has good toughness and high hardness and wear resistance; and in the working process, the graphene can achieve a lubricating effect when the temperature is low, and when the temperature is high, PbO, Mo and TiB2 are subjected to an in-site reaction togenerate PbMoO4, TiO2 and B2O3 to cooperatively work with the micro-structure to achieve a lubricating effect, so that frictional wear is reduced, and the life of the bearing is prolonged.

Owner:SOUTHEAST UNIV

High temperature self-lubrication alloyed steel, smelting method and application thereof

InactiveCN1920082AImprove the lubrication effectImprove temperature resistanceProcess efficiency improvementLubricationHeat treating

The invention relates the hyperthermia automatic lubrication alloyed steel and smelting method and application. The method comprises the following steps: putting scrap steel, castiron, chromium iron, ferro-molybdenum, ferrotungsten, ferro-vanadium, nickel, ferromanganese, ferrosilicium and ferrocolumbium into founding furnace, removing scum trough, deoxidizing, deoxidizing treatment, casting, heat treating, forming alloyed steel with sulfur, which can be used to make inner ring of axle bearing. The product has high heatproof property which is up to 600Deg.C, high intensity, hardness, tenacity and abradability. The product can be used at hostile environment, and there is no noise and non-pollution.

Owner:扬州市金正机电制造有限公司

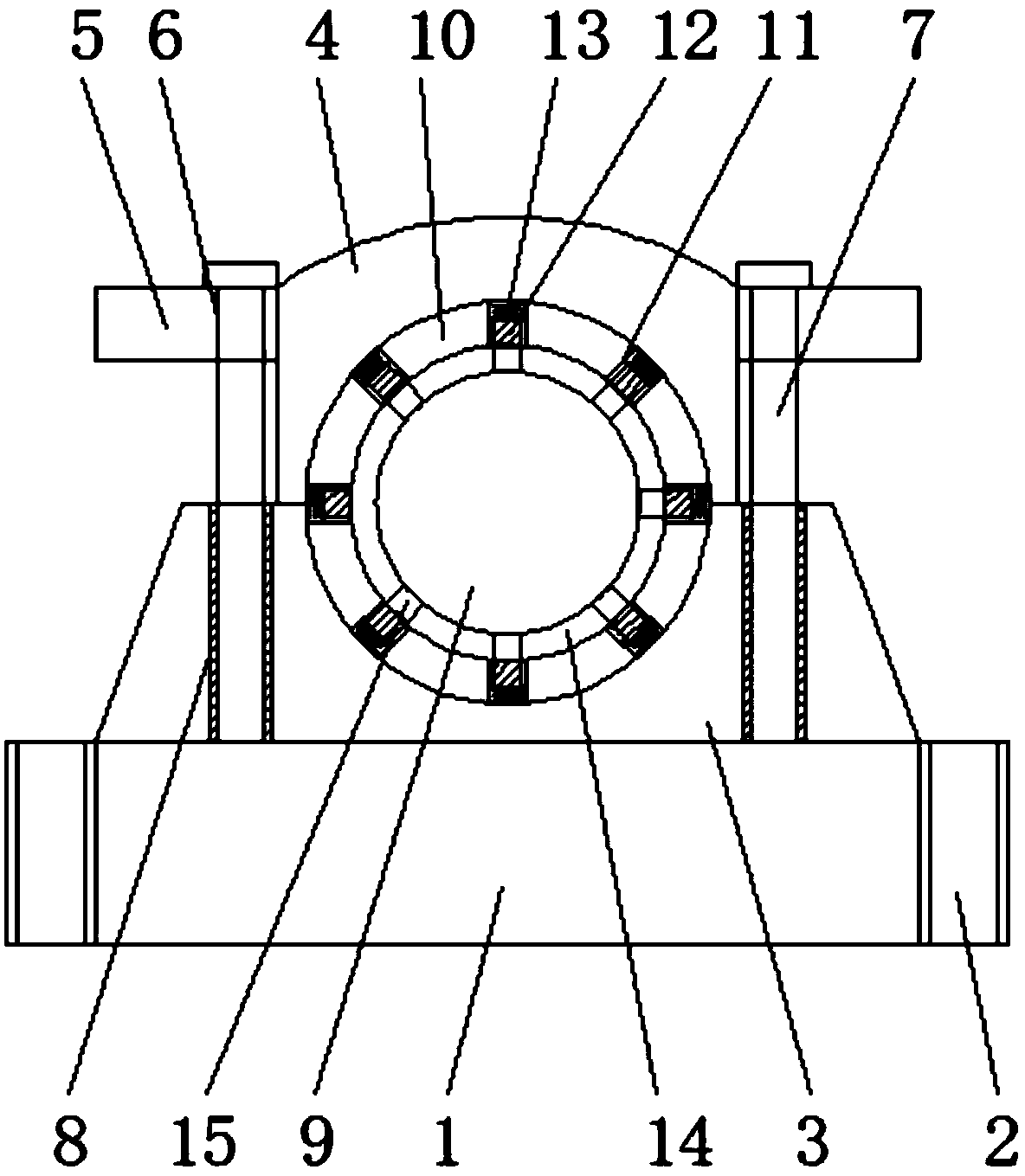

Damping self-lubricating bearing pedestal

InactiveCN108691906APlay a shock absorbing roleExtended service lifeNon-rotating vibration suppressionEngine lubricationEngineeringMechanical engineering

The invention discloses a damping self-lubricating bearing pedestal which comprises a base. First mounting holes are symmetrically formed in the two sides of the base, a bearing pedestal lower cover is fixed to the base, and a bearing pedestal upper cover is arranged on the bearing pedestal lower cover. Mounting plates are symmetrically arranged on the two sides of the bearing pedestal upper cover, second mounting holes are formed in the mounting plates, and long leg screws are mounted in the second mounting holes. Threaded grooves are symmetrically formed in the two sides of the bearing pedestal lower cover, and the long leg screws penetrate through the second mounting holes to be in threaded connection with the threaded grooves. The bearing pedestal lower cover and the bearing pedestal upper cover are matched to form a bearing cavity, and a buffer body is arranged in the bearing cavity. A plurality of lubricant filling holes are evenly formed in the inner wall of the buffer body, andthe lubricant filling holes are filled with self-lubricants. Compression springs are arranged at the bottoms of the self-lubricants, a bearing bush is arranged on the inner side of the buffer body, and a plurality of through holes matched with the lubricant filling holes are formed in the inner side of the bearing bush. The damping self-lubricating bearing pedestal has a self-lubricating effect and a good damping effect, so that the service life is prolonged.

Owner:响水县瑞丰重型轴承座制造有限公司

c/c-sic composite material and its preparation method and application

The invention discloses a C / C-SiC composite material, and a preparation method and an application thereof. The C / C-SiC composite material comprises a carbon fiber prefabricated part, a carbon matrix and a silicon carbide matrix, aperatures of the carbon fiber prefabricated part are filled with the carbon matrix and the silicon carbide matrix, the silicon carbide matrix comprises a first silicon carbide matrix and a second silicon carbide matrix, and the second silicon carbide matrix is introduced through a vapor silicon infiltration sintering technology. The preparation method comprises the following steps: 1, introducing the carbon matrix; and 2, respectively introducing the first silicon carbide matrix and the second silicon carbide matrix. The C / C-SiC composite material has the advantages of uniform components, high density, fine matrix particles, high friction stability, high heat conductivity and excellent mechanical performances. The preparation method is simple, and the composite material has excellent performances.

Owner:NAT UNIV OF DEFENSE TECH

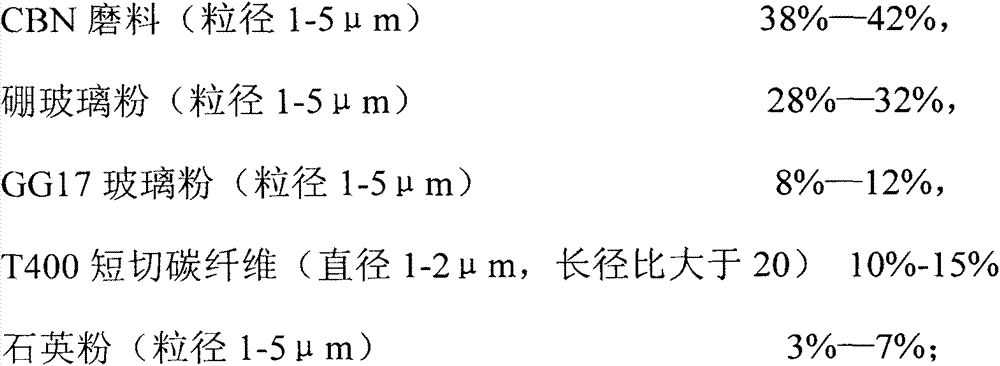

Preparation method of carbon fiber reinforced high-porosity ceramic bonding agent CBN grinding wheel

The invention discloses a preparation method of a carbon fiber reinforced high-porosity ceramic bonding agent CBN grinding wheel. The method comprises the steps that CBN grinding materials, borosilicate glass powder, GG17 glass powder, T400 short carbon fiber and quartz powder are weighed according to weights, the materials are subjected to ball milling and mixed to be uniform, the mixed powder and molten paraffin are stirred and mixed according to the proportion, and CBN grinding wheel molding slurry is prepared; the slurry is injected into a molding die at 80 DEG C, demolding is carried out after cooling, and a CBN grinding wheel blank is obtained; and the grinding wheel blank is subjected to buried sanding through white corundum and then is dewaxed and sintered through a certain heat treatment process under nitrogen atmosphere, the sintered grinding wheel blank is subjected to outer circle, inner circle and plane machining, and the carbon fiber reinforced high-porosity ceramic bonding agent CBN grinding wheel with the porosity higher than 40% and carbon fibers evenly distributed in a grinding wheel base body is prepared.

Owner:江苏华东砂轮有限公司

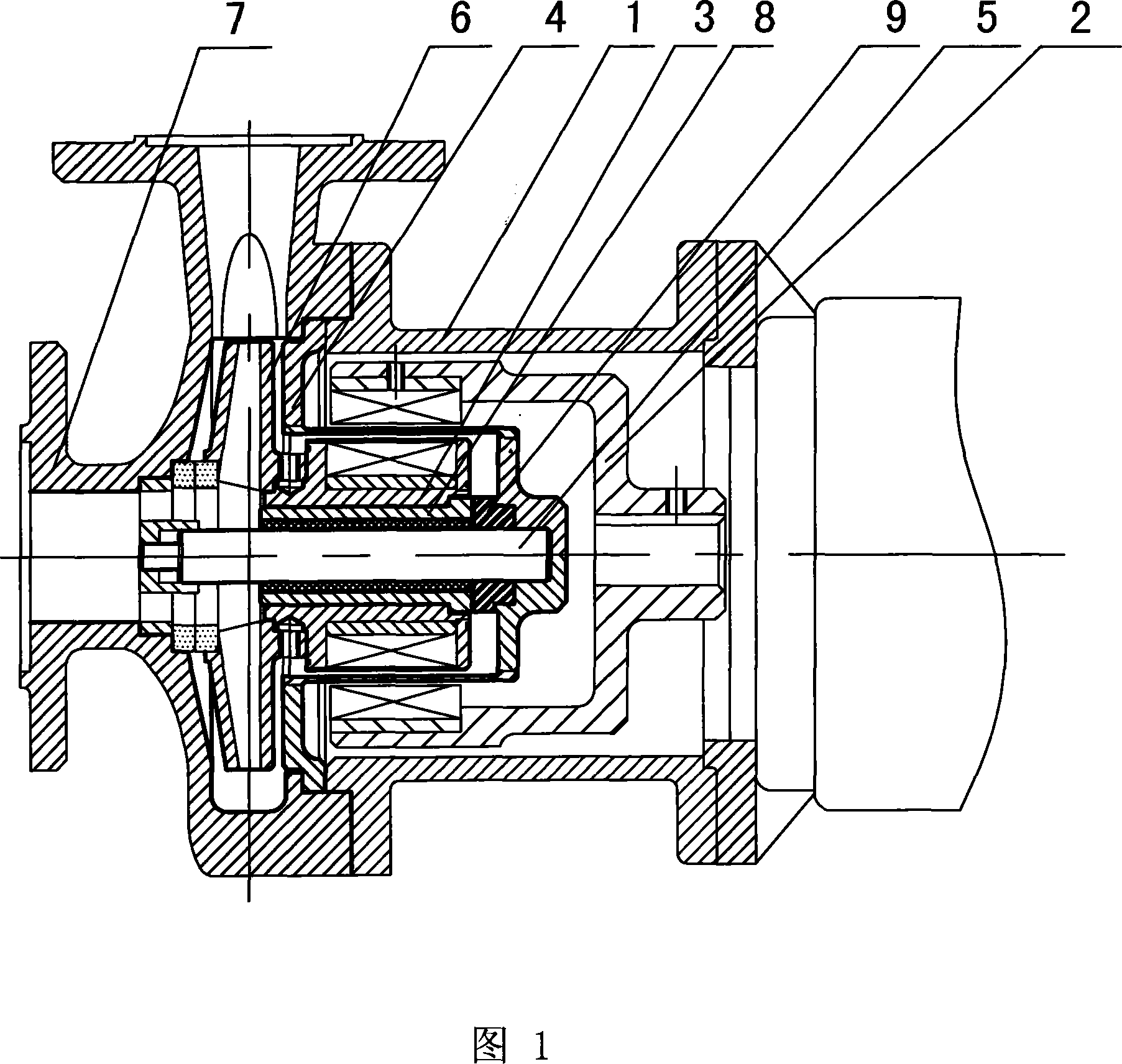

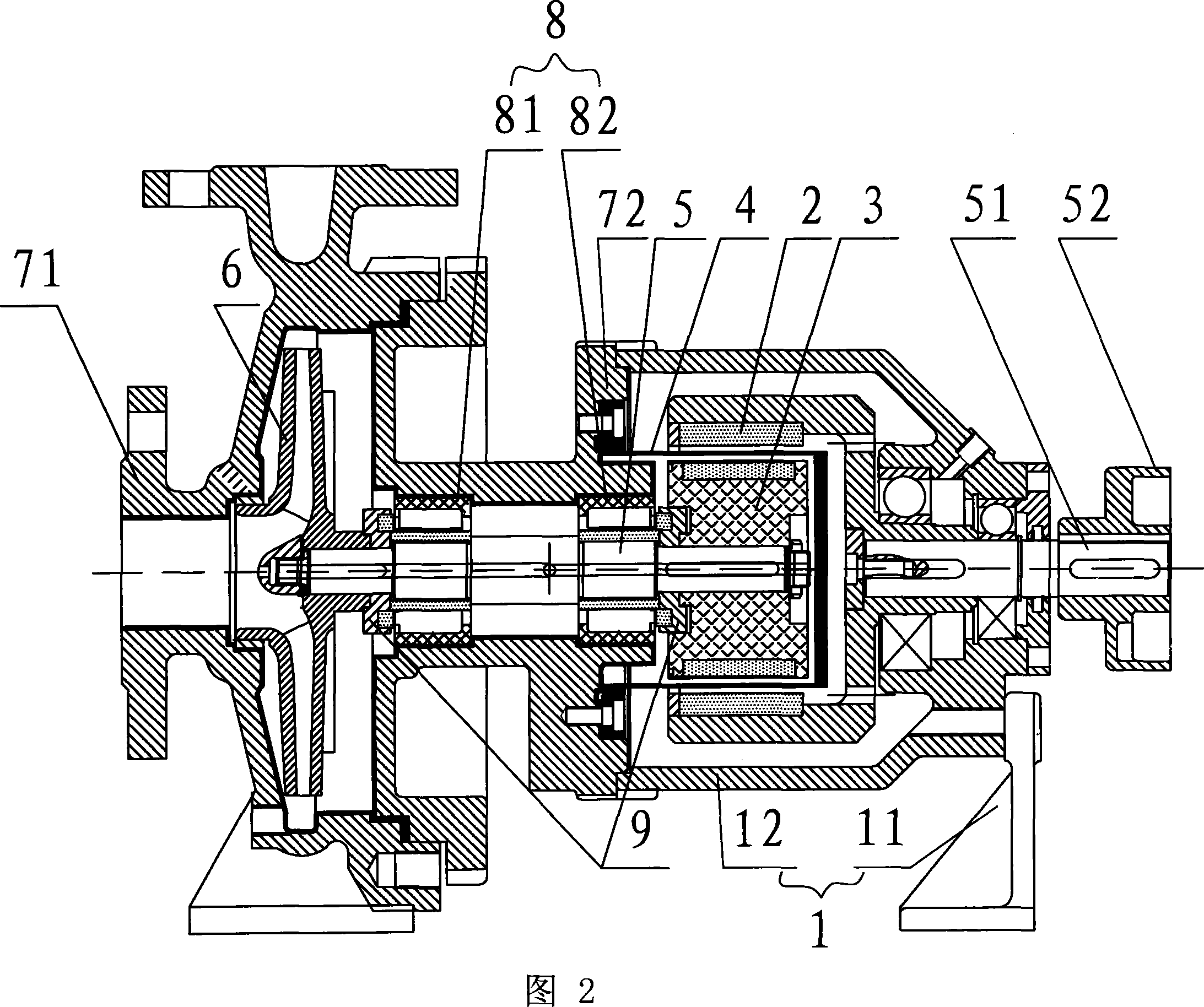

Magnetic force pump

InactiveCN101187377AHigh temperatureHigh modulusSpecific fluid pumpsPump componentsEngineeringMagnetic tension force

The invention relates to a magnetic pump, which comprises a support bracket, a motor, an outer coupler which is driven by the motor, an inner coupler which is concentrically provided with the outer coupler and is driven by the magnetic force of the outer coupler to rotate, a separation sleeve which is arranged between the outer coupler and the inner coupler, a pump shaft of which one end is connected with the inner coupler, a blade wheel which is installed on the pump shaft, a pump casing which is located on the outer portion of the outer pump shaft and is fixedly connected with the support bracket, and a sliding bearing and a trust bearing which are concentrically provided with the pump shaft. The surfaces of the pump casing, the blade wheel, the inner coupler, the pump shaft, the separation sleeve, the sliding bearing and the trust bearing are coated with polyetheretherketone resin, or the blade wheel, the separation sleeve, the pump shaft, the sliding bearing, and the trust bearing are made from polyetheretherketone resin, which can greatly increase the use field and the use temperature of the plastic magnetic pump, reduces the friction resistance and energy consumption in working, avoids elements from deforming, and increases the service life.

Owner:蔡国华

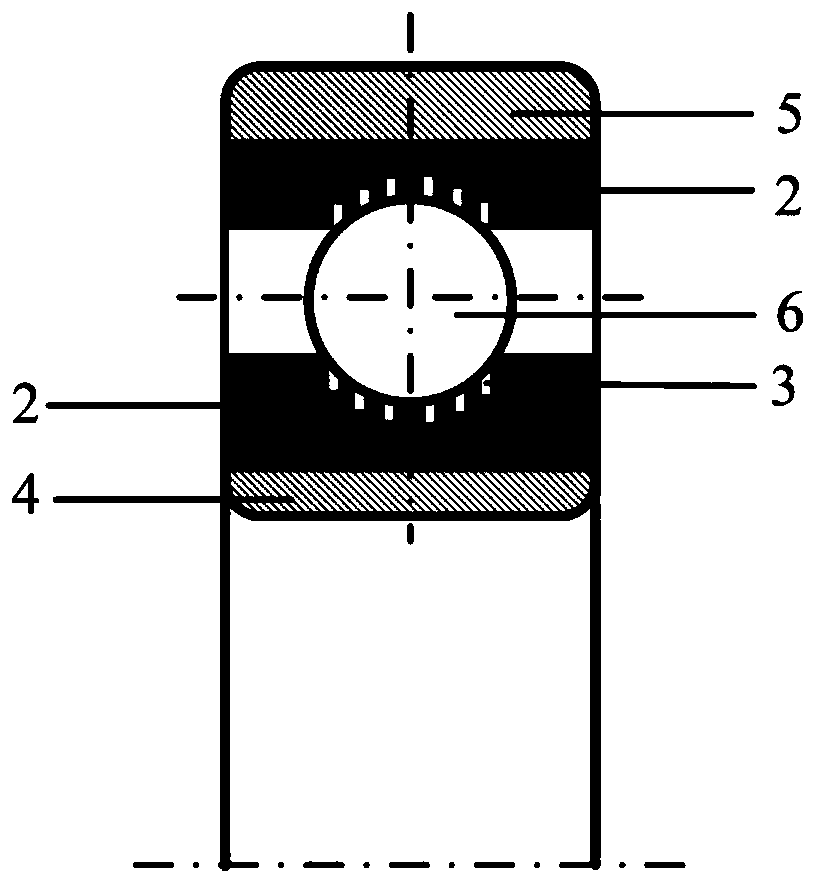

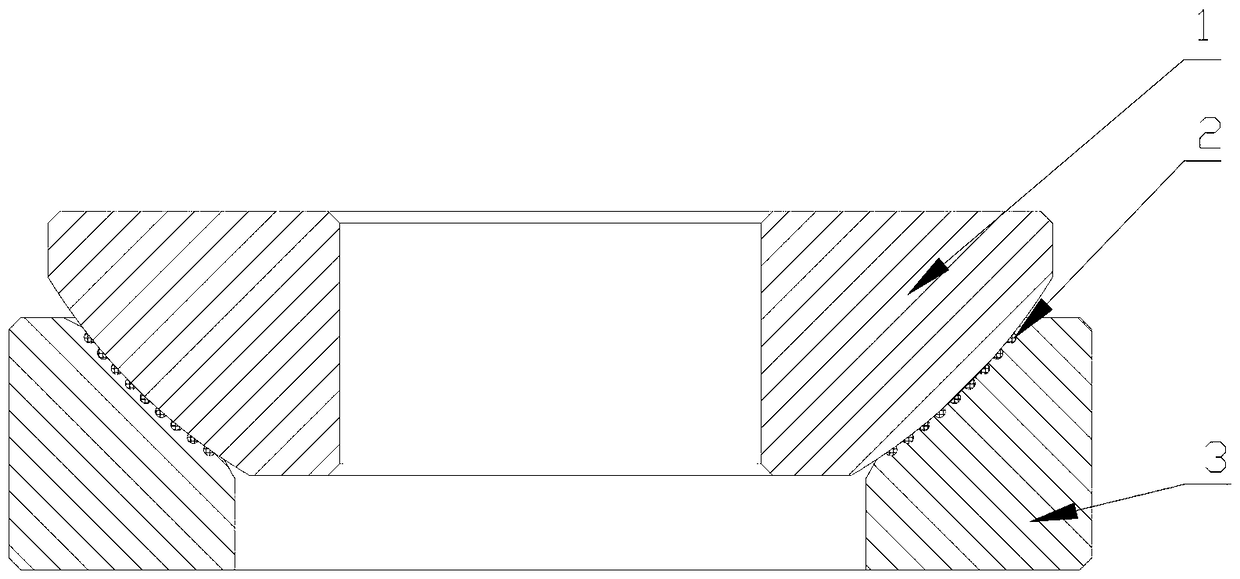

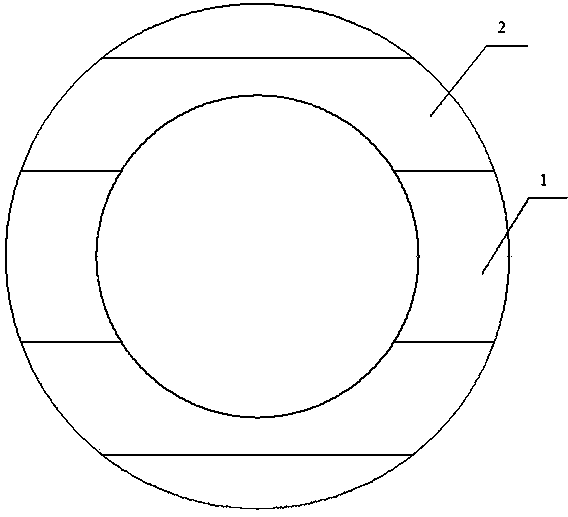

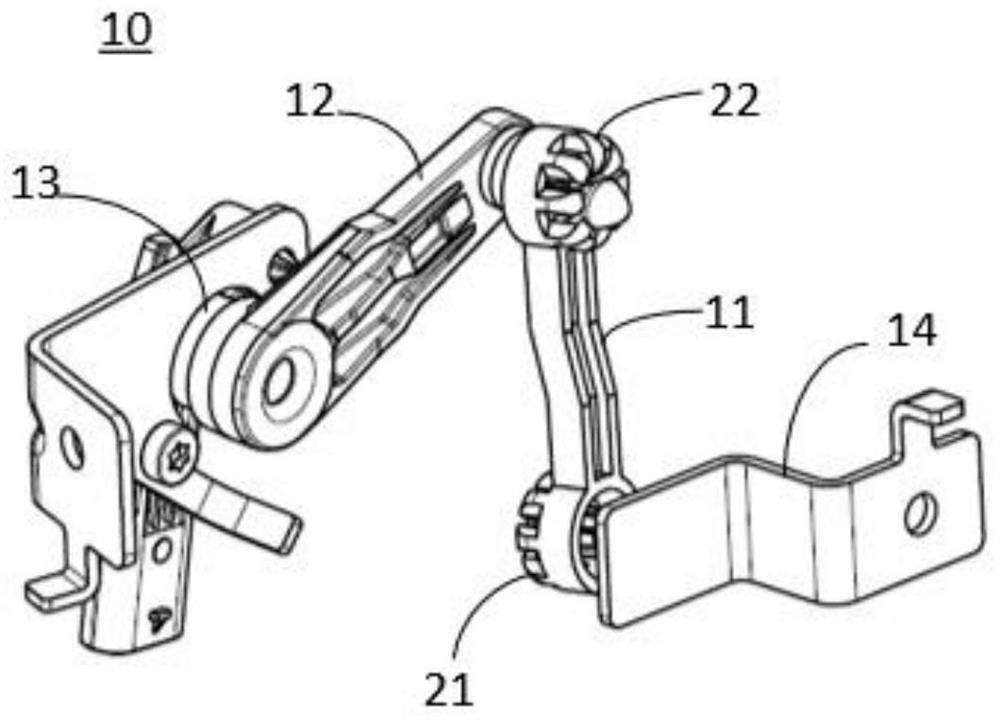

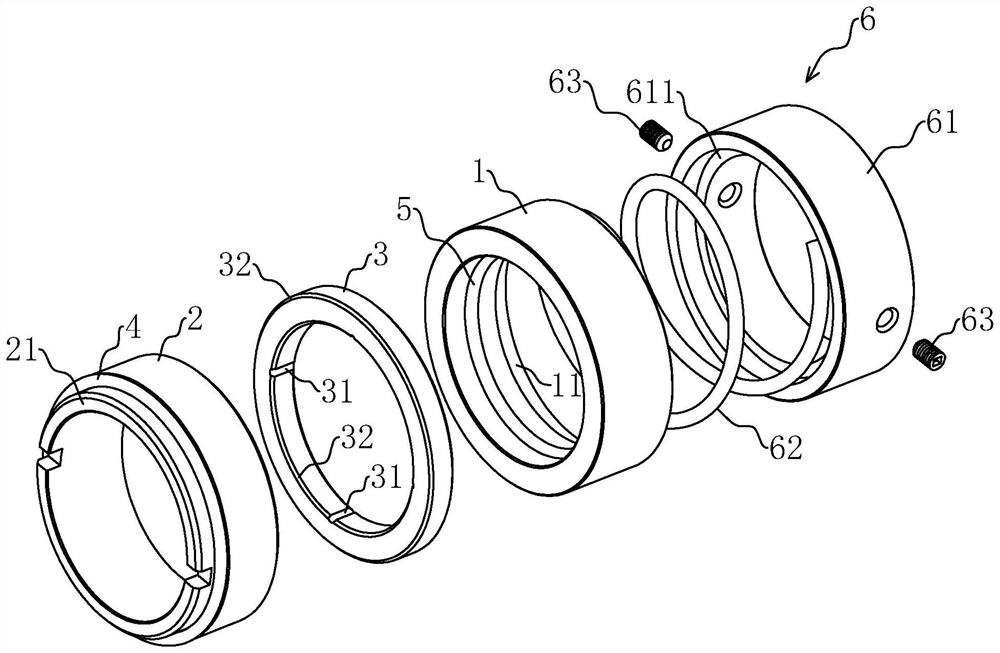

Self-lubricating thrust knuckle bearing and manufacturing method thereof

PendingCN108547860AHas self-lubricating effectExtended service lifeBearing componentsSliding contact bearingsMacroscopic scaleEngineering

The invention discloses a self-lubricating thrust knuckle bearing and a manufacturing method thereof, and relates to the field of thrust knuckle bearing lubrication. The self-lubricating thrust knuckle bearing comprises an inner ring and an outer ring; the self-lubricating thrust knuckle bearing and the manufacturing method thereof is characterized in that the surface of the inner spherical surface of the outer ring is provided with a plurality of micro concave pits with the diameters of 40-120 microns and the depths of 10-20 microns, the ratio of the plurality of micro concave pits to the surface area of the inner spherical surface of the outer ring is 25%-35%, and solid lubricant are filled in the plurality of micro concave pits. According to the self-lubricating thrust knuckle bearing and the manufacturing method thereof, the surface of the inner spherical surface of the outer ring is machined, the plurality of concave pits with certain diameter, depth and area occupancy are formed,polyimide and molybdenum disulfide composite solid lubricant are filled in the concave pits of the inner spherical surface of the outer ring, so that the thrust knuckle bearing has a self-lubricatingeffect; and the supporting structure of the inner spherical surface of the outer ring is not changed on the macroscopic scale, so that the purposes of prolonging the service life and bearing capacityof the self-lubricating thrust knuckle bearing are achieved.

Owner:HUZHOU VOCATIONAL TECH COLLEGE

Preparation method of self-lubricating insulated iron powder for motor magnetic core

InactiveCN101658932BHigh resistivityImprove the lubrication effectMetallic material coating processesMagnetic circuit characterised by insulating materialsElectrical resistance and conductanceIron powder

Owner:UNIV OF SCI & TECH BEIJING +1

High temperature self-lubrication alloyed steel, smelting method and application thereof

InactiveCN100412221CEasy to operateEasy to produceProcess efficiency improvementLubricationHeat treating

The invention relates the hyperthermia automatic lubrication alloyed steel and smelting method and application. The method comprises the following steps: putting scrap steel, castiron, chromium iron, ferro-molybdenum, ferrotungsten, ferro-vanadium, nickel, ferromanganese, ferrosilicium and ferrocolumbium into founding furnace, removing scum trough, deoxidizing, deoxidizing treatment, casting, heat treating, forming alloyed steel with sulfur, which can be used to make inner ring of axle bearing. The product has high heatproof property which is up to 600Deg.C, high intensity, hardness, tenacity and abradability. The product can be used at hostile environment, and there is no noise and non-pollution.

Owner:扬州市金正机电制造有限公司

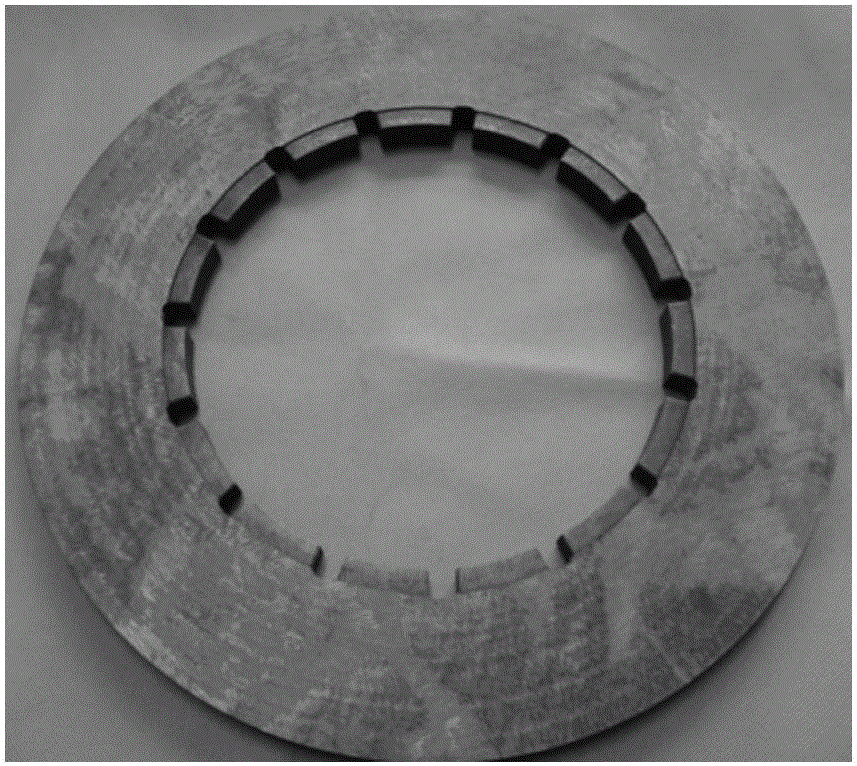

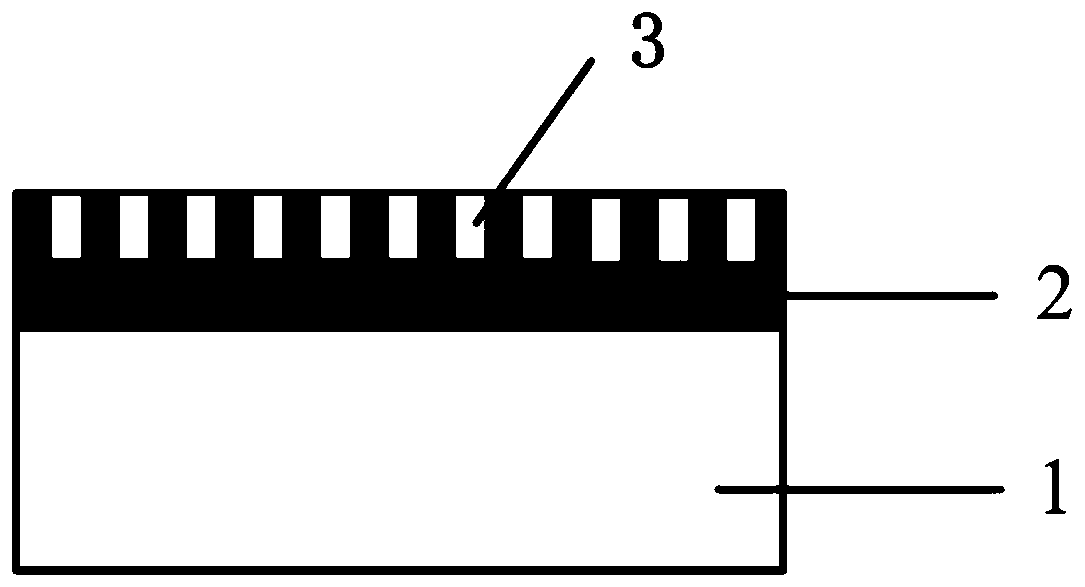

Gasket structure capable of enhancing wear resistance

InactiveCN103410947AImprove wear resistanceReduce wearPortable liftingBearing componentsEngineeringMechanical engineering

The invention discloses a gasket structure capable of enhancing wear resistance. The gasket structure comprises a gasket body. At least one oil through groove which penetrates through the end face is formed in the working end face on one side or the working end faces on the two sides of the gasket body. According to the gasket structure capable of enhancing the wear resistance, due to the fact that the at least one oil through groove which penetrates through the working end face is formed in the working end face of the gasket body, the gasket structure is changed, then, lubricating oil around the gasket body enters the oil through groove, when the gasket body is rotated, the oil through groove rotates along with the gasket body, the lubricating oil in the oil through groove can make contact with the working end face of the gasket body, lubricating oil films are formed on the contact surface, therefore, the gasket body has the self-lubricating effect, and the wear extent of the gasket body is reduced.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

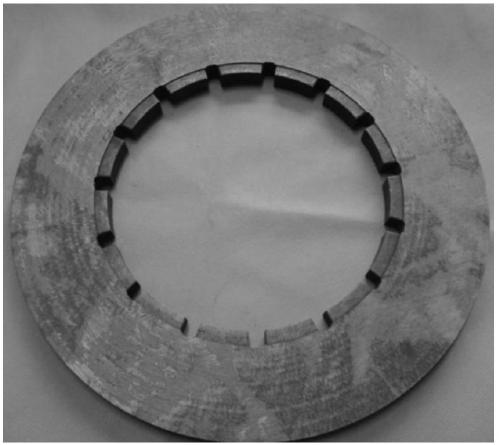

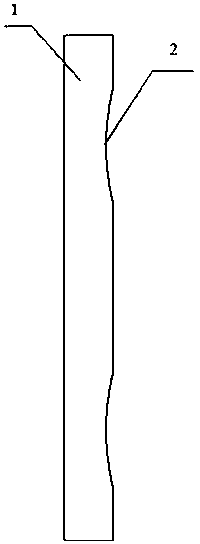

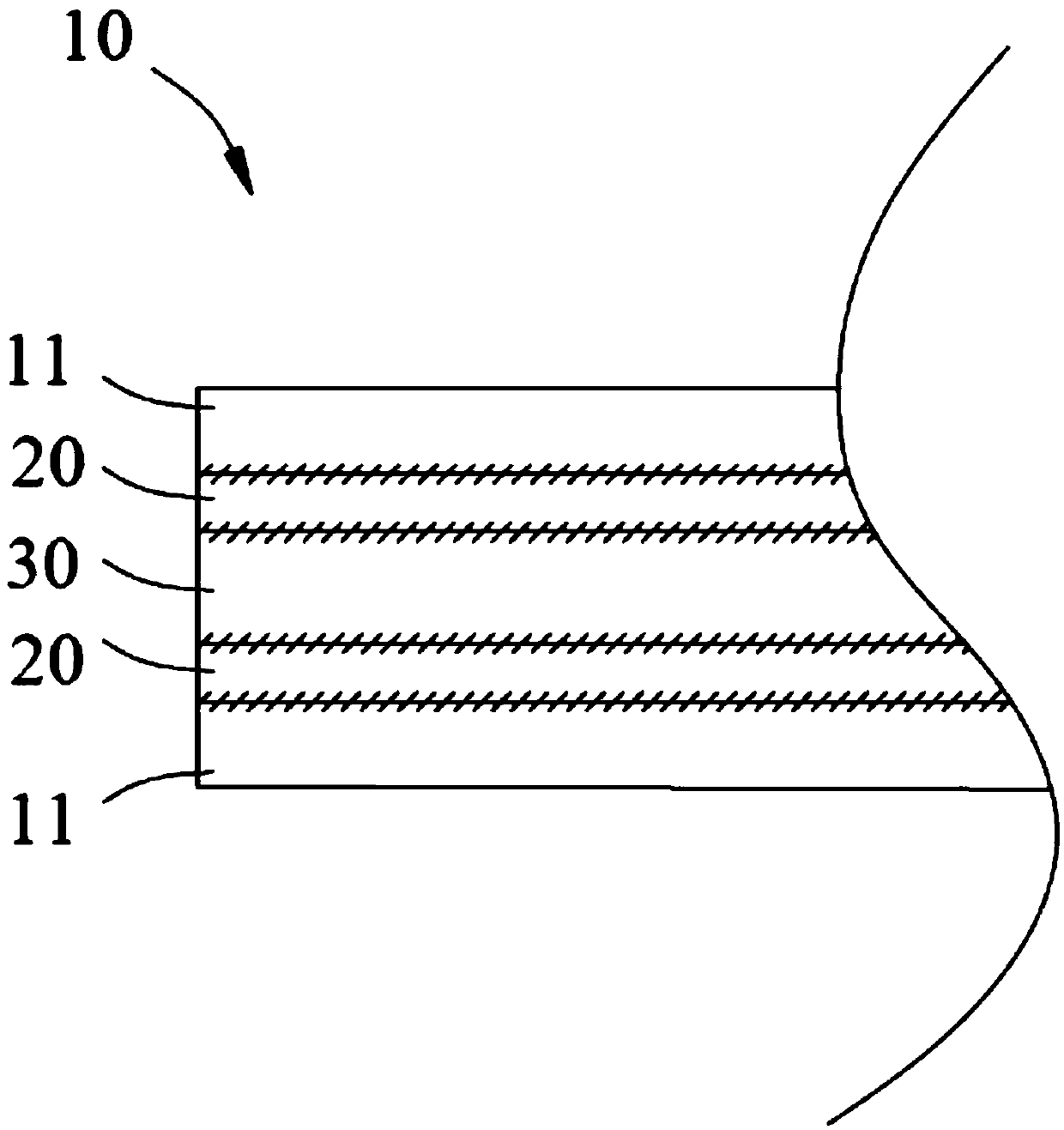

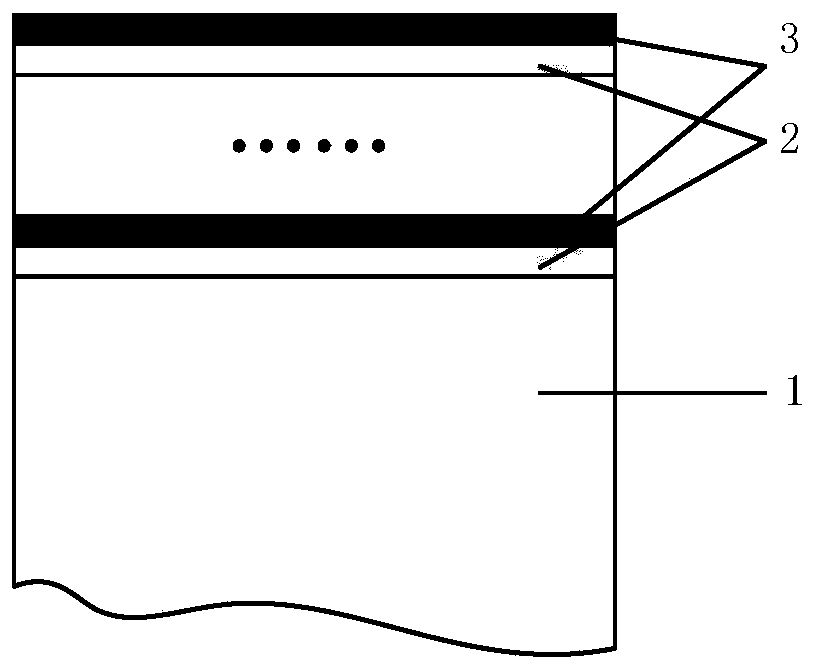

Friction plate structure and manufacturing method thereof

InactiveCN110529531ANo noiseImprove wear resistanceLaminationLamination apparatusFiber bundlePeak area

The invention provides a friction plate structure and a manufacturing method thereof. The thickness of the friction plate structure ranges from 0.45 mm to 1 mm, and the friction plate structure is formed by laminating a carbon fiber sheet, an adhesive material, a support material, an adhesive material, and another carbon fiber sheet orderly, wherein the carbon fiber cloth is formed by weaving a plurality of fiber bundles in a staggered manner, each fiber bundle is formed by twisting a plurality of short fibers and locally overlapping and interwinding the plurality of short fibers in the axialdirection of the fiber bundle, and the length direction of each short fiber corresponds to the axial direction of the fiber bundles; the bonding material permeates into the fiber bundles of the carbonfiber cloth until the impregnation rate is greater than 80%, and the fiber bundles of the carbon fiber cloth are partially exposed out of the bonding material in a peak area of a wave crest. The radial tensile strength of the friction plate structure ranges from 90 MPa to 177 MPa, the axial tensile strength of the friction plate structure ranges from 60 MPa to 136 MPa, and the dynamic and staticfriction ratio of the friction plate structure ranges from 0.8 to 0.98.

Owner:LINKWIN TECH

Preparation method for laser cladding soft and hard composite coating self-lubricating cutter

InactiveCN103522652BImprove toughnessHigh surface hardnessMetallic material coating processesMetal layered productsNano al2o3Hardness

The invention belongs to the field of machinery cutting cutter manufacturing, and relates to a preparation method for a laser cladding soft and hard composite coating self-lubricating cutter. A rake face coating of the cutter is a multi-layer structure. Firstly, a hard coating of nano Al2O3 ceramic or an ultrafine cemented carbide, etc. is clad on the rake face of the cutter by utilization of a CO2 laser synchronous feeding manner, and then a self-lubricating soft coating is clad by utilization of nickel-covered MoS2 powder or nickel-covered WS2 powder. The cutter has characteristics of good toughness, high hardness, a self-lubrication function, and the like. During a drying cutting process, the hard coating bears loads and the rake face self-lubricating soft coating has low shearing strength, thus reducing friction between the cutter and chips, reducing the cutting temperature and the cutting force, and therefore cutter abrasion is reduced. The cutter can be widely used for dry cutting and cutting machining of difficult-to-machine materials.

Owner:SHANDONG UNIV

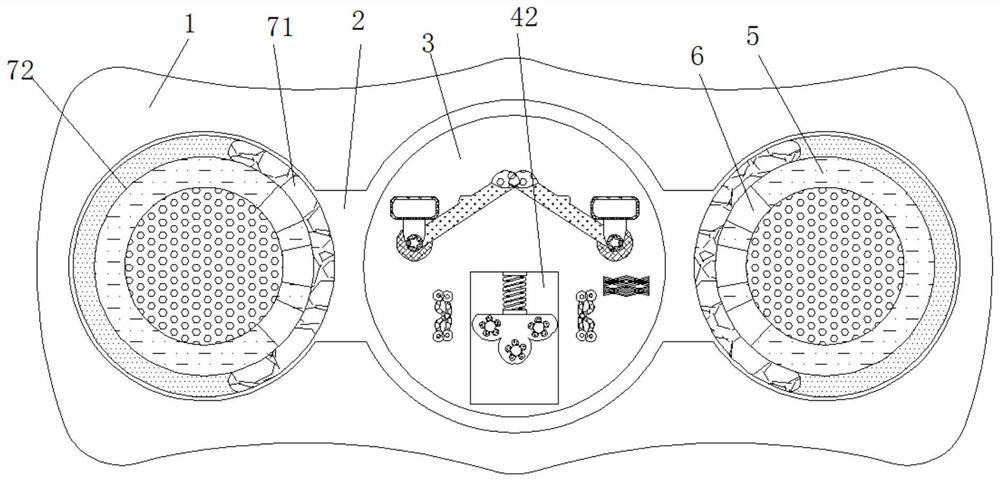

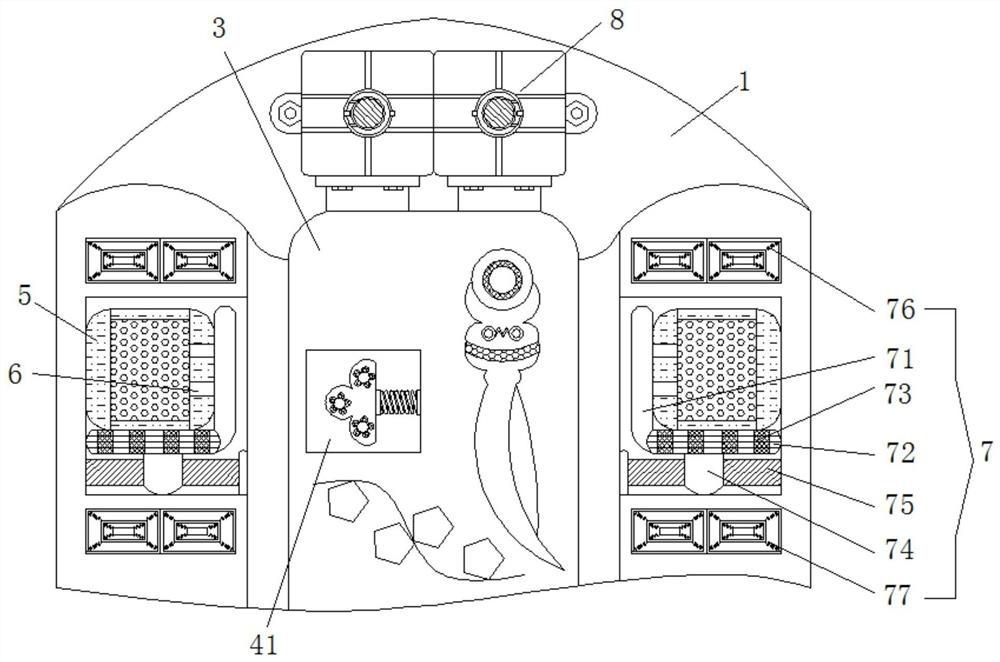

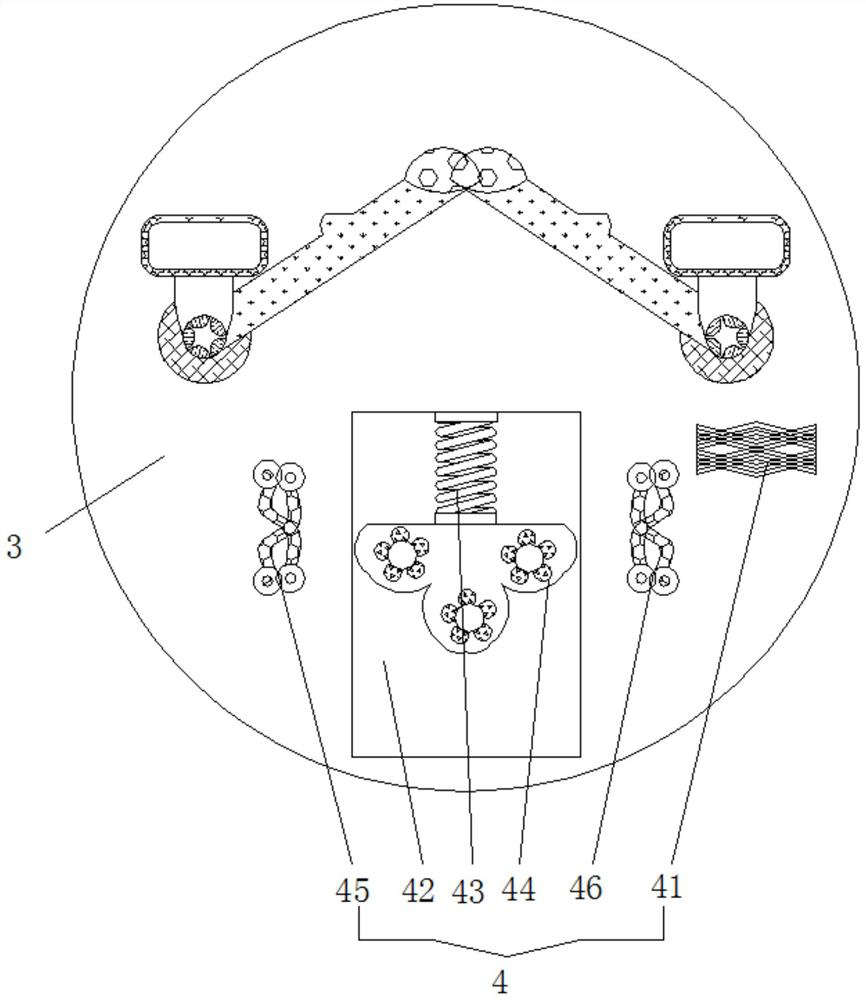

Single-driving dual-fixing seal support with anti-magnetism anti-theft function

ActiveCN111959143AImprove stabilityImprove locking strength and reliabilityStampingStructural engineeringMechanical engineering

The invention provides a single-driving dual-fixing seal support with an anti-magnetism anti-theft function. The single-driving dual-fixing seal support comprises a shell, a dual-output driving deviceand a seal locking mechanism. The dual-output driving device is horizontally arranged in a mounting cavity, and an output shaft of the dual-output driving device is rigidly connected with a pin shaftsliding in a pin hole and can push the pin shaft to stretch and contract axially. The seal locking mechanism comprises a transmission assembly and a locking bolt, wherein the transmission assembly isconnected with the pin shaft and capable of converting linear motion of the pin shaft into circular motion, and the locking bolt is arranged at the output end of the transmission assembly and coaxialwith a locking screw hole. The head portion of the locking bolt is connected to the interior of the locking hole in a threaded mode. The single-driving dual-fixing seal support with the anti-magnetism anti-theft function is compact in structure, convenient to assemble, and good in locking effect and anti-theft and anti-disassembly effects. The dual-locking function of the seal support and a sealbody is realized through a single-driving device. The production cost and the overall volume are reduced, and the production cost is low.

Owner:NANJING YUZHI INTELLIGENT TECH CO LTD

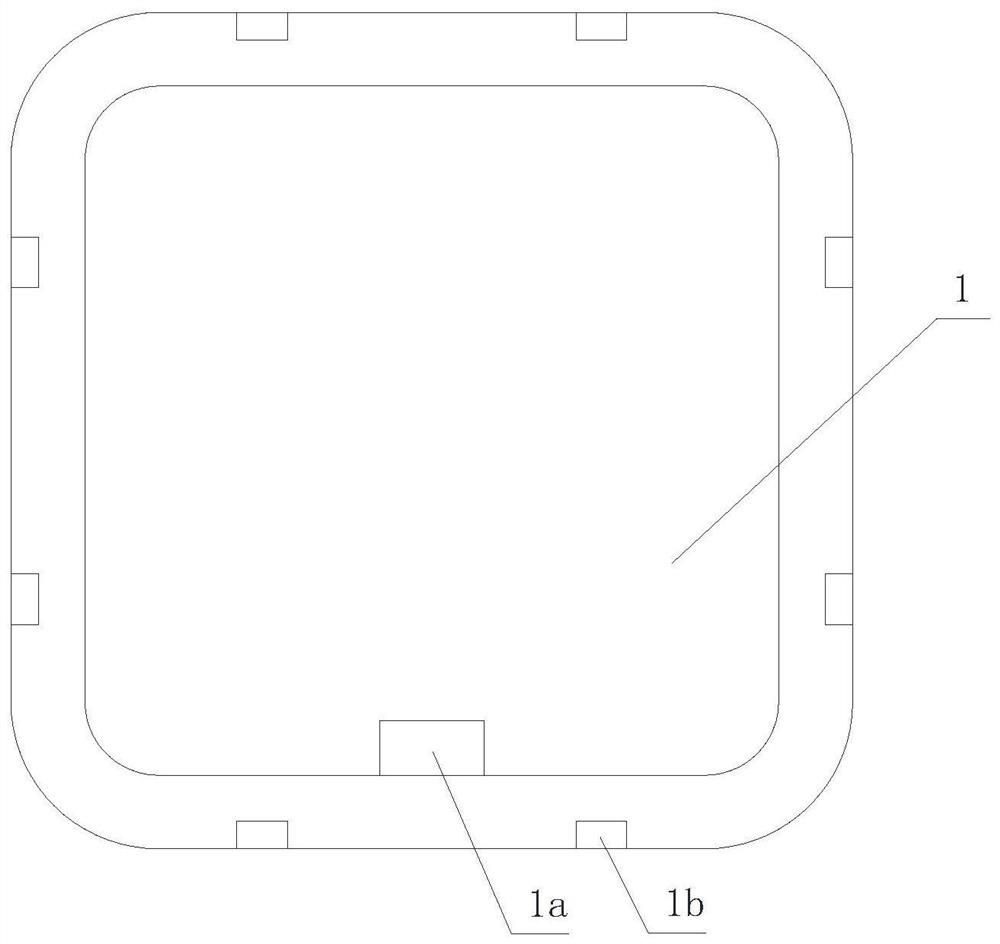

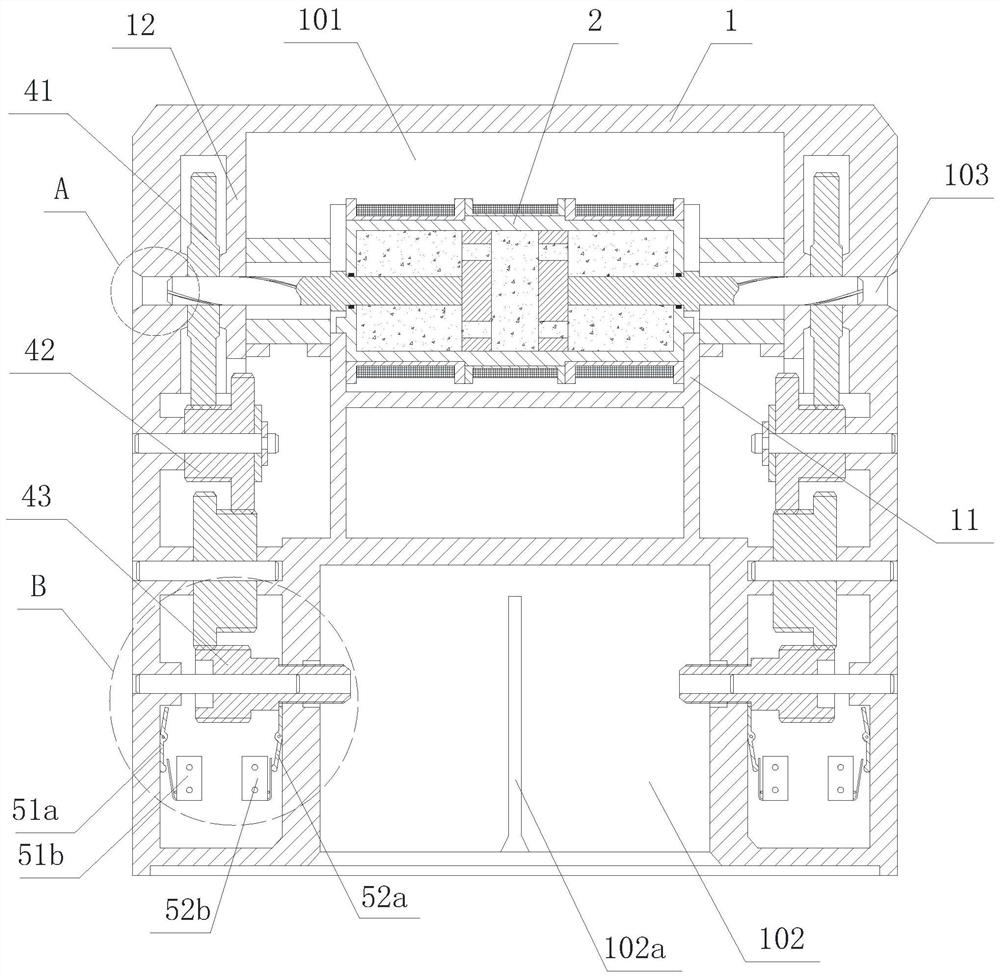

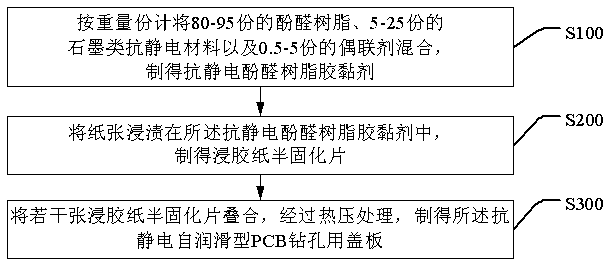

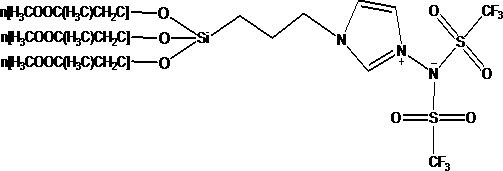

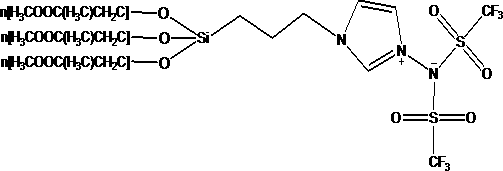

Antistatic self-lubricating PCB drilling cover plate and preparation method thereof

InactiveCN109334179AImprove conductivityHas self-lubricating effectSynthetic resin layered productsLaminationAntistatic MaterialsResin adhesive

The invention discloses an antistatic self-lubricating PCB drilling cover plate and a preparation method thereof. The method comprises the following steps: mixing 80 to 95 parts of a phenolic resin, 5to 25 parts of a graphite antistatic material and 0.5 to 5 parts of a coupling agent by weight to prepare an antistatic phenolic resin adhesive; steeping paper in the antistatic phenolic resin adhesive to prepare a steeped paper prepreg; superposing a plurality of steeped paper prepregs and carrying out hot pressing treatment to obtain the antistatic self-lubricating PCB drilling cover plate. Thecover plate prepared according to the method not only has good electrical conductivity, but also has an effect of self-lubrication, so that the generation of static electricity can be prevented in the drilling process, thereby reducing the risk factor and improving the drilling quality rate. The cover plate meets the safety requirements in the application industry and meets various application properties and the requirements of subsequent production processes in the application field.

Owner:烟台柳鑫新材料科技有限公司

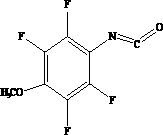

Wear-resistant self-lubricating anti-icing and anti-fog coating and preparation method thereof

The invention belongs to the technical field of coatings, and discloses a wear-resistant self-lubricating anti-icing and anti-fog coating and a preparation method thereof. The wear-resistant self-lubricating anti-icing and anti-fog coating is prepared from a compound shown in a formula I, polyamide resin, gemini quaternary ammonium salt, a fluoro-phenyl isocyanate curing agent, polyethylene wax, afiller, an antifoaming agent and a leveling agent, wherein n is an integer, 1<=n<=10; the terminal group of polyamide resin is carboxyl, and the molecular weight of polyamide resin is 3000-6000 g / mol. The coating is resistant to friction, is not easy to scratch, and has the characteristics of low surface tension, hydrophobicity, ice resistance and fog resistance.

Owner:广东睿智环保科技股份有限公司

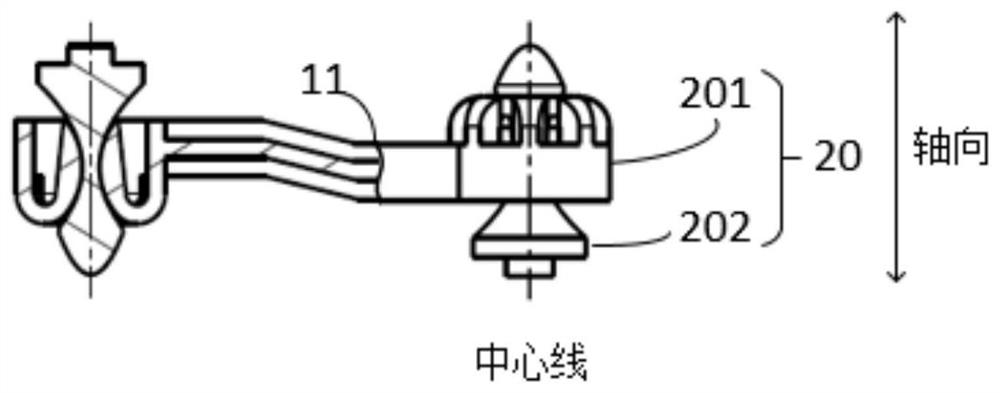

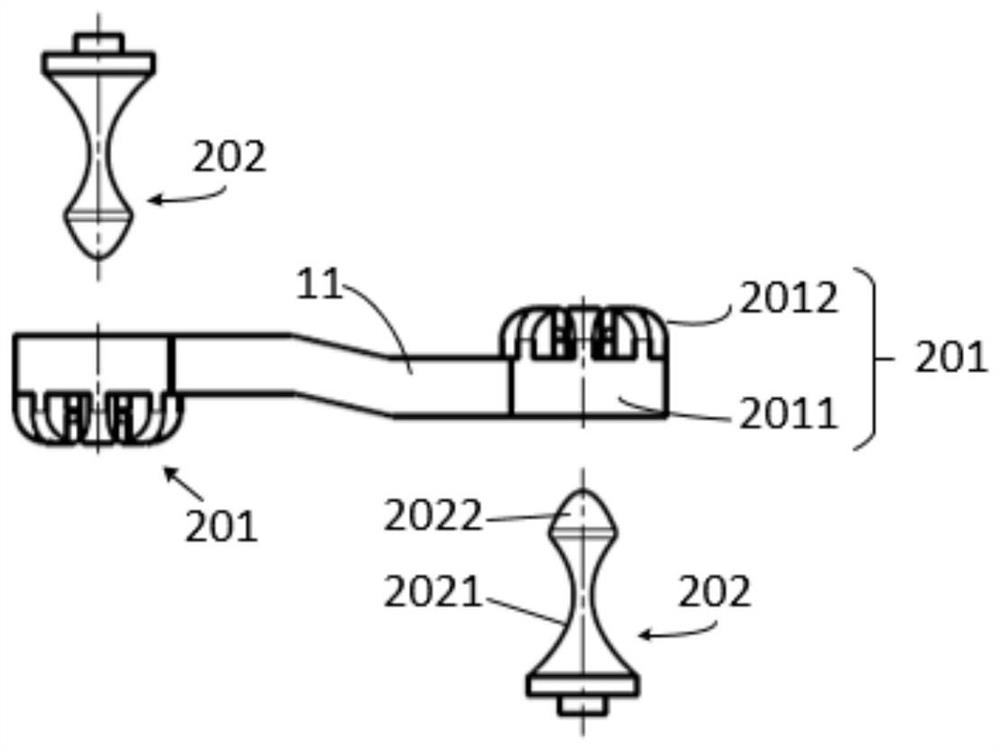

Flexible coupling mechanism and displacement sensing device with same

ActiveCN113483711AHas self-lubricating effectIncrease stiffnessMeasurement devicesBearing assemblyCouplingEngineering

The invention provides a flexible coupling mechanism and a displacement sensing device with the same. The flexible coupling mechanism comprises a flexible bearing part and a connecting shaft inserted into the flexible bearing part. The flexible bearing part comprises a clamping jaw part, the clamping jaw part is composed of a plurality of clamping jaws, each clamping jaw comprises a fixed end and a free end, the free ends of the clamping jaws jointly define a channel allowing the connecting shaft to penetrate through, and the channel is used for supporting and limiting the connecting shaft. The displacement sensing device comprises a connecting rod, a swing arm and an angle sensor. One end of the connecting rod is connected with a tested assembly through the flexible coupling mechanism, the other end of the connecting rod is connected with one end of the swing arm through the flexible coupling mechanism, and the other end of the swing arm is connected to the angle sensor. The flexible coupling mechanism and the displacement sensing device have the advantages of being low in cost, easy to machine, easy to form, high in strength and capable of achieving self-lubrication.

Owner:CONTINENTAL AUTOMOTIVE CORP LIANYUNGANG CO LTD

A kind of rubber for bushing with self-lubricating effect and preparation method thereof

The invention discloses rubber with a self-lubricating effect for a lining. The rubber is prepared from the following components in percentage by weight: 55 to 59 percent of natural rubber, 7 to 14 percent of butadiene rubber, 0.7 to 2 percent of refined vegetable oil oleamide, 0.7 to 2 percent of molybdenum disulfide, 0.7 to 2 percent of carbon nano tubes, 3.5 to 4.1 percent of graphite, 3.2 to 3.5 percent of zinc oxide, 1 percent of stearic acid, 1 to 1.7 percent of antioxidant 6PPD, 1 percent of antioxidant TMQ, 2 percent of microcrystalline wax, 13.1 to 13.8 percent of carbon black N 330, 1.3 to 1.4 percent of sulfur grundum and 1.0 to 1.3 percent of accelerant CZ. The rubber for the lining, disclosed by the invention, has quadruple sustained releasing functions and is suitable for the lining of a self-lubricating high-end car; the problem that common self-lubricating rubber easily fails in lubricating can be solved, and the abrasion resistance of the rubber is increased; by combining specific situations of rubber abrasion at different stages, the service life of rubber and lining products can be prolonged. Meanwhile, the invention provides a preparation method of the rubber with the self-lubricating effect for the lining.

Owner:BOGE ELASTMETALL SHANGHAI CO LTD

Environment-friendly light anti-corrosion PVC vehicle floor and preparation method thereof

The invention discloses an environment-friendly light anti-corrosion PVC vehicle floor. The vehicle floor is prepared from the following raw materials in parts by weight: 80-90 parts of PVC resin, 20-30 parts of 4, 4-diaminodiphenyl sulfide / 2-(trifluoromethyl)-1H-imidazole-4, 5-dicarboxylic acid polycondensate, 10-20 parts of an environment-friendly plasticizer, 2-5 parts of 2, 4, 6-tri(4-aminophenyl)-1, 3, 5-triazine, 0.5-1.5 parts of borene, 10-15 parts of nano aluminium oxide fibers and 2-4 parts of a coupling agent. The invention further discloses a preparation method of the environment-friendly light anti-corrosion PVC vehicle floor. The environment-friendly light anticorrosive PVC vehicle floor disclosed by the invention is light in weight, excellent in anticorrosive performance, safe and environment-friendly to use, good in flame retardance and wear resistance, and good in weather resistance and performance stability.

Owner:朱冬梅

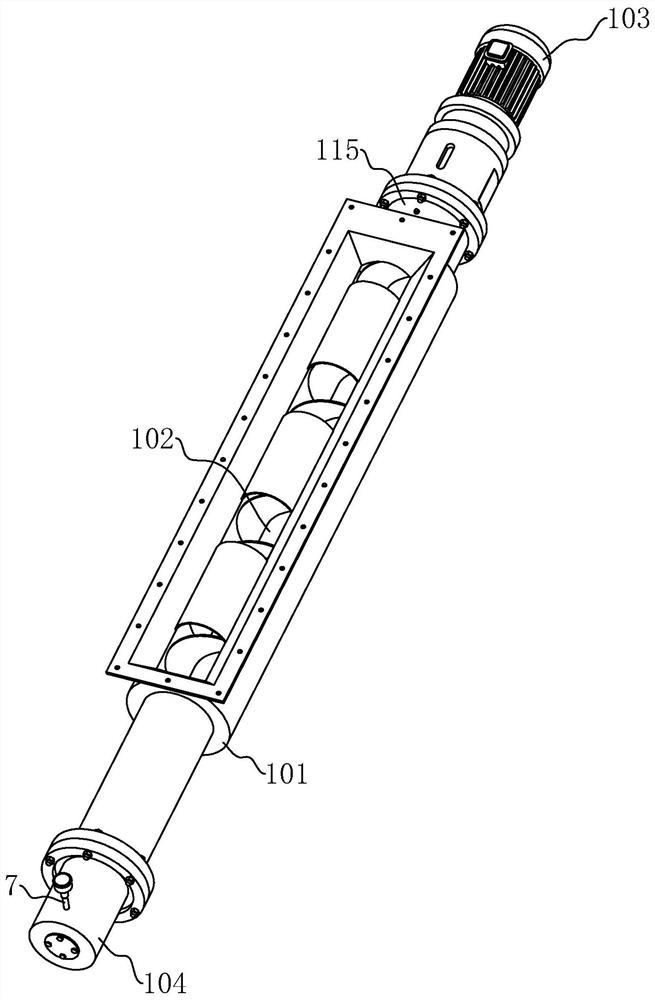

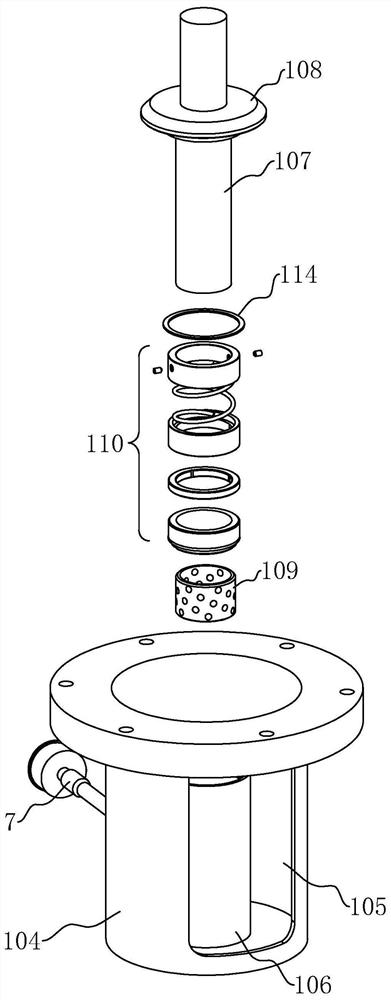

Spiral conveyor

ActiveCN112623650AReduce rolling frictionExtended service lifeCleaningPackagingPhysicsScrew conveyor

The invention relates to a spiral conveyor. The spiral conveyor comprises a main machine shell, a spiral body and a power source, the spiral body is arranged in the main machine shell in a rotating mode, one end of the spiral body is connected to the power source, the power source drives the spiral body to rotate, a tail end shell is fixedly arranged at the end, away from the power source, of the main machine shell, the end, close to the main machine shell, of the tail end shell is open and communicates with the interior of the main machine shell, a discharging port is formed in the peripheral side of the tail end shell, a mounting cylinder is fixedly arranged in the tail end shell, a rotating shaft is fixedly arranged at the end, away from the power source, of the spiral body, a mounting cavity is formed in the mounting cylinder, an opening of the mounting cavity faces the spiral body, one part of the rotating shaft is inserted into the mounting cavity, a sealing ring is arranged on the rotating shaft and seals the opening of the mounting cavity, a self-lubricating structure is arranged between the rotating shaft and the mounting cylinder, and the self-lubricating structure is located between the outer circumferential wall of the rotating shaft and the inner circumferential wall of the mounting cavity. The spiral conveyor has the advantages of being capable of achieving the self-lubricating function, better in sealing performance, capable of almost achieving the maintenance-free effect and longer in service life.

Owner:武汉宇格电力设备有限公司

Hardware and electrical equipment machining drilling equipment with self-lubricating effect

InactiveCN113245580AReduce centrifugal forceReduce speedMaintainance and safety accessoriesLubrication containersElectrical conductorEngineering

The invention relates to the technical field of hardware and electrical equipment machining, and discloses hardware and electrical equipment machining drilling equipment with a self-lubricating effect. The hardware and electrical equipment machining drilling equipment comprises an equipment shell and a driving drilling shaft, wherein an installing groove is formed inside the equipment shell, the driving drilling shaft is movably connected inside the installing groove, a detection mechanism is fixedly connected inside the driving drilling shaft, an oil storage tank is fixedly connected into the installing groove, an oil outlet groove is formed inside the oil storage tank, and a driving mechanism is fixedly connected to the bottom of the oil storage tank. According to the hardware and electrical equipment machining drilling equipment with the self-lubricating effect, the rotating speed of the driving drilling shaft is reduced, centrifugal force borne by a dielectric plate is reduced, the dielectric plate controls the magnitude of circuit voltage passing through a negative plate, after the working voltage of a voltage dependent resistor is reached at the same time, a closed conductor is electrified to rotate between a first magnet and a second magnet under the action of Ampere force, a rotating shaft drives a baffle to rotate inside the installing groove, the oil outlet groove is exposed, and lubricating oil inside the oil storage tank makes contact with the driving drill shaft for lubrication.

Owner:杭州谢康堂贸易有限公司

Self-lubricating gear based on additive manufacturing and preparation method thereof

ActiveCN112483626AHas self-lubricating effectImprove toughnessPortable liftingGearing elementsManufacturing technologyGear wheel

The invention provides a self-lubricating gear based on additive manufacturing and a preparation method thereof. The self-lubricating gear has good toughness, the working surface has high hardness andwear resistance, and a good self-lubricating effect is achieved within the wide-temperature-range working range. The self-lubricating gear based on additive manufacturing comprises a gear substrate and a CBN-based self-lubricating coating, wherein the CBN-based self-lubricating coating is arranged on the surface of the gear substrate; the CBN-based self-lubricating coating is formed by CBN-basedmixed powder through an additive manufacturing technology; and the CBN-based mixed powder comprises graphene, ZnO, W2N, VN, Ag, BNNTs and CNFs. When the working temperature is relatively low, the graphene can play a lubricating role, and when the temperature is high, the W2N, the ZnO, the VN and the Ag can be subjected to in-situ reaction to generate ZnWO4, Ag2WO4 and V2O5 compounds with a lubricating effect, so that the gear has the good self-lubricating effect at the high temperature, the frictional wear is reduced, and the service life of the gear is prolonged.

Owner:SOUTHEAST UNIV

Novel nickel-copper alloy material and preparation method thereof

The invention discloses a novel nickel-copper alloy material and a preparation method thereof; the novel nickel-copper alloy material is prepared from, by weight, 15-20 parts of nickel bronze powder, 15-20 parts of copper, 5-6 parts of manganese, 1-2 parts of bismuth, 1-2 parts of rhenium, 1-2 parts of silver, 5-10 parts of samarium sesquioxide, 5-8 parts of iron, 1-8 parts of calcium dichloride, 2-6 parts of aluminum oxide, 5-6 parts of alcohol, and 1 part of adhesive. The novel nickel-copper alloy material is a replacement for conventional lead-bearing wear-resistant copper alloy and is an environment-friendly wear-resistant nickel-copper alloy material.

Owner:钦州市科学技术开发中心

Gradient coating tool and its preparation method

ActiveCN108165988BGood self-lubricating performanceReduce wearMetallic material coating processesHardnessAlloy

The invention discloses a gradient coating cutter and a preparation method thereof. A basal body material of the gradient coating cutter is high-speed steel; a multilayer coating layer is arranged onthe surface of a basal body; and the coating layer is a gradient laminated coating layer of alternating hard alloy layers, added with MoS2, BN and LaF3, and Al2O3 base ceramic layers. The cutter coating layer is prepared by adopting a laser cladding method; and the preparation steps are (1) pretreatment, (2) cladding of the hard alloy layers, (3) cladding of the Al2O3 base ceramic layers, (4) alternate cladding of the hard alloy layers and the Al2O3 base ceramic layers, and (5) aftertreatment. Compared with the prior art, the gradient coating layer on the surface of a cutter has the characteristics of Al2O3 base ceramic and hard alloys, and achieves higher hardness and excellent toughness; and through adding of MoS2, BN and LaF3, the cutter achieves excellent self-lubrication effect in wider cutting temperature range. The coating cutter can be applied to dry cutting and cutting of difficultly machined materials.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com