Hardware and electrical equipment machining drilling equipment with self-lubricating effect

A drilling equipment and hardware technology, applied in metal processing equipment, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problem of affecting the drilling effect, the drill shaft cannot reach the predetermined speed, and the friction coefficient of transmission parts problems such as increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

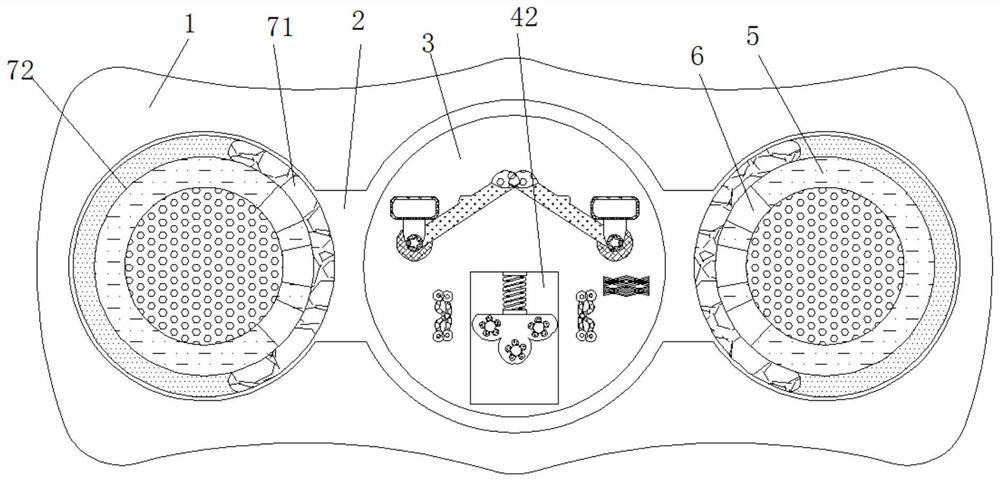

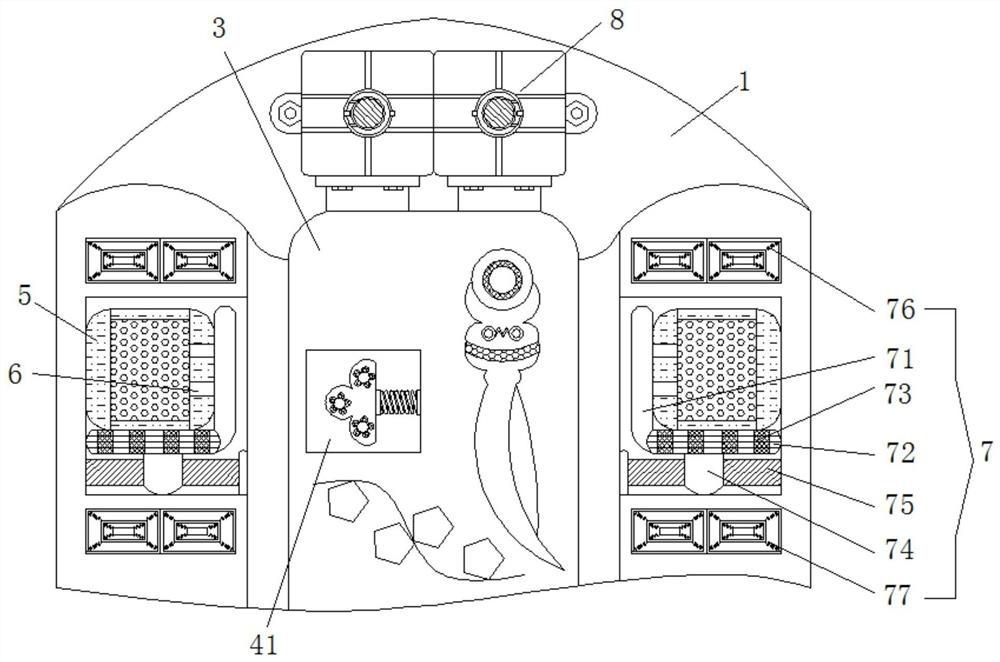

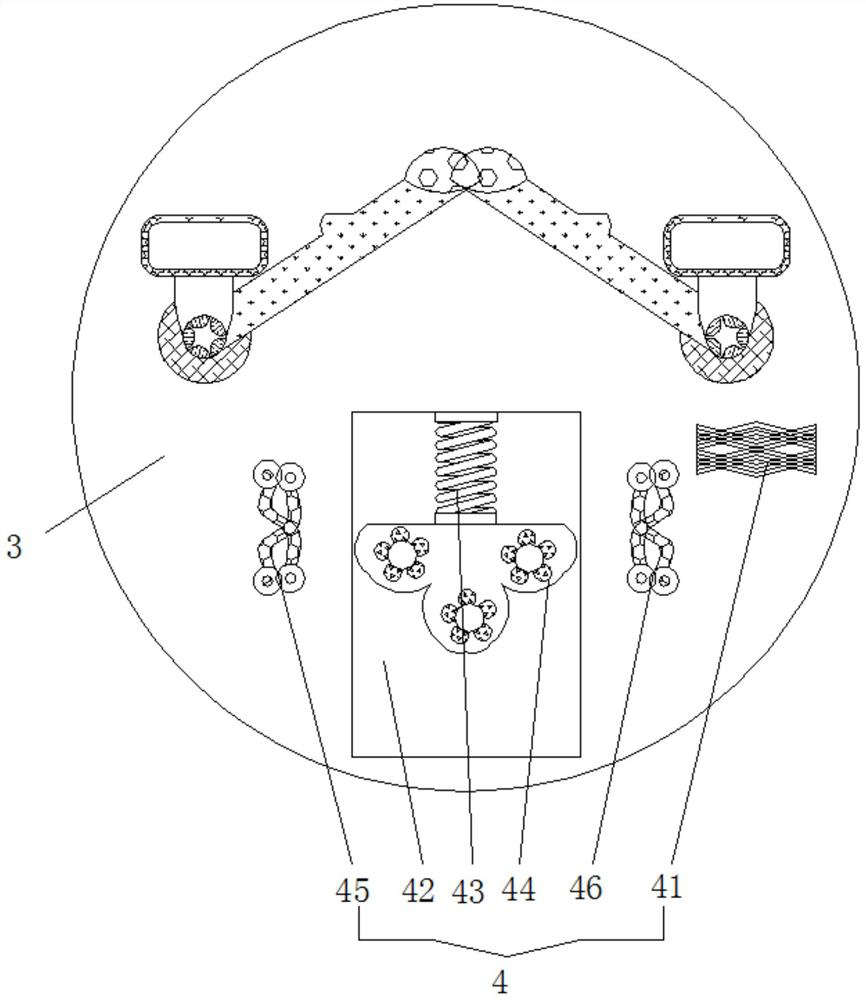

[0026] see Figure 1-3 , a drilling device for Wujinjiaodian processing with self-lubricating effect, comprising a device housing 1 and a driving drill shaft 3, an installation groove 2 is opened inside the equipment housing 1, and a driving drill shaft 3 is movably connected inside the installation groove 2 The inside of the driving drill shaft 3 is fixedly connected with the detection mechanism 4, the inside of the installation groove 2 is fixedly connected with the oil storage tank 5, the inside of the oil storage tank 5 is provided with an oil outlet tank 6, the bottom of the oil storage tank 5 is fixedly connected with the driving mechanism 7, and the equipment shell A drive motor 8 is fixedly connected inside the body 1, the bottom of the drive motor 8 is fixedly connected to the top of the drive drill shaft 3, and the drive motor 8 drives the drive drill shaft 3 to rotate;

[0027] The detection mechanism 4 includes a movable groove 42, a connecting spring 43 is fixedly...

Embodiment 2

[0029] see figure 1 , figure 2 and Figure 4 , a drilling device for Wujinjiaodian processing with self-lubricating effect, comprising a device housing 1 and a driving drill shaft 3, an installation groove 2 is opened inside the equipment housing 1, and a driving drill shaft 3 is movably connected inside the installation groove 2 The inside of the driving drill shaft 3 is fixedly connected with the detection mechanism 4, the inside of the installation groove 2 is fixedly connected with the oil storage tank 5, the inside of the oil storage tank 5 is provided with an oil outlet tank 6, the bottom of the oil storage tank 5 is fixedly connected with the driving mechanism 7, and the equipment shell A drive motor 8 is fixedly connected inside the body 1, the bottom of the drive motor 8 is fixedly connected to the top of the drive drill shaft 3, and the drive motor 8 drives the drive drill shaft 3 to rotate;

[0030] The driving mechanism 7 includes a baffle plate 71, the bottom o...

Embodiment 3

[0032] see Figure 1-4 , a drilling device for Wujinjiaodian processing with self-lubricating effect, comprising a device housing 1 and a driving drill shaft 3, an installation groove 2 is opened inside the equipment housing 1, and a driving drill shaft 3 is movably connected inside the installation groove 2 The inside of the driving drill shaft 3 is fixedly connected with the detection mechanism 4, the inside of the installation groove 2 is fixedly connected with the oil storage tank 5, the inside of the oil storage tank 5 is provided with an oil outlet tank 6, the bottom of the oil storage tank 5 is fixedly connected with the driving mechanism 7, and the equipment shell A drive motor 8 is fixedly connected inside the body 1, the bottom of the drive motor 8 is fixedly connected to the top of the drive drill shaft 3, and the drive motor 8 drives the drive drill shaft 3 to rotate;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com