Preparation method for laser cladding soft and hard composite coating self-lubricating cutter

A laser cladding, soft and hard composite technology, applied in coatings, chemical instruments and methods, metal material coating processes, etc., can solve problems such as laser cladding soft and hard composite coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

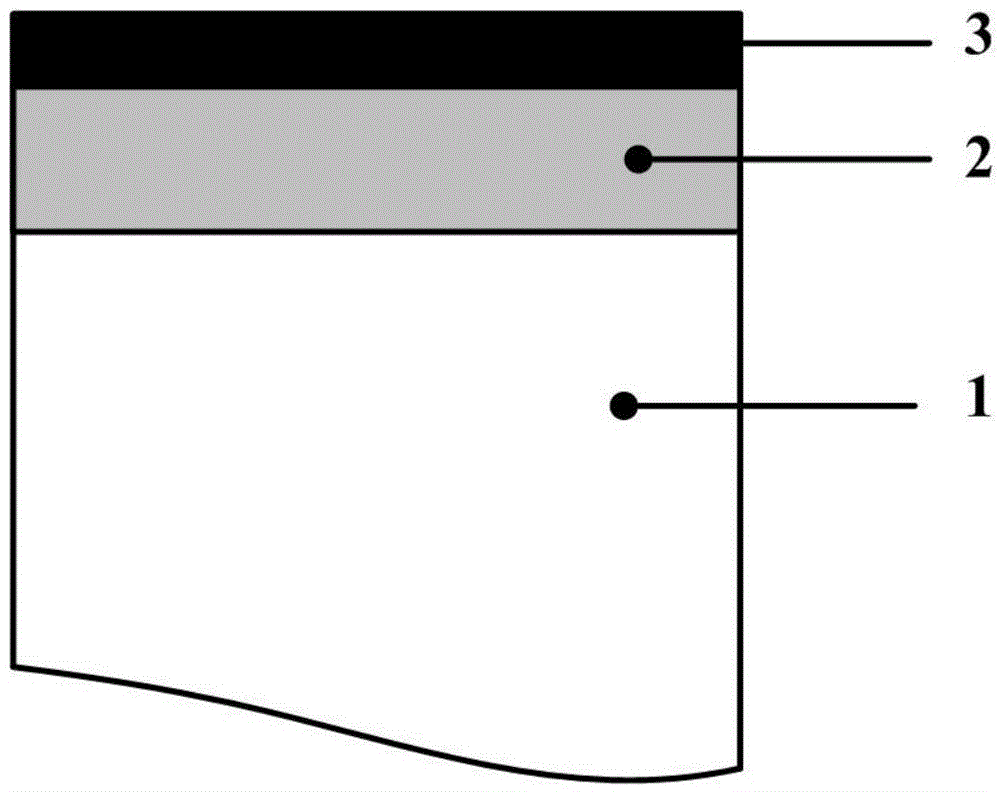

[0018] A preparation method of laser cladding soft-hard composite coating self-lubricating tool, the base material is W18Cr4V high-speed steel tool; the surface self-lubricating soft coating material is nickel-coated MoS 2 , the hard coating material is nano-Al 2 o 3 Ceramic; cladding method is CO 2 Laser synchronous powder feeding method cladding. Its preparation method is as follows:

[0019] (1) Put the W18Cr4V high-speed steel tool in the alcohol and acetone solution for 20 minutes to ultrasonically clean it for degreasing treatment.

[0020] (2) The experiment uses CO with a wavelength of 10.6 μm 2 For the laser, the laser parameters are adjusted as follows: the laser power is 600W, the spot diameter is 2mm, the scanning speed is 5mm / s, and the overlap rate Φ=25%.

[0021] (3) Al with a particle size of 100-150nm 2 o 3 The ceramic powder is fully mixed, and its main component (weight percent): 97% Al 2 o 3 , 2% Ni and 1% Al; the prepared nano-Al 2 o 3 Ceramic p...

example 2

[0026] A preparation method of self-lubricating tool with laser cladding soft-hard composite coating. The base material is W6Mo5Cr4V2 high-speed steel tool; the surface self-lubricating soft coating material is nickel-coated WS 2 , the hard coating material is ultrafine cemented carbide; the cladding method is CO 2 Laser synchronous powder feeding method cladding. Its preparation method is as follows:

[0027] (1) Put the W6Mo5Cr4V2 high-speed steel tool in the alcohol and acetone solution for 20 minutes and ultrasonically clean it for degreasing treatment.

[0028] (2) The experiment uses CO with a wavelength of 10.6 μm 2 laser. The laser parameters were adjusted as follows: the laser power was 600W, the spot diameter was 3mm, the scanning speed was 4mm / s, and the overlapping rate Φ=30%.

[0029] (3) Fully mix ultrafine cemented carbide powder with a particle size of 100-500nm, its main components (weight percent): 80% WC, 10% Co, 5% W, 1.5% VC, 1% Cr 3 C 2 And 1% Ni, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com