Gradient coating tool and its preparation method

A gradient coating and cutting tool technology, which is applied in the coating, metal material coating process, etc., can solve the problems that the toughness of the cutting tool coating needs to be further improved, the bonding strength between coatings is low, and the brittleness of ceramic cutting tools is large, and achieve good Effects of thermal stability and wear resistance, high hardness, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

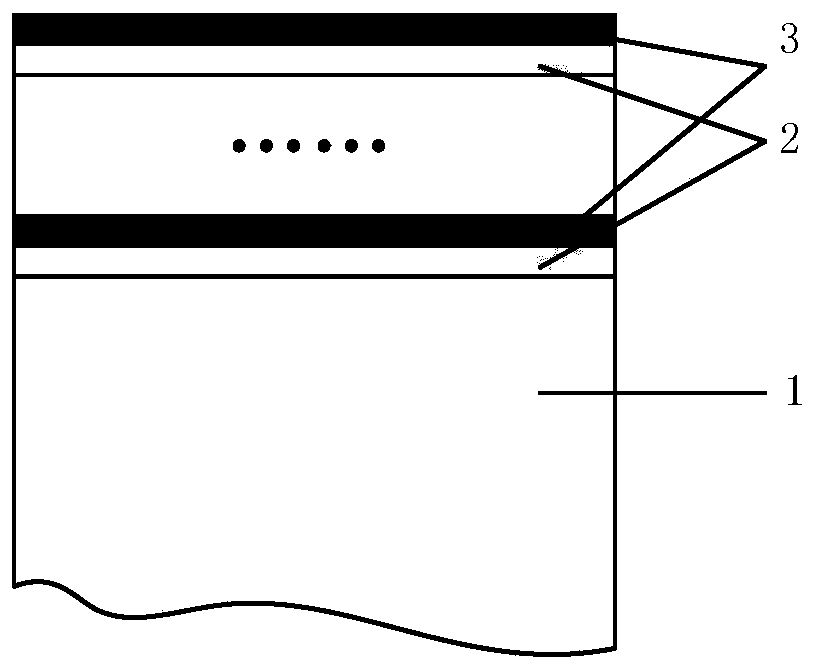

Image

Examples

Embodiment 1

[0022] Example 1: The gradient coating tool adopts a laser cladding method and is prepared on the rake face of the tool. The specific preparation steps are:

[0023] (1) Pre-treatment: Put the tool in an alcohol and acetone solution for 30 minutes ultrasonic cleaning, and then carry out degreasing treatment;

[0024] (2) Cladding hard alloy layer: MoS 2 , BN and LaF 3 The powder is added to the cemented carbide mixed powder to configure the mixed powder. The weight percentages of its main components are: 80% WC, 8% TiC, 6% Co, 1% TaC, 2% MoS 2 , 1% BN, 2% LaF 3 , The total weight percentage of each material is 100%; put the prepared cemented carbide mixed powder into the powder feeder, and adjust the powder feeder rate to 20g / cm 3 ; Using CO with a wavelength of 10.6μm 2 The laser cladding the cemented carbide mixed powder on the rake face of the tool. The laser cladding adopts the synchronous powder feeding method. Both the powder feeding gas and the shielding gas adopt argon gas; t...

Embodiment 2

[0028] Embodiment 2: The preparation method of the gradient coating tool in this embodiment adopts the laser cladding method to prepare the rake face of the tool. The difference from embodiment 1 is that the weight percentage of the material components in steps (2) and (3) , The thickness of the coating and the laser processing parameters are different from those of Example 1, and the thickness of the gradient coating in step (4) is different from that of Example 1. The specific preparation steps of the tool are as follows:

[0029] (1) Pre-treatment: Put the tool in an alcohol and acetone solution for 30 minutes ultrasonic cleaning, and then carry out degreasing treatment;

[0030] (2) Cladding hard alloy layer: MoS 2 , BN and LaF 3 The powder is added to the cemented carbide mixed powder to configure the mixed powder. The weight percentages of its main components are: 65% WC, 15% TiC, 10% Co, 2% TaC, 3% MoS 2 , 2% BN, 3% LaF 3 , The weight percentage of each material is 100%; put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com