Rubber with self-lubricating effect for lining and preparation method of rubber

A bushing and rubber technology is applied in the field of self-lubricating rubber for bushings and its preparation, which can solve the problems of single use, wear of rubber raw materials, failure of rubber parts, etc., and achieves improved service life, good lubrication and noise reduction effect, The effect of improving the abrasion resistance of rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

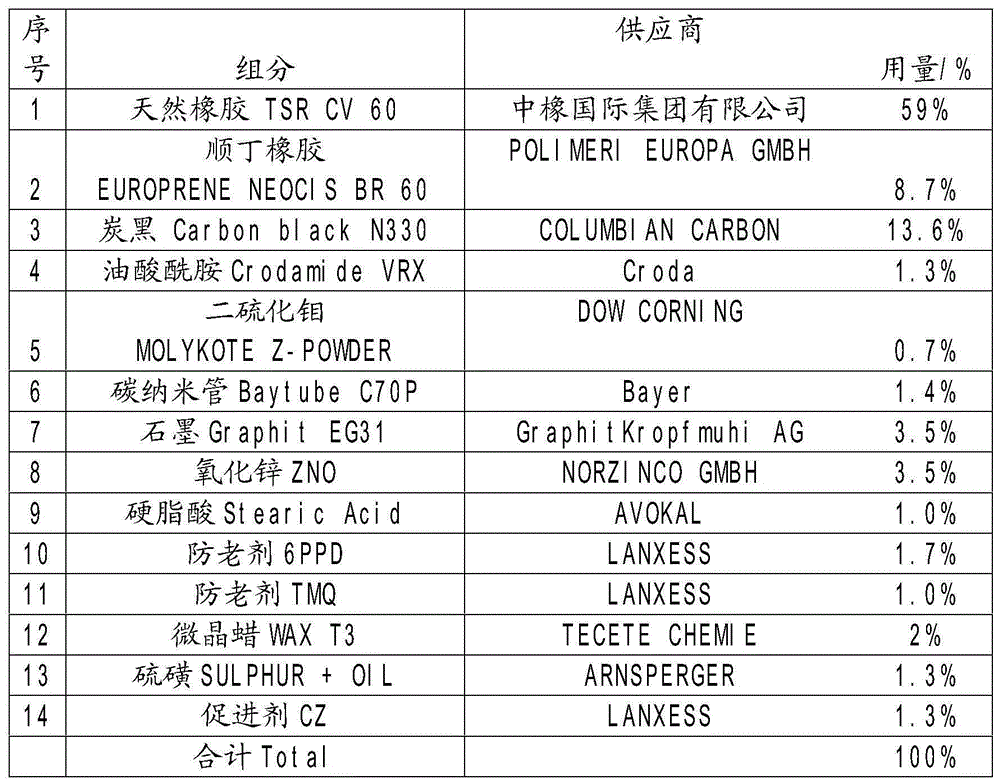

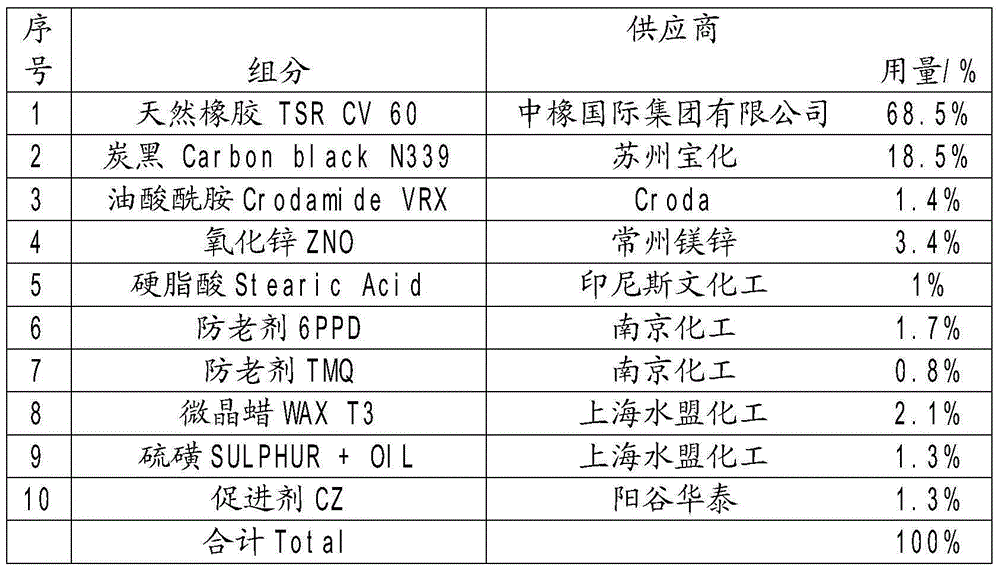

[0018] A kind of bush rubber with self-lubricating effect, its formula is as shown in table 1. The bush rubber with self-lubricating effect is prepared through the following steps:

[0019] S1, the mixing step, includes the following two processes:

[0020] S11, one-stage rubber mixing process: add natural rubber and butadiene rubber into the intermeshing rotor internal mixer in sequence, mix the rubber for 30s, heat the temperature in the intermeshing rotor internal mixer to 90°C, and then add carbon black N330 into the intermeshing Mixed in a type rotor internal mixer for 90s, then added oleic acid amide, molybdenum disulfide, carbon nanotubes, graphite, zinc oxide, stearic acid, anti-aging agent 6PPD, anti-aging agent TMQ and microcrystalline wax into the meshing type rotor density In the mixing machine, the glue output temperature of a section of glue is 160°C, and the pieces are cooled for use to make a piece of glue;

[0021] S12, second-stage rubber mixing process: af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com