Self-lubricating thrust knuckle bearing and manufacturing method thereof

A thrust spherical plain bearing and manufacturing method technology, applied in sliding contact bearings, bearing components, shafts and bearings, etc., can solve problems such as reducing the bearing capacity of thrust spherical plain bearings, and achieve the effect of improving service life and bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be briefly described below in conjunction with the accompanying drawings.

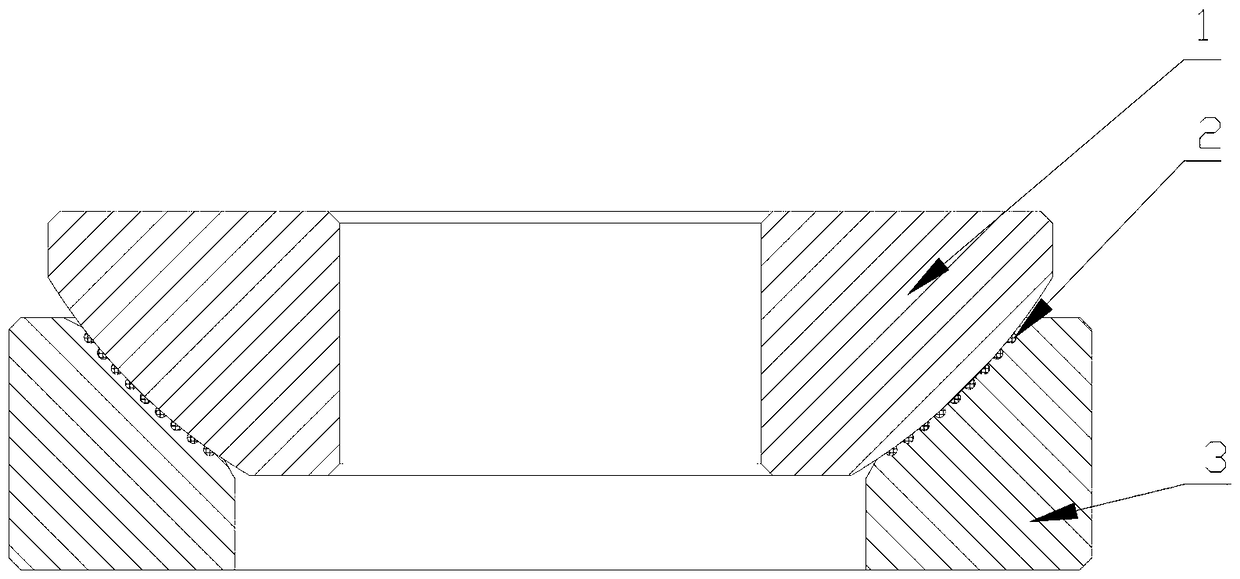

[0021] Such as figure 1 As shown, a self-lubricating thrust spherical joint bearing includes an inner ring 1 and an outer ring 3, and the surface of the inner spherical surface of the outer ring 3 is processed with a plurality of tiny holes with a diameter of 40-120 microns and a depth of 10-20 microns. Dimples 2, the proportion of the plurality of tiny dimples 2 occupying the surface area of the inner spherical surface of the outer ring 3 is 25%-35%, and the plurality of tiny dimples 2 are filled with solid lubricant.

[0022] The present invention also protects a method for manufacturing a self-lubricating thrust joint bearing. The thrust joint bearing includes an inner ring 1 and an outer ring 3. The manufacturing method includes the following steps:

[0023] (1) Process a plurality of tiny pits 2 with a diameter of 40-120 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com