A motor shaft current eliminating structure and motor

A motor shaft and shaft current technology, which is applied in the direction of structural connection, electrical components, electromechanical devices, etc., can solve the problems of complex motor structure, large volume, and weakened shaft current elimination effect, and achieve a compact structure, low cost, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

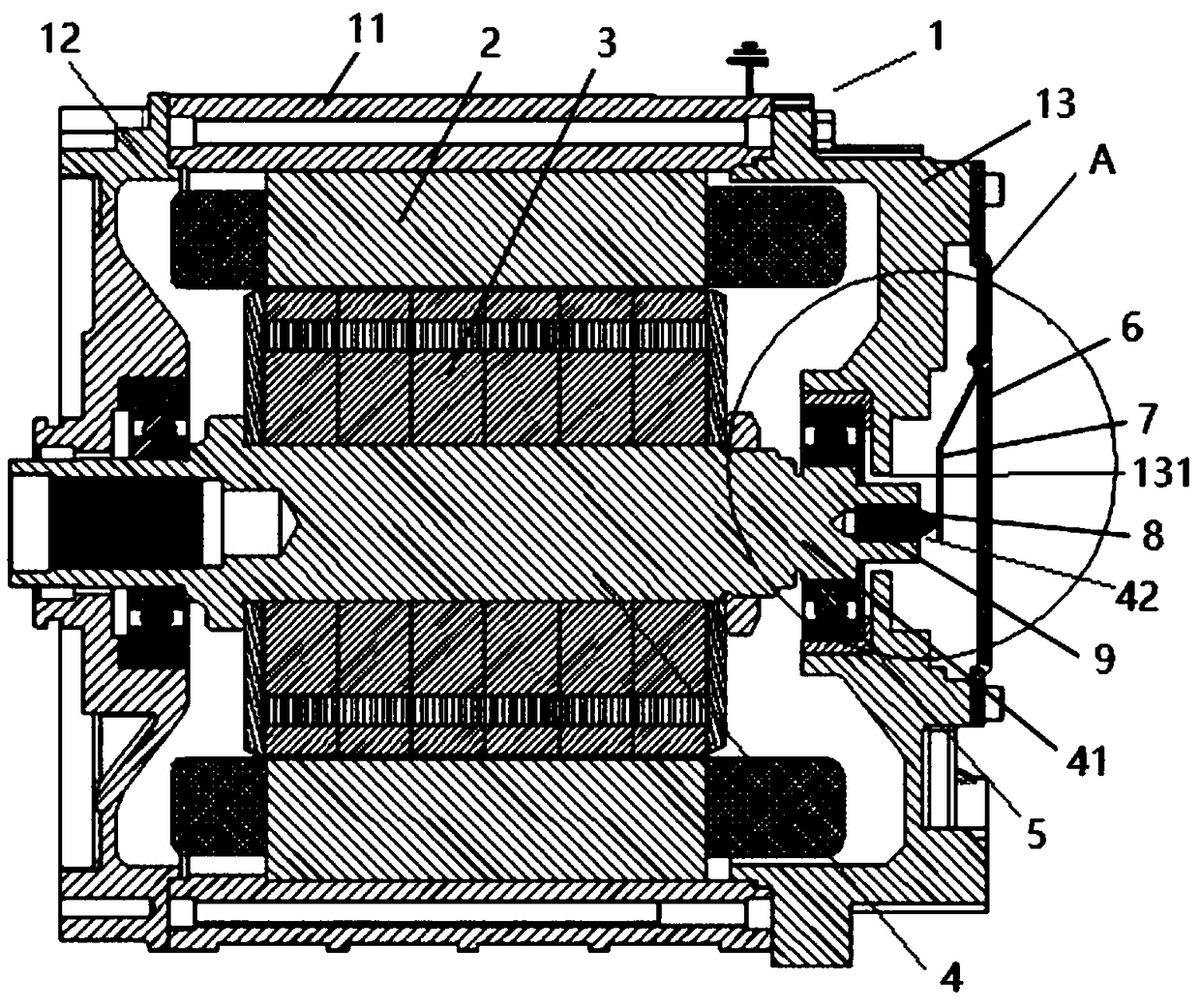

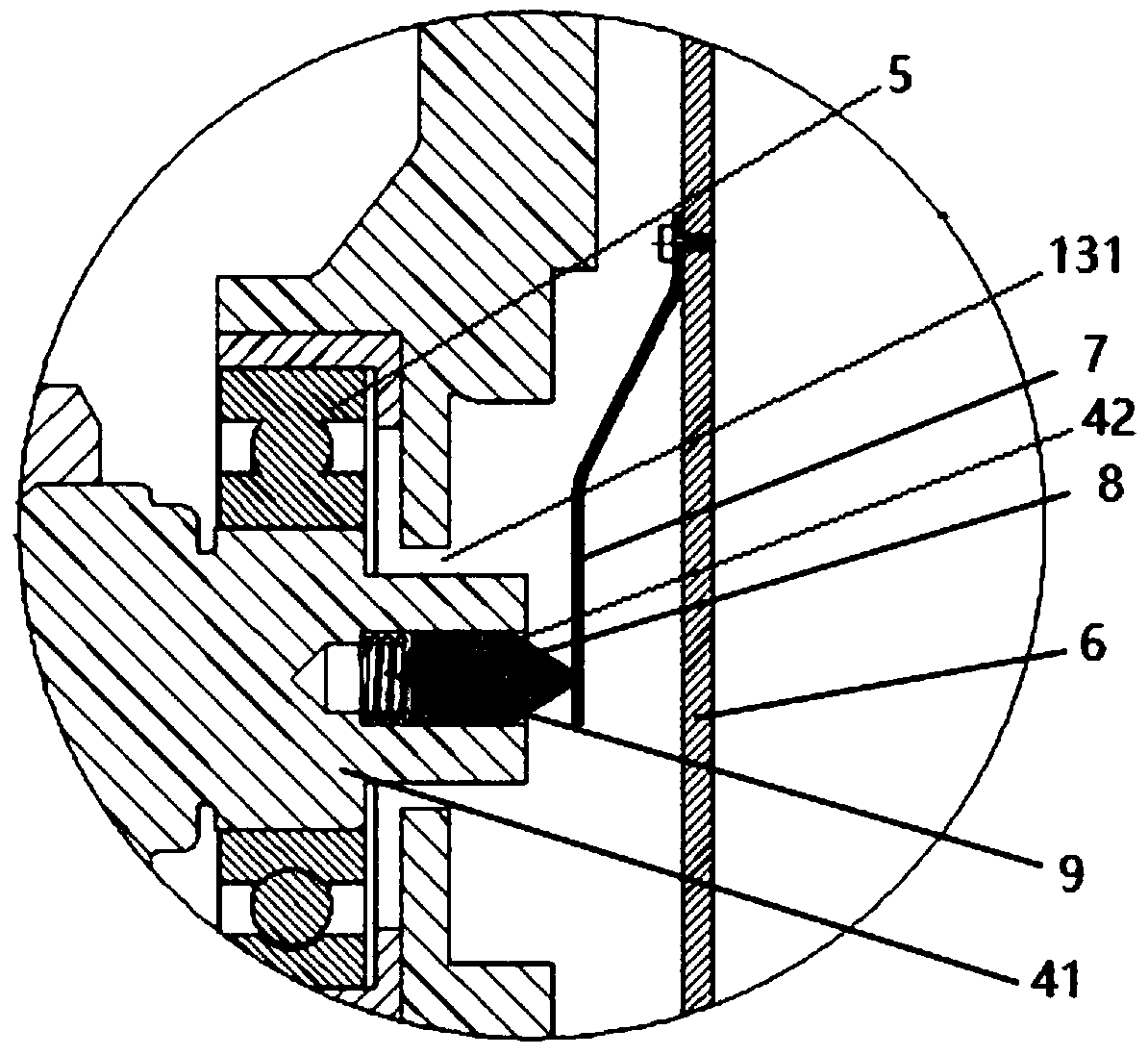

[0039] The shaft current eliminating structure A is arranged at the rear of the motor casing 1 , specifically on the outside of the rear end cover 13 of the motor casing 1 . The shaft current elimination structure A includes a back cover 6 , a conductive shrapnel 7 , a graphite rod 8 and a conductive spring 9 .

[0040] The rear cover 6 is electrically connected to the housing 1 of the motor. In this embodiment, the rear cover 6 is fixed on the rear end cover 13 of the housing 1 of the motor.

[0041] The conductive spring 9 and the graphite rod 8 are put into the graphite rod mounting hole 42 of the motor rotating shaft 4 in turn, one end of the conductive spring 9 is pressed against the graphite rod mounting hole 42, and the other end of the conductive spring 9 faces the graphite rod mounting hole 42 The outer side of the graphite rod 8 presses against the first end of the graphite rod 8, and the second end of the graphite rod 8 extends out of the graphite rod installation h...

no. 2 example

[0047] Compared with the first embodiment, the axial current elimination structure A in the second embodiment does not include the conductive spring 7, but includes the rear cover 6, the graphite rod 8 and the conductive spring 9 (not shown).

[0048] The rear cover 6 is electrically connected to the housing 1 of the motor. The conductive spring 9 and the graphite rod 8 are put into the graphite rod mounting hole 42 of the motor rotating shaft 4 in turn, one end of the conductive spring 9 is pressed against the graphite rod mounting hole 42, and the other end of the conductive spring 9 faces the graphite rod mounting hole 42 The outer side of the graphite rod 8 presses against the first end of the graphite rod 8 , and the second end of the graphite rod 8 extends out of the graphite rod installation hole 42 and is pressed against the inner side of the rear cover plate 6 .

[0049] Therefore, the shaft current conduction path formed by the shaft current elimination structure of ...

no. 3 example

[0053] Compared with the first embodiment, the axial current elimination structure A in the third embodiment does not include the conductive spring 9, but includes the rear cover plate 6, the graphite rod 8 and the conductive shrapnel 7 (not shown).

[0054] The rear cover 6 is electrically connected to the housing 1 of the motor.

[0055] The graphite rod 8 is put into the graphite rod mounting hole 42 of the motor shaft 4, the first end of the graphite rod 8 is pressed against the graphite rod mounting hole 42, and the second end of the graphite rod 8 stretches out of the graphite rod mounting hole 42.

[0056] The conductive elastic piece 7 is Z-shaped, and the first end of the conductive elastic piece 7 is electrically connected and fixed on the inner side of the rear cover 6, for example, by a screw, and the second end of the conductive elastic piece 7 is a free end, facing the graphite rod installation hole. The outer side of 42 presses against the second end of the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com