Patents

Literature

51 results about "Axial current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

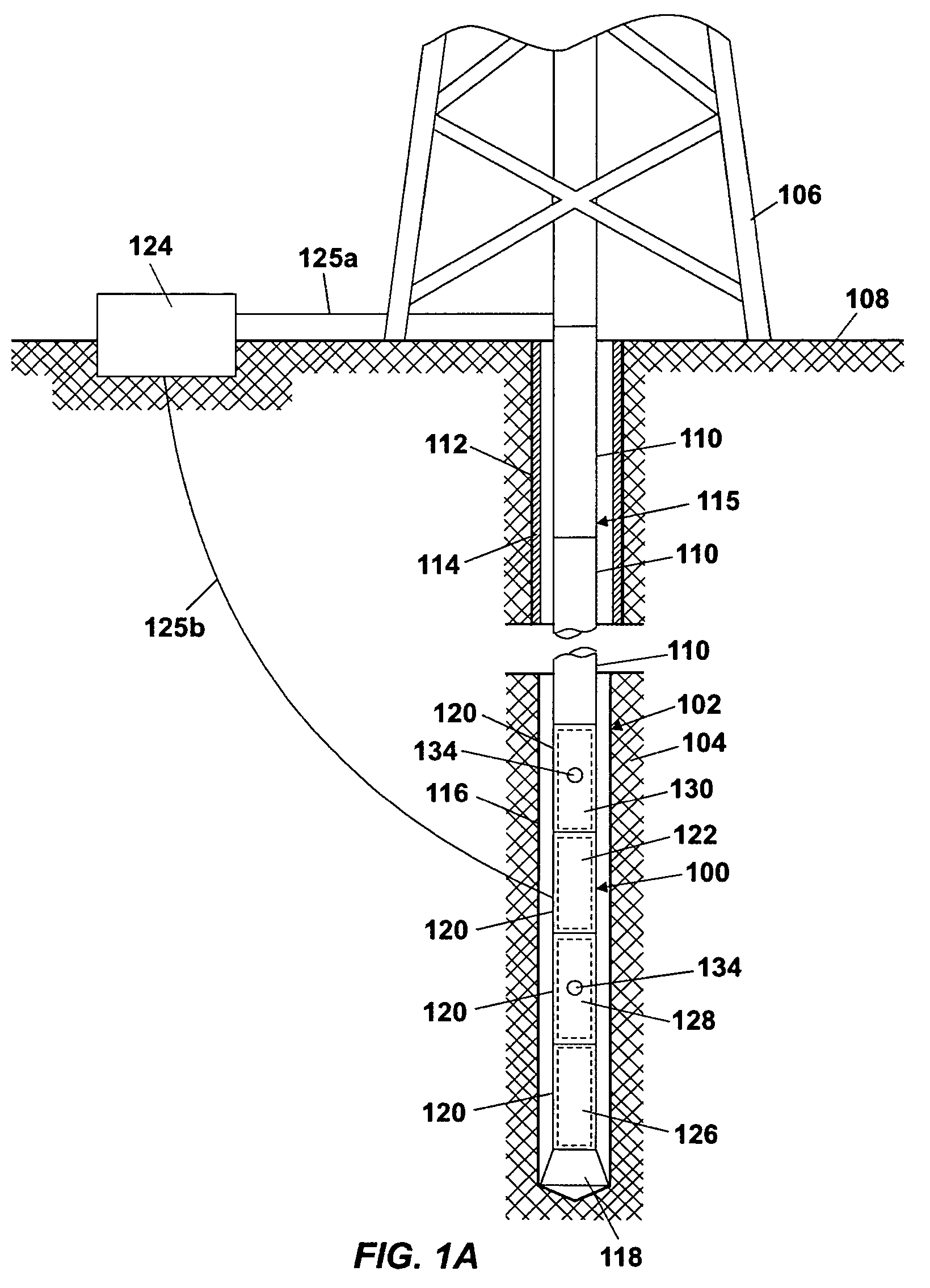

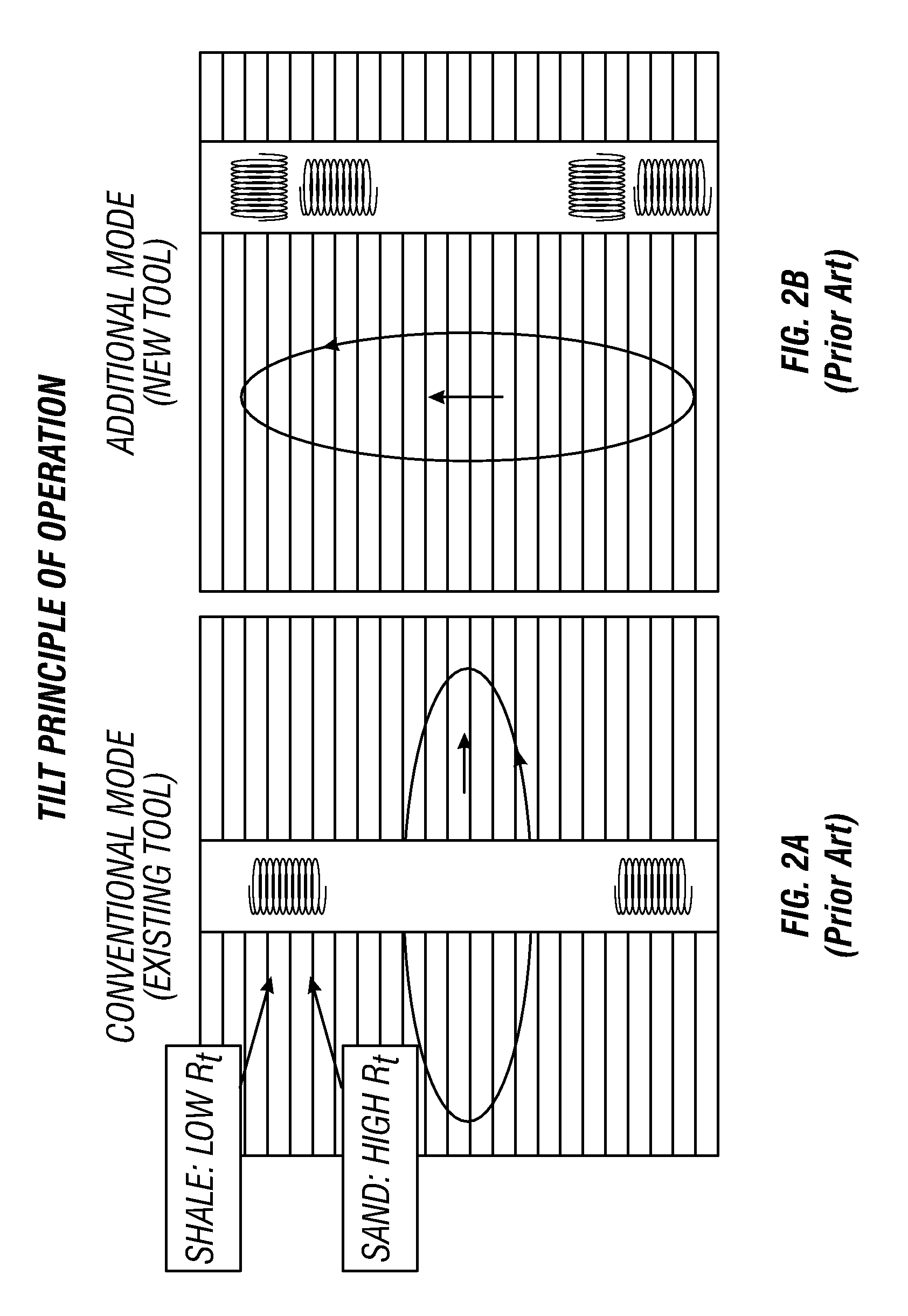

Wireless electromagnetic telemetry system and method for bottomhole assembly

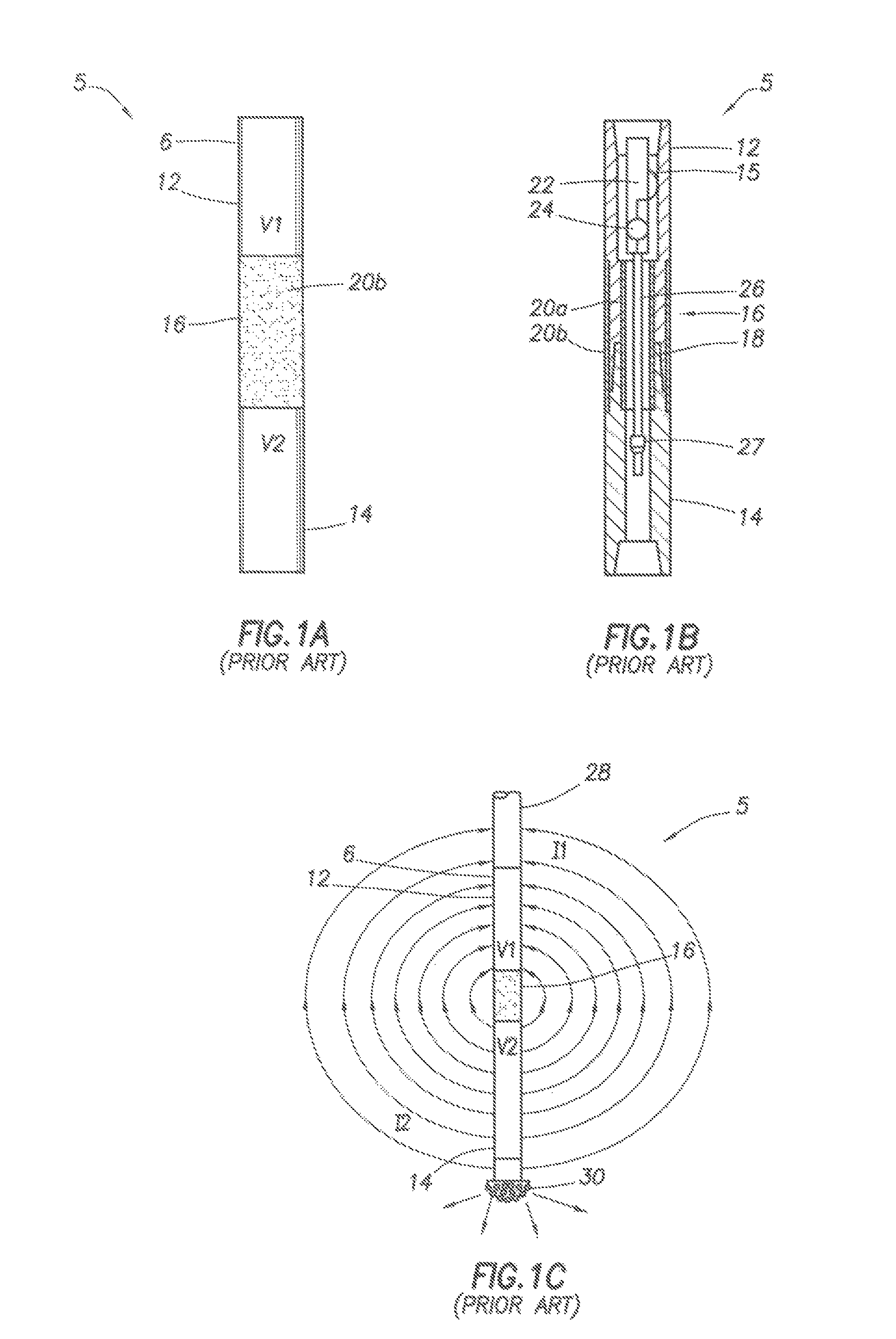

A wireless electromagnetic telemetry system for broadcasting signals across a bottomhole assembly disposed in a borehole drilled through a subterranean formation includes an insulated gap at a first point in the bottomhole assembly, at least one magnetic field sensor at a second point in the bottomhole assembly which measures a magnetic field, and a circuitry which modulates a voltage across the insulated gap, wherein the voltage creates an axial current along the bottomhole assembly that results in the magnetic field.

Owner:SCHLUMBERGER TECH CORP

Wireless electromagnetic telemetry system and method for bottomhole assembly

A wireless electromagnetic telemetry system for broadcasting signals across a bottomhole assembly disposed in a borehole drilled through a subterranean formation includes an insulated gap at a first point in the bottomhole assembly, at least one magnetic field sensor at a second point in the bottomhole assembly which measures a magnetic field, and a circuitry which modulates a voltage across the insulated gap, wherein the voltage creates an axial current along the bottomhole assembly that results in the magnetic field.

Owner:SCHLUMBERGER TECH CORP

Integrated Electrode Resistivity and EM Telemetry Tool

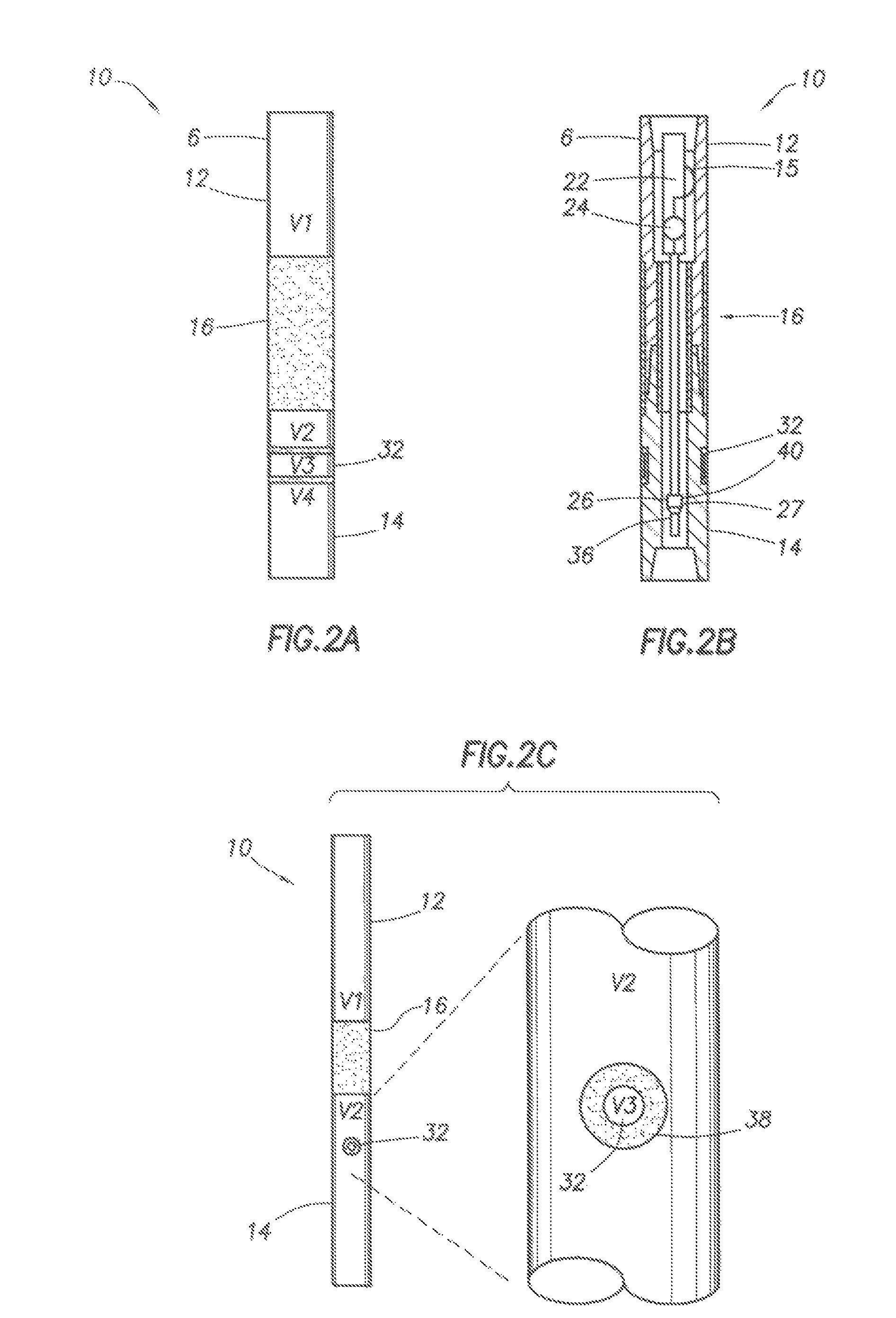

An integrated electrode resistivity and EM telemetry tool and obtaining both formation resistivity and telemetry data from the integrated tool. An integrated electrode resistivity and EM telemetry tool having a drill collar including a first portion and a second portion separated by an insulated gap and telemetry cartridge carrying telemetry circuitry including a voltage source generating a voltage drop across the insulated gap and an axial current on a drill string that returns through an earthen formation includes an insulated measure electrode connected to the first portion, and resistivity measurement circuitry functionally connected to the measure electrode and the telemetry circuitry.

Owner:SCHLUMBERGER TECH CORP

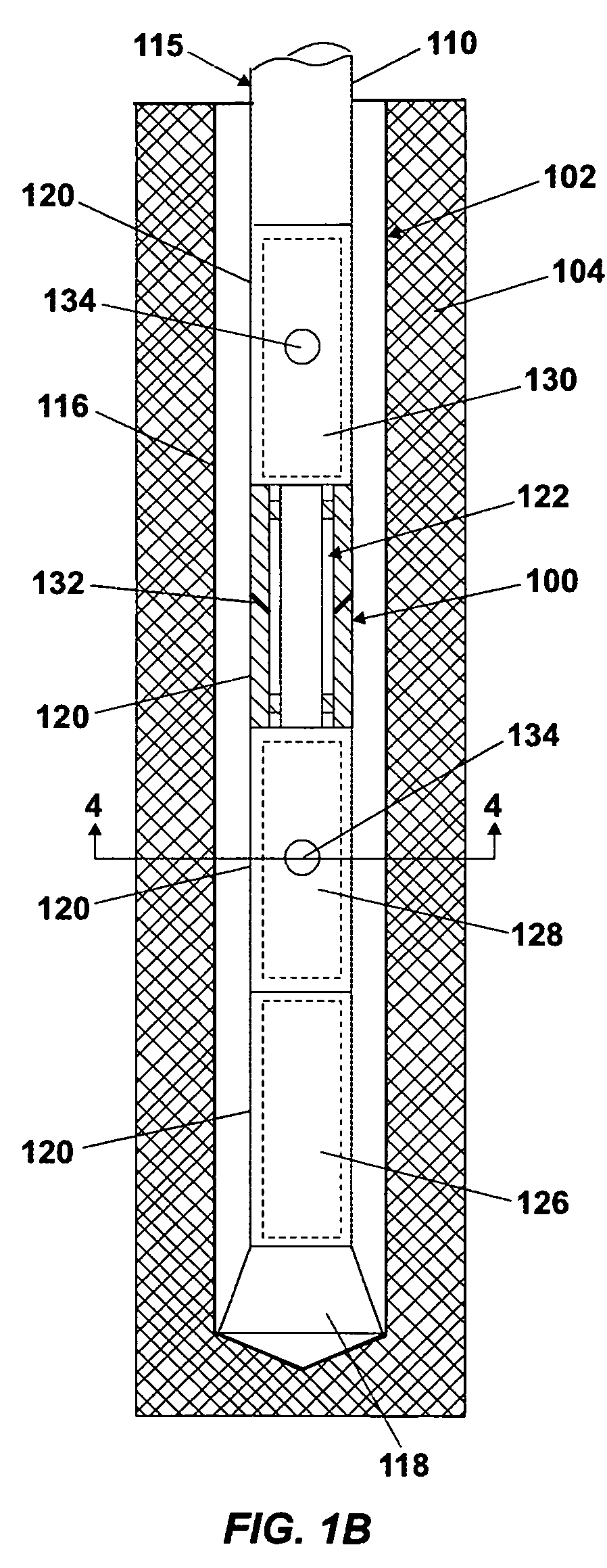

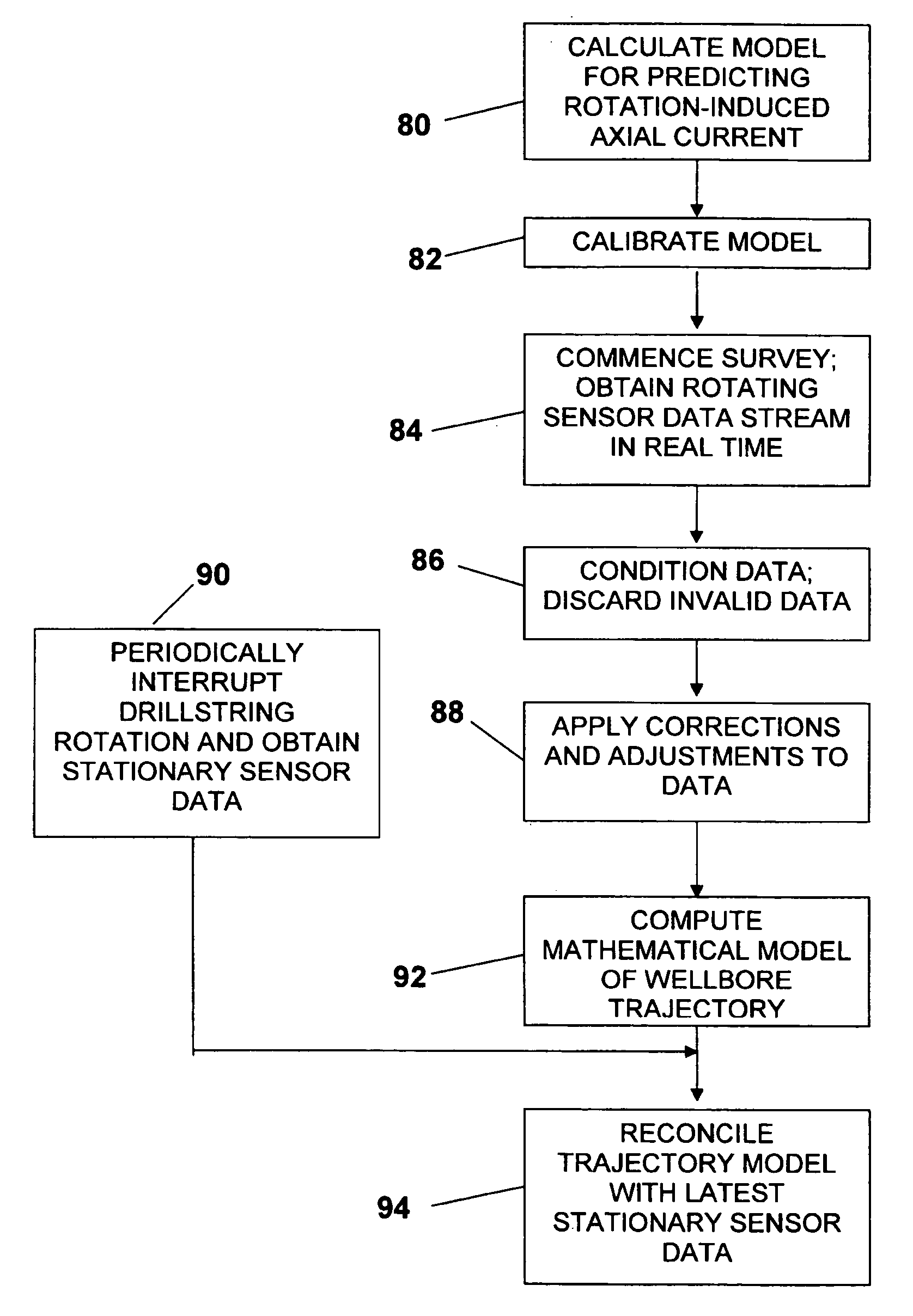

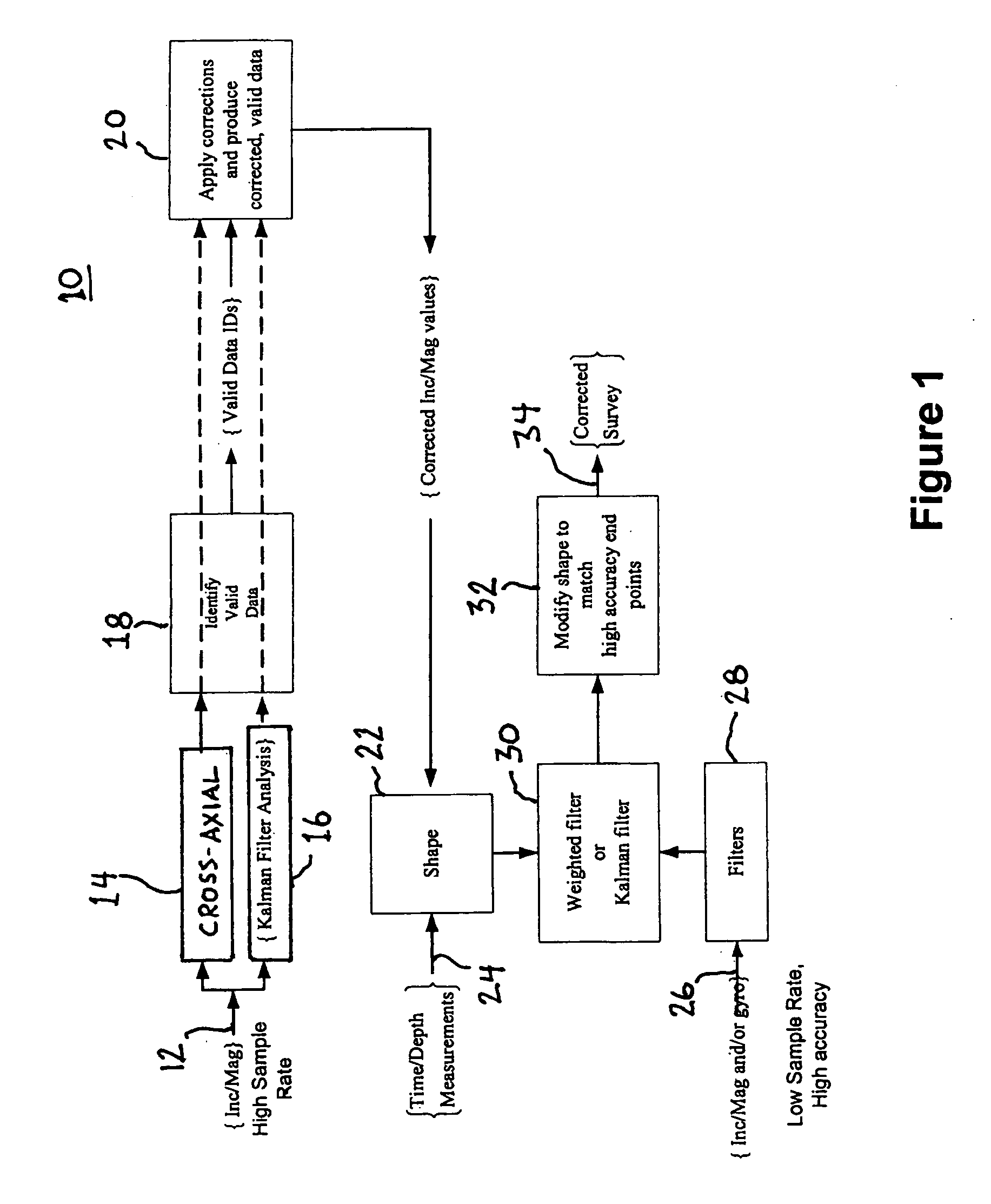

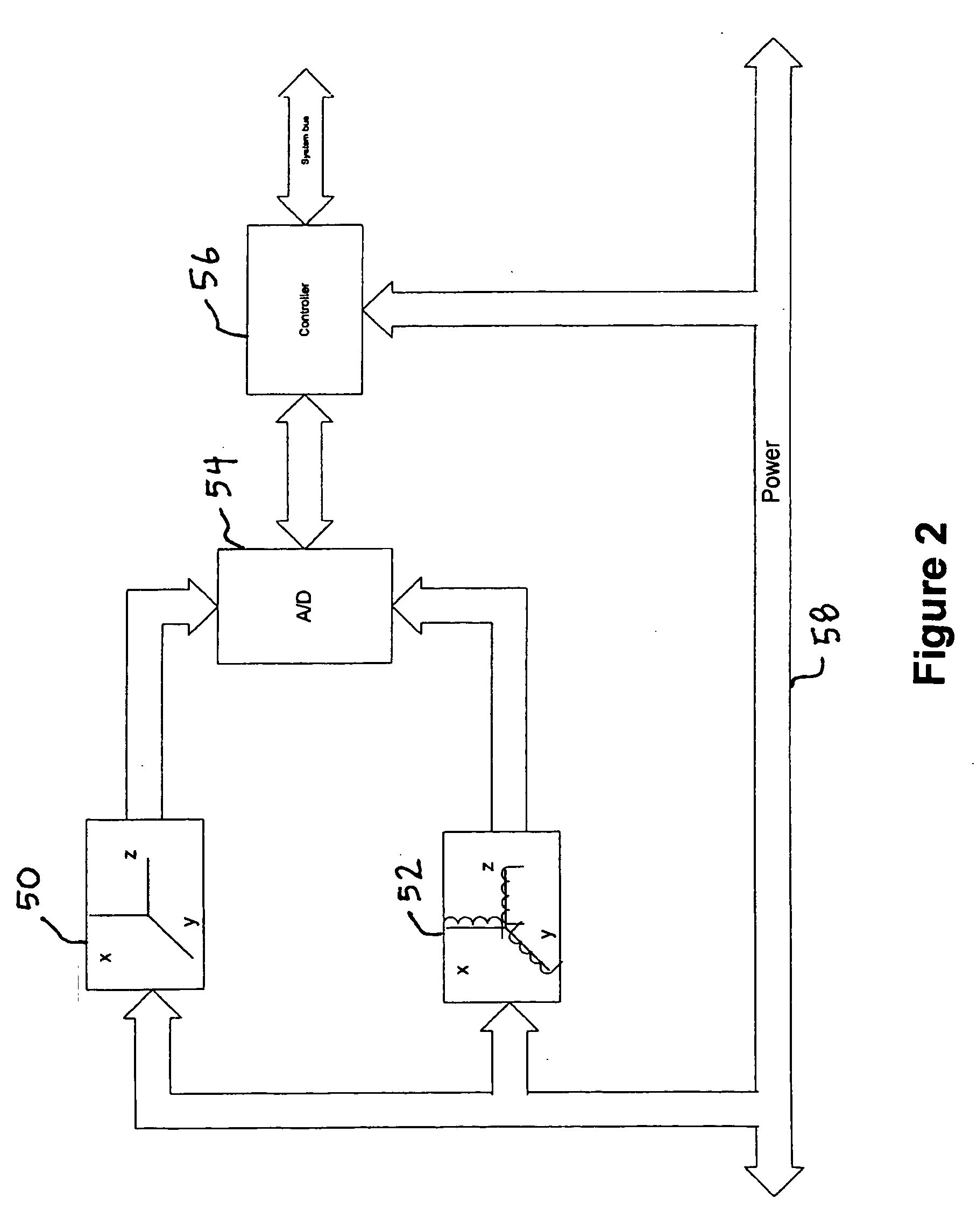

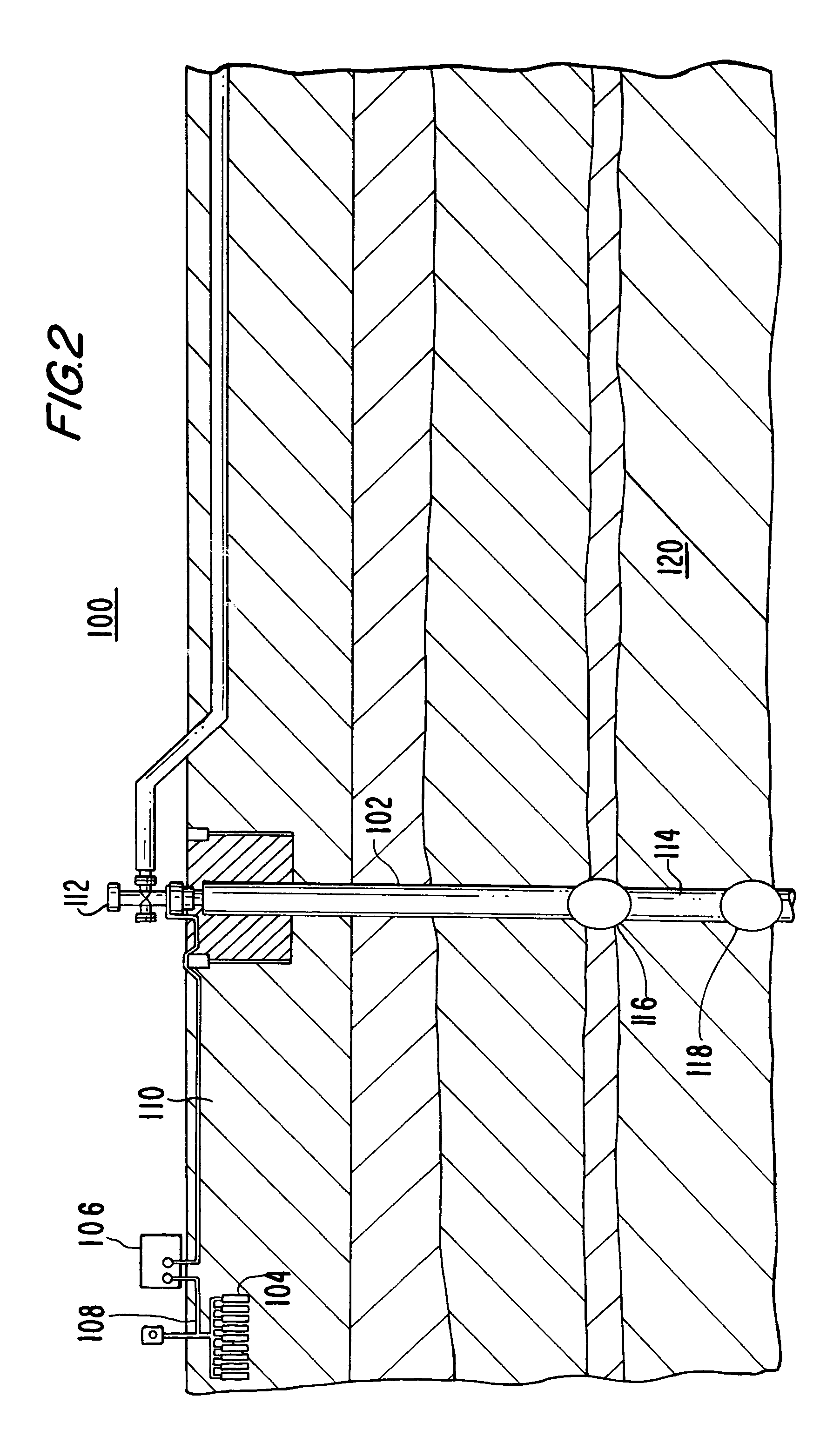

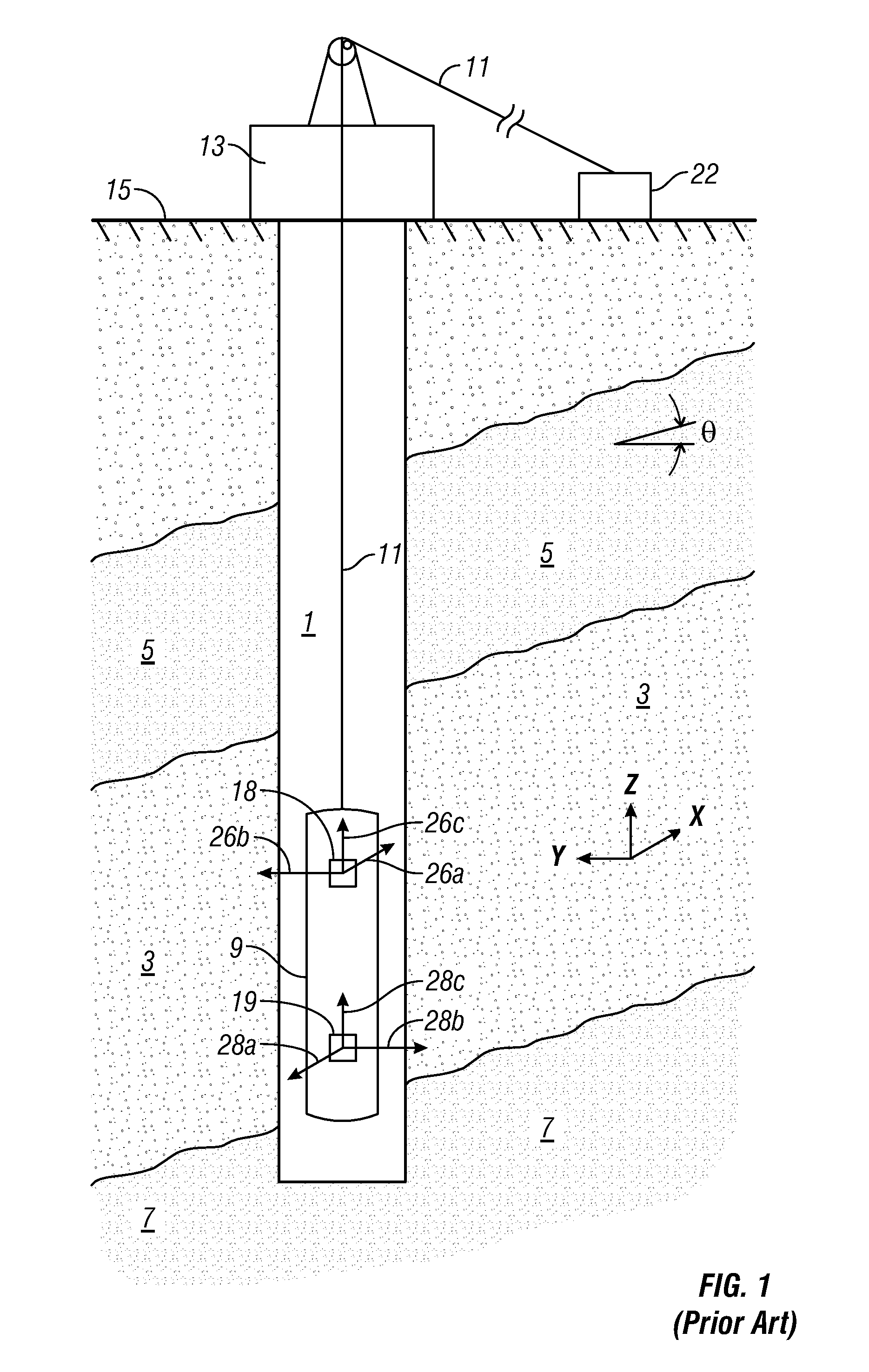

Method and apparatus for surveying a borehole with a rotating sensor package

ActiveUS7650269B2Avoid it happening againEliminate currentComputation using non-denominational number representationSeismology for water-loggingSensor arrayConductive materials

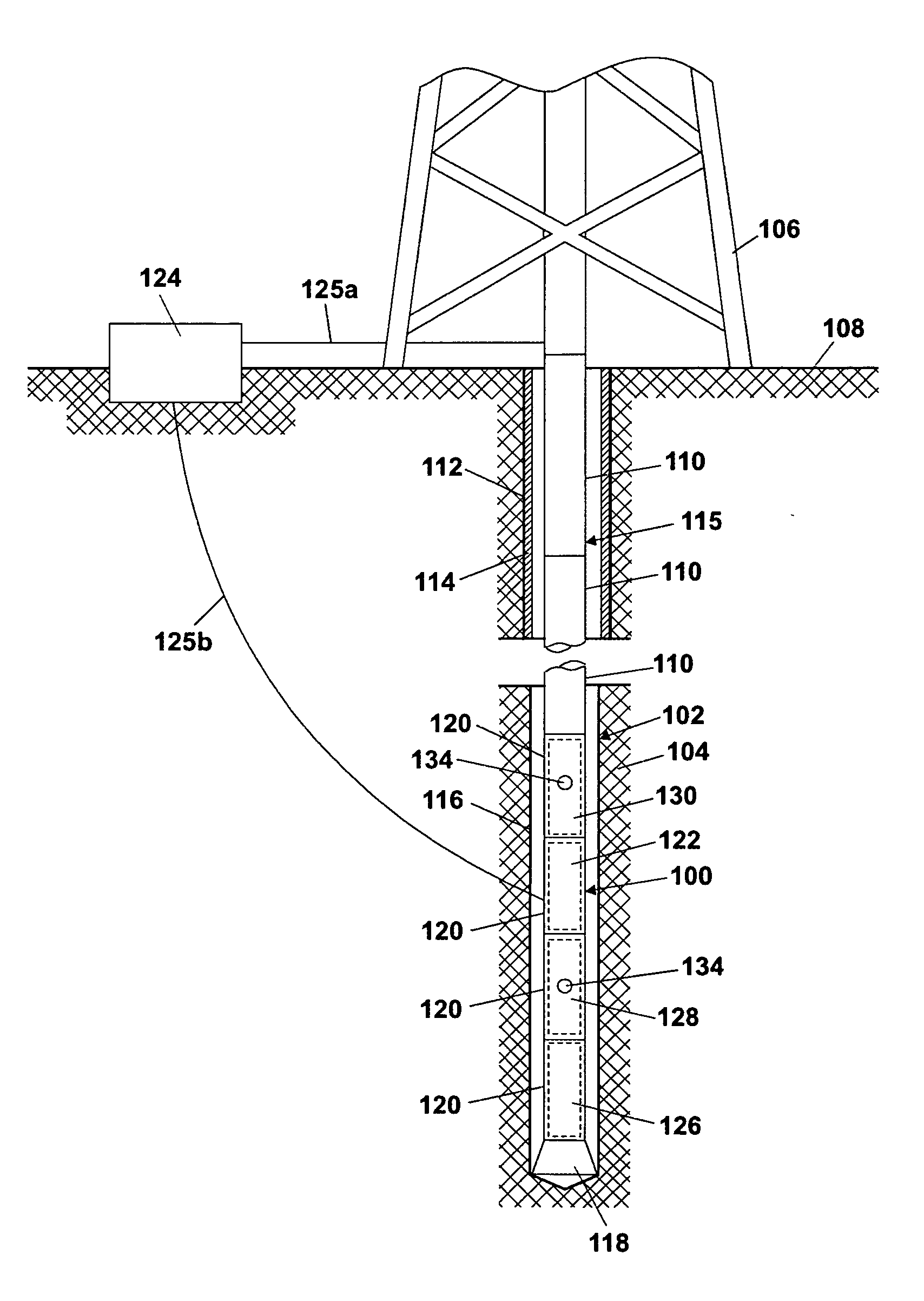

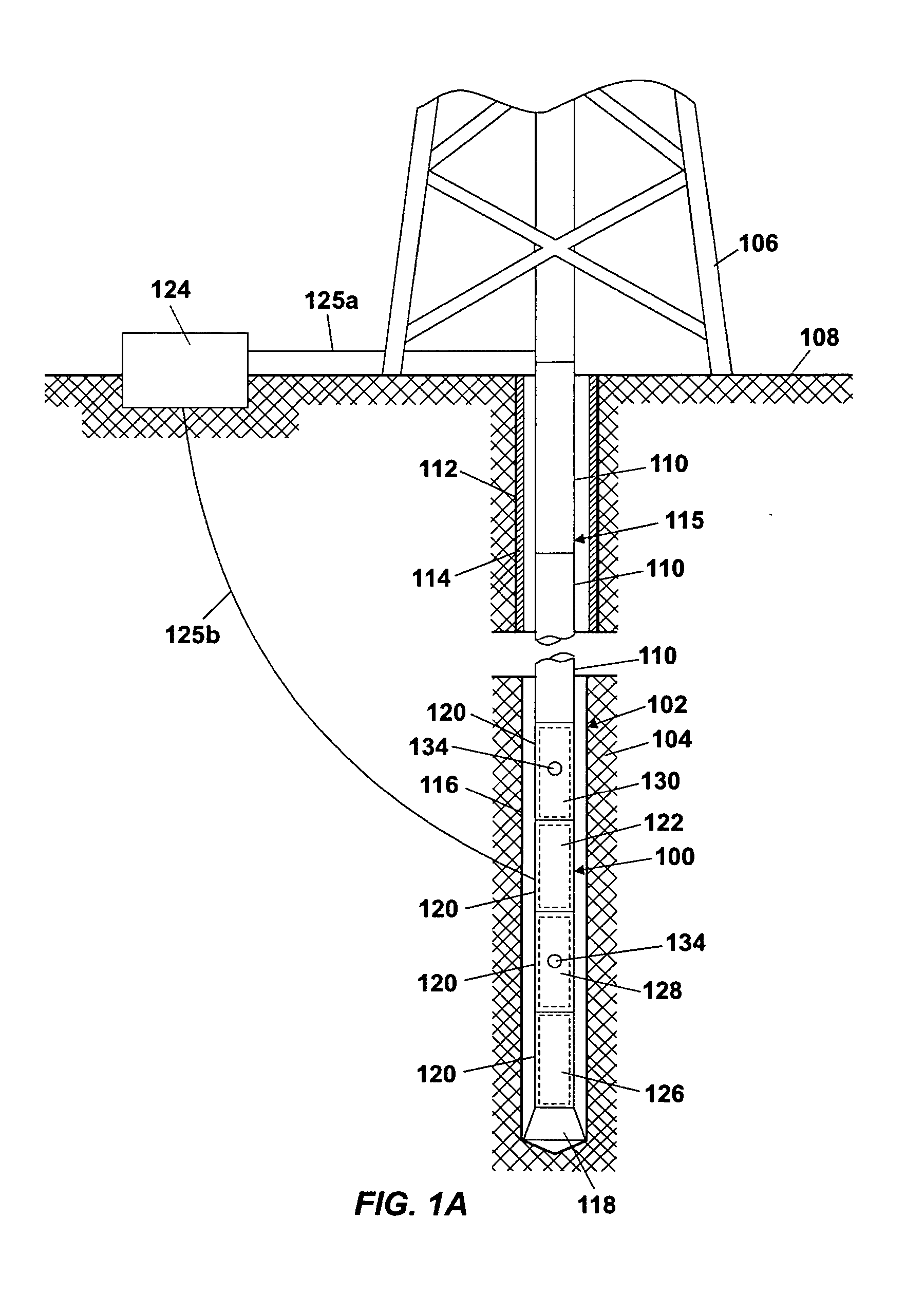

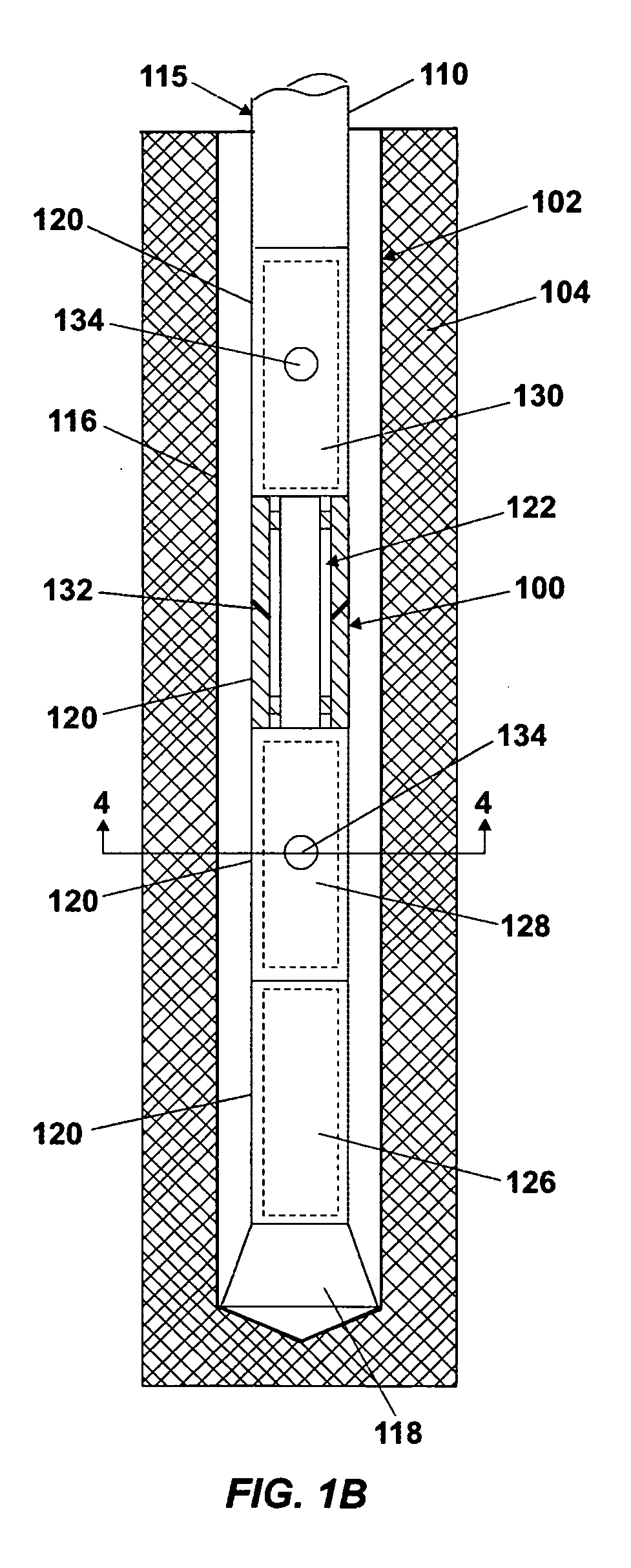

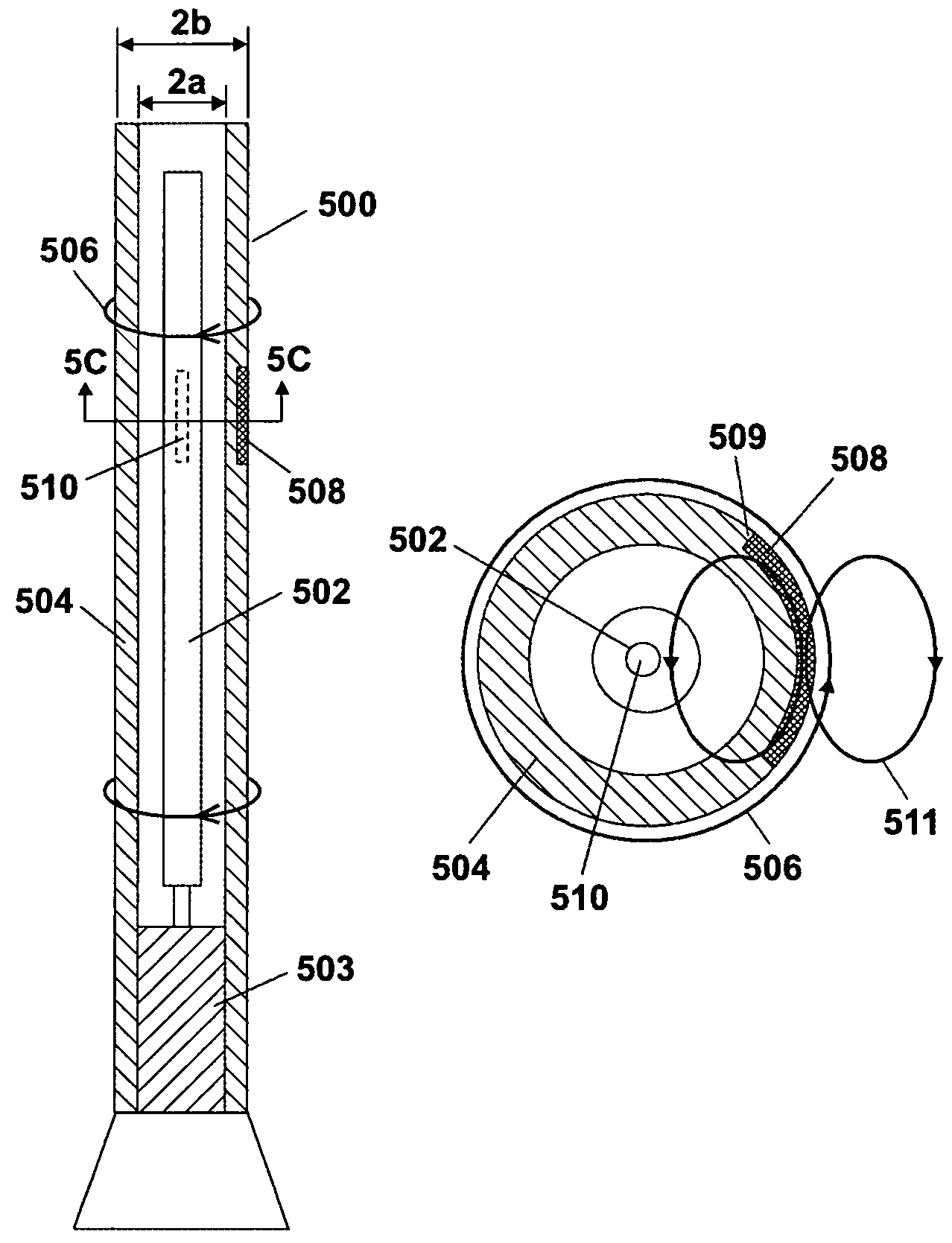

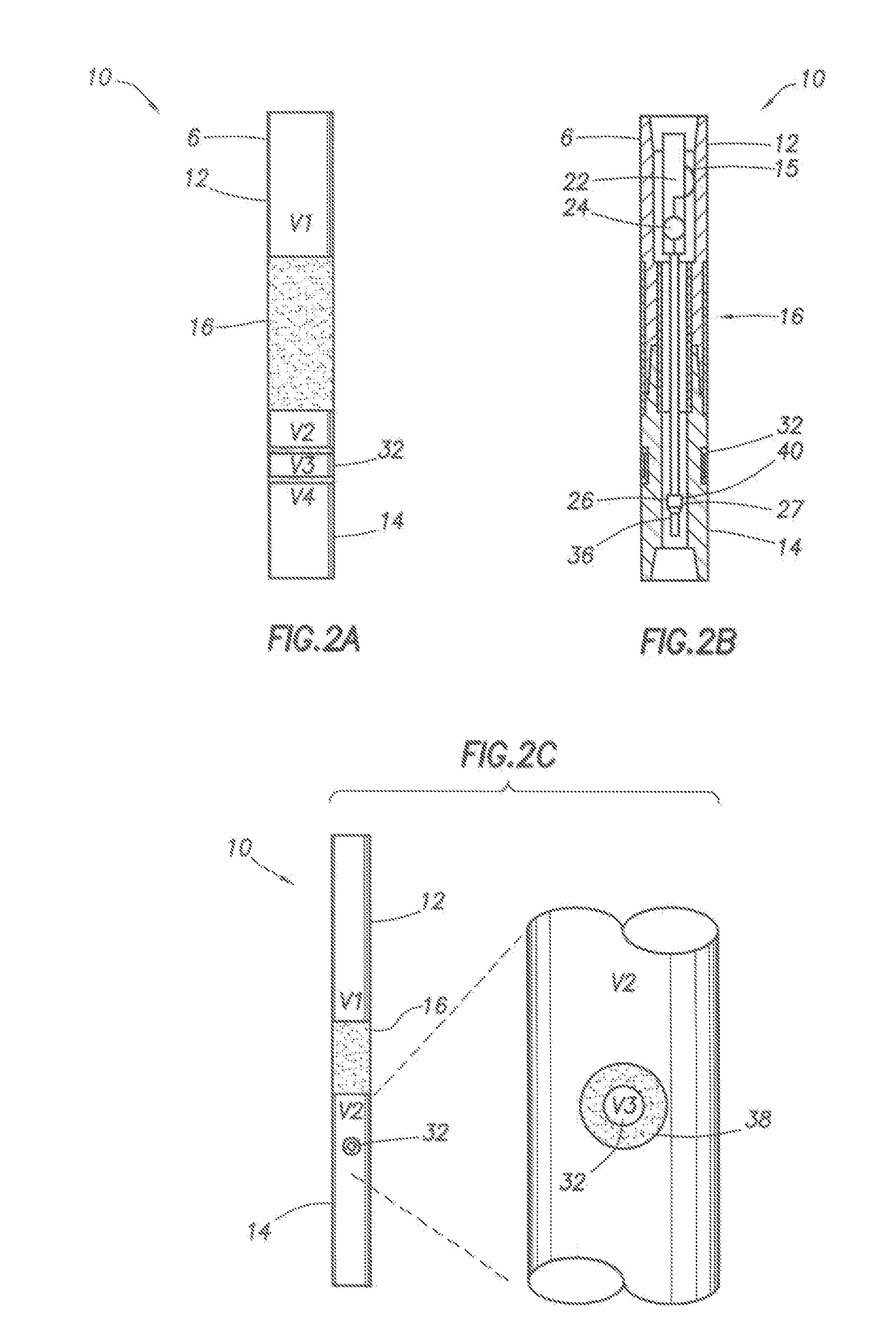

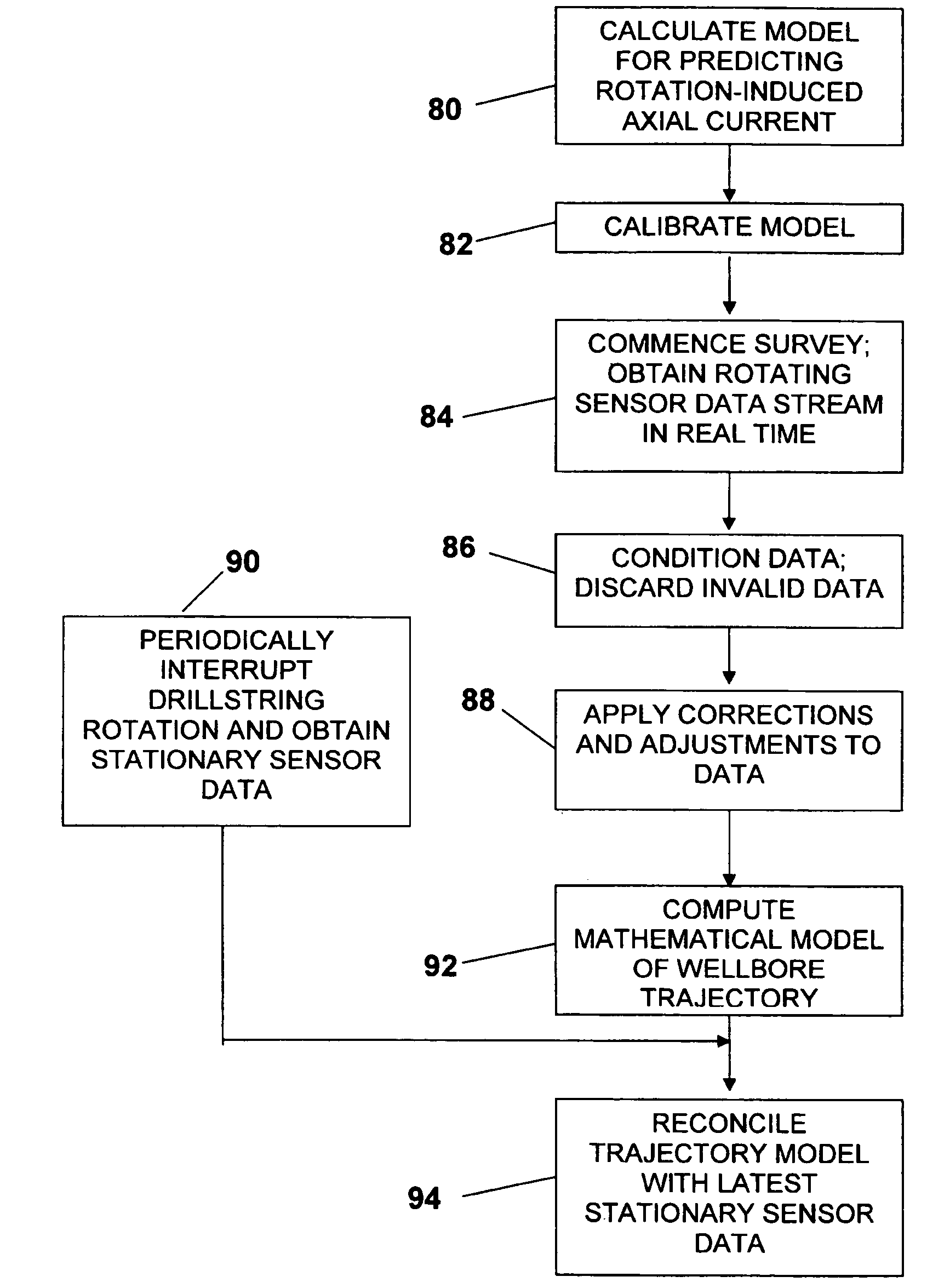

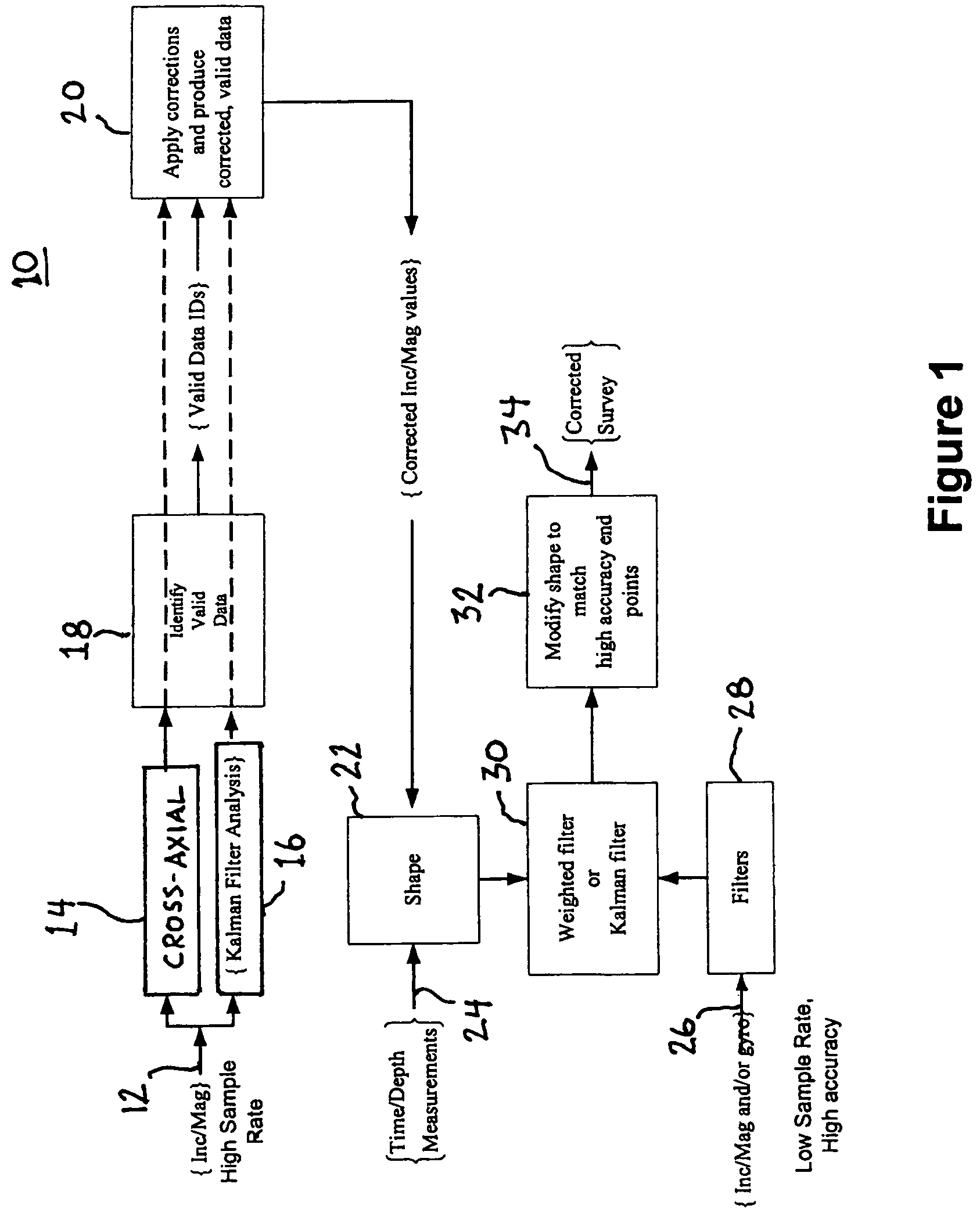

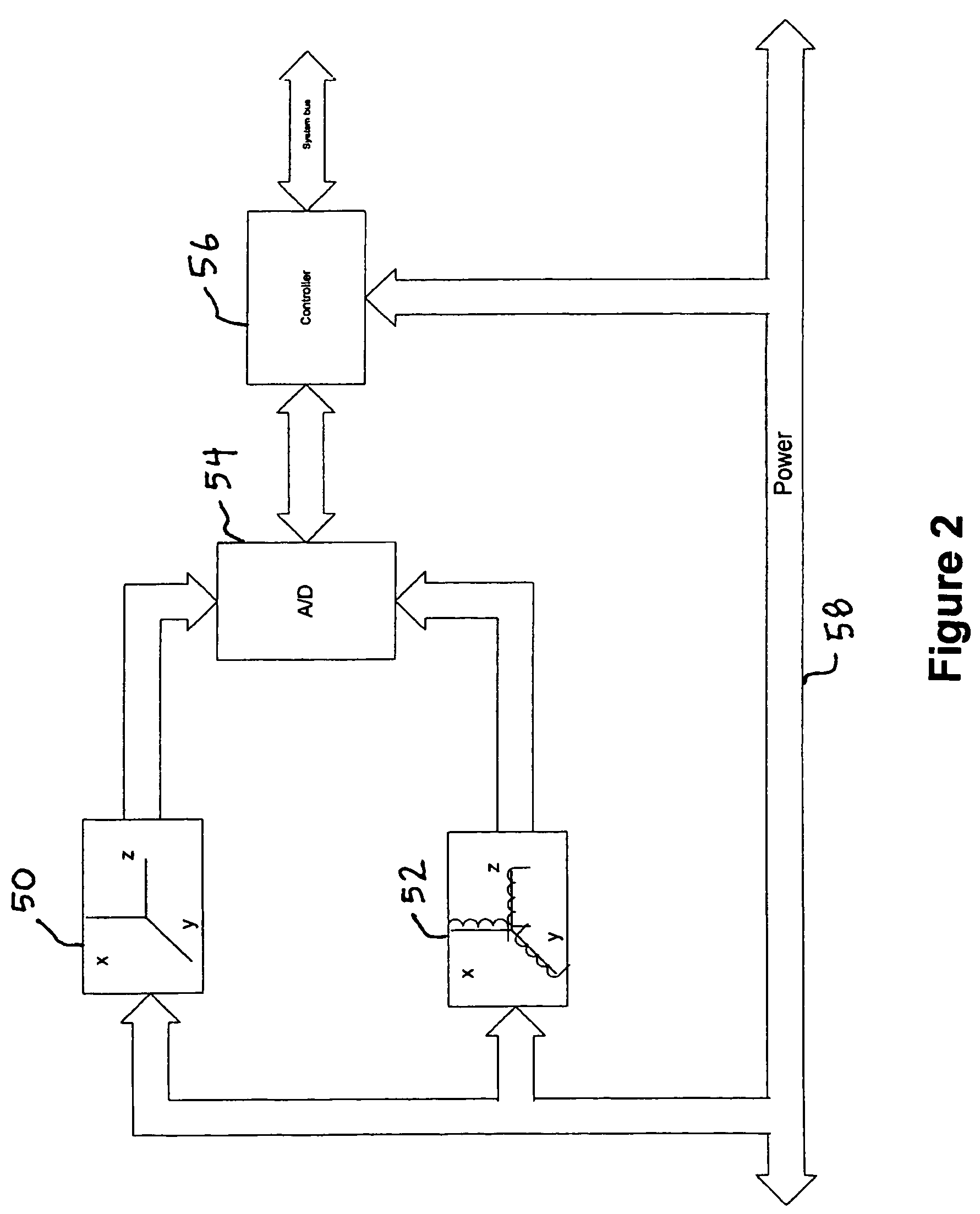

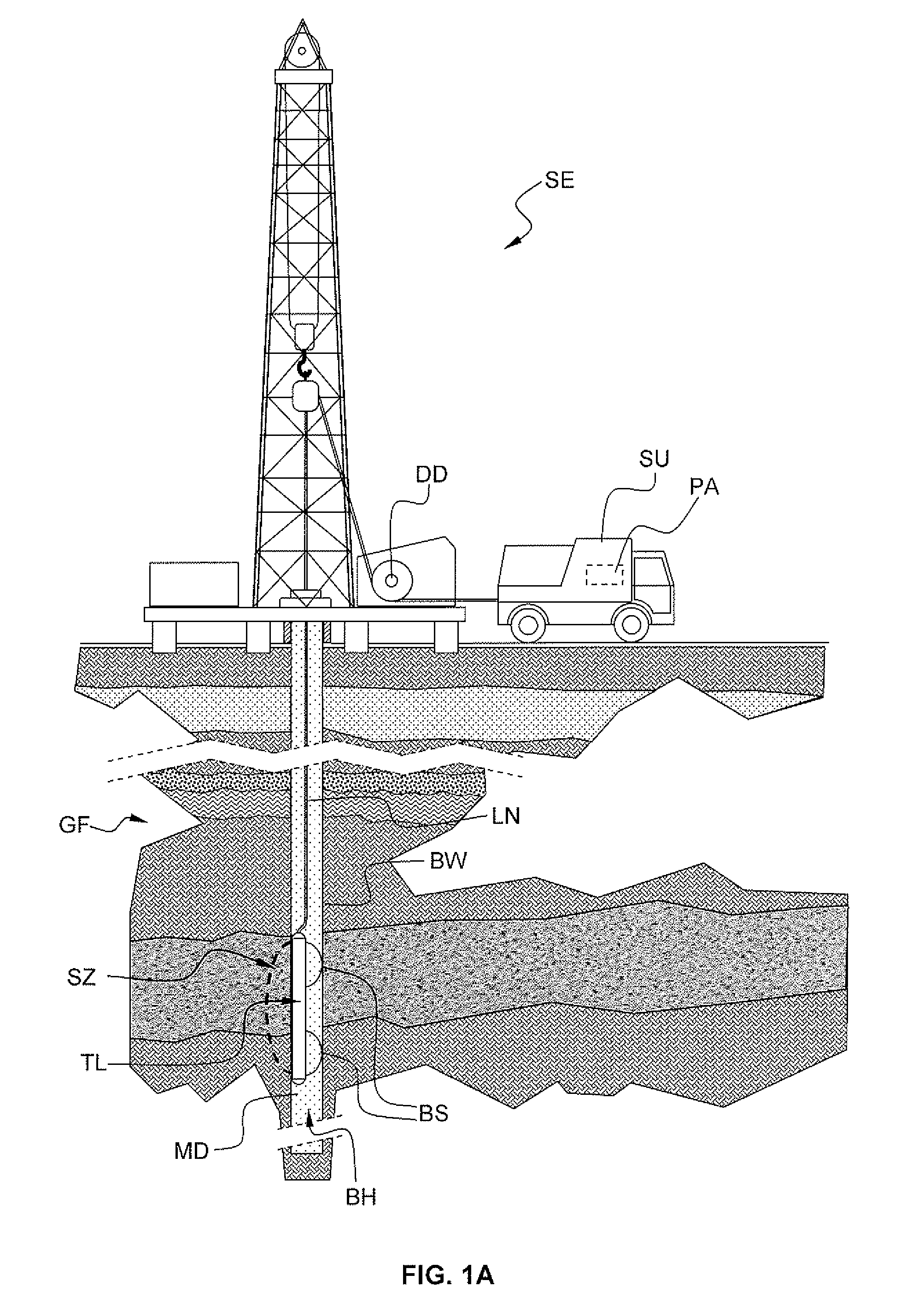

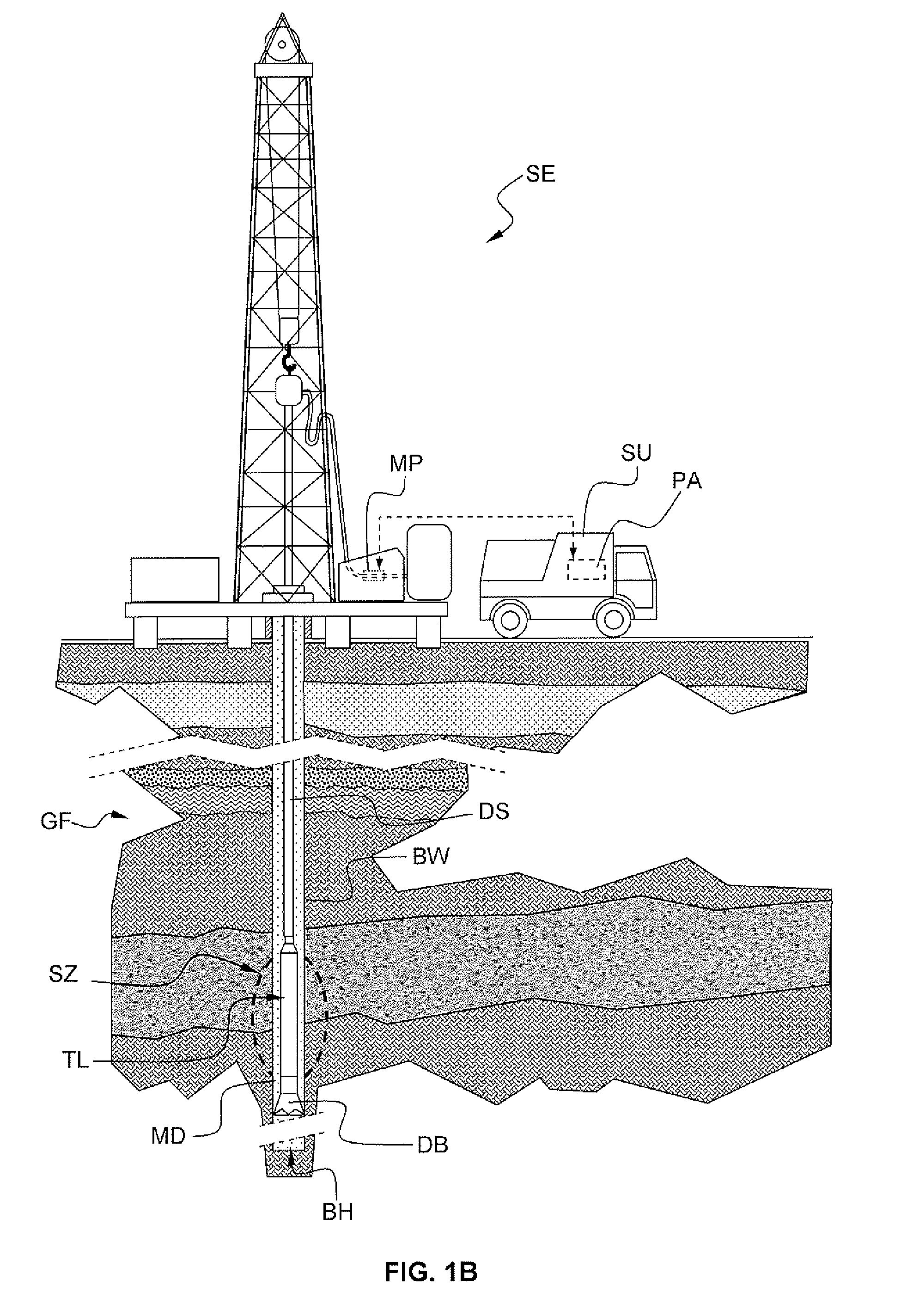

A method and apparatus for surveying a borehole using a rotating sensor package. A sensor tool preferably including a magnetometer sensor array is disposed in the bottom hole assembly of a drillstring. Conditioning circuitry in the sensor tool processes the sensor readings from the sensor array taken while the drillstring is rotating. In one embodiment, the conditioning circuitry includes processing circuitry adapted to adjust the sensor readings to account for an analytically predicted level of axial current induced in the drillstring as a result of its rotation in the Earth's magnetic field. In another embodiment, a current generator is provided to generate a counter-current intended to cancel the analytically predicted level of axial current induced in the drillstring as a result of rotation in the Earth's magnetic field. In another embodiment, insulating members are disposed above and / or below the sensor tool to prevent conduction of rotation-induced current therein. In still another embodiment, the sensor tool is disposed in a drill collar that is composed of a non-conducting material, such that no rotation-induced current is conducted through the sensor tool.

Owner:HALLIBURTON ENERGY SERVICES INC

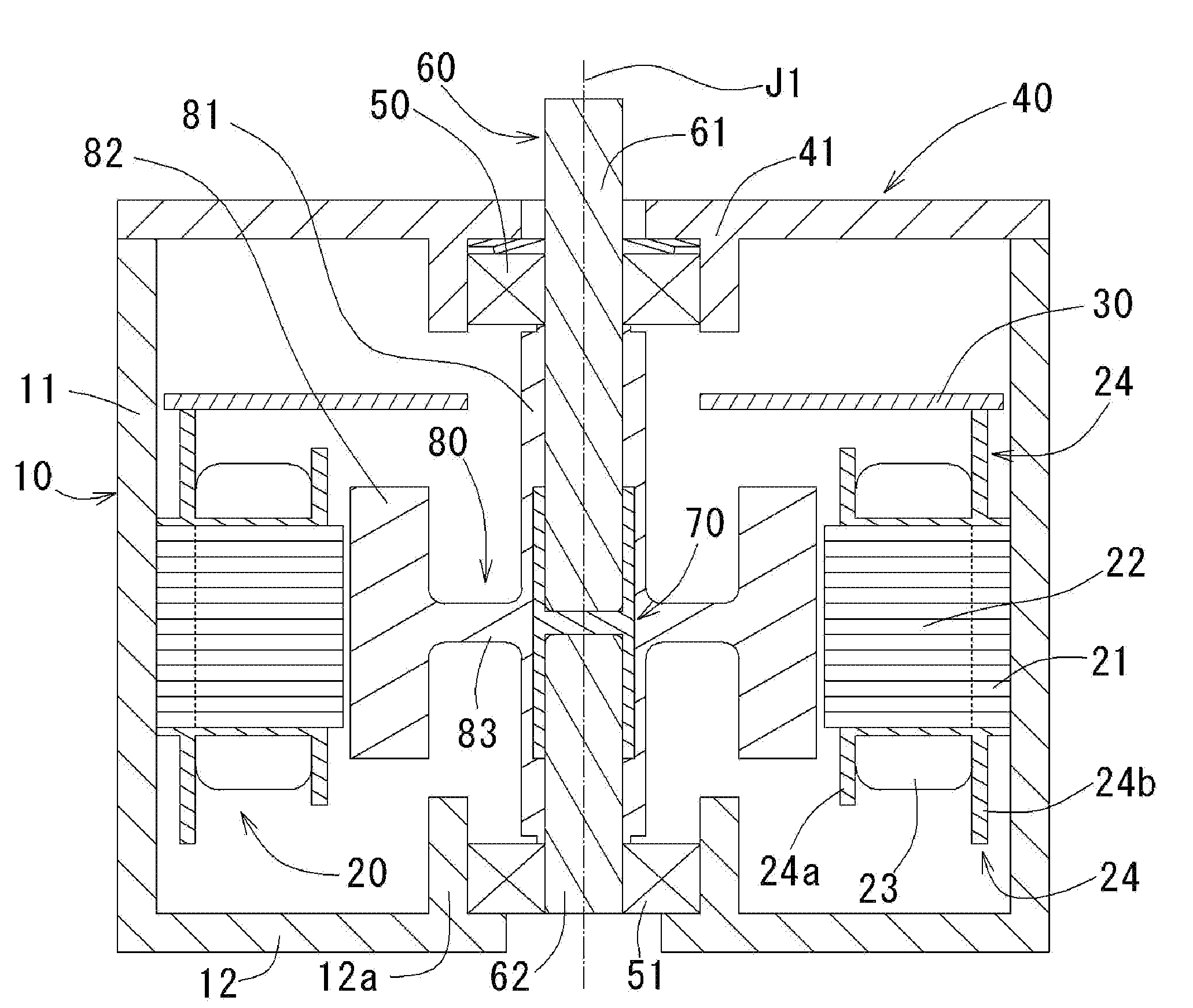

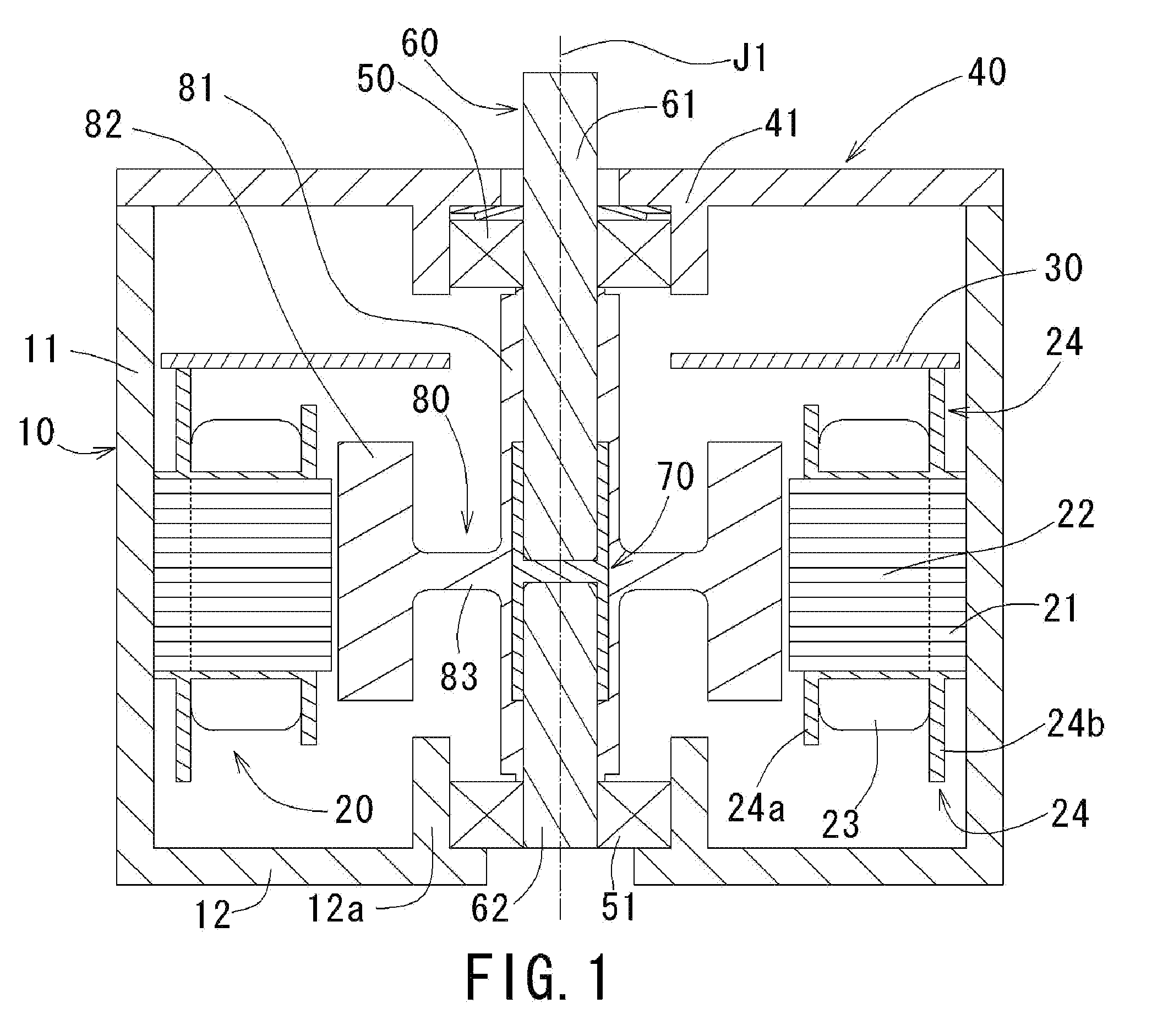

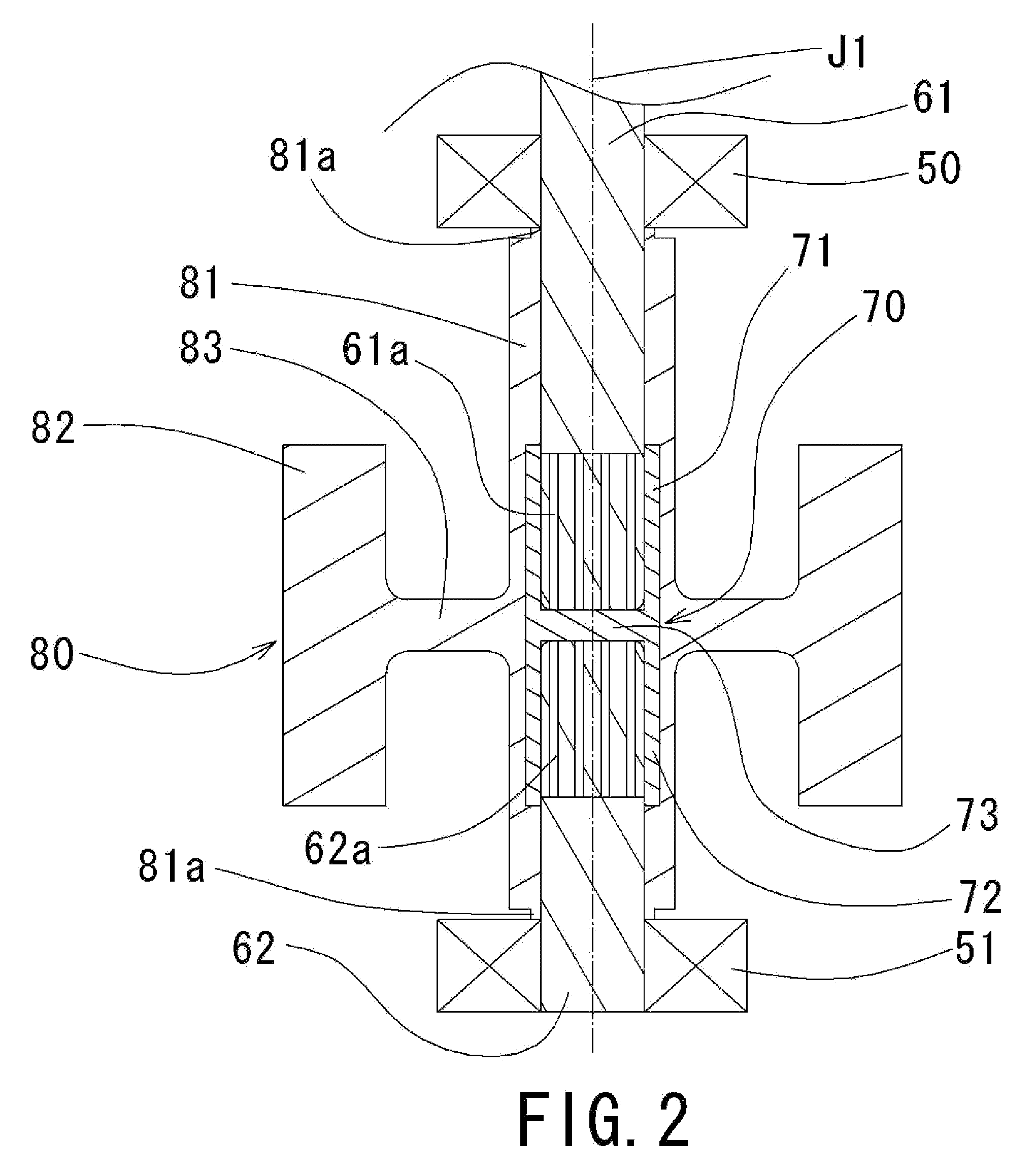

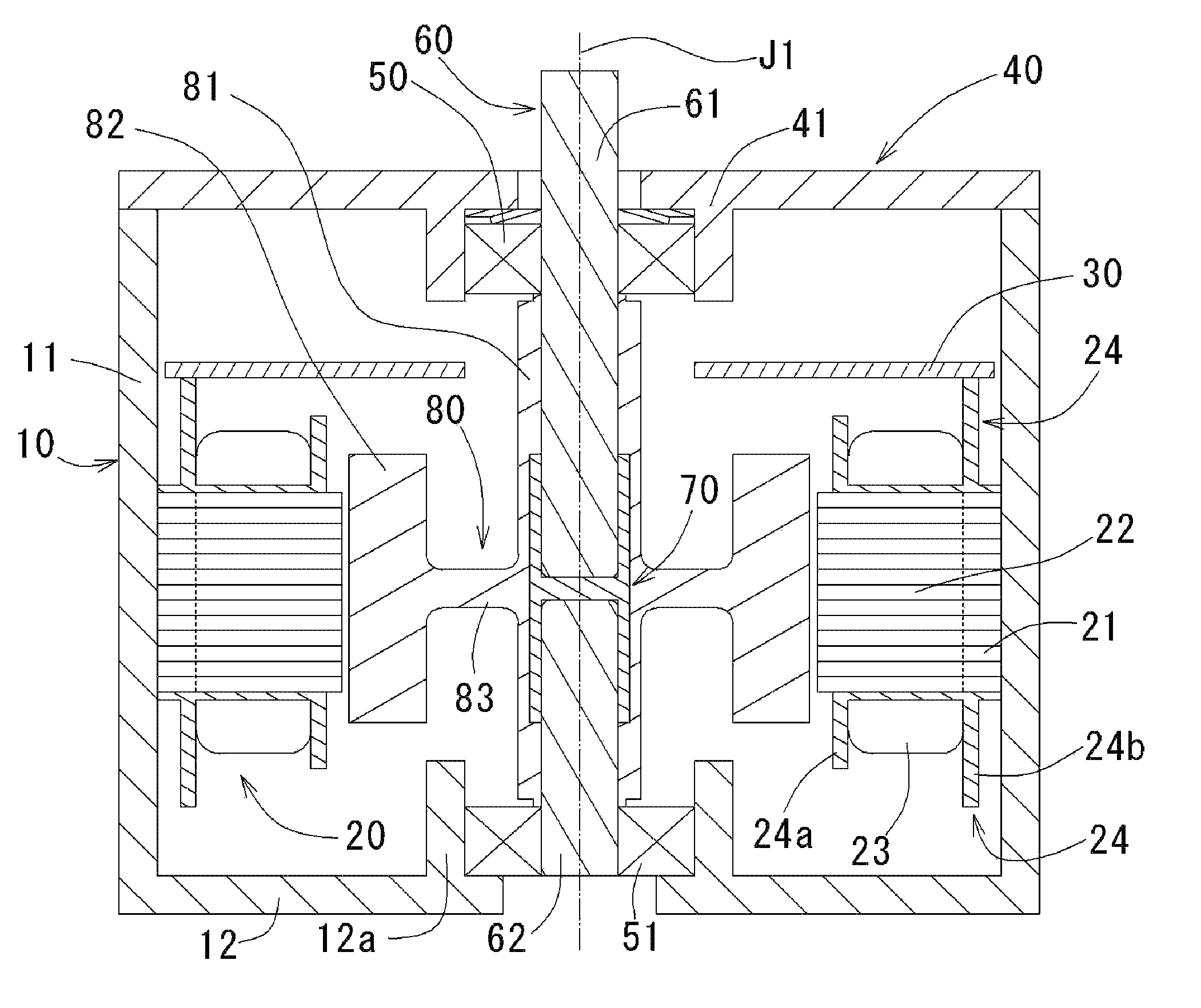

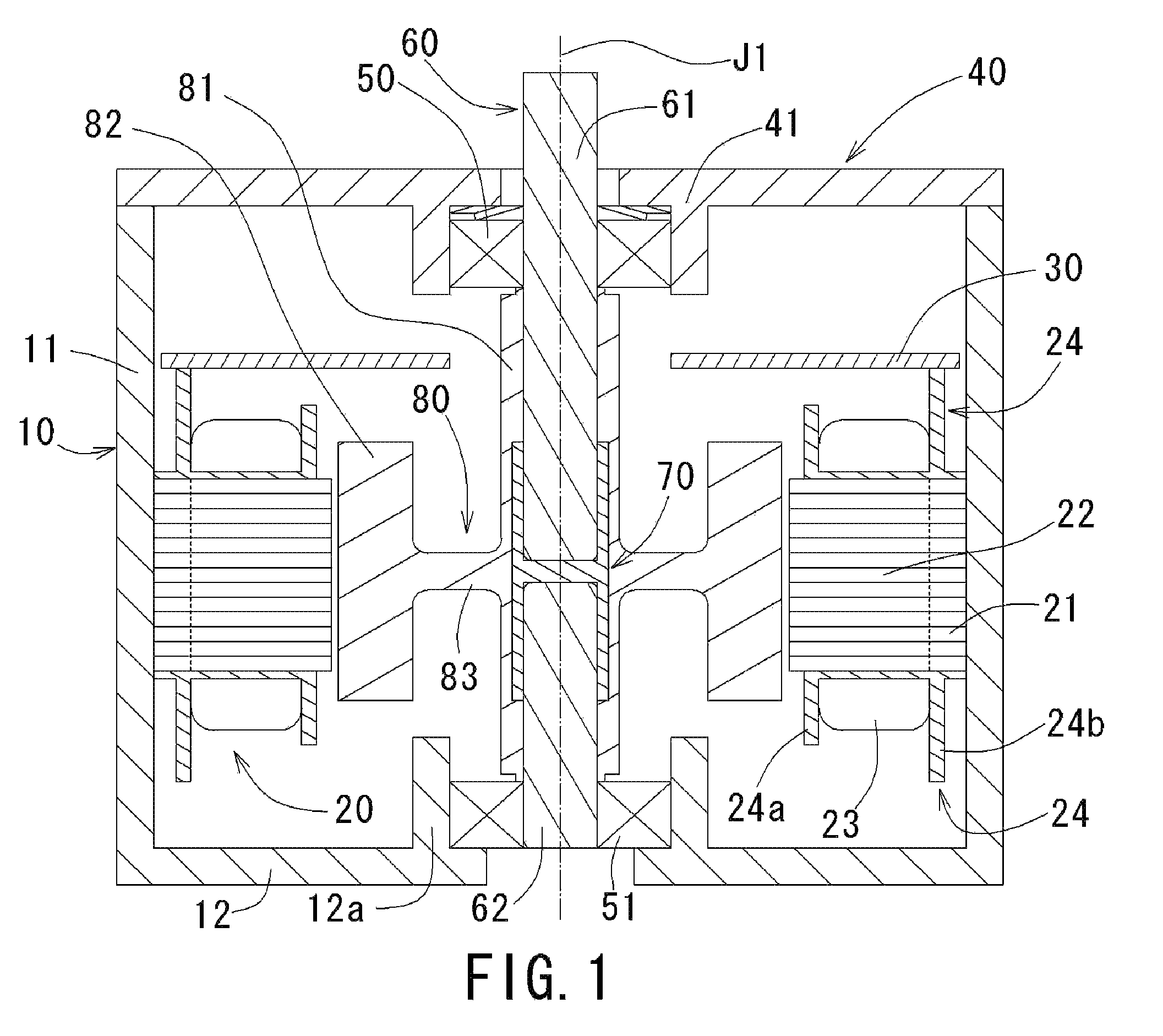

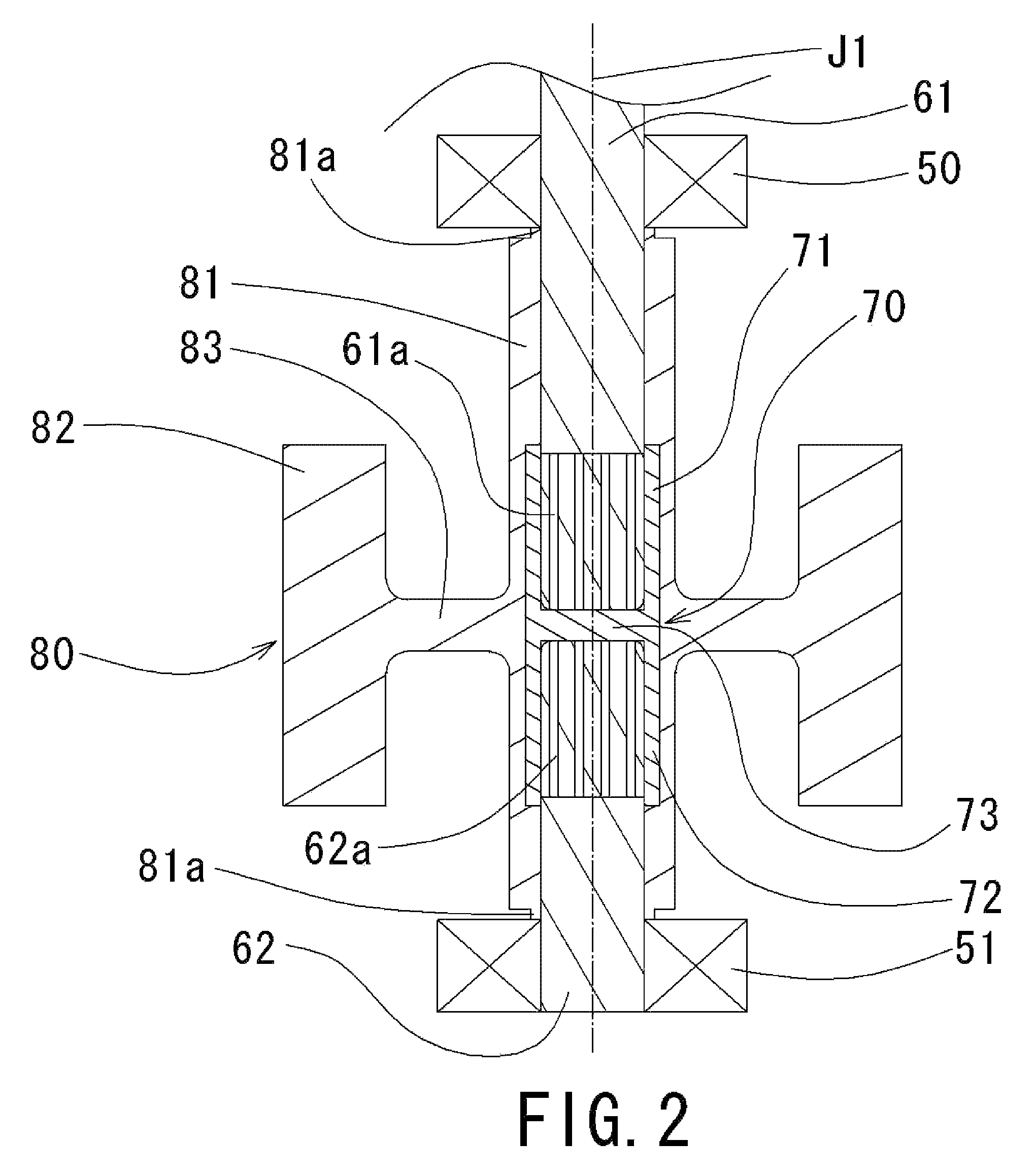

Motor

InactiveUS20070290570A1Avoid flowImprove insulation performanceMagnetic circuit rotating partsMaster clocksRotor magnetsElectric current

A motor includes a shaft including upper and lower shaft members spaced axially away from each other. A shaft connecting member made of electrically insulating material is arranged axially between the upper and lower shaft members. The shaft connecting member is provided with fitting portions to which the upper and lower shaft members are to be fitted. While the upper and lower shaft members are secured to the shaft connecting member, the rotor magnet is integrally formed with the upper and lower shaft members and the shaft connecting member. With this configuration, an axial electric current is prevented from flowing through the shaft by the shaft connecting member.

Owner:NIDEC SHIBAURA CORP

Integrated electrode resistivity and EM telemetry tool

Owner:SCHLUMBERGER TECH CORP

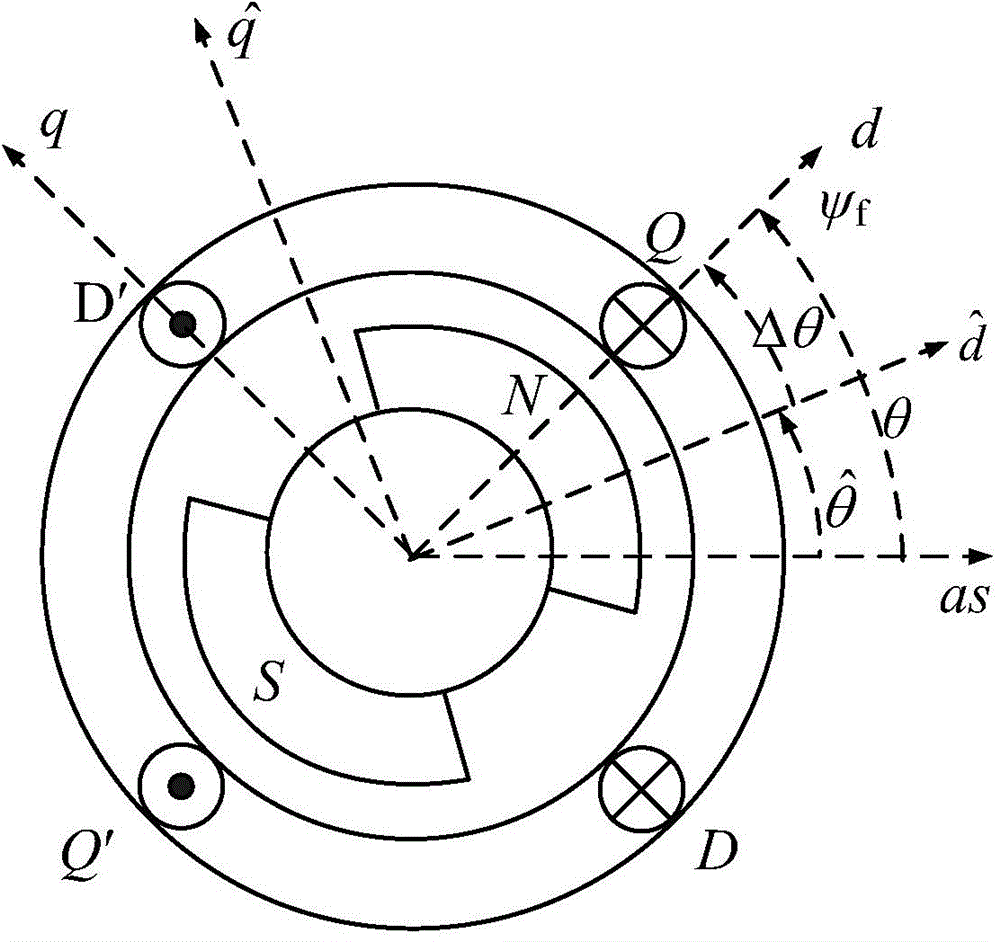

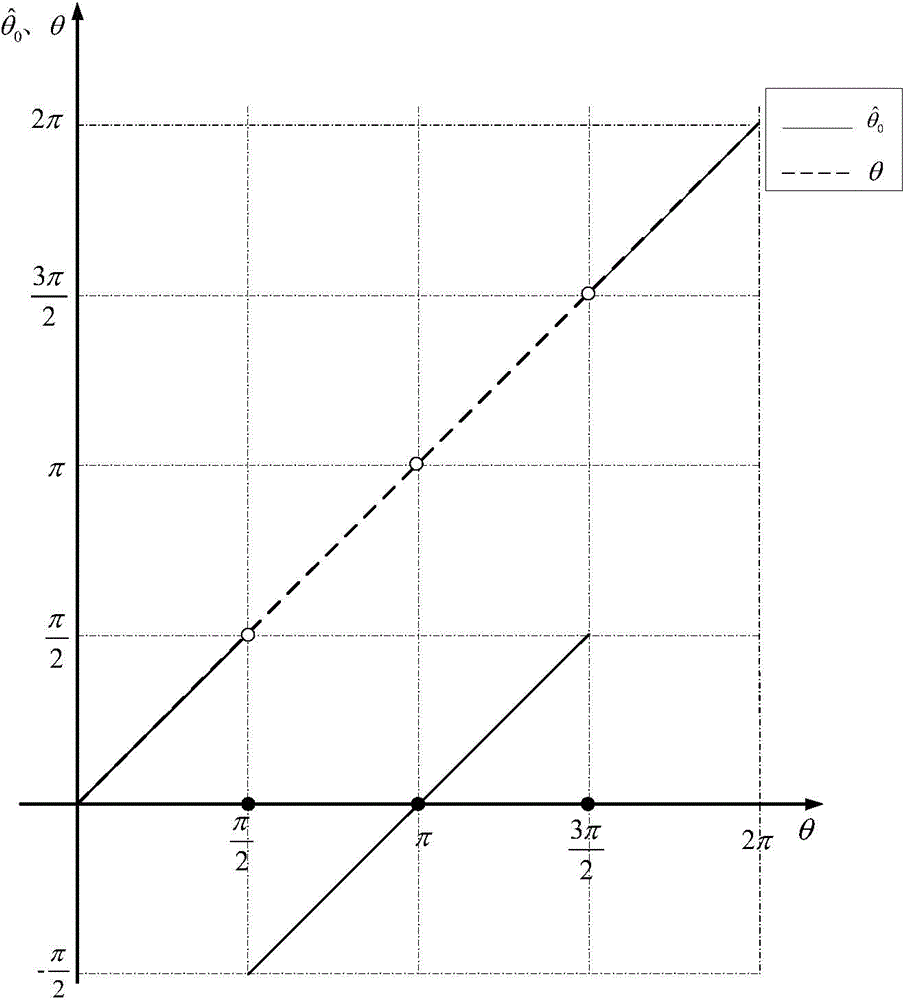

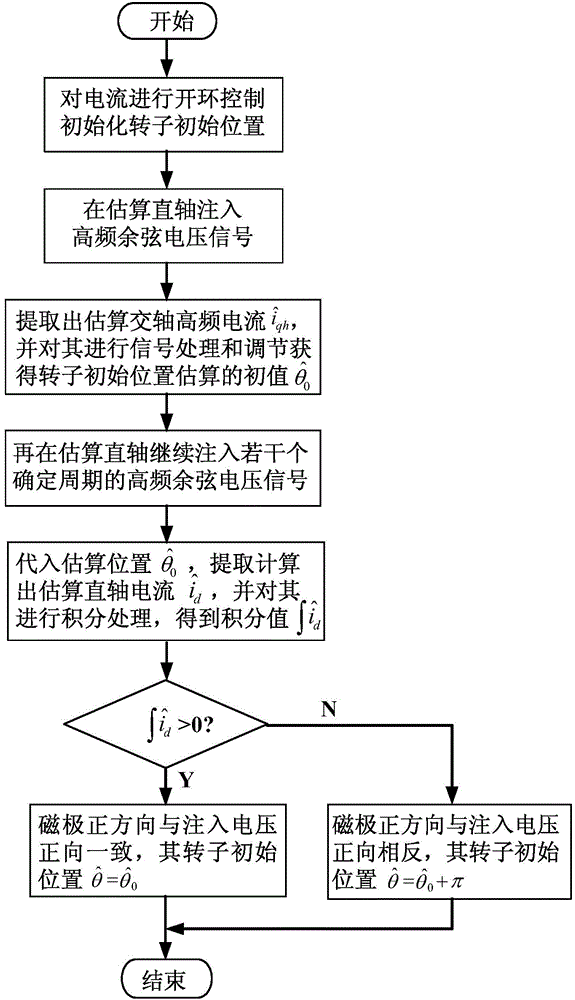

Method for detecting initial position of sensorless permanent magnet synchronous motor

InactiveCN104158462AAvoid the problem of rotation, identification signal detection difficultyAccurate acquisitionElectronic commutation motor controlVector control systemsLoop controlPower flow

The invention relates to a method for detecting the initial position of a sensorless permanent magnet synchronous motor. On the basis of ensuring the static state of the motor, open-loop control is carried out on current, the initial position of a rotor is initialized, estimated high-frequency alternating axial current is extracted by injecting high-frequency cosine voltage signals into an estimation direct axis of an estimated synchronous rotating coordinate system, and signal processing and adjusting are carried on the high-frequency alternating axial current to obtain the estimated initial value of the initial position of the rotor; then a plurality of high-frequency cosine voltage signals of the determined period are continuously injected into the estimation direct axis, and the magnetic polarity is judged and the accurate initial position of the rotor is obtained by judging whether an integral value of the direct axis current is positive or negative. Motor parameters do not need to be obtained, the problem that as an existing rotor initial position detecting method possibly causes motor rotation, identification signals are difficult to detect is effectively avoided, hardware does not need to be additionally arranged, implementation is convenient, and the initial position of any rotor magnetic pole can be accurately obtained when the motor is in the static state.

Owner:中山市蒙力电机电器有限公司

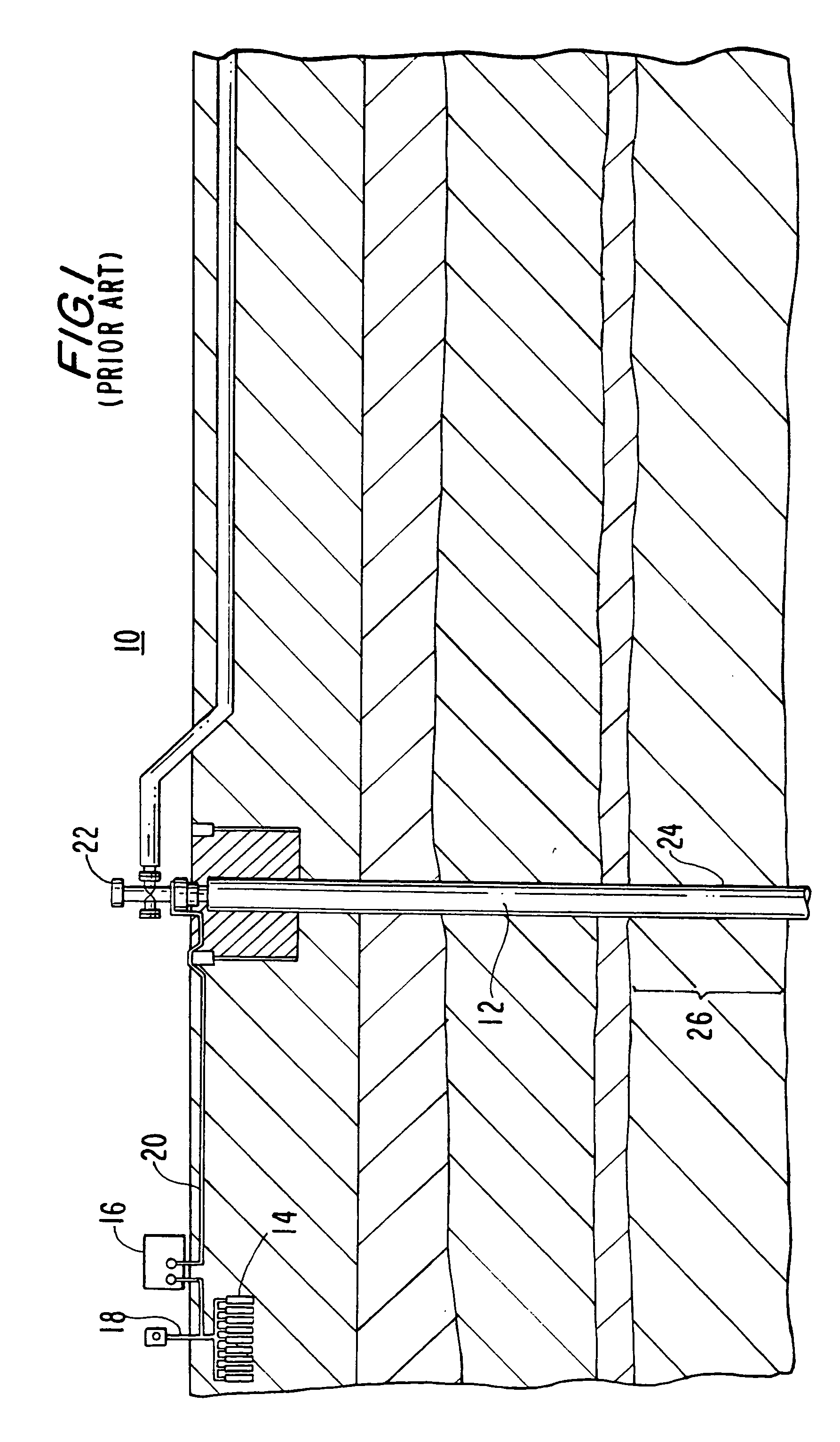

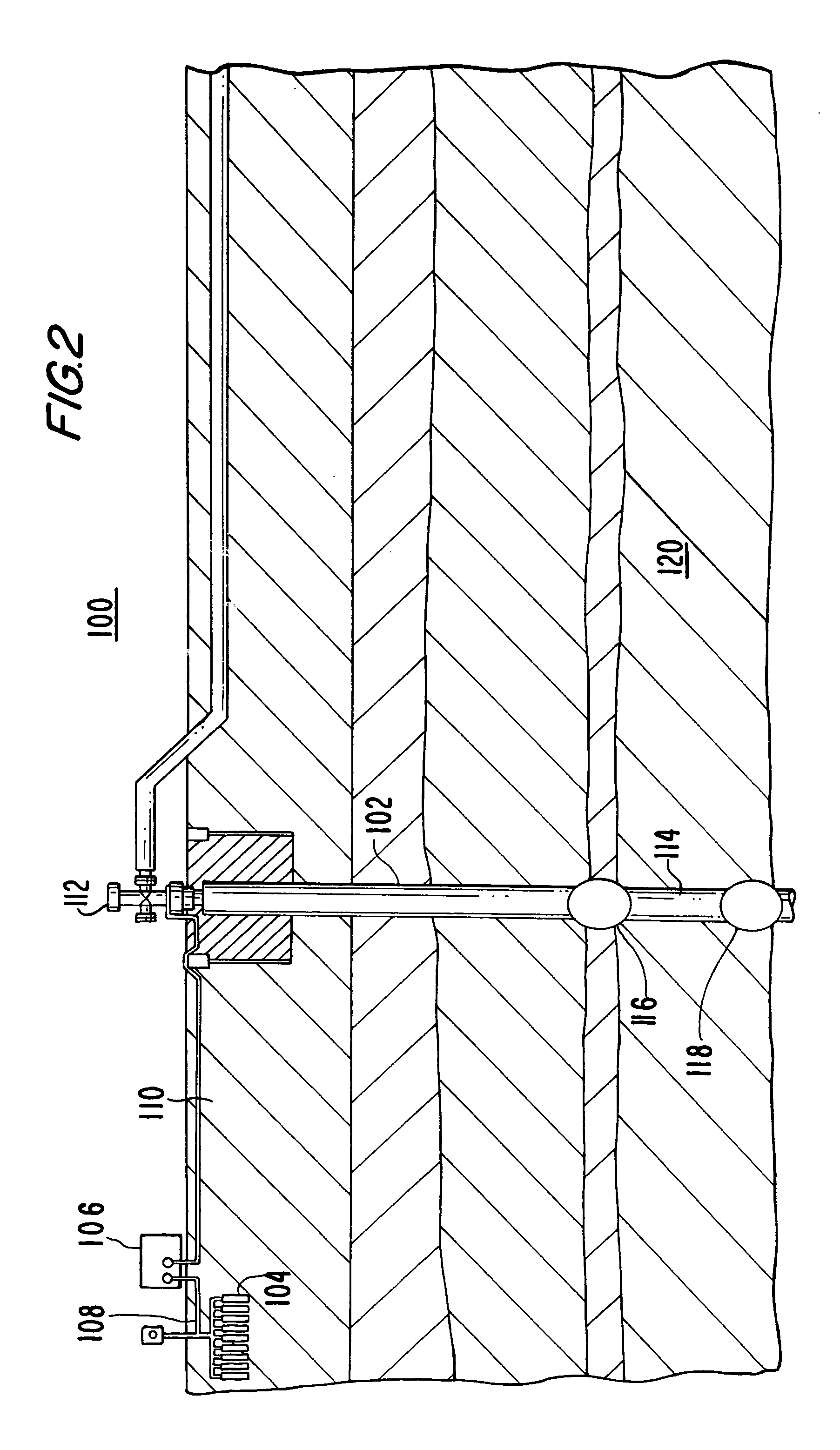

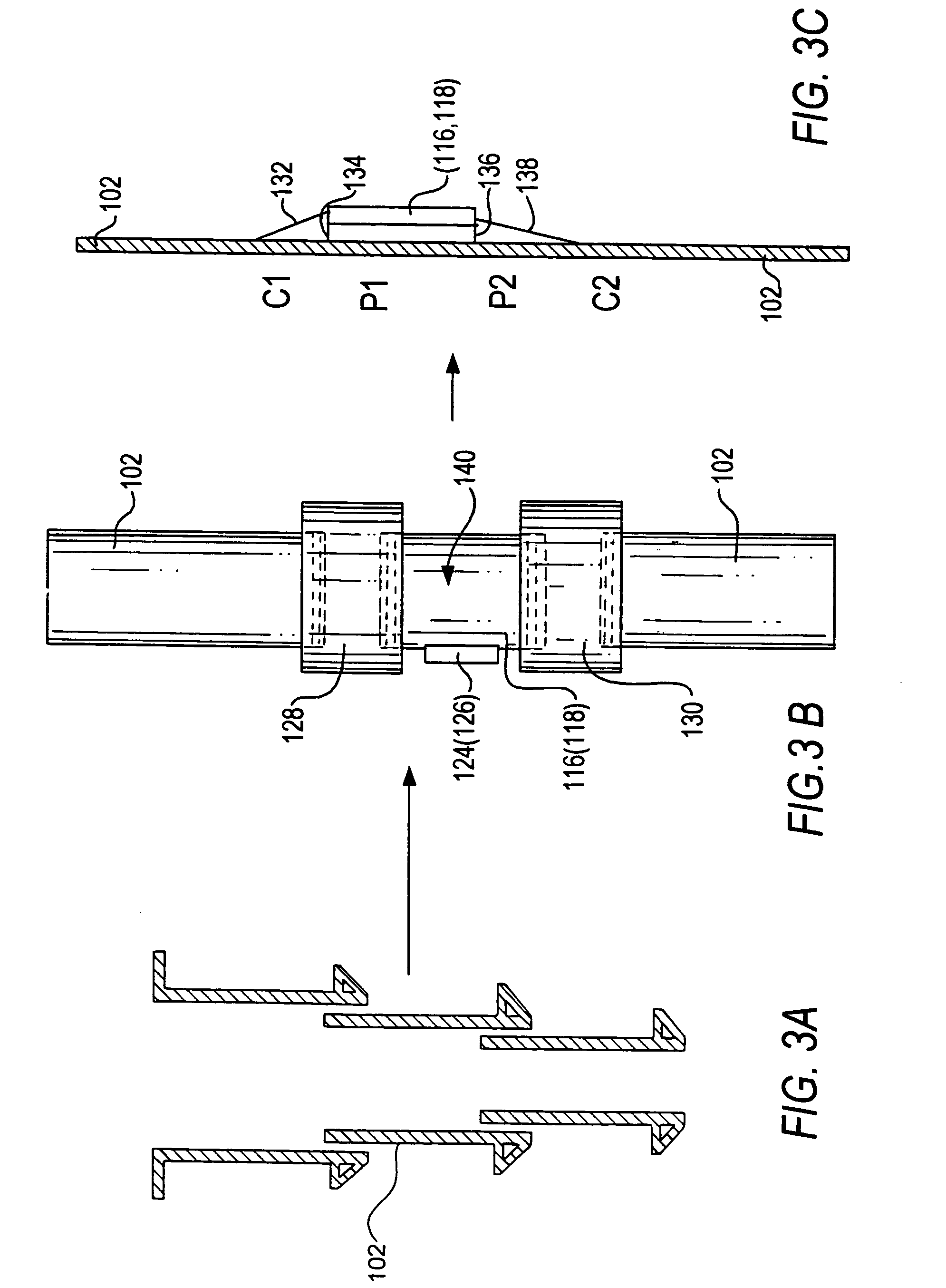

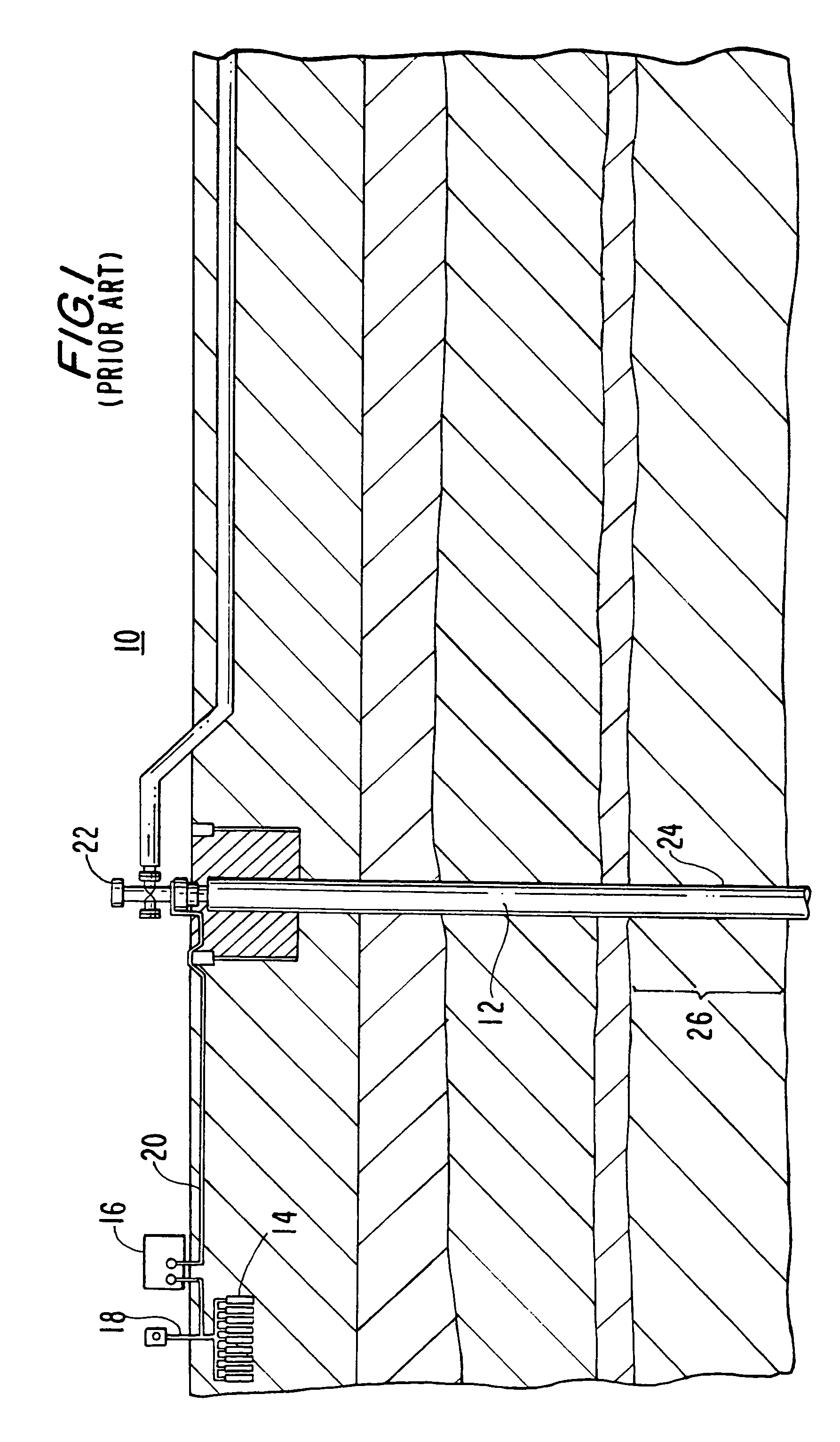

Method and apparatus for surveying a borehole with a rotating sensor package

ActiveUS20060106587A1Avoid it happening againEliminate currentComputation using non-denominational number representationSeismology for water-loggingSensor arrayEngineering

A method and apparatus for surveying a borehole using a rotating sensor package. A sensor tool preferably including a magnetometer sensor array is disposed in the bottom hole assembly of a drillstring. Conditioning circuitry in the sensor tool processes the sensor readings from the sensor array taken while the drillstring is rotating. In one embodiment, the conditioning circuitry includes processing circuitry adapted to adjust the sensor readings to account for an analytically predicted level of axial current induced in the drillstring as a result of its rotation in the Earth's magnetic field. In another embodiment, a current generator is provided to generate a counter-current intended to cancel the analytically predicted level of axial current induced in the drillstring as a result of rotation in the Earth's magnetic field. In another embodiment, insulating members are disposed above and / or below the sensor tool to prevent conduction of rotation-induced current therein. In still another embodiment, the sensor tool is disposed in a drill collar that is composed of a non-conducting material, such that no rotation-induced current is conducted through the sensor tool.

Owner:HALLIBURTON ENERGY SERVICES INC

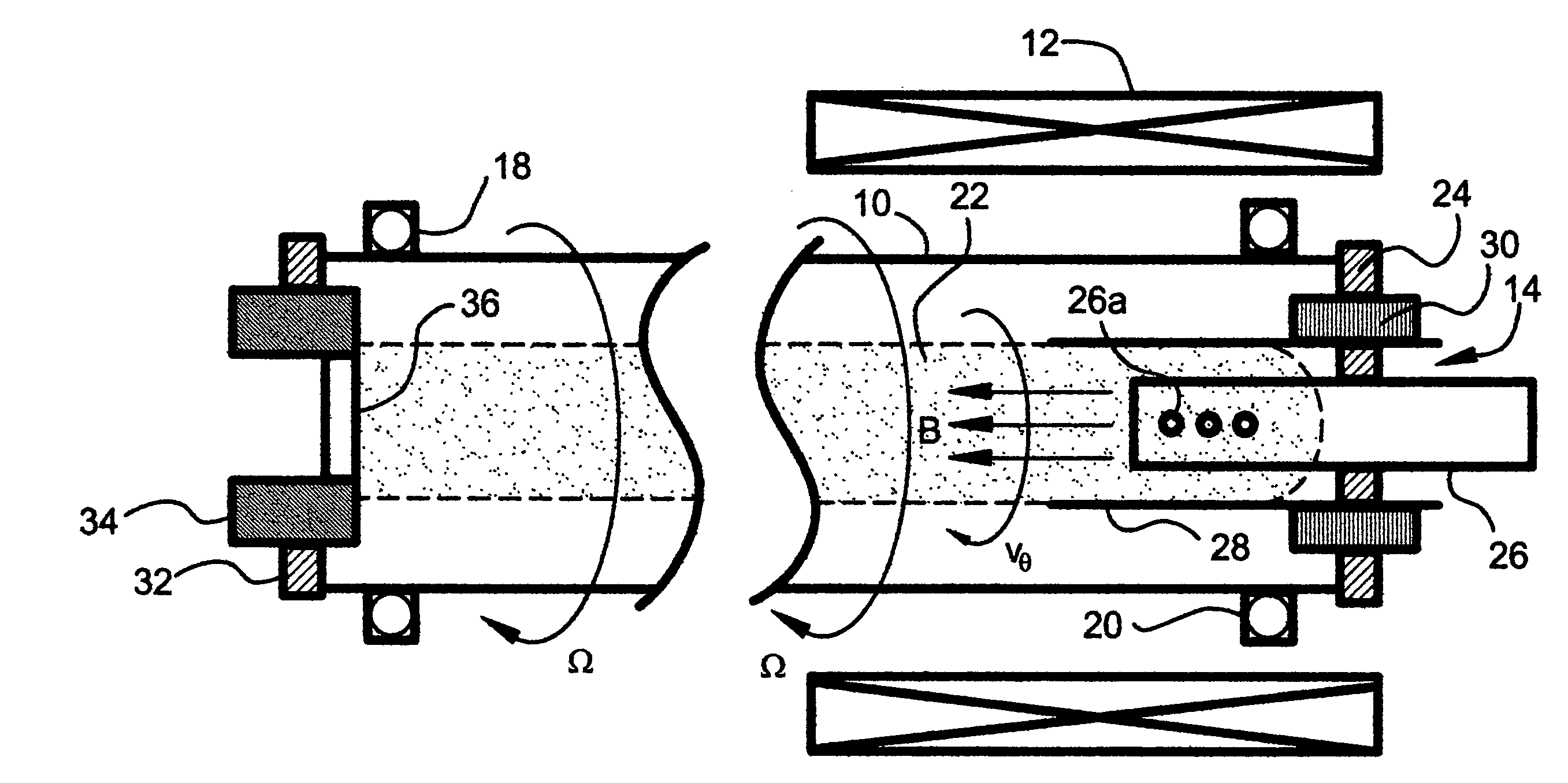

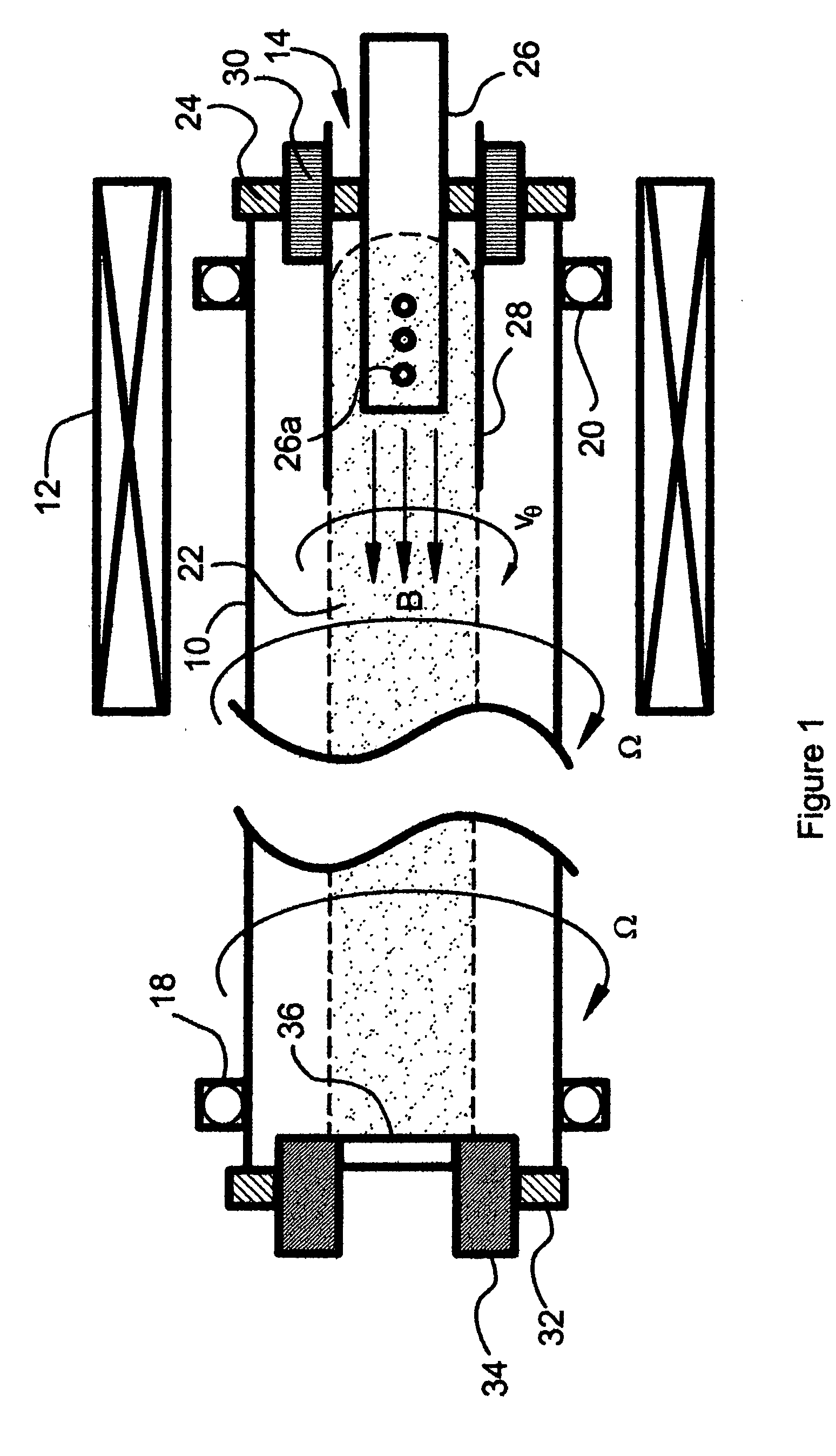

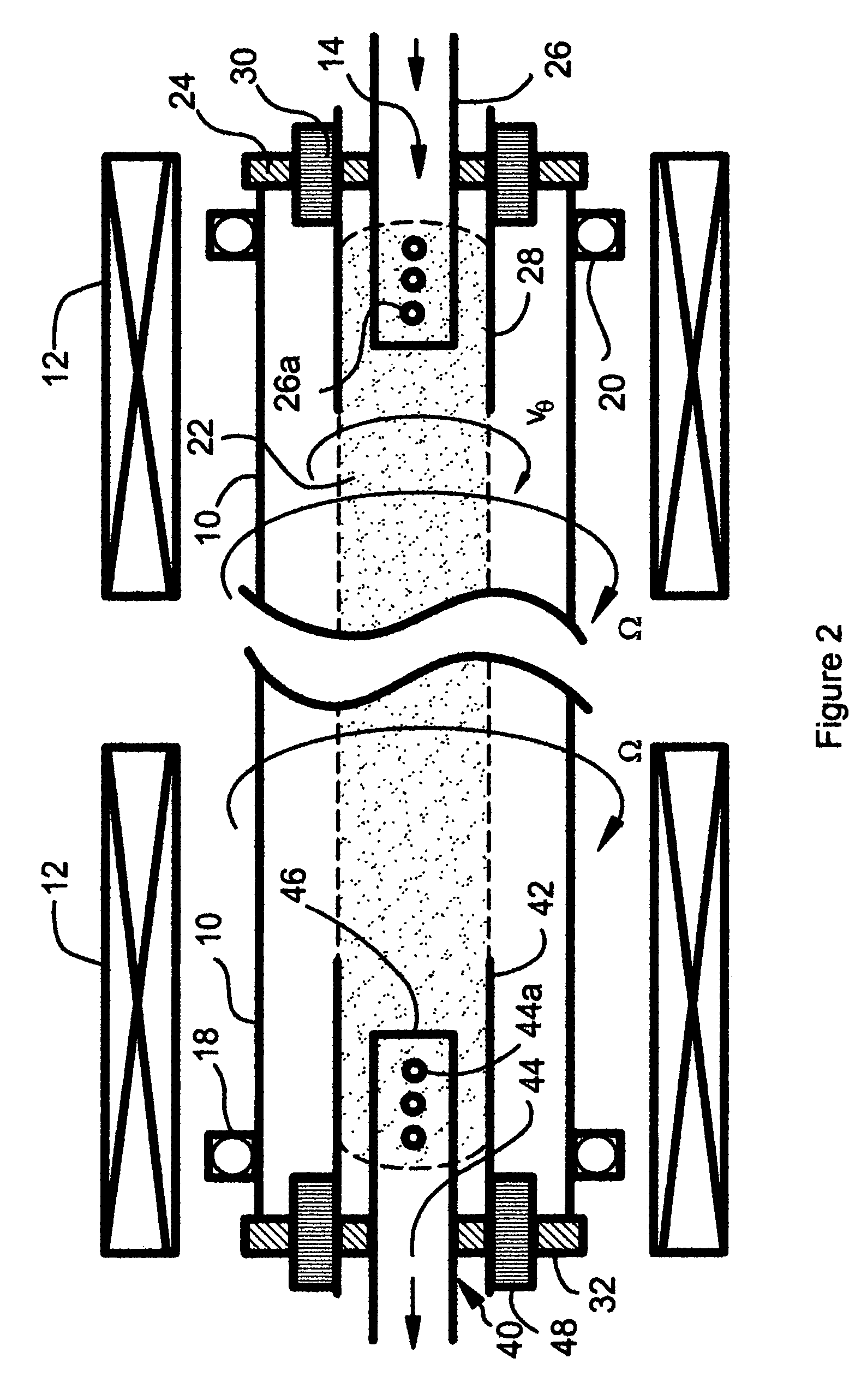

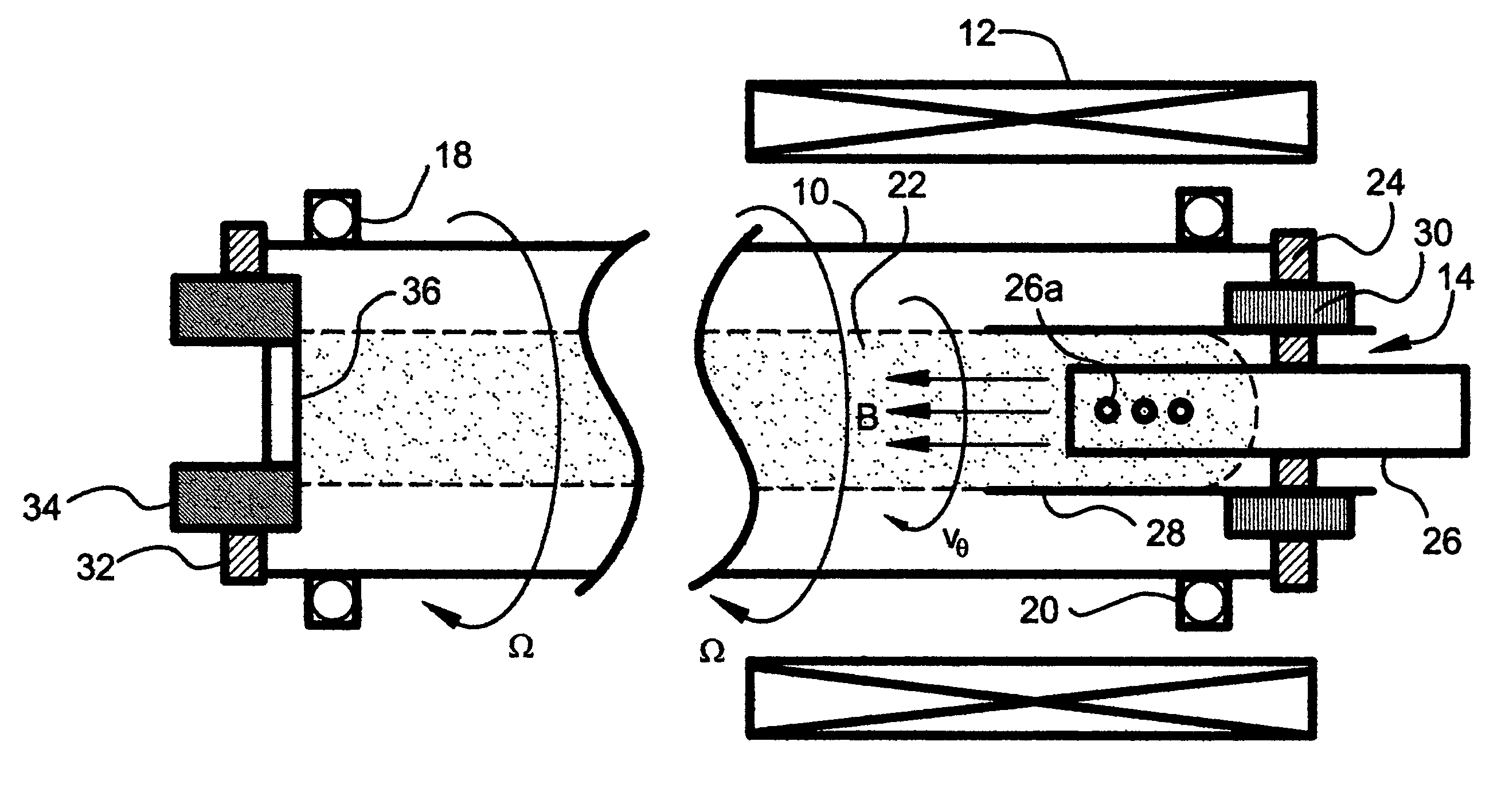

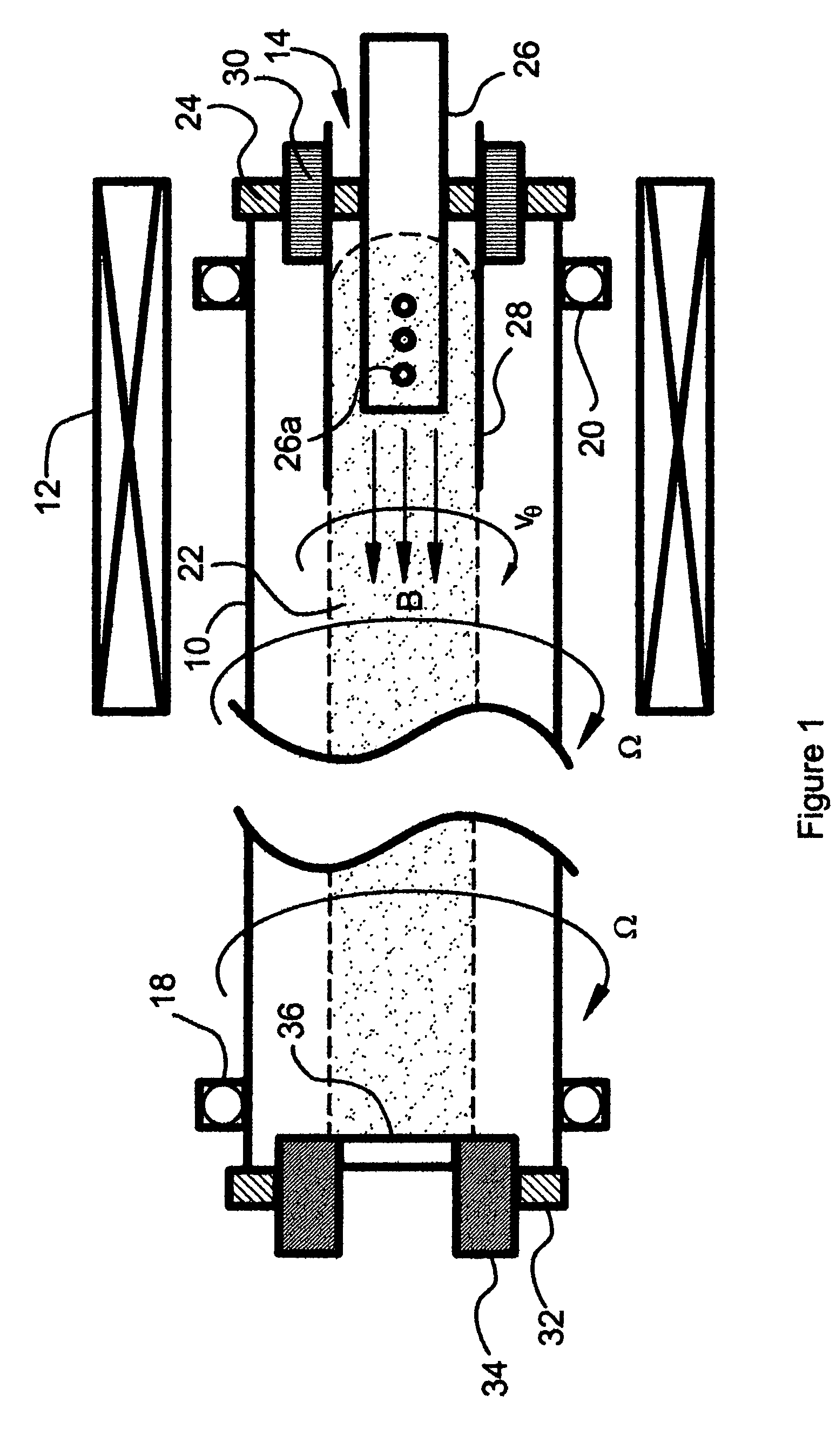

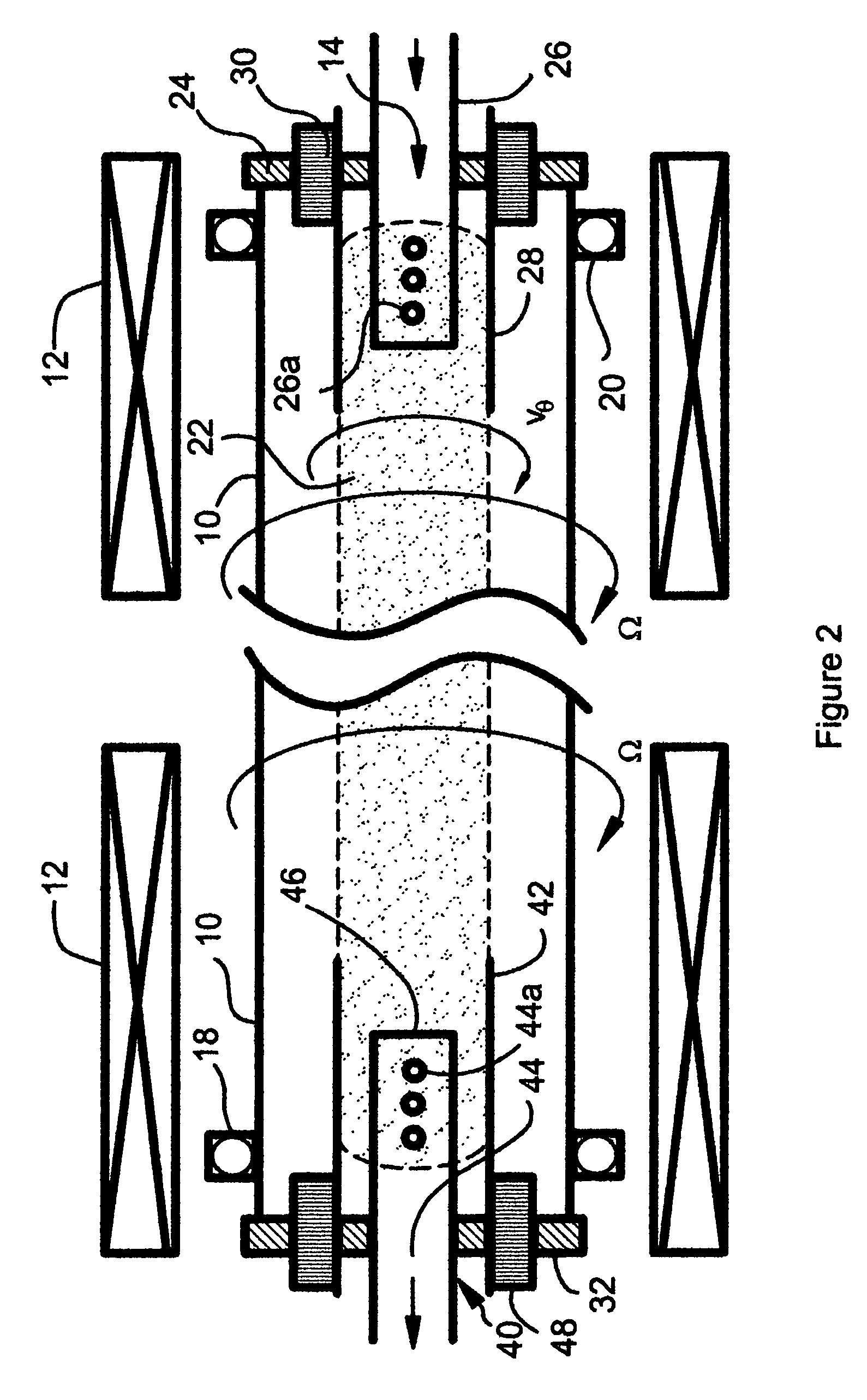

Soft x-ray laser based on Z-pinch compression of rotating plasma

InactiveUS20060232215A1Reduce light lossIncrease currentBeam/ray focussing/reflecting arrangementsBeam/ray deflecting arrangementsMagnetic tension forceVolumetric Mass Density

A method and apparatus for producing soft x-ray laser radiation based on z-pinch compression of a rotating low pressure plasma column are disclosed. A rotating, low pressure plasma column is created by electric discharge or by laser excitation inside a containment tube. Rotation of the plasma may be induced by viscous drag caused by rotation of the tube, or by magnetically driven rotation of the plasma as it is created in a plasma gun in the presence of an axial magnetic field, or both. A high power electrical discharge is then passed axially through the rotating plasma column to produce a rapidly rising axial current, resulting in z-pinch compression of the rotating plasma column radially inwardly with resultant stimulated emission of soft x-ray radiation in the axial direction. A rotating containment tube used in combination with magnetically driven rotation of the plasma column results in a concave electron density profile that in turn results in reduced wall ablation and also reduced refraction losses of the resultant soft x-rays.

Owner:FARTECH

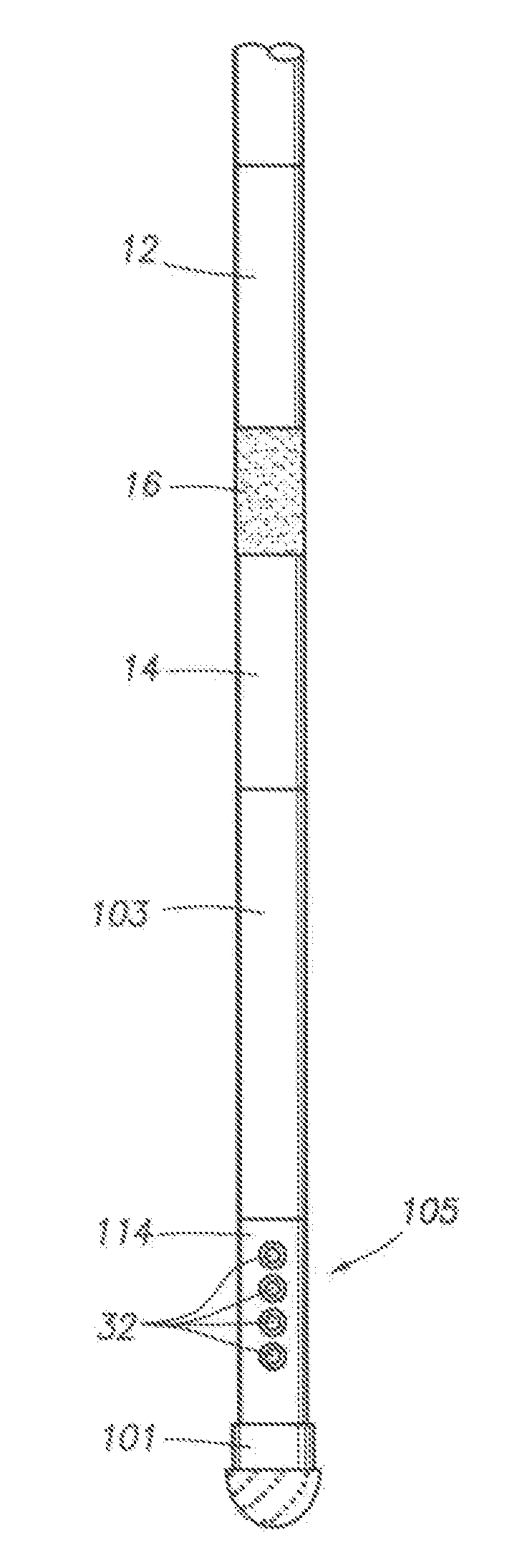

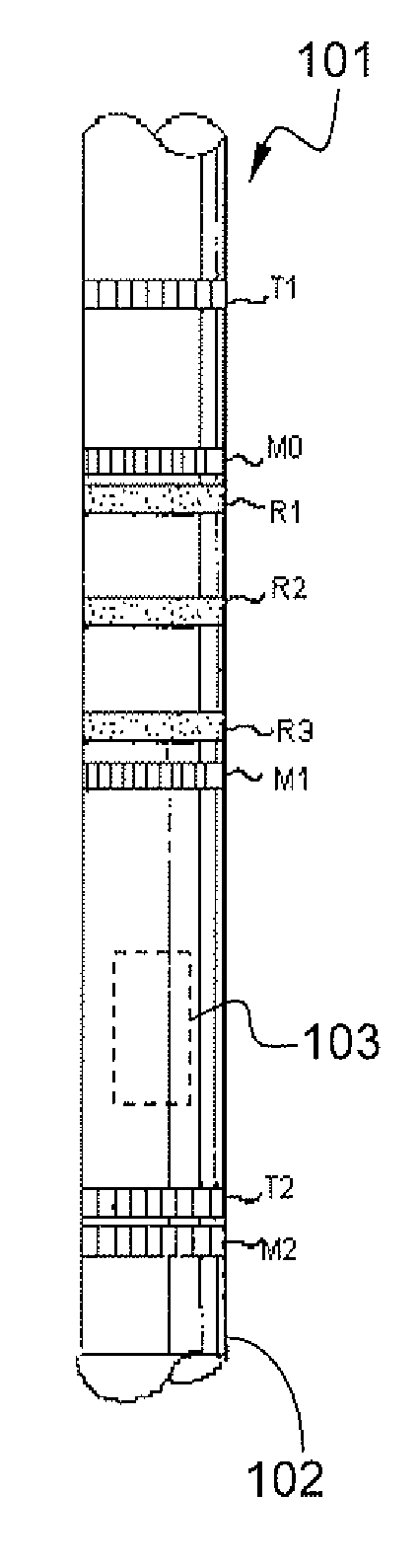

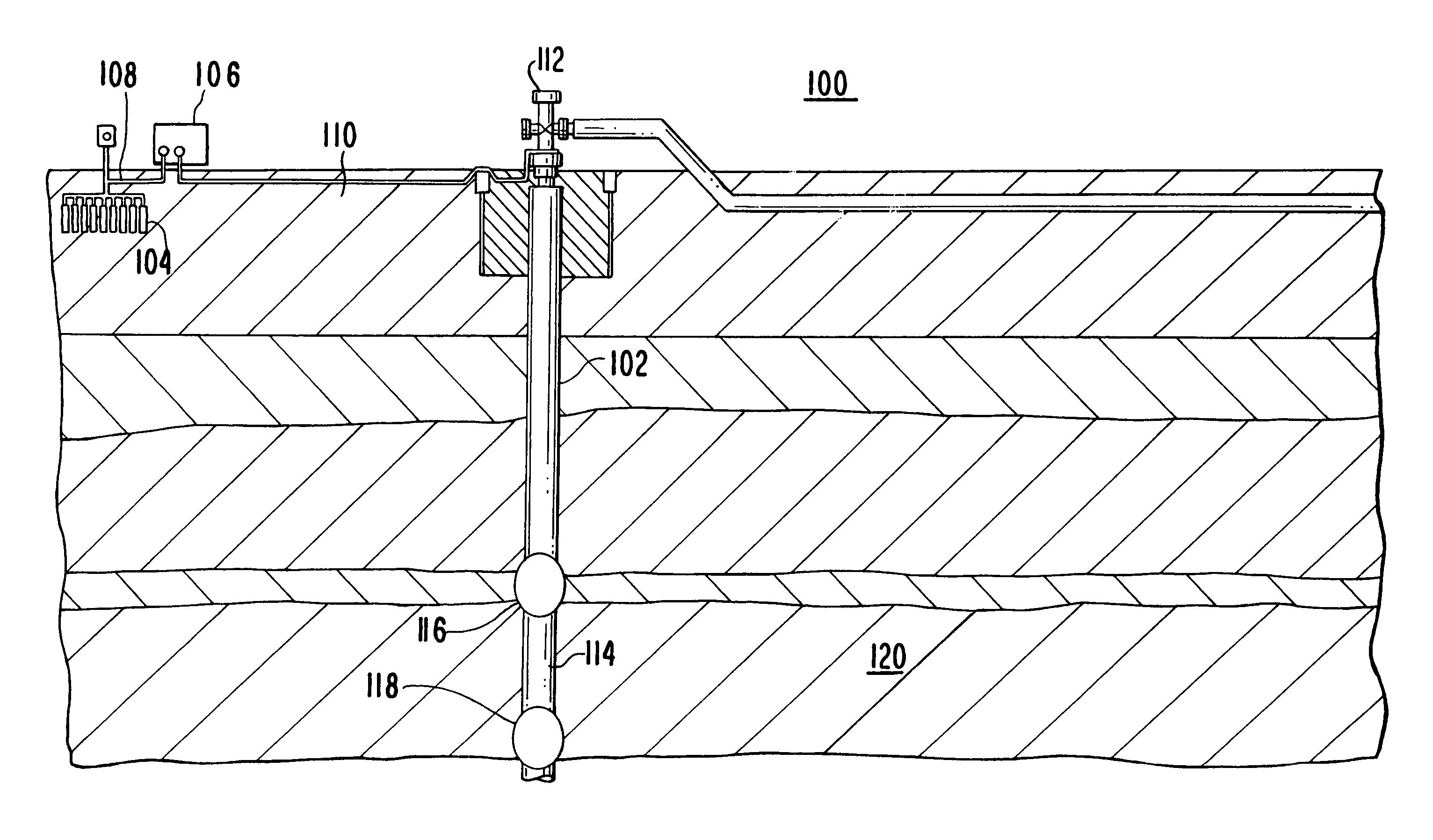

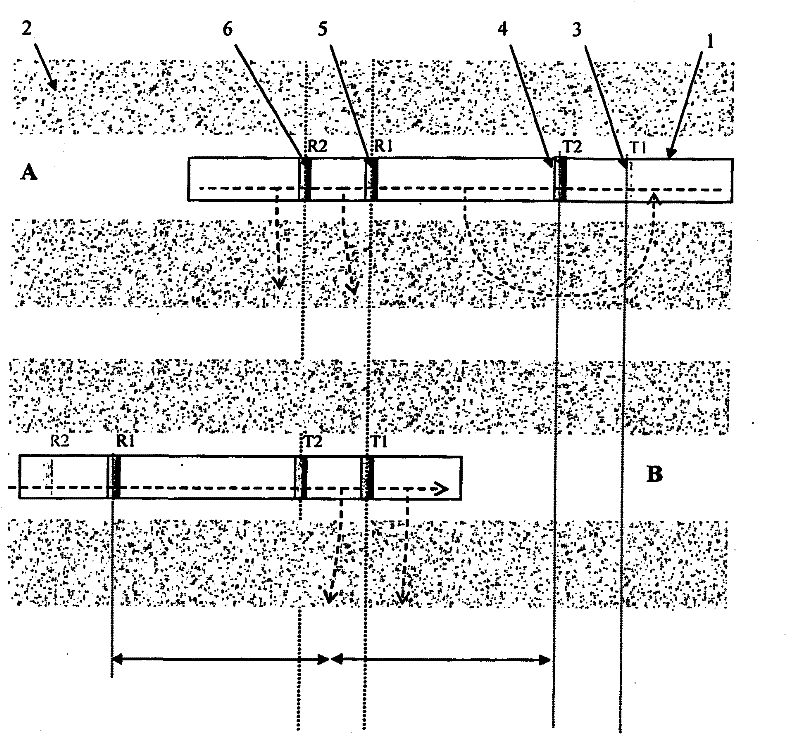

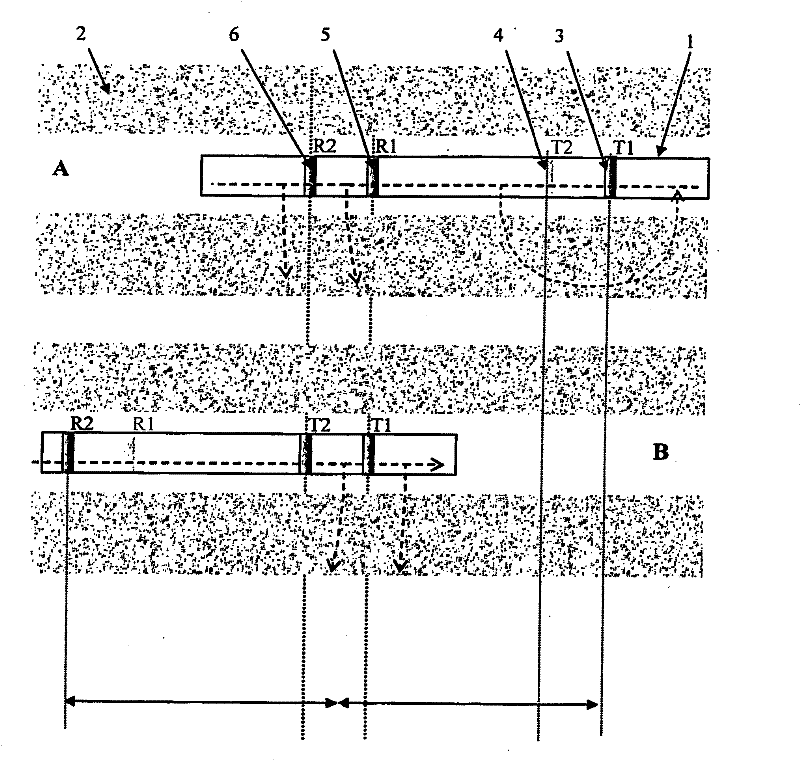

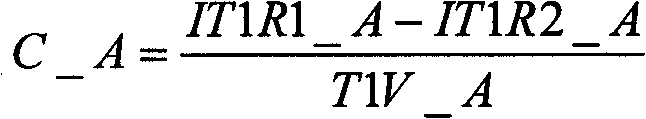

Apparatus and Method for Electrically Investigating a Borehole

InactiveUS20090066336A1Improve concentrationHigh resolutionElectric/magnetic detection for well-loggingSeismology for water-loggingElectricityCurrent sensor

An apparatus used in electrical investigation of geological formations GF surrounding a borehole BH, comprises:an electrically conductive body 102 movable through the borehole BH,at least one first transmitter T1 for inducing a first current from a first transmitter position and traveling in a path that includes a first portion of the body and a selected zone SZ of the geological formations GF,at least one second transmitter T2 for inducing a second current from a second position and traveling in a path that includes a second portion of the body and the selected zone SZ, the second transmitter T2 position being different from the first transmitter T1 position on the body,at least a first M0, second M1 and third M2 axial current sensors for measuring a first, a second and a third axial current flowing along the body, respectively, the first, second and third axial current sensor position on the body being different from each other, andat least one lateral current sensor R2 disposed on the body for measuring a first electrical signal resulting from the first current and a second electrical signal resulting from the second current.The apparatus further comprises:a virtual axial current sensor providing a virtual axial current measurement by interpolating or extrapolating two axial current measurements made at different positions which are not adjacent to the lateral current sensor, andan electronic module 103 for deriving an indication of the resistivity or conductivity of the selected zone SZ based on the measured first electrical signal, second electrical signal, axial currents and the calculated virtual axial current.

Owner:SCHLUMBERGER TECH CORP

Soft x-ray laser based on z-pinch compression of rotating plasma

InactiveUS7679027B2Increase currentImprove uniformityBeam/ray focussing/reflecting arrangementsBeam/ray deflecting arrangementsElectric dischargeStimulated emission

A method and apparatus for producing soft x-ray laser radiation. A low pressure plasma column is created by electric discharge or by laser excitation inside a rotating containment tube. Rotation of the plasma is induced by viscous drag caused by rotation of the tube, or by magnetically driven rotation of the plasma as it is created in a plasma gun in the presence of an axial magnetic field, or both. A high power electrical discharge is then passed axially through the rotating plasma column to produce a rapidly rising axial current, resulting in z-pinch compression of the rotating plasma column, with resultant stimulated emission of soft x-ray radiation in the axial direction. A rotating containment tube used in combination with magnetically driven rotation of the plasma column results in a concave electron density profile that results in reduced wall ablation and also reduced refraction losses of the soft x-rays.

Owner:FARTECH

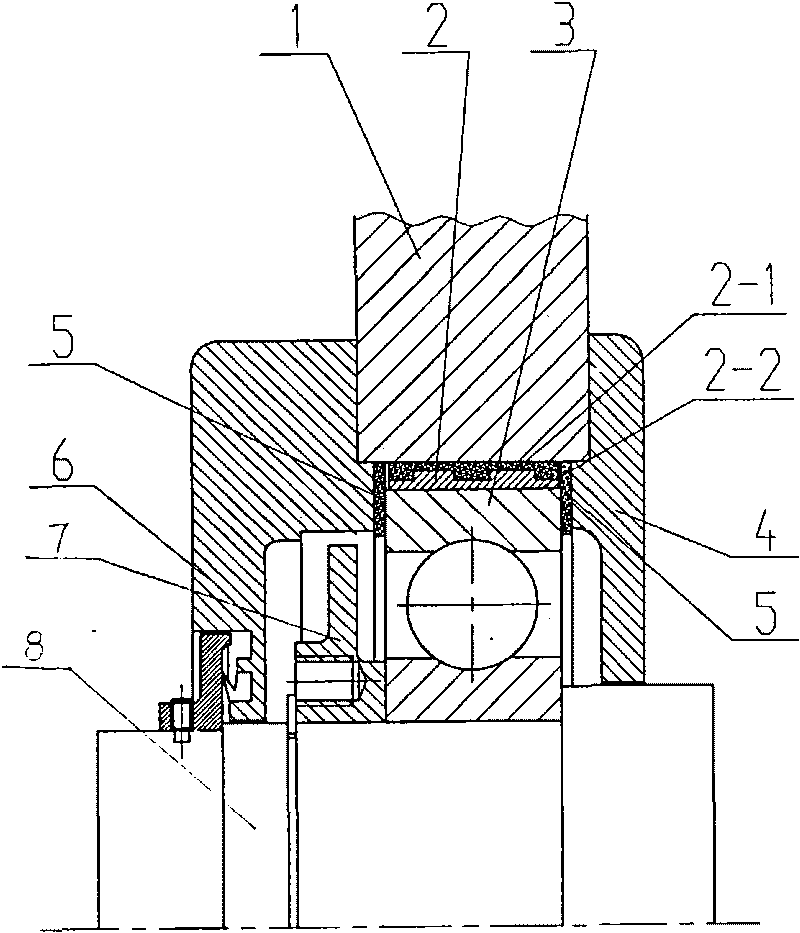

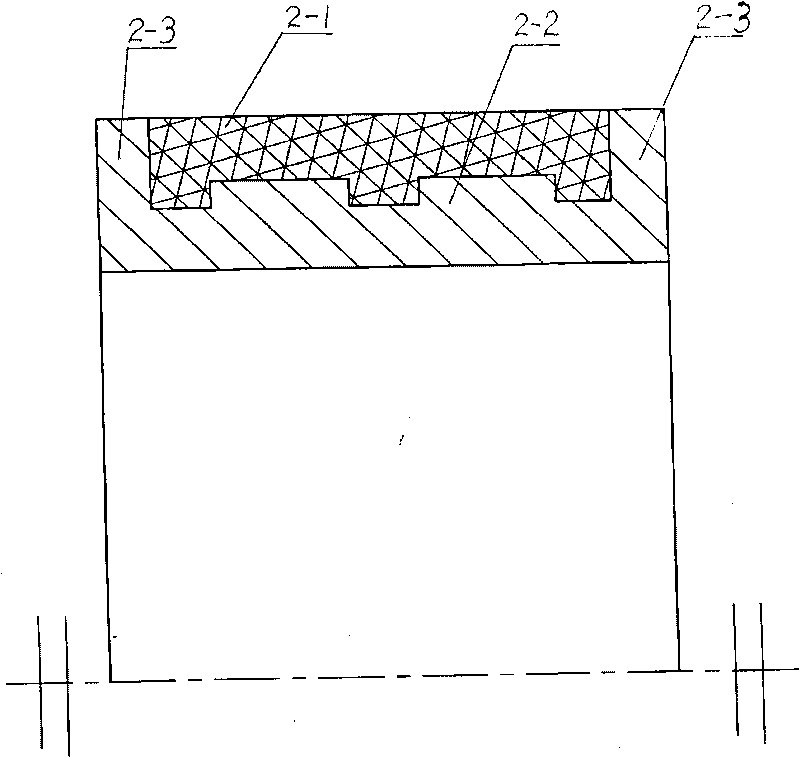

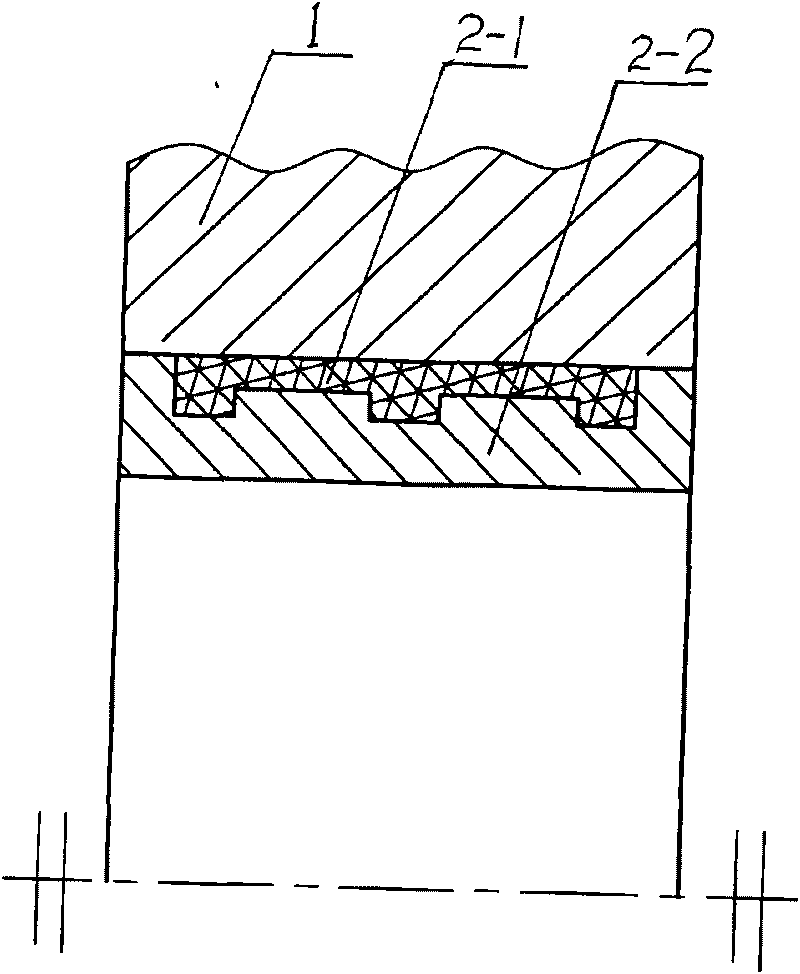

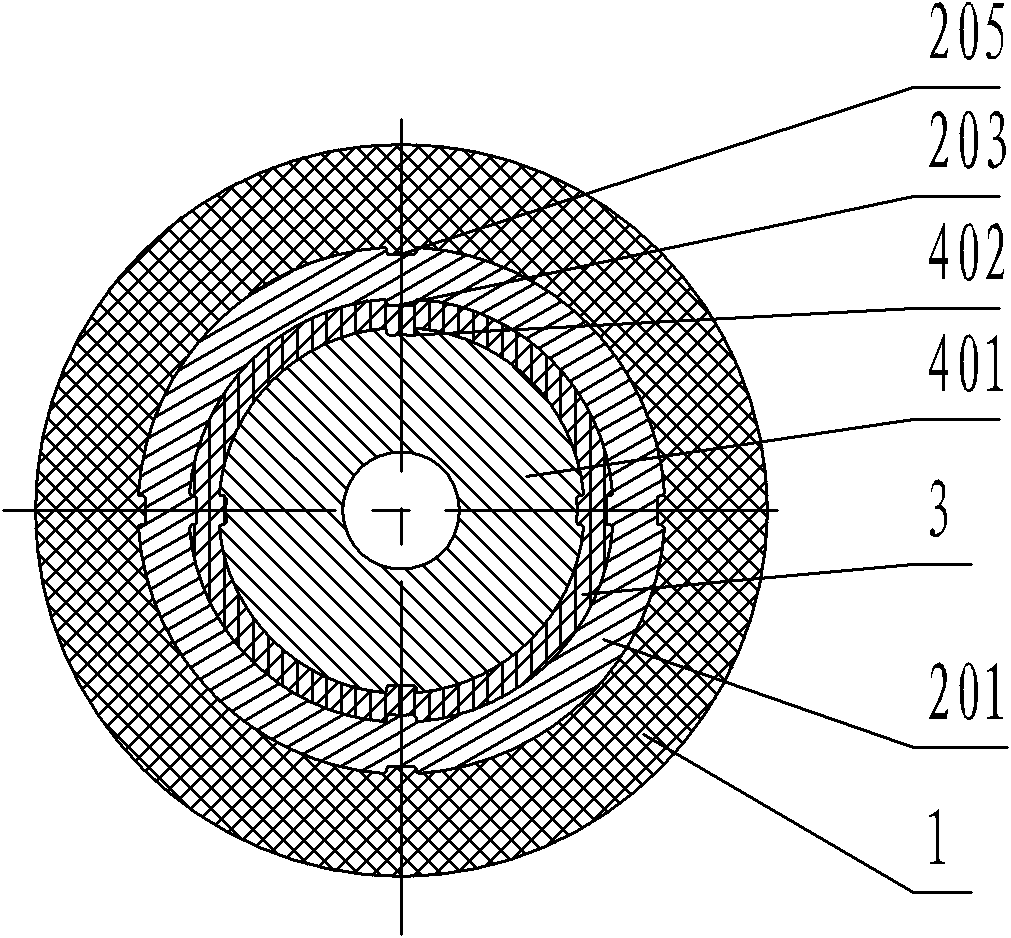

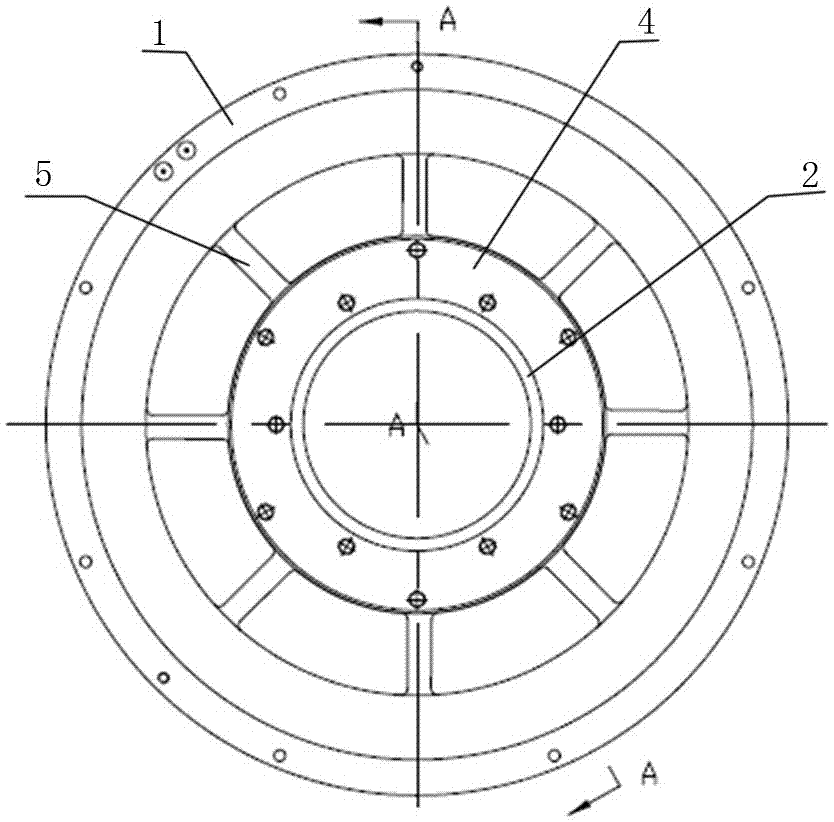

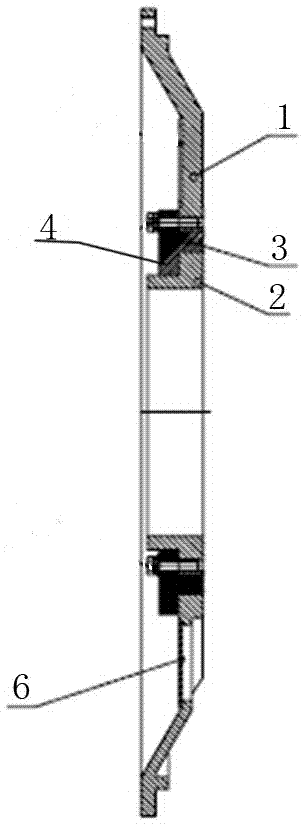

Motor insulating bearing device and manufacturing method thereof

InactiveCN101692590AGuaranteed uptimeExtended service lifeSupports/enclosures/casingsMotor insulationEngineering

The invention relates to a motor insulating bearing device and a manufacturing method thereof. The bearing device is characterized in that an insulating bushing is positioned at a circumference part between a bearing pedestal and a motor bearing, insulating space rings are arranged between the end of the insulating bushing and the motor bearing and an outer bearing cover and between the end thereof and an inner bearing cover, and a gap is left between the insulating space ring and the insulating bushing. The motor insulating bearing device is manufactured by a unique method, the formation of rotor axial current loop is prevented effectively and the electric corrosion damage of the motor bearing is avoided, thereby ensuring the reliable operation of the motor, prolonging the service life of the motor and decreasing the reactive power loss of the electric energy at the same time; the motor insulating bearing device has the advantages of reasonable structure design, reliable operational performance and convenient installation and maintenance, etc.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

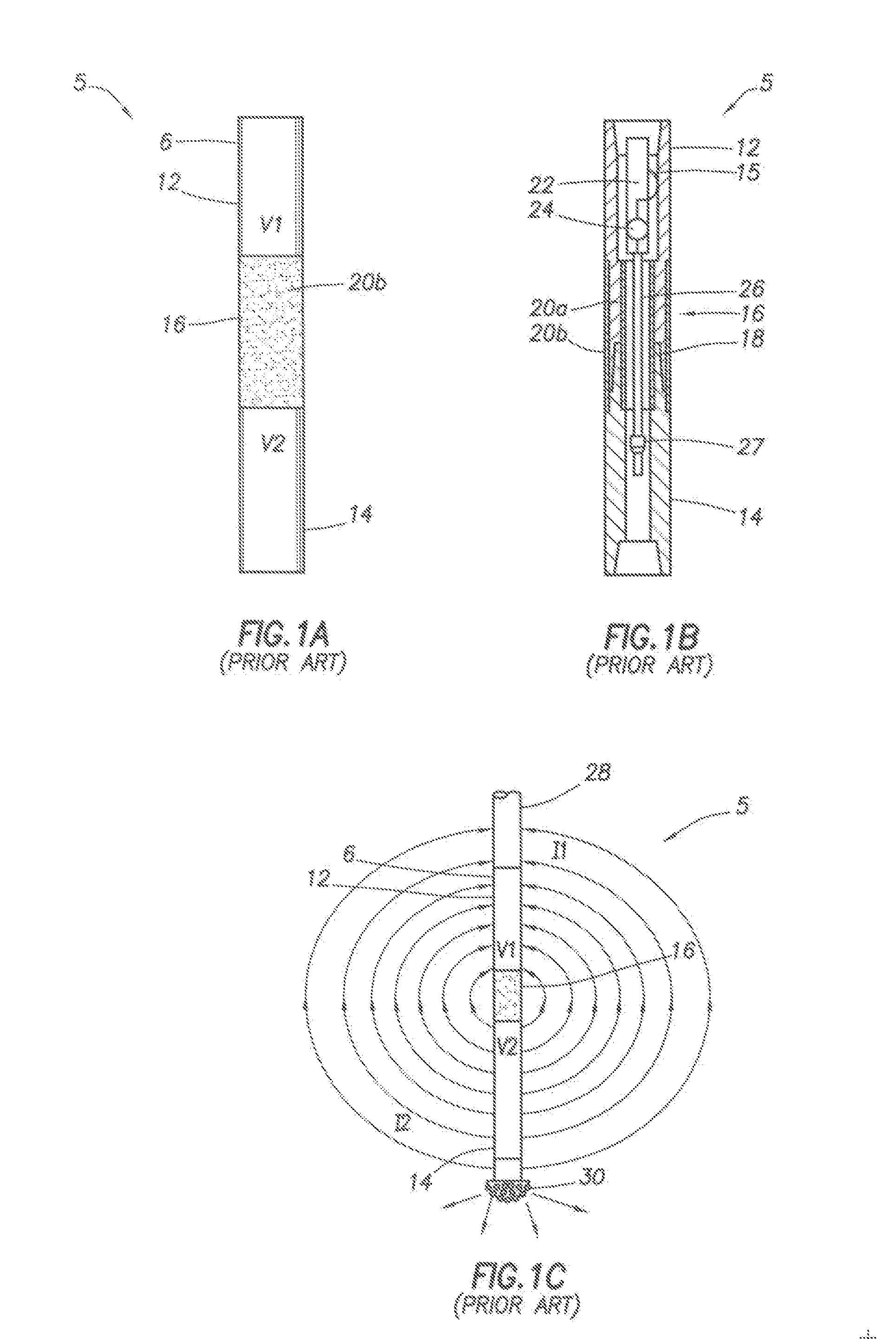

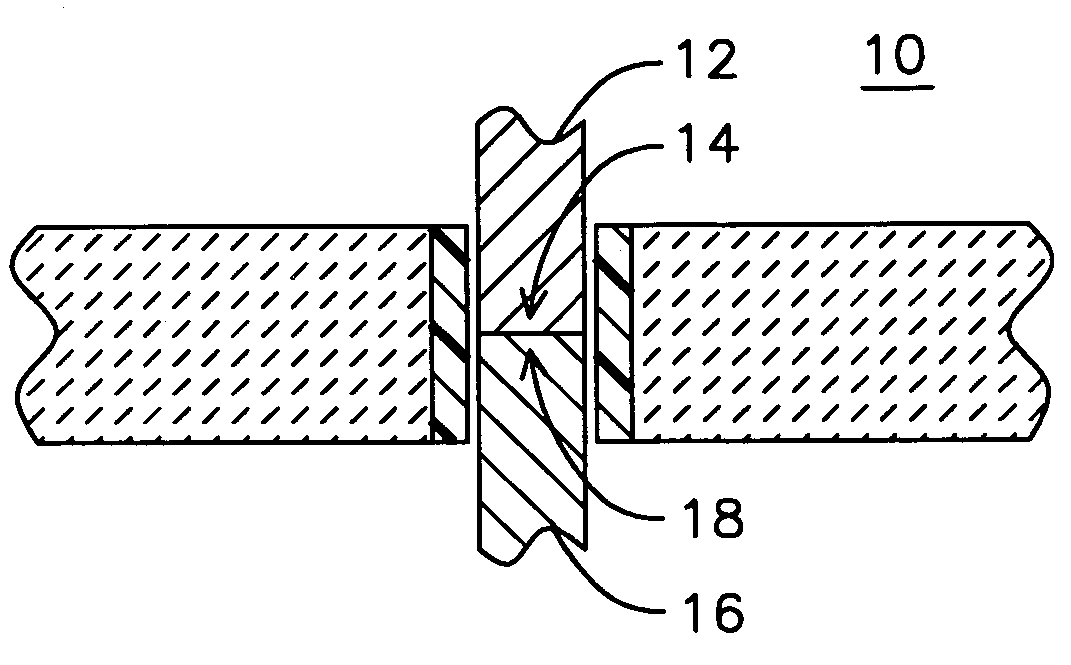

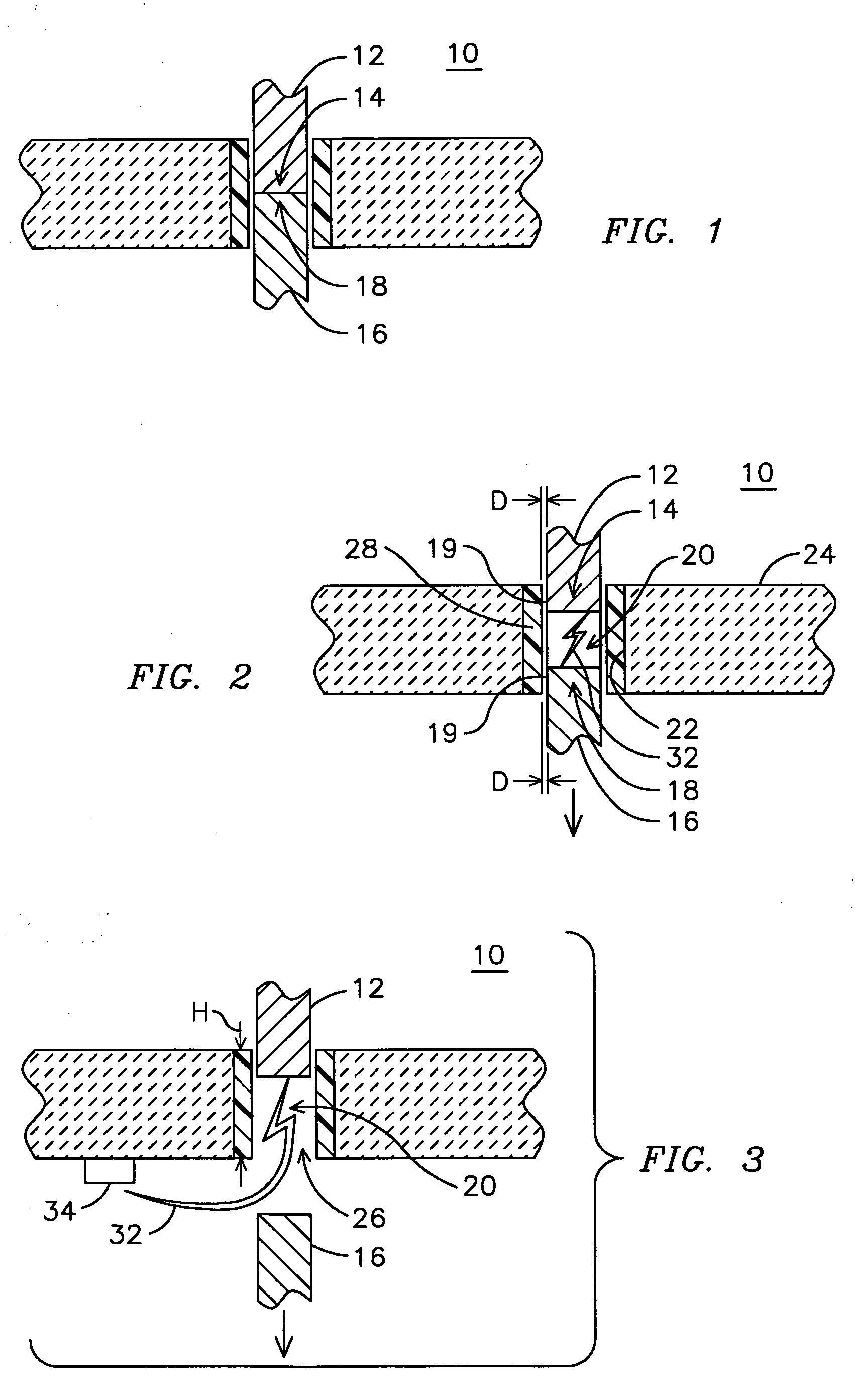

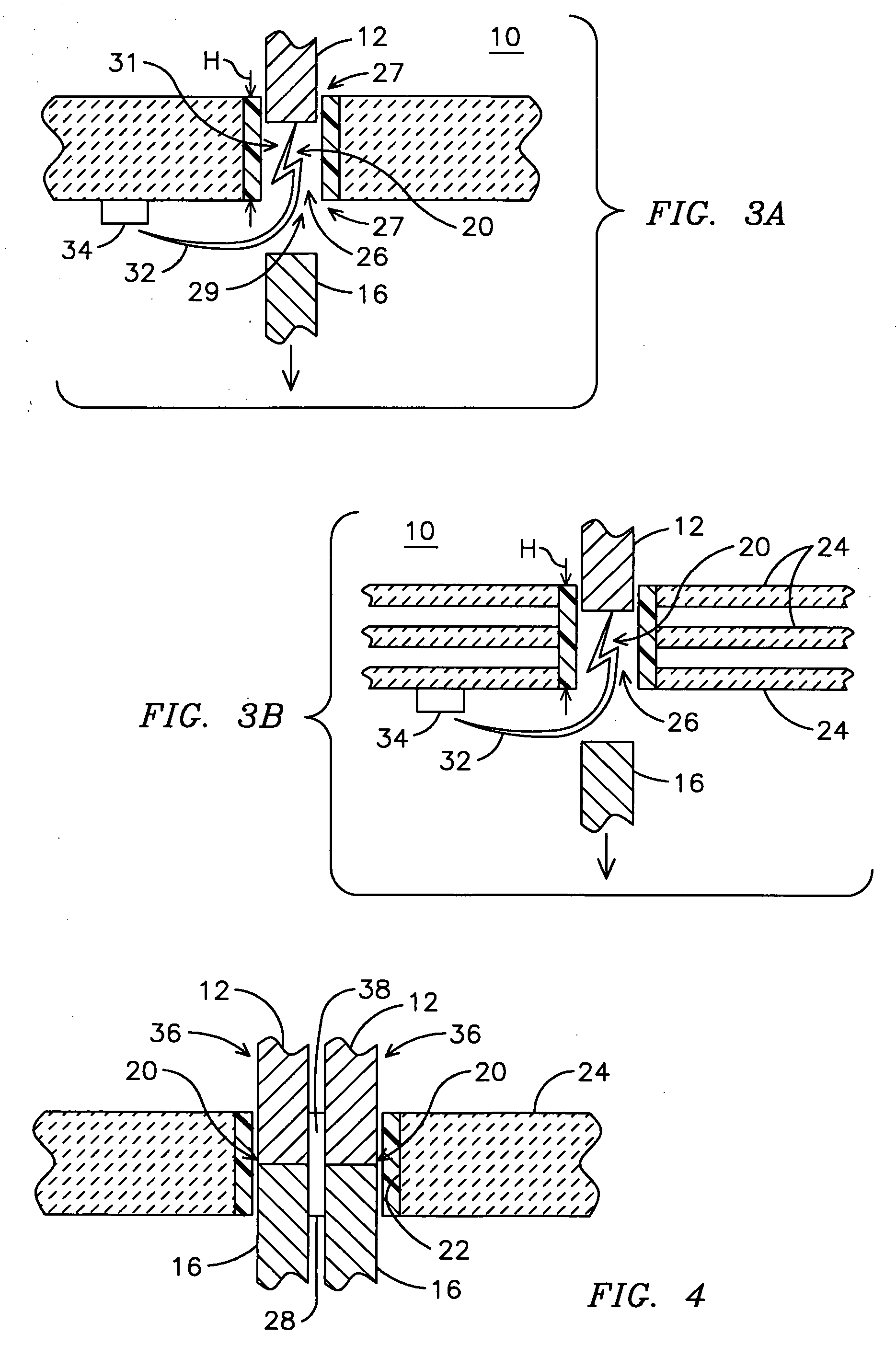

Axial current interrupter

InactiveUS20070119819A1High-tension/heavy-dress switchesAir-break switchesAxial currentElectrical current

An apparatus (e.g., 12) for interrupting an electrical current between two contacts includes a first contact (12) and a second contact (16). The first and second contacts are separable away from one another to interrupt an electrical current flowing between the contacts. An arc constrictive zone (20) may be disposed around the contacts confining an arc (32) generated between the contacts during a separation of the contacts. An ablative material (28) may be disposed in the arc restrictive zone to be ablated by the arc to form a vapor for cooling the arc and producing an increased pressure in the restrictive zone responsive to the arc to force separation of the contacts.

Owner:GENERAL ELECTRIC CO

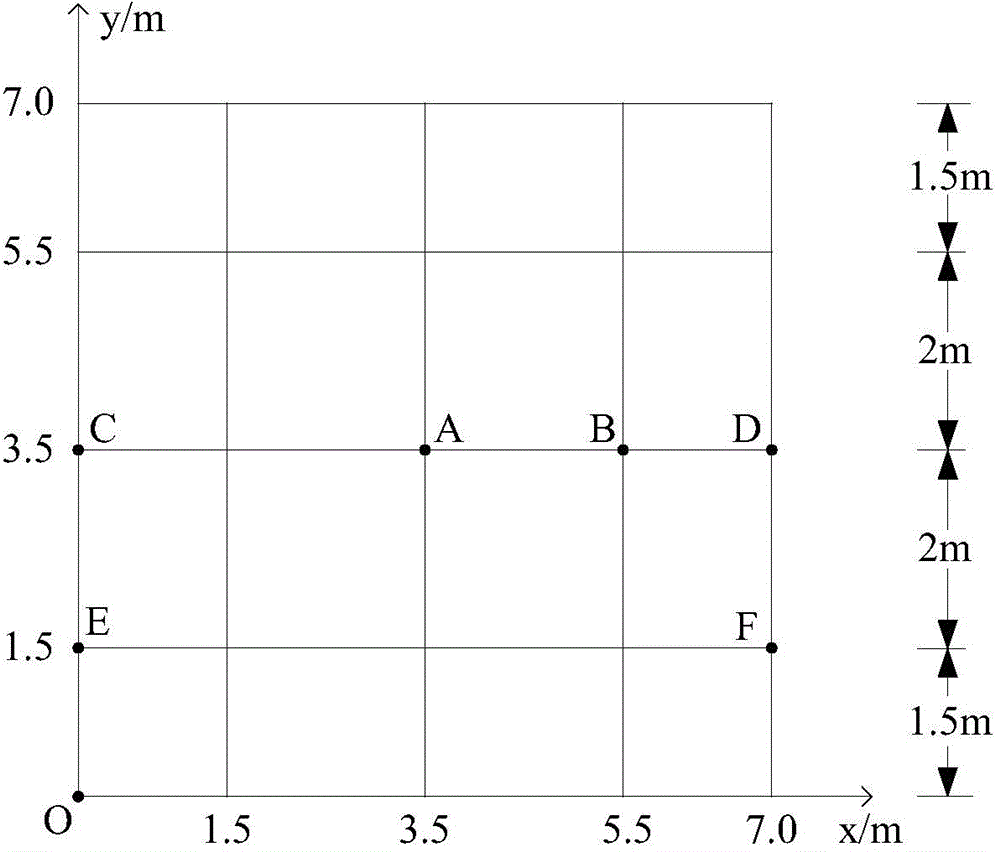

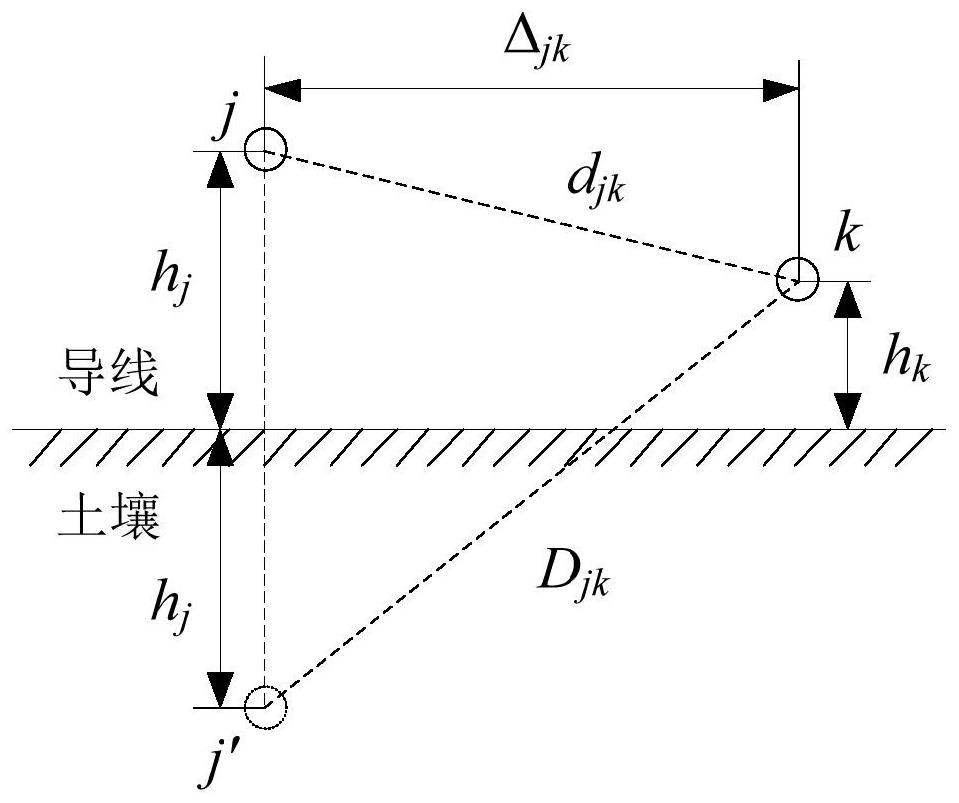

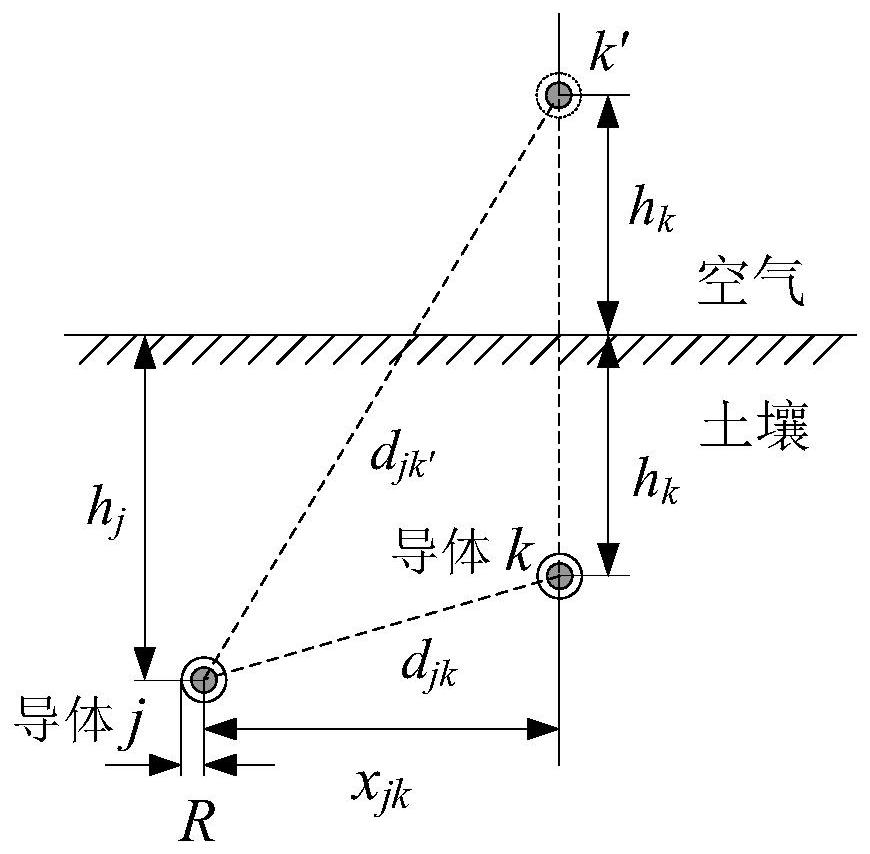

Transformer station grounding network corrosion diagnosis method based on magnetic field inverse problem solving

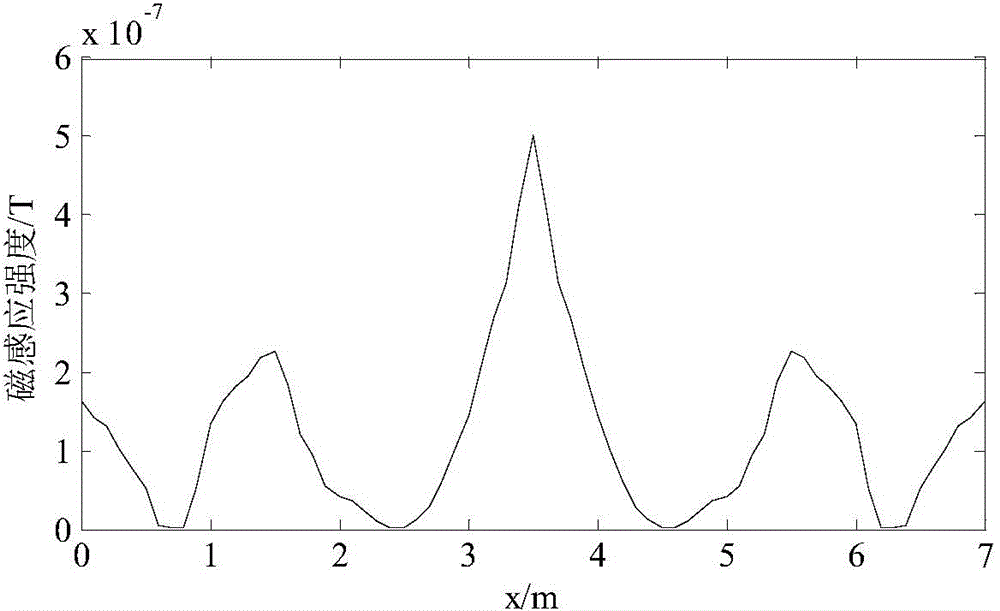

InactiveCN104897996AAccurate judgmentReduce on-site testing workloadFault locationElectrical conductorTransformer

The invention relates to a transformer station grounding network corrosion diagnosis method based on magnetic field inverse problem solving, which comprises the following steps: calculating a theoretical ground surface magnetic induction strength of a transformer station grounding network according to a number calculation method; inputting an AC excitation current into the transformer station grounding network, sensing a ground surface magnetic field by a detecting coil along the upper part of the grounding network, and acquiring an induction voltage signal by a data acquisition device; calculating magnetic induction strengths at n measuring points according to the acquired induction voltage signal; according to the magnetic induction strengths at the n measuring points, calculating the axial current of n conduction segments of the grounding network by means of a Tikhonov regularization algorithm; obtaining an actual calculation result for the ground surface magnetic induction strength of the grounding network; and comparing the actual ground surface magnetic induction strength of the grounding network with the ground surface magnetic induction strength which is obtained through calculation under a normal working condition. Compared with the prior art, the transformer station grounding network corrosion diagnosis method has advantages such as improving operation reliability of the transformer station grounding network.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

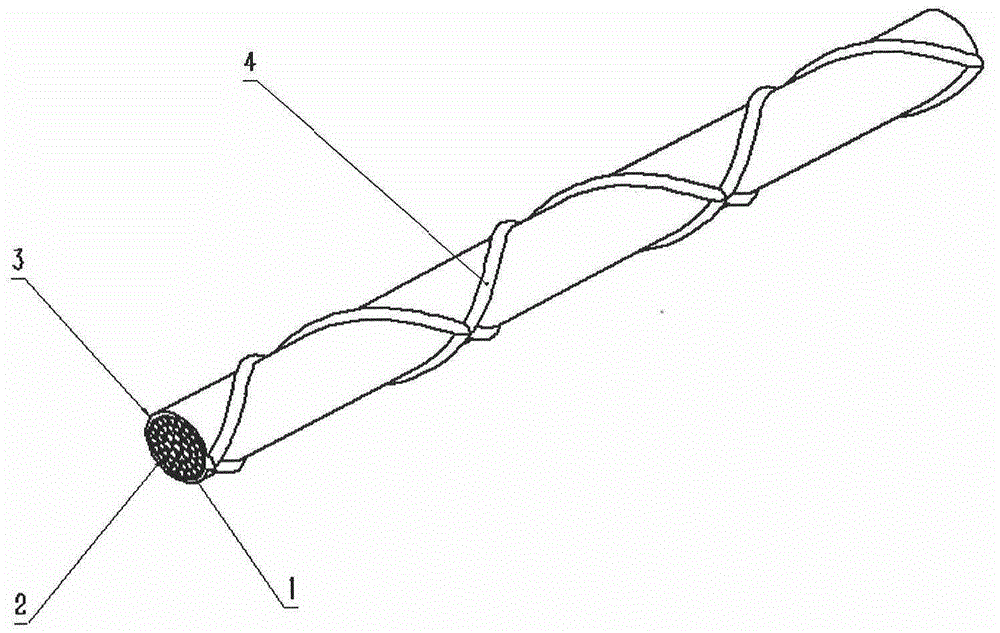

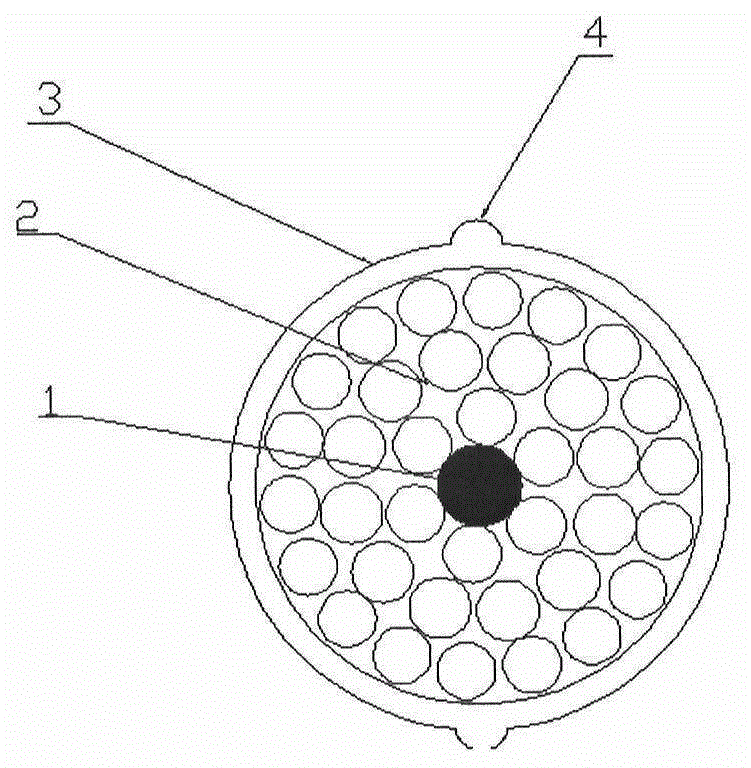

Device inhibiting transmission lines from wind-rain induced vibration and galloping

InactiveCN104836184AReduce the impactInhibition of gallopingDevices for damping mechanical oscillationsActive forceAxial current

The invention relates to a device inhibiting transmission lines from wind-rain induced vibration and galloping. The device is composed of central transmission lines and a surface sheath. The device is characterized in that the surface of the surface sheath includes two spiral projections in two opposite directions. The bidirectional spiral projections can change separation points of an air flow field at the boundary layer of the surface of the transmission lines, and avoids ruled Kaman vortex shedding; the projections in the opposite directions can destroy axial current eddy formed in the axial direction of the lines, change 3D structure of the cross section of the lines, reduce influence of pneumatic active force on lines, and inhibit the lines from galloping; and the bidirectional spiral destroys a waterway in which rainwater flows downwardly along the surface of the lines, prevents formation of continuous water lines, avoids the water lines from oscillation at the surface of the lead, and avoids the lines from wind-rain induced vibration.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Axial current meter for in-situ continuous monitoring of corrosion and cathodic protection current

InactiveUS20050178673A1Avoid corrosionWeather/light/corrosion resistanceVolume/mass flow measurementCurrent meterEngineering

First and second axial current meters (ACM) are mechanically connected to a well casing just above and below a corrosive zone and a master axial current meter (MACM) is connected to the casing at the earth's surface, the MACM periodically obtaining measurements of axial current from the ACMs to determine how much cathodic protection current is to be applied to the casing to avoid corrosion.

Owner:SAUDI ARABIAN OIL CO

Speed sensorless starting method for synchronization motor

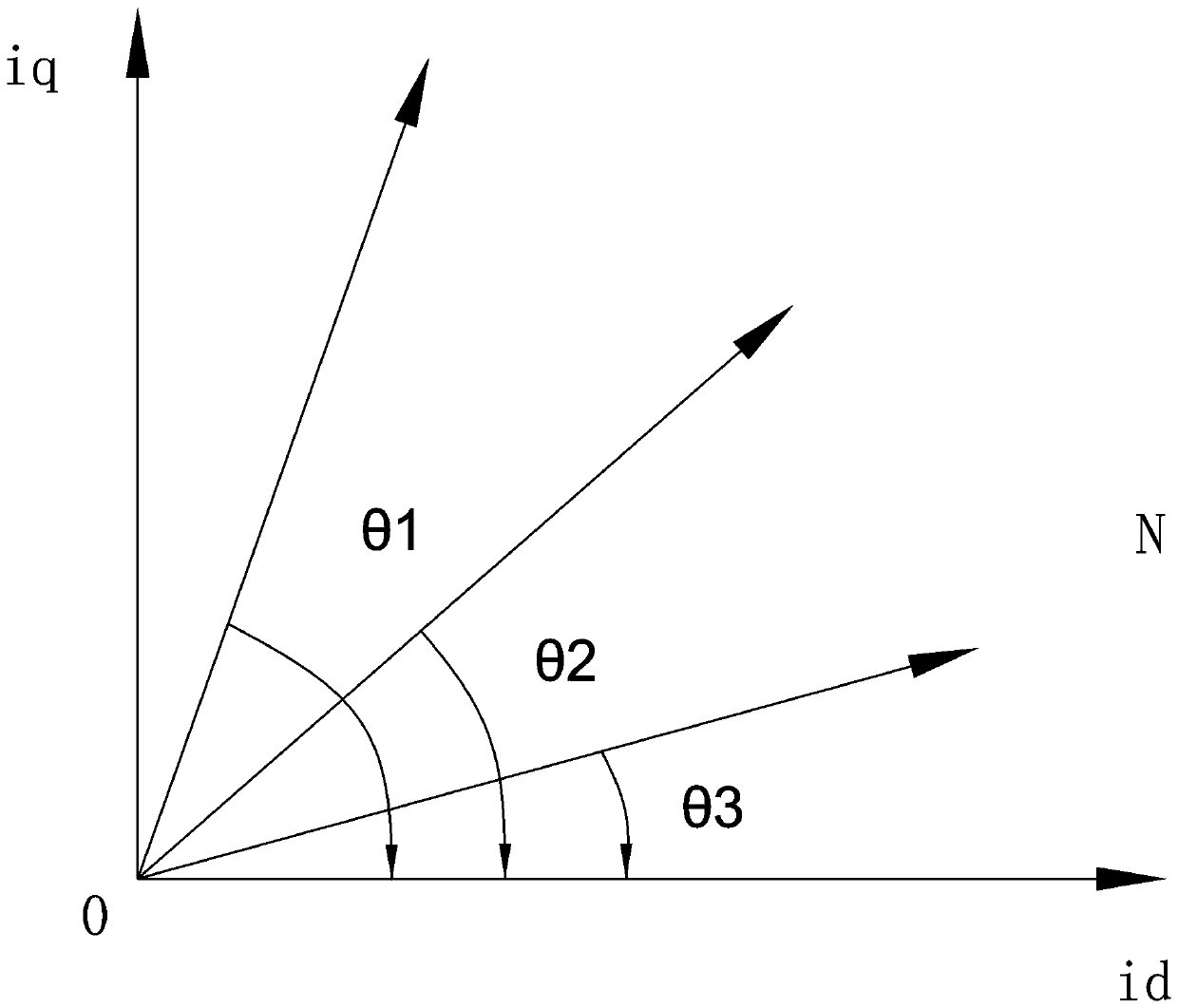

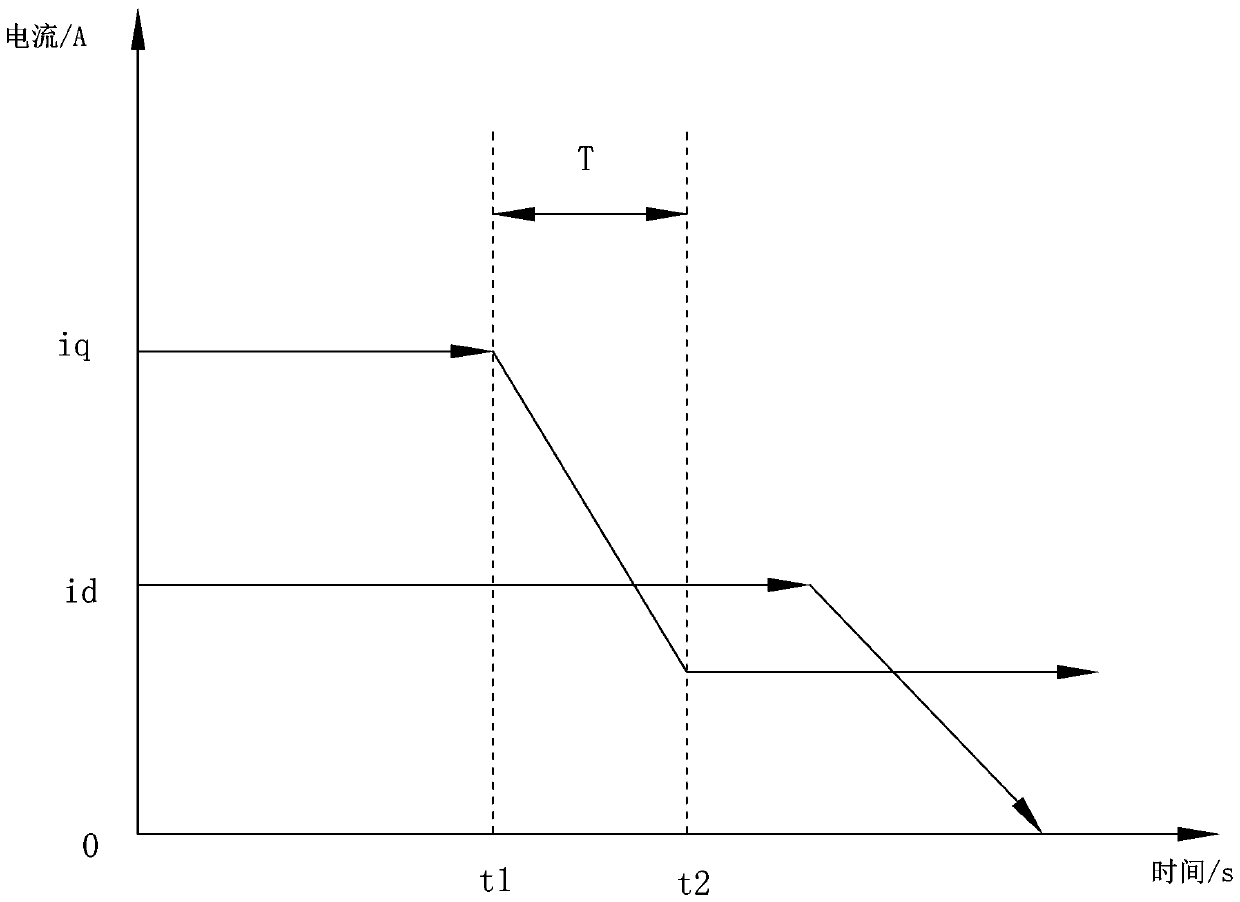

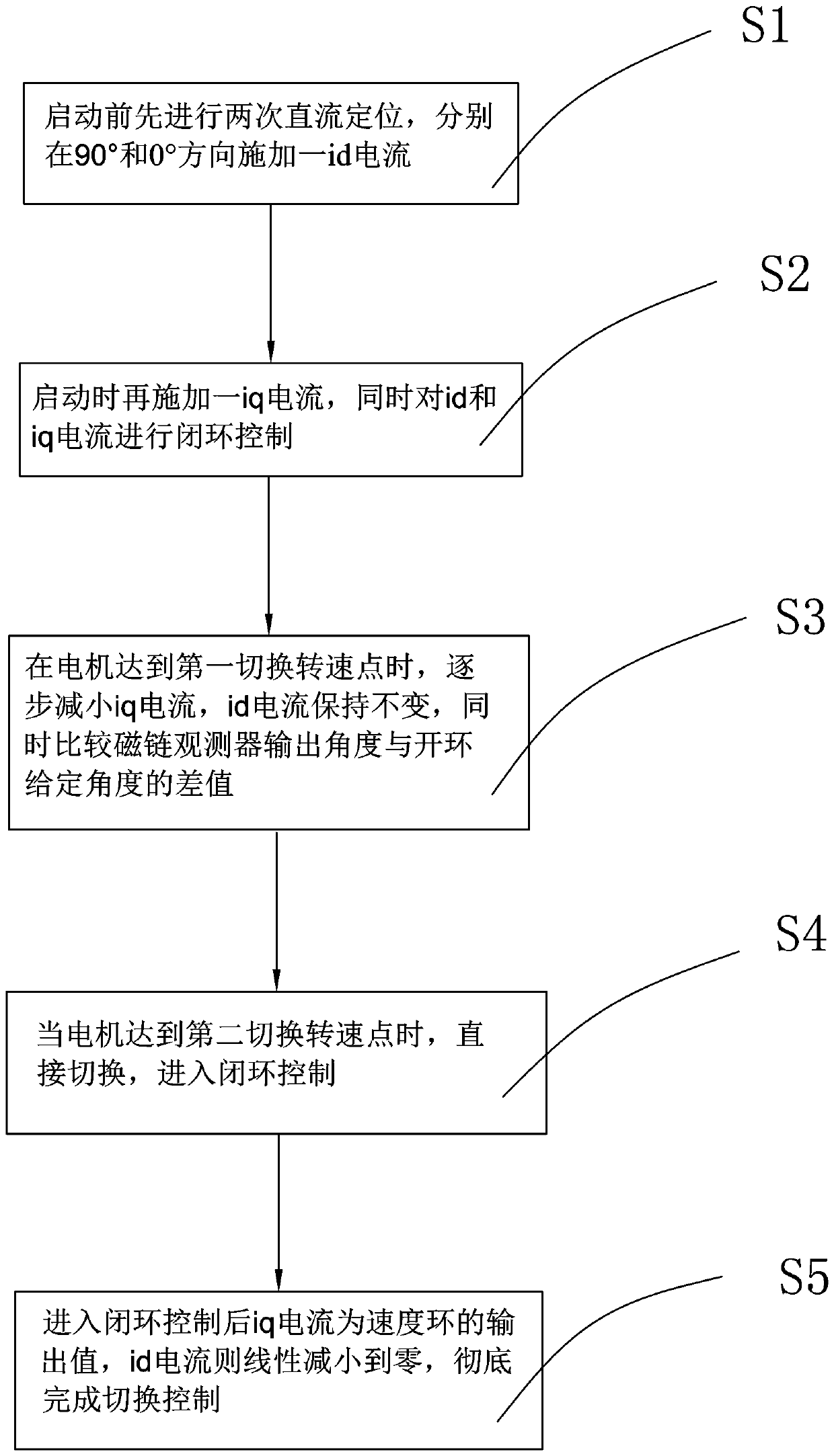

ActiveCN107623467APlay a positioning roleWon't get out of stepStarter arrangementsPower flowElectric machine

The invention relates to a speed sensorless starting method for a synchronization motor. The method includes performing two processes of DC positioning before starting, applying id current in a 90-degree direction and a 0-degree direction separately, and applying iq current when starting, and performing closed-loop control on id and iq current at the same time; when the motor reaches a first switch rotation speed point, reducing the iq current gradually, keeping the id current unchanged, and comparing to obtain a difference value between an output angle and an open loop given angle of a flux observer; when the motor reaches a second switch rotation speed point, switching directly and entering into closed-loop control. According to the invention, new id axial current is introduced and a positioning effect is achieved for the motor. Smooth switching can be realized during the switching process of the motor. Besides, even a load has comparatively large fluctuation during the switching process, motor out-of-step can also be prevented. The method has excellent stability and switching quickness.

Owner:厦门金龙汽车新能源科技有限公司

Axial current meter for in-situ continuous monitoring of corrosion and cathodic protection current

InactiveUS7189319B2Avoid corrosionWeather/light/corrosion resistanceVolume/mass flow measurementCurrent meterContinuous monitoring

First and second axial current meters (ACM) are mechanically connected to a well casing just above and below a corrosive zone and a master axial current meter (MACM) is connected to the casing at the earth's surface, the MACM periodically obtaining measurements of axial current from the ACMs to determine how much cathodic protection current is to be applied to the casing to avoid corrosion.

Owner:SAUDI ARABIAN OIL CO

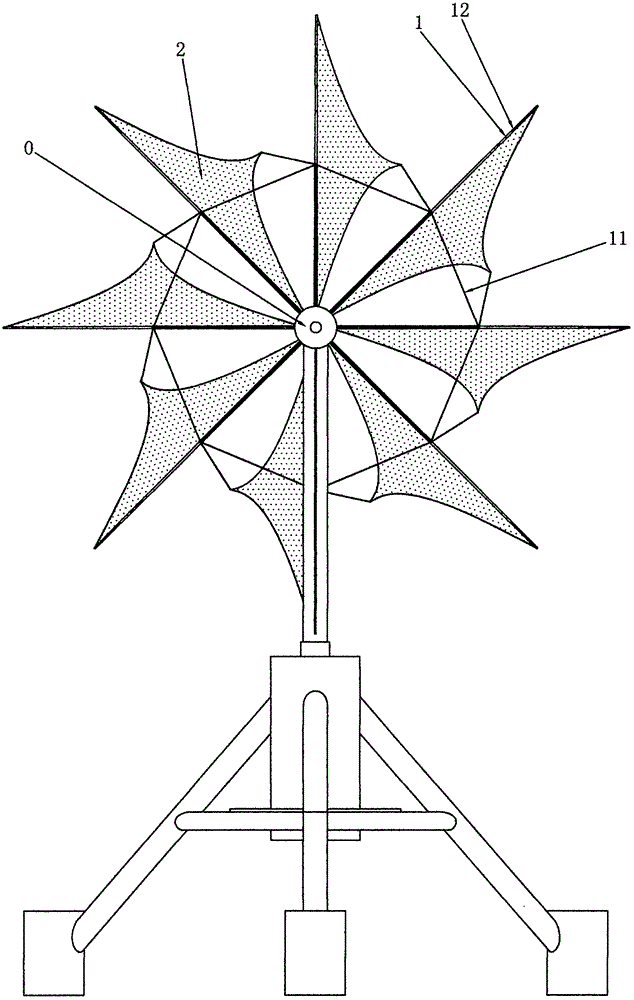

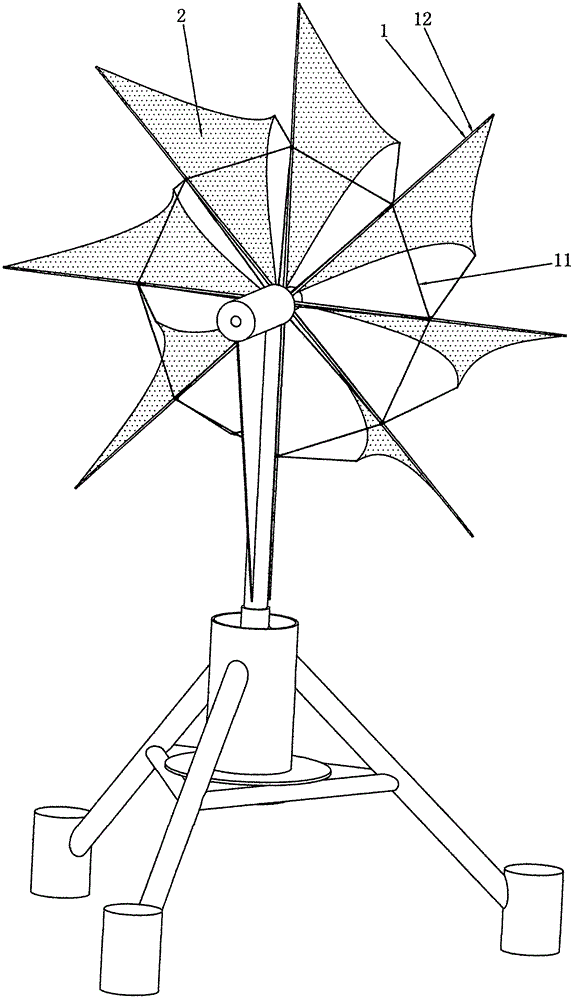

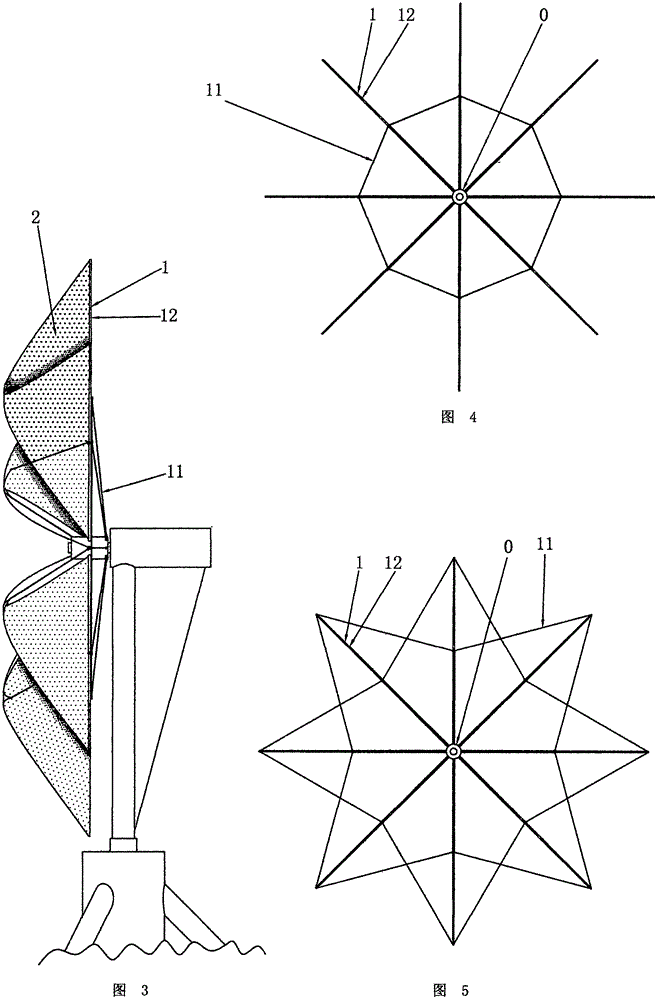

Axial current force curtain sail current wheel

PendingCN106640517AReduce weightLow selectivityWind motor controlFinal product manufactureManufacturing cost reductionFiber

The invention discloses an axial current force curtain sail current wheel. The axial current force curtain sail current wheel comprises a current wheel frame and curtain sails. The current wheel frame is made from stainless steel pipe body chain links or lightweight alloy pipe body chain links or rubber-plastic pipe body chain links or fiber medium pipe body chain links or fiber metal synthetic pipe body chain links or fiber strengthened plastic pipe body chain links or plastic metal synthetic pipe body chain links, fibers are carbon fibers or graphene carbon fibers, the current wheel frame is made from a lightweight raw material, and the fabric or non-woven fabric curtain sails are used as wind scraping blades, so that the lightweight current wheel is formed; reels or oscillating bars and pulley sets are used for automatically adapting to the current force environment so as to automatically and movably unwind, stretch, retract or rotatably swing the curtain sails, so that controllable variable current scraping is achieved, power is balanced by pressurizing slow current and depressurizing rapid current, meanwhile, strong current damage is coped, and weak current power is greatly improved; or paper curtain sails are used as the wind scraping blades, traditional fixed blade current wheels are replaced in a consumable mode, the weight and manufacturing cost of the current wheel are lowered, the slow current power is increased, the selectivity of a wind wheel to the environment is reduced, and wind power driving of sky wheels in fairgrounds is achieved.

Owner:毛永波

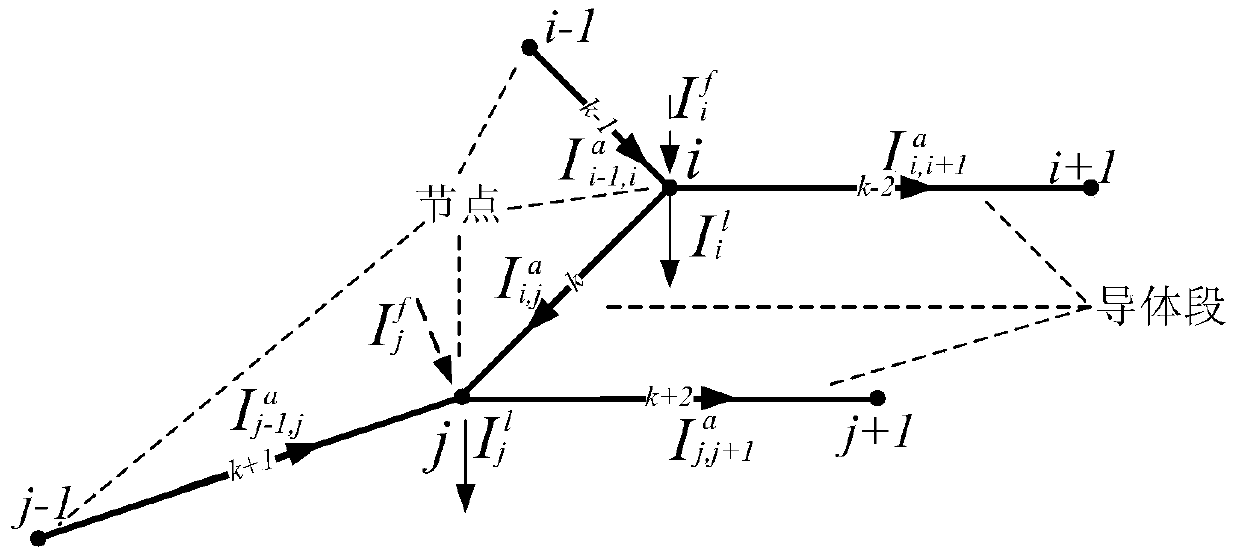

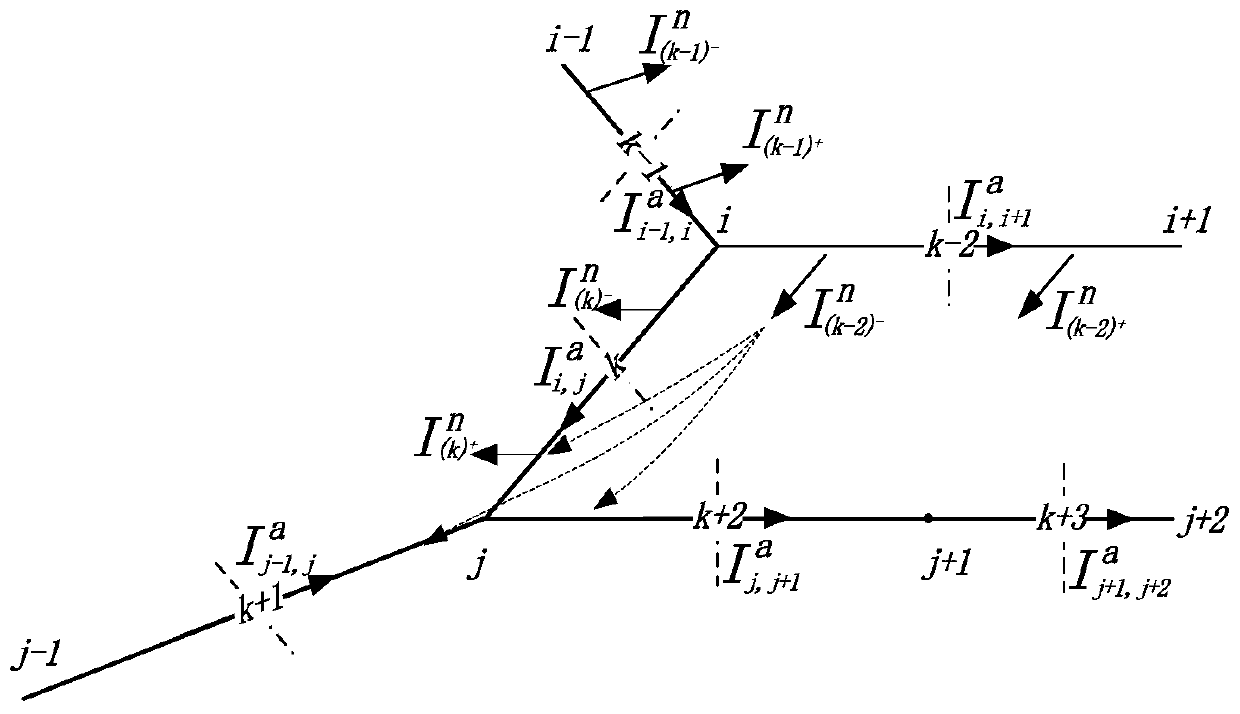

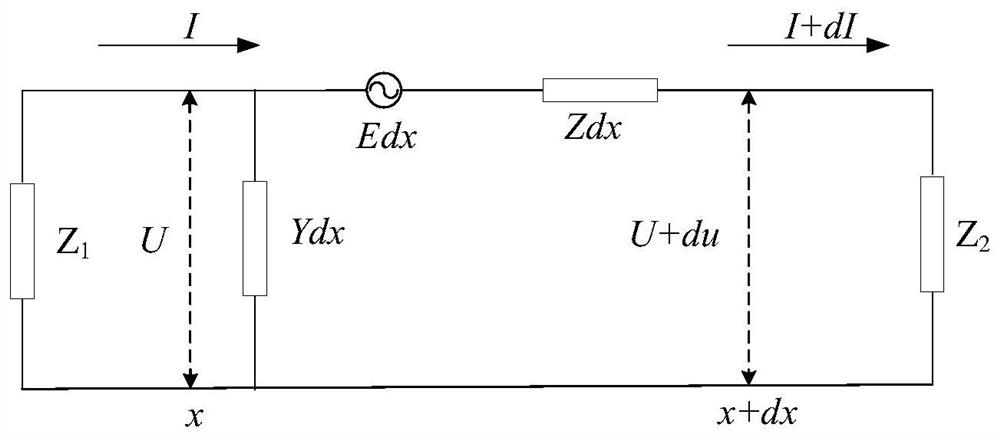

Impulse grounding resistance calculation method considering spark discharge effect

InactiveCN105486929AClose to volt-ampere characteristicsAccurate and efficient measurementEarth resistance measurementsElectrical conductorEngineering

The invention relates to an impulse grounding resistance calculation method considering a spark discharge effect. The method comprises the following steps: respectively determining relations among leakage current, axial current, and node potential of a grounding body conductor; determining the leakage current, axial current, and node potential of the grounding body conductor; determining an equivalent radius of a grounding body conductor segment; determining axial resistance, self-inductance, and frequency-dependent property of the grounding body conductor; determining self-resistance of the grounding body conductor over ground, mutual resistance among conductors, and time-variant characteristic; and determining the relation of the leakage current of the node of the grounding body conductor and the equivalent radius of the conductor segment. An analytical method of combining an electromagnetic field with a circuit is used, an electromagnetic field method is used to solve conductor parameters, and a circuit method is used to solve transient response. The method can adapt to grounding bodies in complex shapes, and can give comprehensive consideration to conditions which may occur in spark discharge effect, inductive effect, potential shielding effect, and other impulse heavy current conditions. Compared with a conventional calculation method, the method is closer to volt-ampere characteristics of a grounding device under an impact condition.

Owner:STATE GRID CORP OF CHINA +3

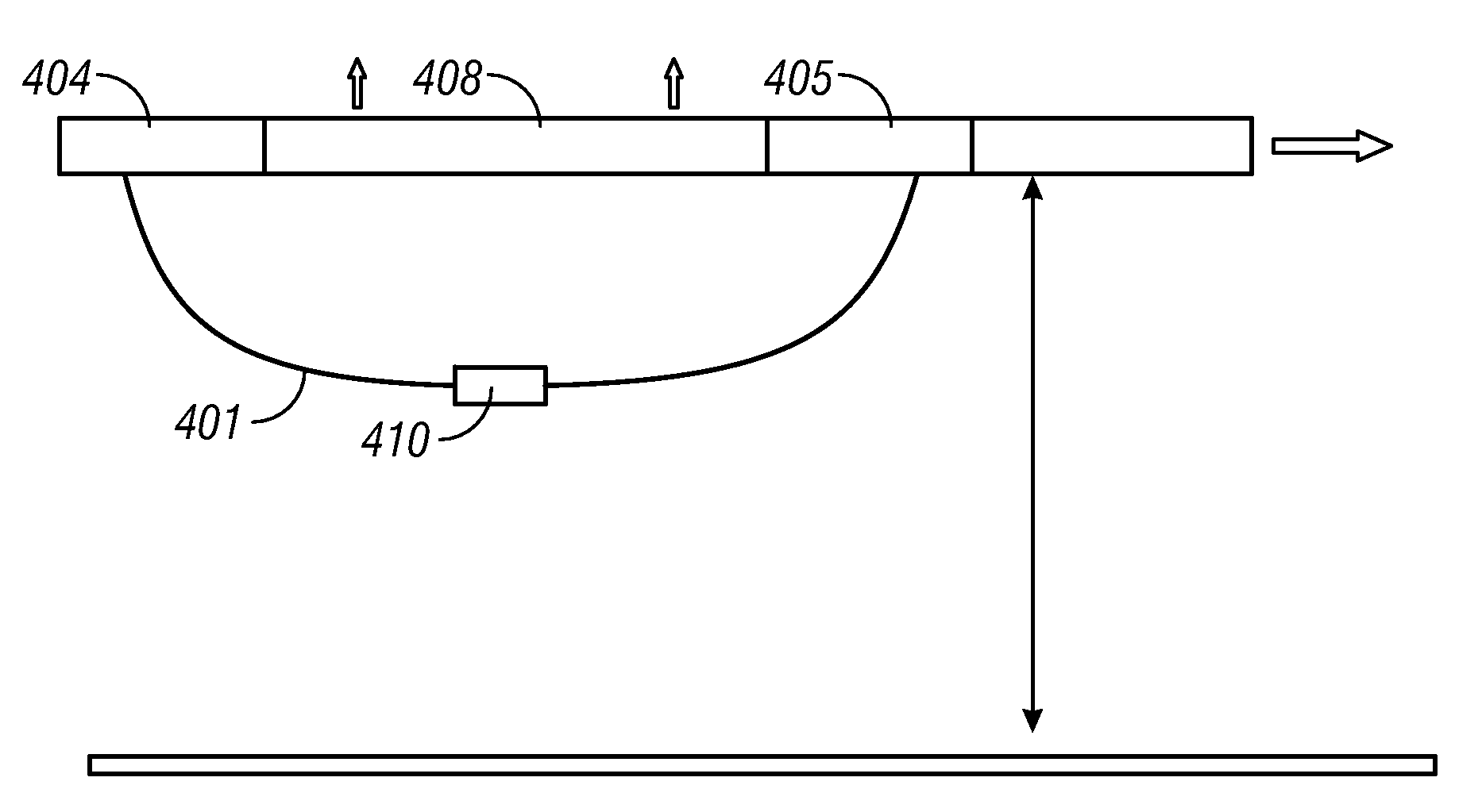

Borehole Conductivity Simulator Verification and Transverse Antenna Balancing

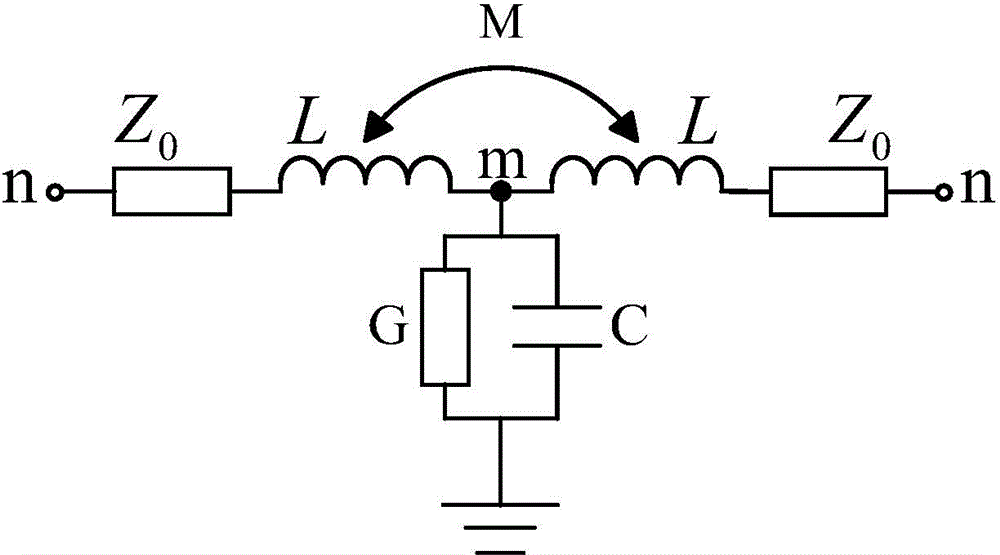

ActiveUS20080297160A1Reduce the impactReduce impactElectric/magnetic detection for well-loggingAcoustic wave reradiationInductorTransmitter antenna

A reactance is introduced into a flow path of axial currents in an induction logging tool. The reactance may be a capacitor or an inductor. A transmitter antenna is operated at a frequency defined by a cutoff frequency related to the reactance.

Owner:BAKER HUGHES INC

Motor having shaft members

InactiveUS7667357B2Avoid flowImprove insulation performanceMagnetic circuit rotating partsManufacturing dynamo-electric machinesRotor magnetsEngineering

Owner:NIDEC SHIBAURA CORP

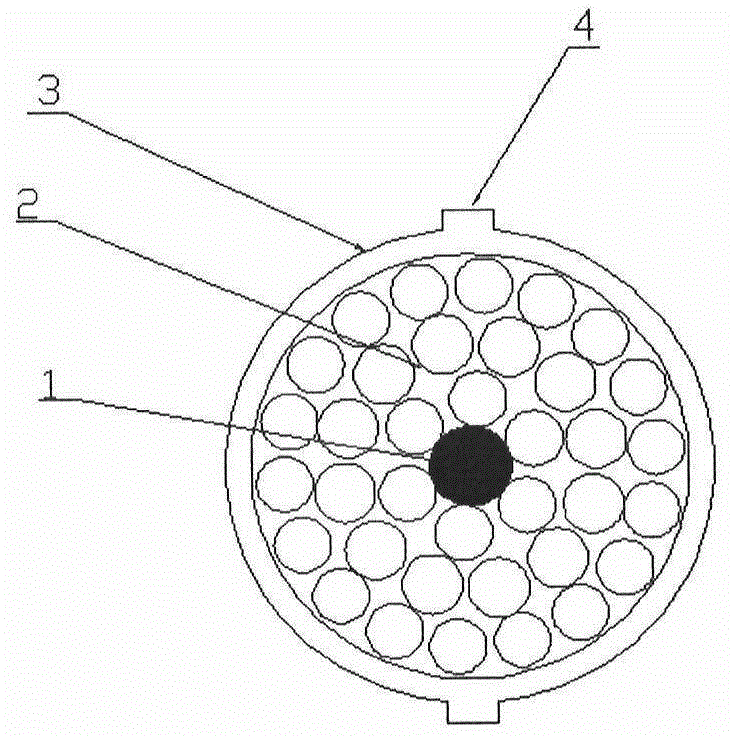

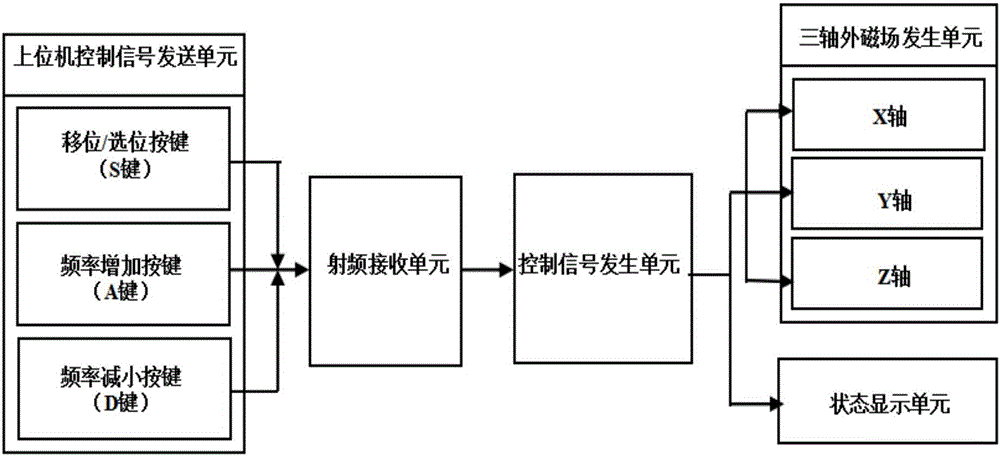

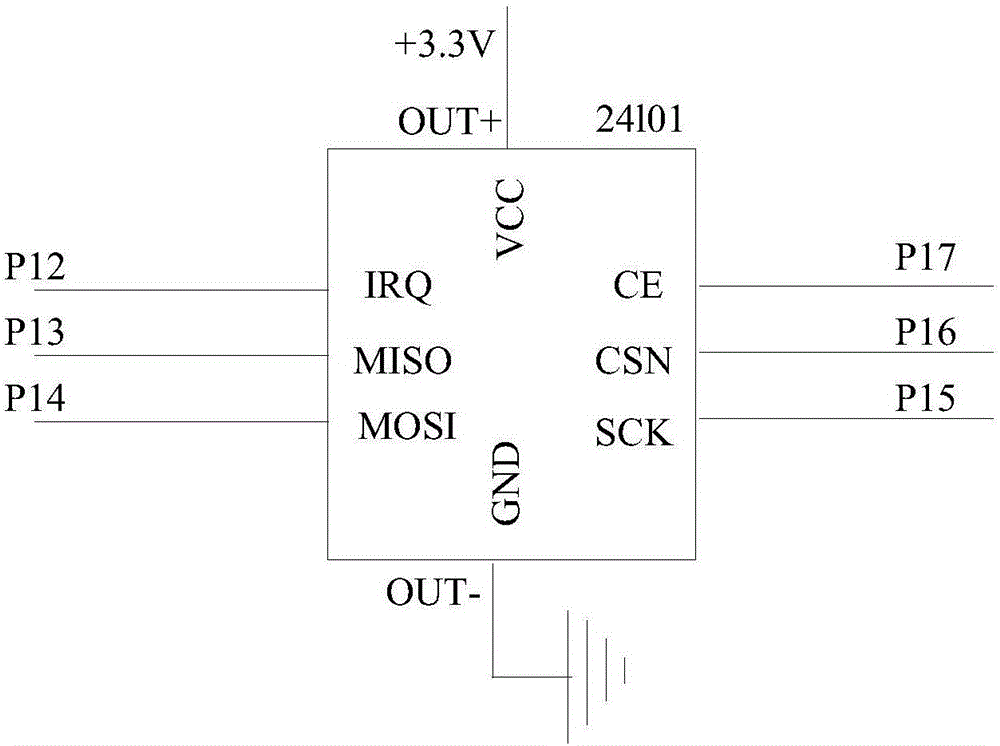

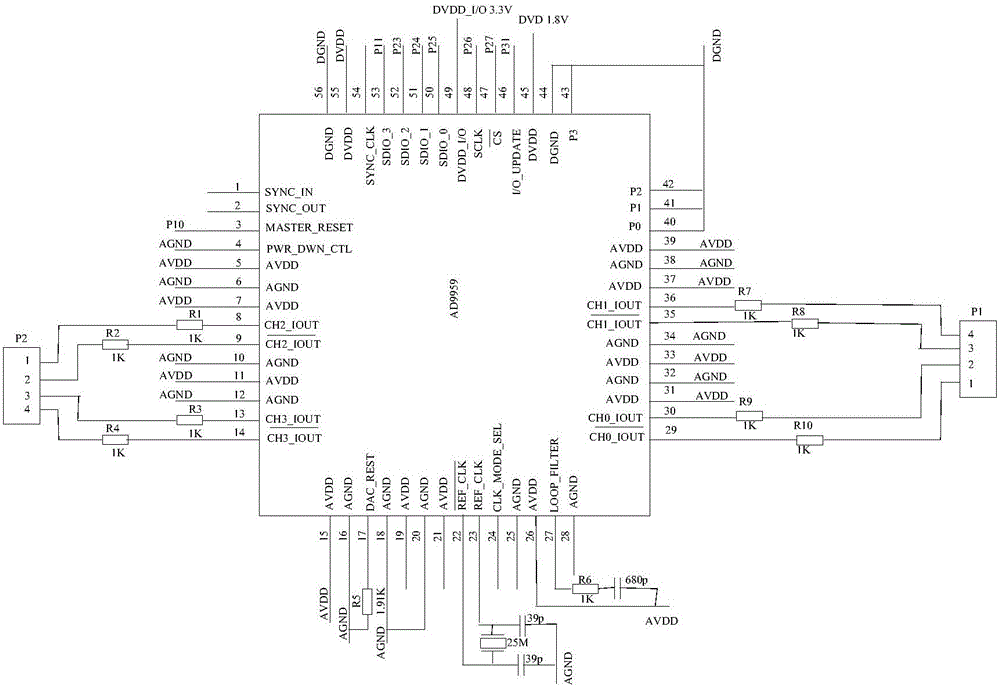

Medical spherical micro robot remote control system and working method thereof

InactiveCN106361259AAchieving horizontal advancementImplement backGastroscopesOesophagoscopesControl signalRadio frequency

The invention discloses a medical spherical micro robot remote control system. The medical spherical micro robot remote control system is characterized by comprising an upper computer control signal transmission unit, a radio frequency receiving unit, a control signal generation unit, a state display unit and a tri-axial outer magnetic field generation unit. A working method of the medical spherical micro robot remote control system comprises the following steps: driving a robot to move under the action of a tri-axial outer magnetic field; deducing a corresponding relationship between frequency and the magnetic field; changing a tri-axial current signal frequency parameter; displaying a state; controlling a motion way. The medical spherical micro robot remote control system has the advantages that remote control and wireless motion control of a spherical micro robot are realized; high flexibility is realized; the potential threat of irradiation is lowered; the medical spherical micro robot remote control system is low, and is convenient to carry; the motion form of the medical spherical micro robot is controlled through a key instruction.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

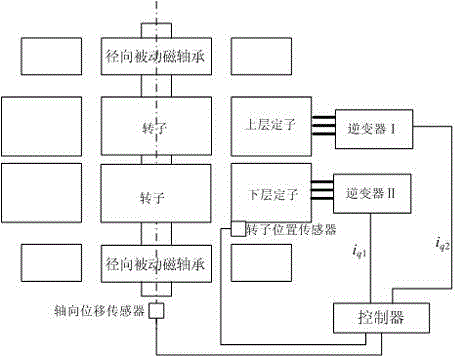

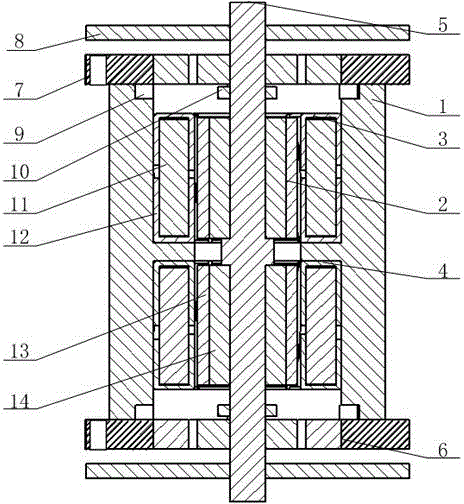

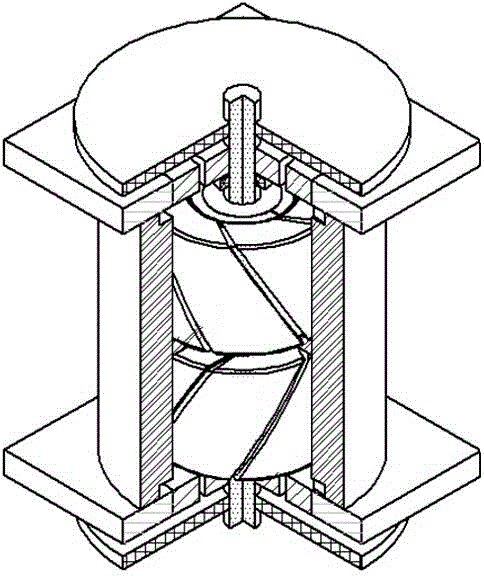

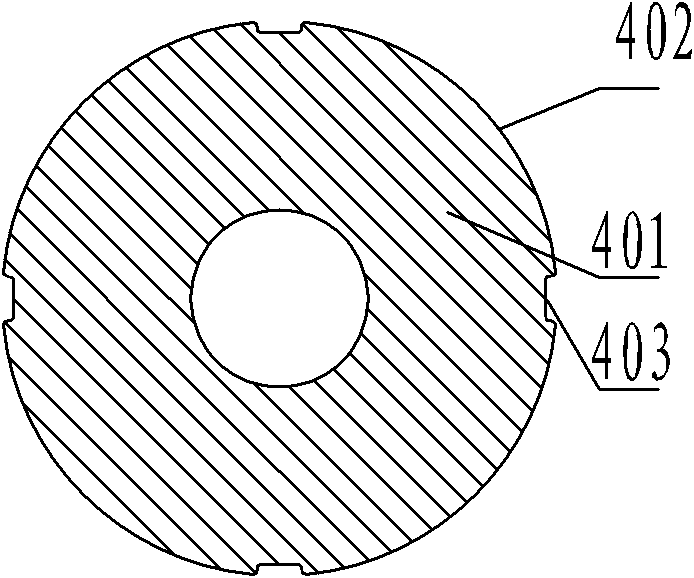

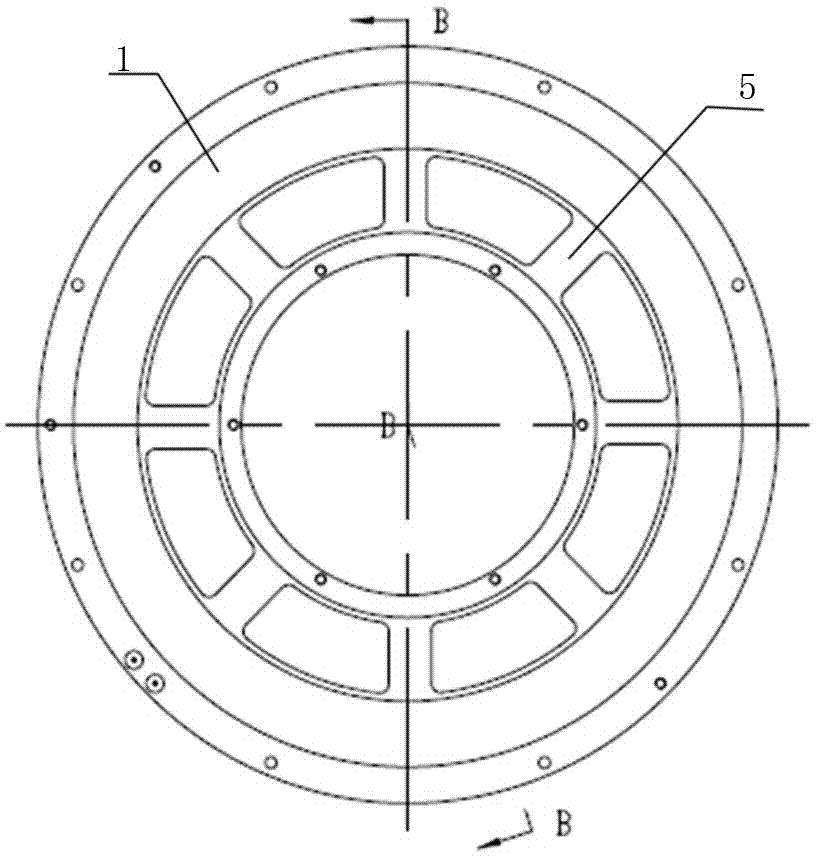

Slotless skew winding axial active suspension bearingless motor and control method

ActiveCN104810998AReduce torque fluctuationGuaranteed uptimeElectronic commutation motor controlVector control systemsAxial displacementMagnetic bearing

The invention discloses a slotless skew winding axial active suspension bearingless motor, and belongs to the field of motor manufacture. The slotless skew winding axial active suspension bearingless motor comprises a shell, a rotor, an upper stator, a lower stator, a non-magnetic rotating shaft, a rotor position sensor and an axial displacement sensor, radial driven magnetic bearings are mounted at two ends of the non-magnetic rotating shaft respectively, the upper stator and the lower stator respectively comprise a slotless stator yoke and an axial skew annular winding, skew direction angles of the windings of the upper stator and the lower stator are axially symmetric about the motor, three-phase inverters are connected onto the windings of the upper stator and the lower stator respectively and connected with a controller, and the rotor position sensor and the axial displacement sensor are connected with the controller. The stators are of slotless structures, motor slot effects are eliminated, axial suspension and rotation of the rotor are controlled in a decoupled manner by adjusting given current of the windings of the upper stator and the lower stator, and the problem of permanent magnet demagnetization caused by controlling axial suspension through axial current. The invention further discloses a control method of the slotless skew winding axial active suspension bearingless motor.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

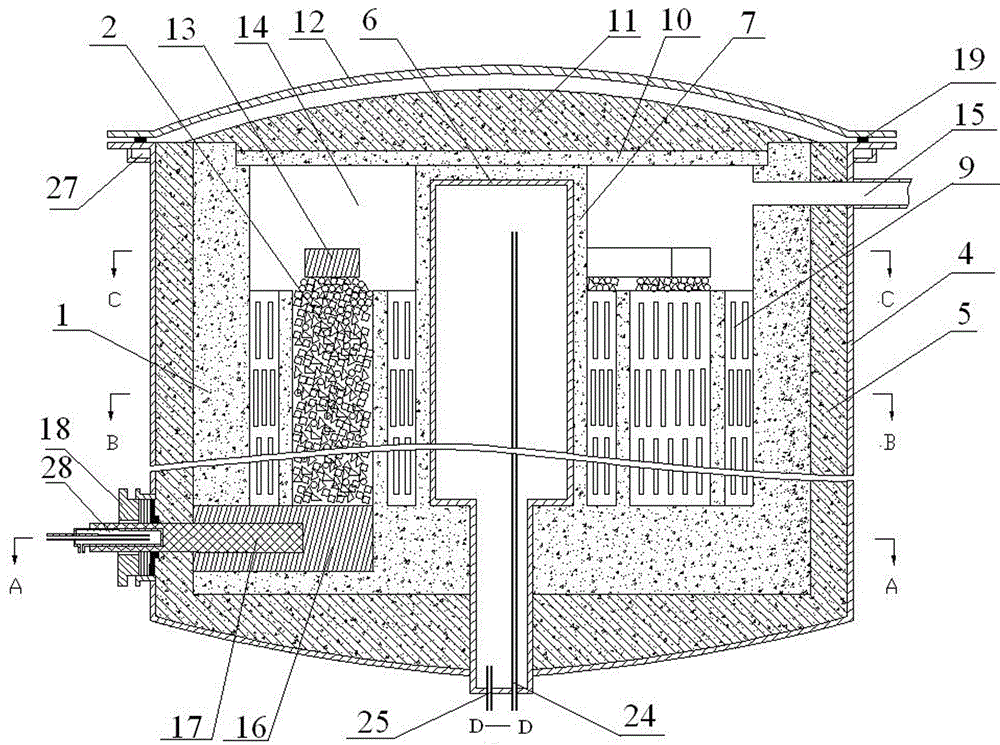

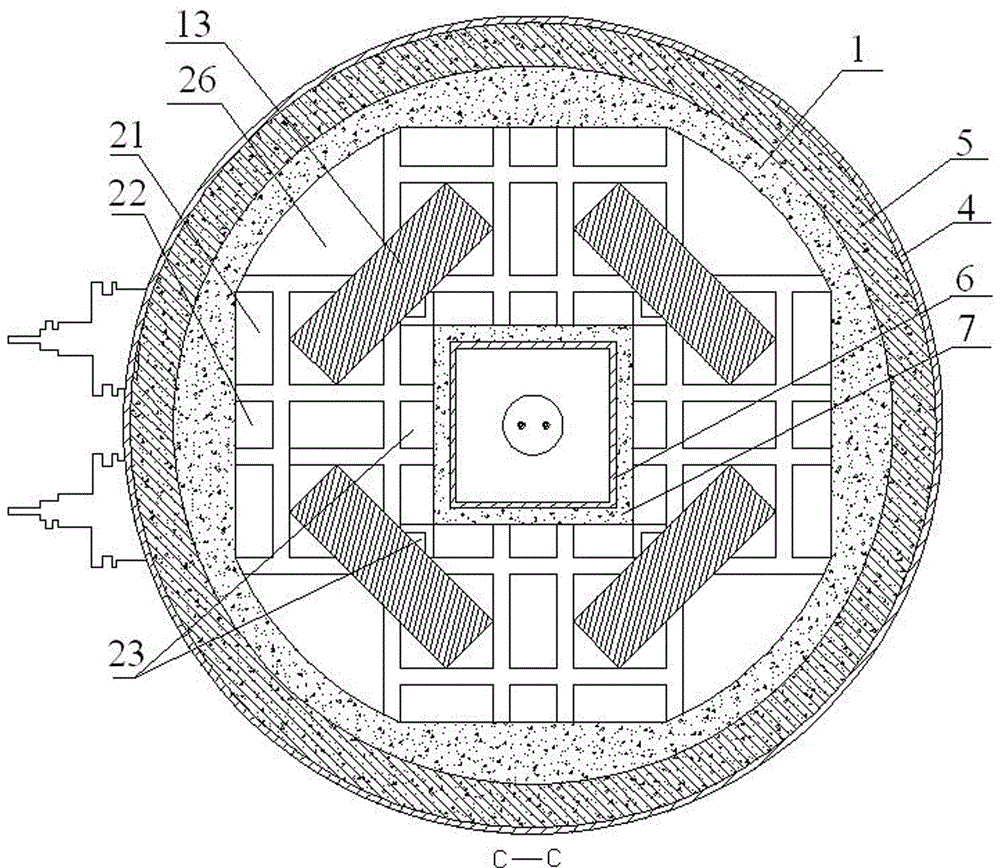

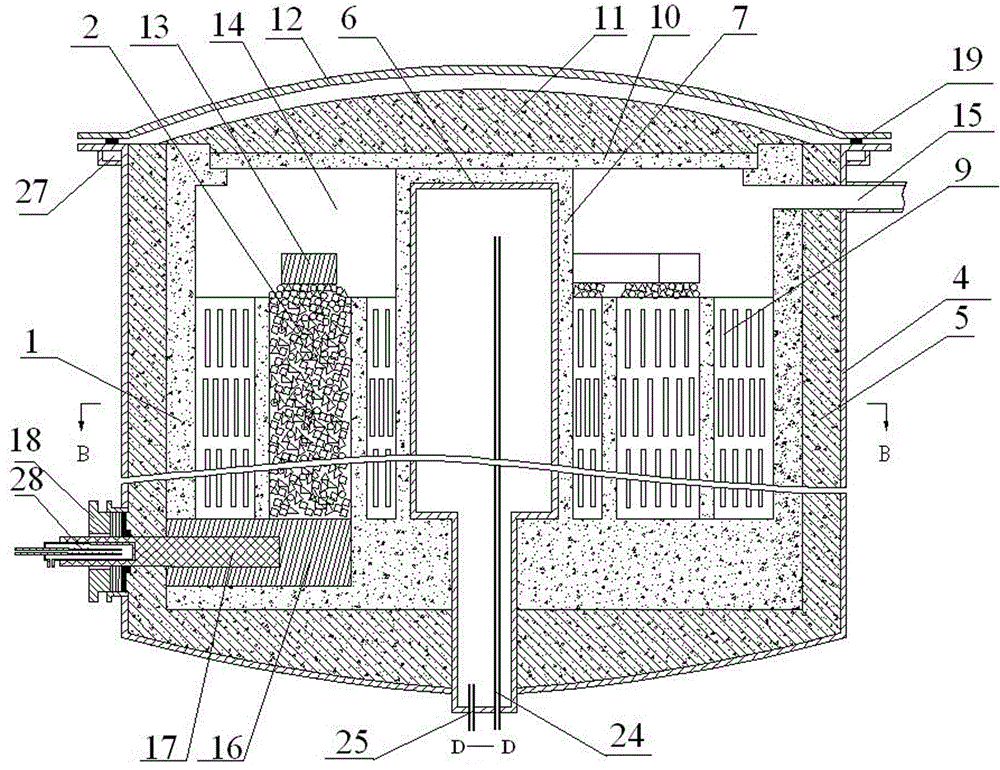

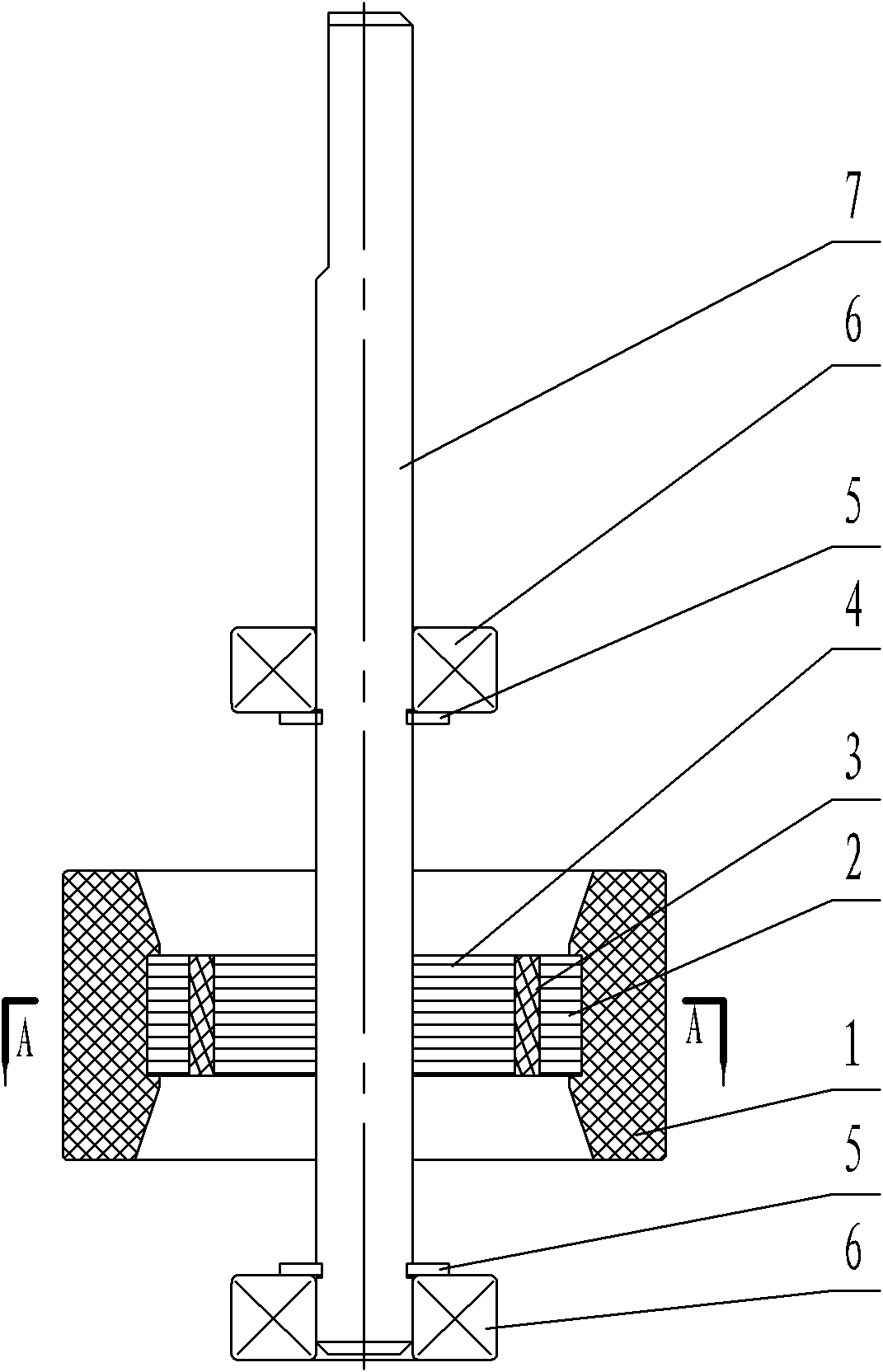

Resistance furnace for separating and recycling aluminum reduction cell lining solid waste and petroleum coke for desulfurization

InactiveCN106643120AUniform radial temperature distributionIncrease loading capacityCharge composition/stateVertical furnacesElectrical resistance and conductanceGraphite electrode

The invention relates to a resistance furnace for separating and recycling aluminum reduction cell lining solid waste and petroleum coke for desulfurization. The resistance furnace comprises a furnace shell, a ball coronary furnace lid, a furnace lining, cylinder-type fire-resistant concrete masonry, a fire-resistant concrete top plate, a heat insulating cover plate and two graphite electrodes; a well type main material chamber, a well type auxiliary material chamber and a well type cavity which are formed by multiple fire-resistant concrete walls in an enclosure mode are arranged between the inner wall of the cylinder-type fire-resistant concrete masonry and a fire-resistant concrete sleeve, the well type main material chamber is filled with resistance heating elements formed by fragment materials of aluminum reduction cell cathode carbon blocks or fragment materials of a petroleum coke top plate, and an upper graphite electric conductor and a lower graphite electric conductor connects the resistance heating elements in series. According to the device, by means of vertically arranged resistance heating elements, at the same time of uniformly distributing the temperature in the radial direction of a cylinder type furnace body, the effect of uniformly distributing an axial current is achieved, compared with a traditional technology, a single furnace loading capacity can be further expanded, and the production efficiency and separation effect are improved.

Owner:SHENYANG BEIYE METALLURGIGAL TECH CO LTD

Electric corrosion prevention rotor and production method thereof

ActiveCN102570658APrevent flowPrevent Galvanic CorrosionWindings insulation shape/form/constructionMagnetic circuit rotating partsPower flowEngineering

The invention discloses an electric corrosion prevention rotor and a production method thereof, and relates to a direct current high-voltage plastic package motor rotor and a production method thereof. At present, the electric corrosion phenomenon is normal for a direct current plastic package motor; an oil membrane is broken down by current between a bearing ball and an inner ring as well as an outer ring to discharge to produce high temperature, so that local surface of a bearing is melted to form spots and pits, and further, the hardness of the material of the inner ring and the outer ring of the bearing is reduced. The rotor comprises a rotating shaft, an iron core and a magnet, wherein the iron core is sleeved on the rotating shaft; the magnet is arranged outside the iron core; the rotor is characterized in that: the iron core comprises an inner yoke iron core and an outer yoke iron core which is arranged at the periphery of the inner yoke iron core and is concentric with the inner yoke iron core; and an insulating framework is arranged between the inner yoke iron core and the outer yoke iron core. According to the technical scheme, a current loop is cut off through the insulating framework which is arranged between the rotor inner yoke iron core and the rotor outer yoke iron core, so that the axial current flows to the bearing through the rotating shaft, and further, the electric corrosion of the bearing is effectively prevented, and the service life of the bearing of the direct current high-voltage plastic package motor is prolonged.

Owner:WOLONG ELECTRIC GRP CO LTD +1

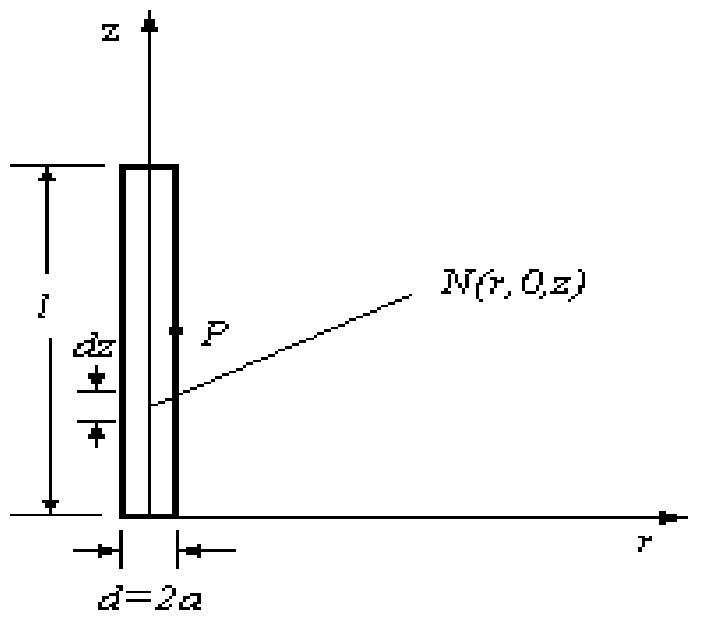

Method for calculating electromagnetic interference of power grid to buried pipe network

PendingCN113946923ARealize harmonious coexistenceGeometric CADDesign optimisation/simulationElectrical conductorPotential difference

The invention discloses a method for calculating electromagnetic interference of a power grid to a buried pipe network, which comprises the following steps of: dividing a conductor into conductor micro-sections, enabling a potential difference between two ends of the outer surface of each conductor micro-section to be equal to a potential difference between two ends in each conductor micro-section, and establishing an equation set according to the characteristics of continuity, calculating the potential difference between two ends of the outer surface of the conductor micro-segment according to the leakage current, and calculating the potential difference between two ends in the conductor micro-segment according to the product of the impedance of the conductor micro-segment and the axial current; and according to the Kirchhoff's law, obtaining a relational expression between axial current and leakage current on each conductor micro-segment, comprehensively establishing a group of linear algebraic equations, and solving the linear algebraic equations to obtain leakage current distribution on the conductor. The result is used for evaluating the influence of electromagnetic interference on the buried pipe network, so that the risk is controlled in advance, and harmonious co-existence of the power grid and the oil-gas pipe network is realized.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD SHAOXING POWER SUPPLY CO +3

Method and apparatus for measuring resistivity of formations

InactiveCN102177445AElectric/magnetic detection for well-loggingTransmitter antennaElectric resistivity

An apparatus for determining the resistivity of formation (2) surrounding a borehole comprising: an elongate conductive body (1); a pair of transmitter antennas comprising first and second antennas (3,4) mounted on the body for inducing a current in the formation; and a pair of receiver antennas comprising first and second antennas (5,6) mounted on the body for measuring an axial current running in the tool body at the location of the receivers; wherein the pair of transmitter antennas is located to one side of the pair of receiver antennas.

Owner:PRAD RES & DEV LTD

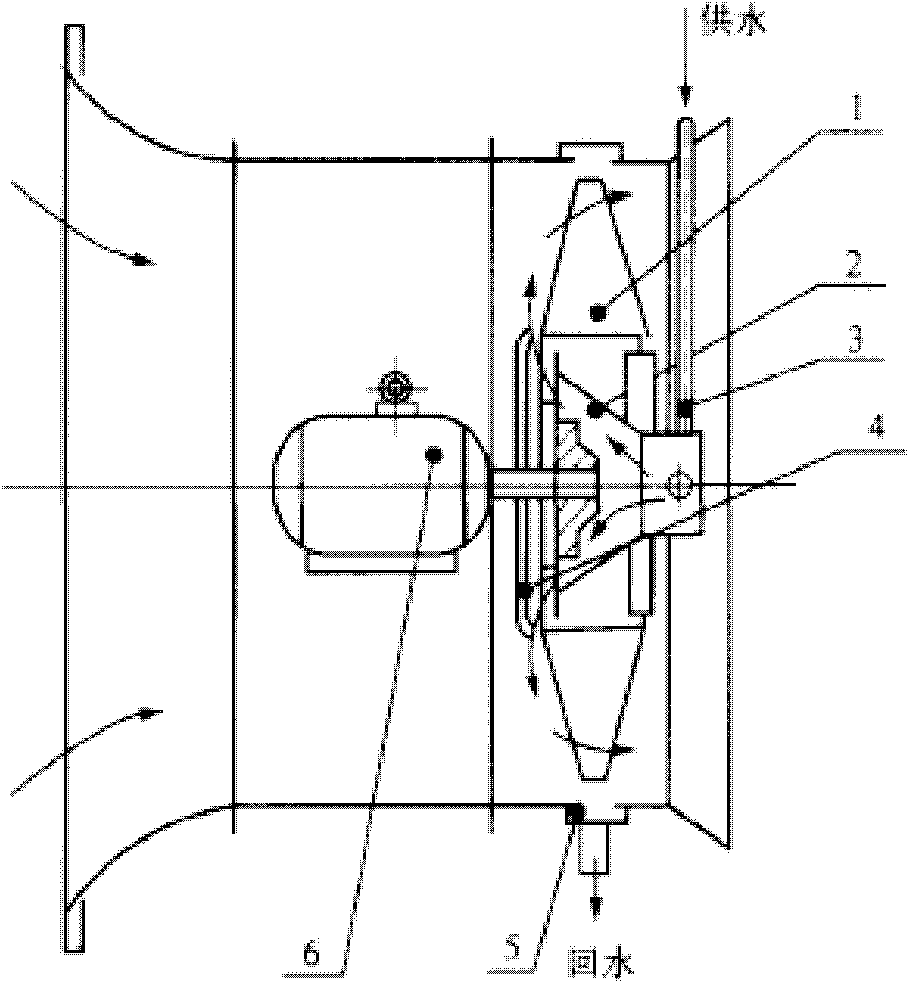

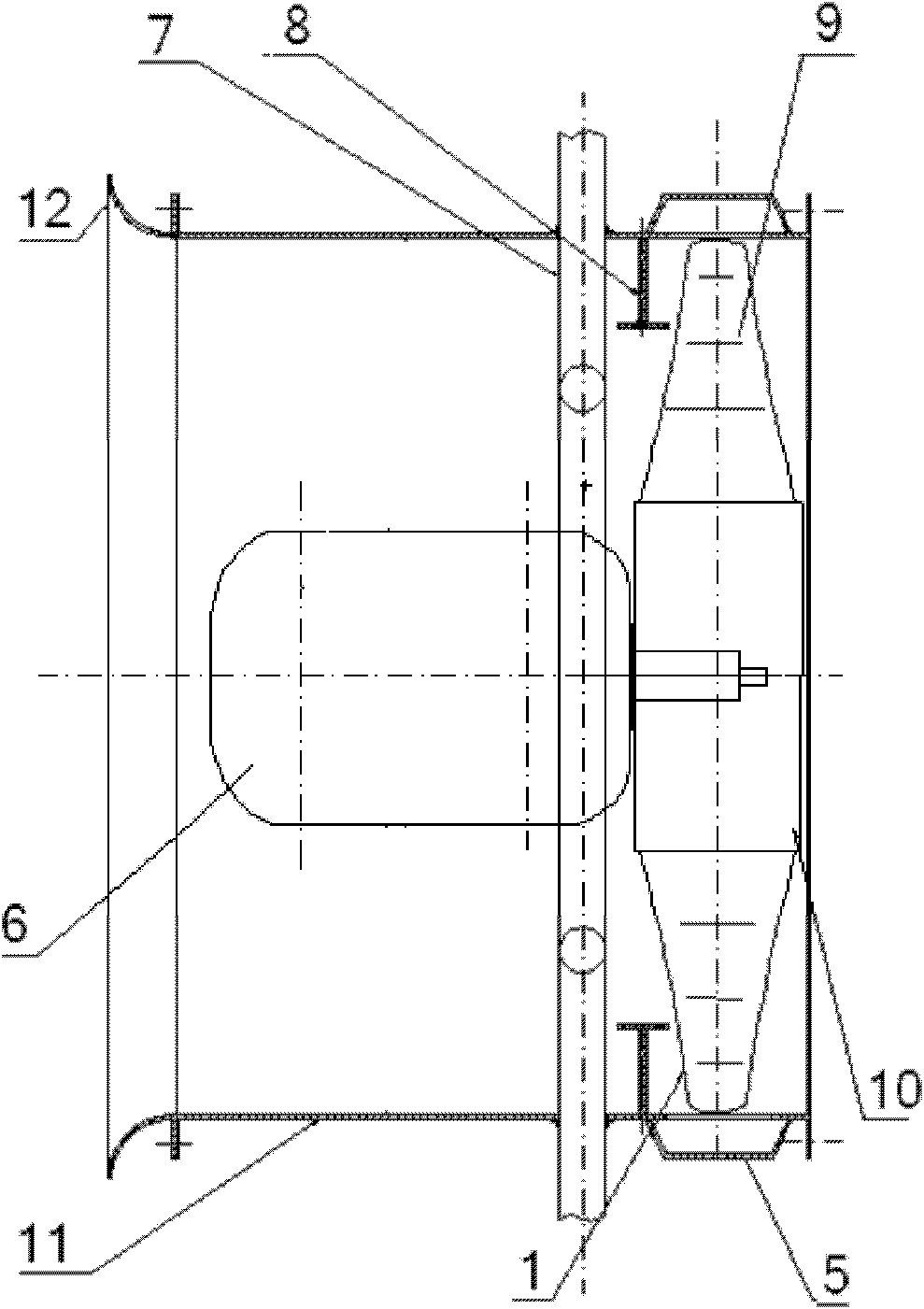

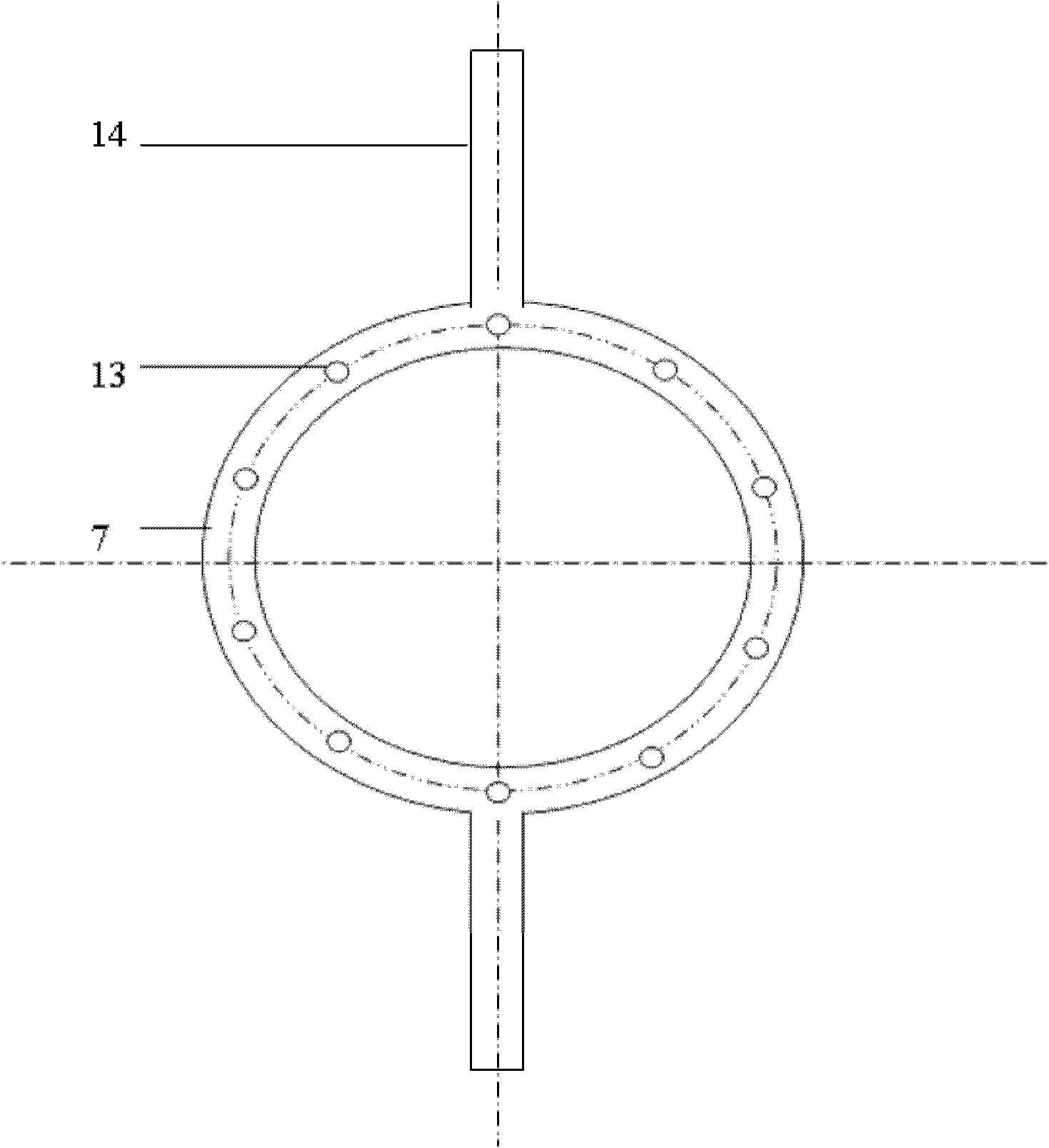

Spraying axial-current fan with ring-shaped water-jet pipe

InactiveCN101782078AReduce energy consumptionRaise all-inLighting and heating apparatusPump installationsTotal efficiencyWater flow

The invention discloses a spraying axial-current fan with a ring-shaped water-jet pipe. The fan comprises a fan drum, an inlet of the fan drum is provided with a current-collector, a drainage gate is arranged close to the fan drum, a motor is arranged in the fan drum, and an output shaft of the motor is connected with a wheel hub provided with moving blades. The fan is characterized in that: the ring-shaped water jet pipe is arranged between the motor and the axial direction of the hub wheel and fixed on the fan drum by a water delivery pipe; the side, facing the moving blades, of the ring-shaped water-jet pipe is provided with water-jet holes uniformly distributed along the circumferential direction; and water current enters the ring-shaped water-jet pipe through the water delivery pipe and then is nearly axially sprayed to rotating moving blades by the water-jet holes. Compared with the conventional spraying axial-current fan, the spraying fan of the invention can work under a condition of bigger water-air ratio, so that the application range of the spraying fan in a spinning air-conditioning room is widened, and simultaneously with the increase of the water-air ratio, the increasing rate of motor power consumption is obviously reduced in relation to the conventional spraying fan, and the decreasing rate of the fan total efficiency is also obviously lowered.

Owner:XI AN JIAOTONG UNIV

Combined insulating end cover for wind driven generator

InactiveCN107154698AReduce capacitive currentThick insulationSupports/enclosures/casingsWind drivenCapacitance

The invention relates to an end cover for a wind driven generator, specifically a combined insulating end cover for the wind driven generator. The invention solves a problem that the end cover of the wind driven generator is poor in insulation. The end cover comprises an end cover body and a bearing room. An insulating connection ring is fixed between the end cover body and the bearing room in a sleeving manner, i.e., enabling the inner annular surface of the end cover body to be connected to the outer annular surface of the insulating connection ring in a sleeved manner, and enabling the inner annular surface of the insulating connection ring to be connected to the outer annular surface of the bearing room. Compared with a conventional weftless insulating end cover, the end cover employs a brand-new insulating structure, is larger in insulation thickness, is higher in strength, is smaller in capacitance, is good in insulation effect for a low-frequency axial current generated by a motor and a high-frequency axial current generated by a frequency converter, and also greatly reduces the capacitive current of the insulating end cover. The end cover can be assembled through several parts, so the technology is simple and the manufacturing cycle is short. The end cover can be used for completely replacing a weftless insulating end cover, and various performances of the end cover are better than the performances of the weftless insulating end cover.

Owner:CRRC YONGJI ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com