Electric corrosion prevention rotor and production method thereof

A technology of anti-electrocorrosion and rotor, which is applied in the manufacture of stator/rotor body, magnetic circuit rotating parts, shape/style/structure of winding insulation, etc. It can solve the problem of shortening the service life of bearings, accelerating wear speed, and the material of inner and outer rings of bearings. Hardness reduction and other problems, to achieve the effect of improving the service life of the bearing, preventing axial or radial movement, and preventing electric corrosion of the bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

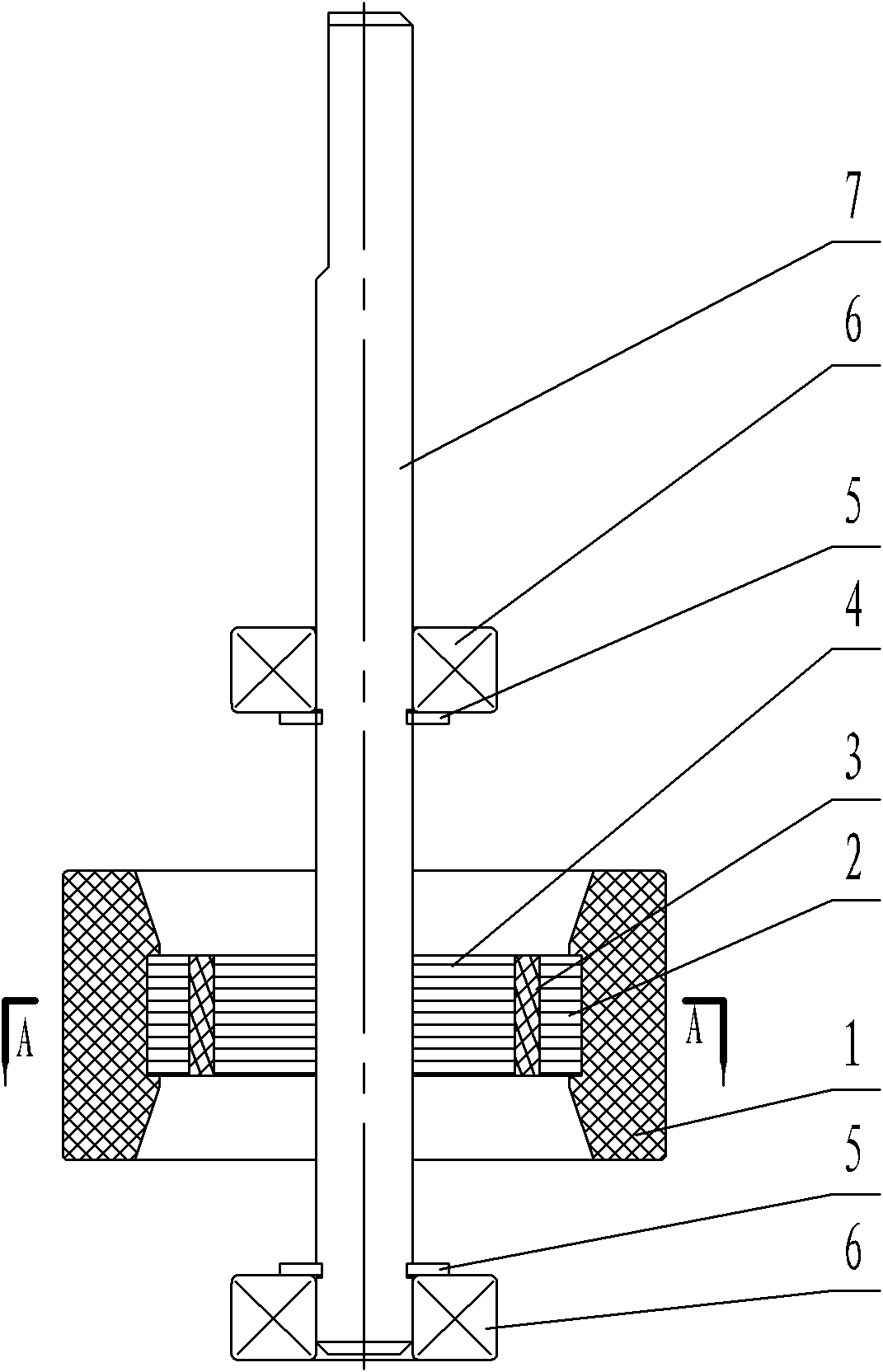

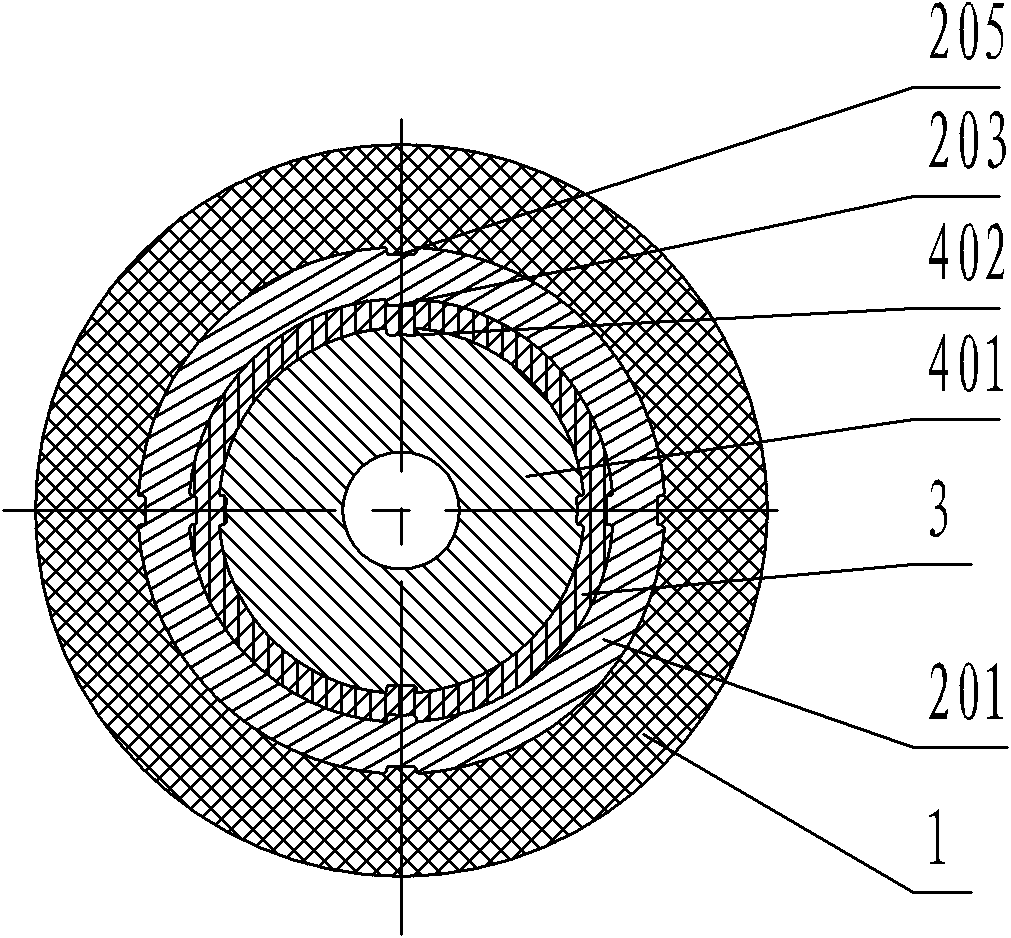

[0033] like figure 1 , 2 As shown, the present invention includes a rotating shaft 7, an iron core sleeved on the rotating shaft 7, and a magnet 1 externally arranged on the iron core. The core 4 is concentric with the outer yoke core 2 , and an insulating frame 3 is provided between the inner yoke core 4 and the outer yoke core 2 . The inner yoke core 4 is formed by stacking several inner yoke core punches 401; the outer yoke core 2 is formed by stacking several outer yoke core punches 201; the first insulating skeleton of the inner yoke core punches 401 The positioning portion 403 is opposite to the second insulating frame positioning portion 203 of the outer yoke core punching piece 201 of the same layer. The magnet 1 is covered on the outer peripheral surface and the upper and lower end surfaces of the outer yoke core 2 .

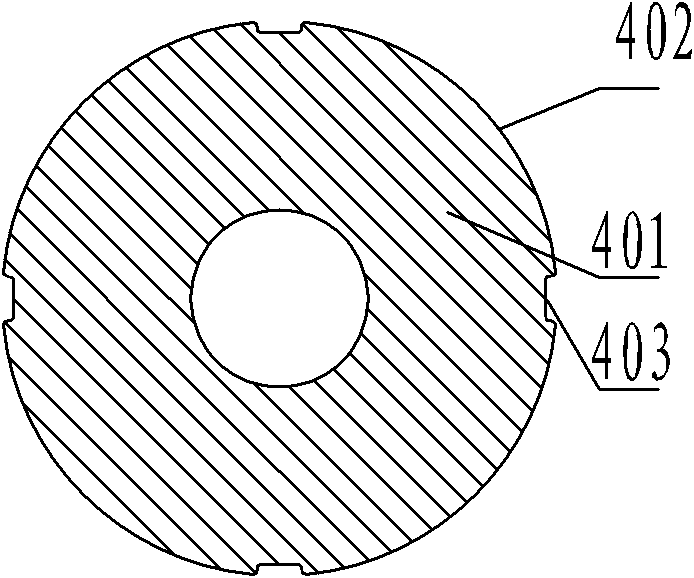

[0034] like image 3 As shown, the inner yoke iron core punching piece 401 is in the shape of a ring, the middle of which is a through hole for pas...

Embodiment 2

[0043] Embodiment 2: The same parts as Embodiment 1 will not be repeated. The difference lies in that the first insulation frame positioning parts 403 of the outer yoke core punches 201 of adjacent layers are aligned and stacked.

Embodiment 3

[0044] Embodiment 3: The first insulating frame positioning side 402 of the inner yoke iron core punching piece 401 is provided with five evenly distributed first insulating frame positioning parts 403, and the first insulating frame positioning parts 403 protrude from the first insulating frame positioning The edge 402 forms a convex point; the wall of the insulating hole 202 of the outer yoke iron core punching piece 201 is provided with four evenly distributed second insulating skeleton positioning parts 203, and the second insulating skeleton positioning part 203 is recessed in the wall of the insulating hole 202 to form a groove. The magnet positioning side 204 of the outer yoke core punching piece 201 is provided with four evenly distributed magnet positioning parts 205 , and the magnet positioning parts 205 protrude from the magnet positioning side 204 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com