Motor insulating bearing device and manufacturing method thereof

A technology of insulated bearings and motor bearings, applied in the direction of electromechanical devices, casings/covers/supports, electrical components, etc., can solve problems such as bearing electric corrosion, equipment failure, rotor bore sweeping, etc., to ensure reliable operation and avoid electric shocks Corrosion damage, prolonging the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

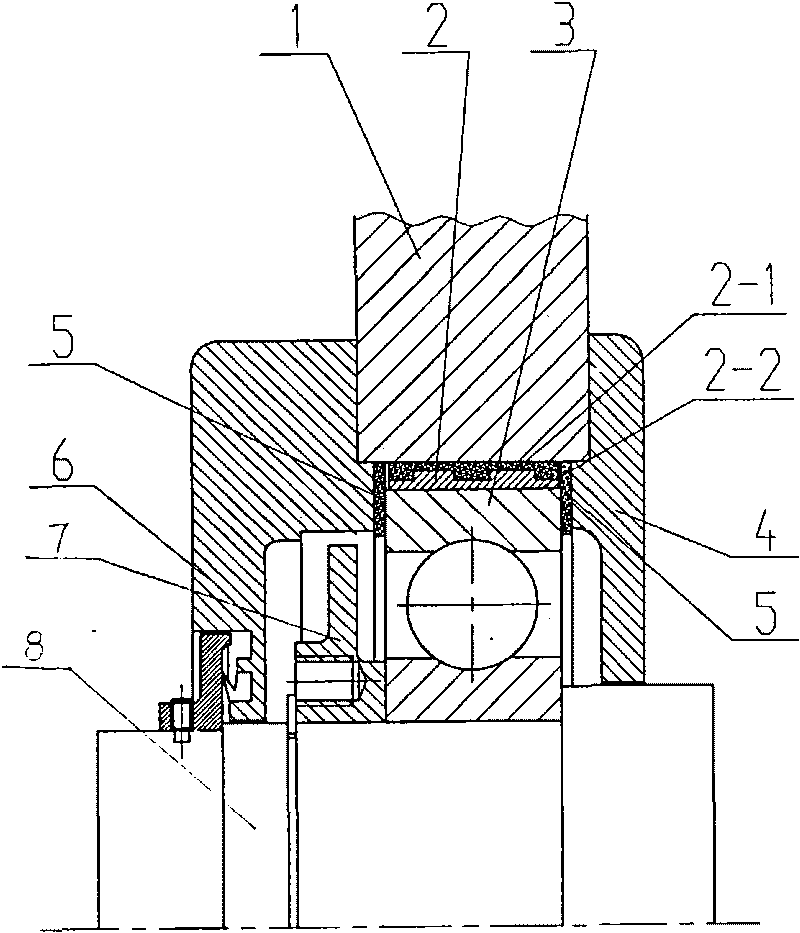

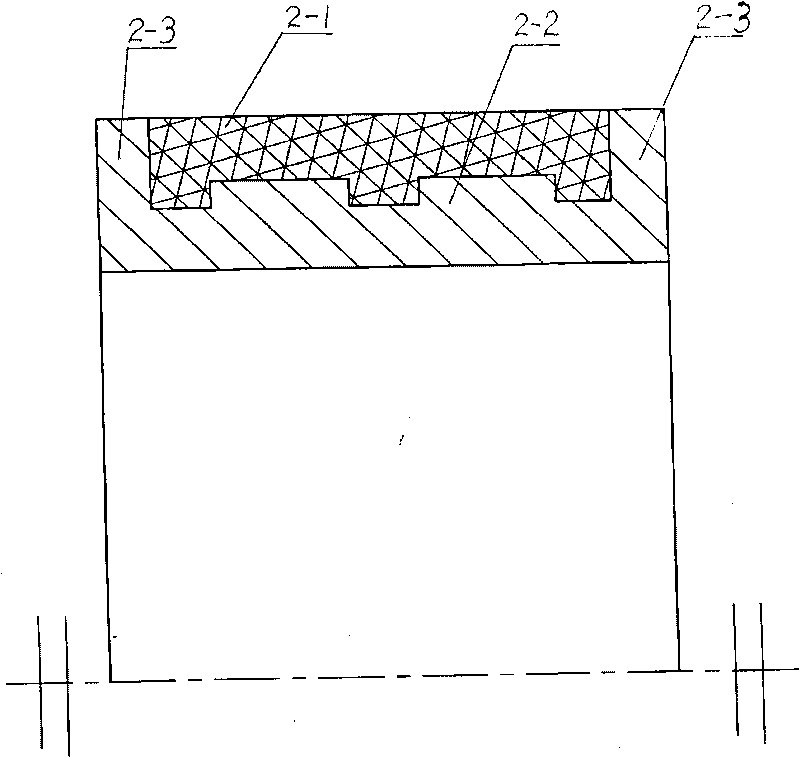

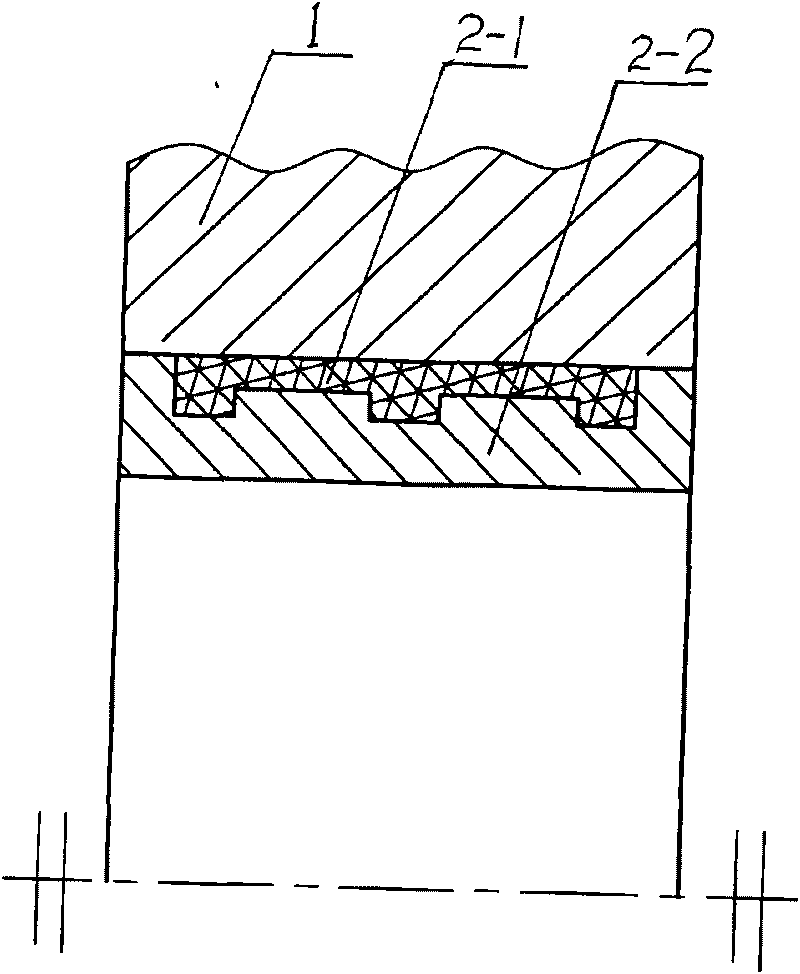

[0021] see figure 1 , the motor insulated bearing device of the present invention is made up of bearing block 1, motor bearing 3, bearing outer cover 6, bearing inner cover 4, insulating bushing 2 and insulating spacer 5, wherein, motor bearing 3 can adopt radial rolling bearing , the inner ring of the bearing is tightly connected with the motor main shaft 8 and rotates together, and the outer ring of the bearing is connected with the bearing seat 1 in a set. The insulating bushing 2 is located between the outer ring of the motor bearing and the inner hole of the bearing seat 1 , and is used for current isolation between the motor bearing 3 and the bearing seat 1 . The insulating bushing 2 includes an inner bushing 2-2 and an insulating layer 2-1 arranged on the outer circumference of the inner bushing 2-2, and the inner bushing 2-2 is made of metal for supporting the insulating layer 2-1 , the insulating layer 2-1 is made of insulating latitude-free tape. In order to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com