Preparation method of carbon fiber reinforced high-porosity ceramic bonding agent CBN grinding wheel

A ceramic bond, high porosity technology, used in manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as large surface area, high porosity, grinding wheel cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

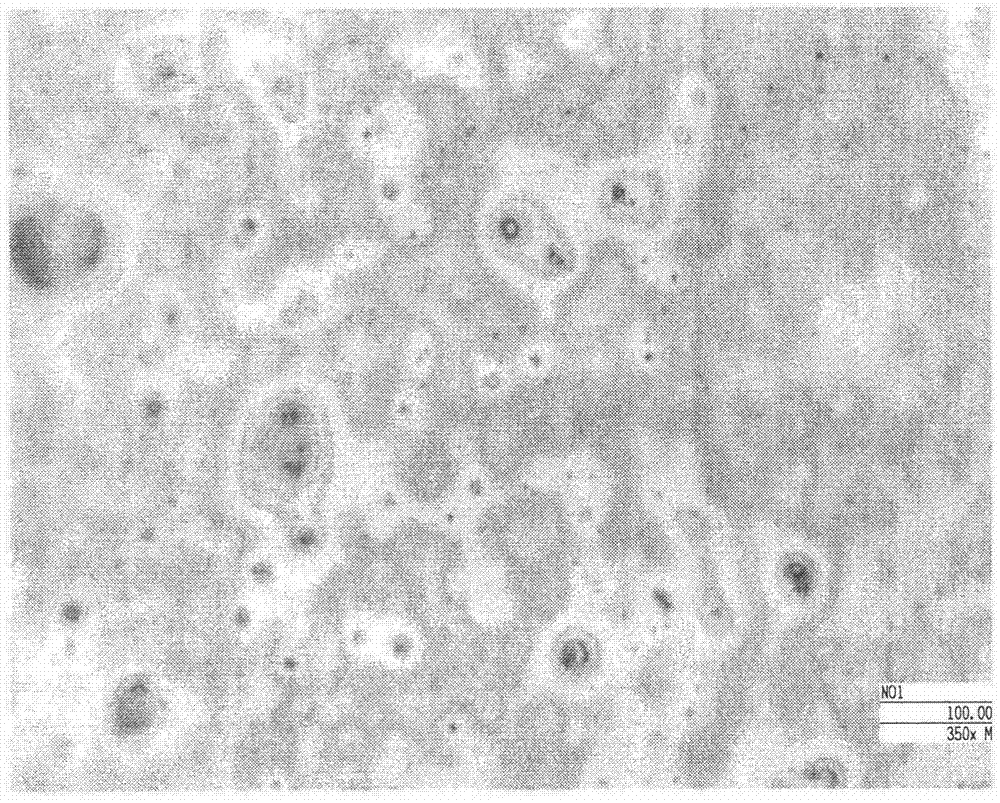

Image

Examples

Embodiment Construction

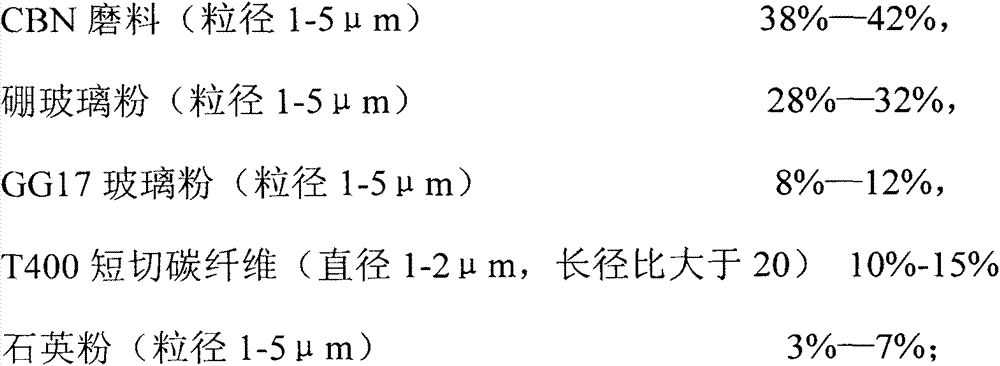

[0016] The specific steps of the carbon fiber reinforced high porosity vitrified bond CBN grinding wheel preparation method are:

[0017] (1) Weigh the CBN abrasive, boron glass powder, GG17 glass powder, T400 chopped carbon fiber and quartz powder in a weight ratio of 40:30:10:15:5, and then mix the raw materials evenly under ball milling conditions, and the ball stone It is a plastic ball, the diameter of the ball milling altar is 500 mm, the rotating speed is 50 rpm, and the ball milling time is 1 hour;

[0018] (2) Get 70% of the dry powder material obtained in step (1) and 30% of industrial grade paraffin by weight percentage. Heat the paraffin wax to 80°C in a water bath, then pour it into the weighed dry powder, and use a vertical mixer to mix it evenly at 80°C at a speed of 3000 rpm for 1 hour to obtain a CBN grinding wheel molding slurry.

[0019] (3) Clean the surface of the iron injection mold prepared according to the specifications of the grinding wheel, heat it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com