Gasket structure capable of enhancing wear resistance

A technology of wear resistance and gaskets, applied in the direction of components with teeth, hoisting devices, shafts and bearings, etc., to reduce wear and enhance wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

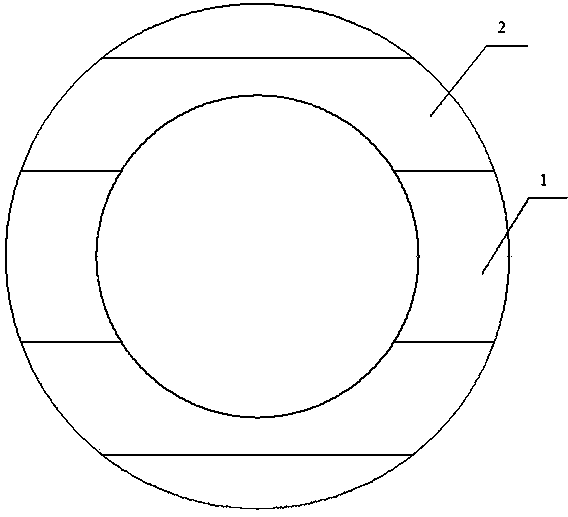

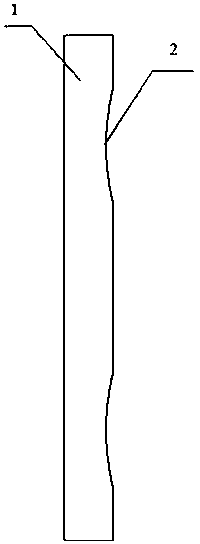

[0019] The invention discloses a gasket structure with enhanced wear resistance, which comprises a gasket 1 body, and at least one oil passage groove 2 penetrating through the working end surface is arranged on one end surface or both sides of the gasket 1 .

[0020] Generally, the gasket 1 is set in the axial gap between the gear and the gear or between the bearing assembly and the bearing surface. When the original gasket structure is in working condition, there is a certain amount of lubricating oil around the gasket 1. , but the gasket 1 is in contact with the gear or bearing and the bearing surface and generates friction on one or both sides of the end surface. Due to the effect of pressure, it is closely attached to the gear, so the lubricating oil cannot enter the working end surface of the gasket 1.

[0021] In the present invention, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com