Antistatic self-lubricating PCB drilling cover plate and preparation method thereof

An anti-static and self-lubricating technology, applied in the fields of static electricity, printed circuit manufacturing, chemical instruments and methods, etc., can solve the problems of easy generation of static electricity, affecting the drilling quality of products, and increasing the risk factor, so as to prevent the generation of static electricity and improve drilling The effect of hole quality rate and risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

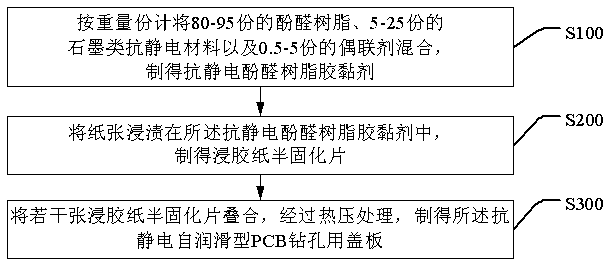

[0023] Based on the above problems, the invention provides a kind of preparation method of antistatic self-lubricating type PCB drilling cover plate, wherein, such as figure 1 shown, including steps:

[0024] S100, mixing 80-95 parts by weight of phenolic resin, 5-25 parts of graphite antistatic material and 0.5-5 parts of coupling agent to prepare an antistatic phenolic resin adhesive;

[0025] S200, immersing the paper in the antistatic phenolic resin adhesive to prepare a prepreg for impregnated paper;

[0026] S300, stacking several sheets of rubber-impregnated paper prepregs, and subjecting them to hot-pressing treatment, to prepare the antistatic self-lubricating cover plate for drilling holes in PCB.

[0027] Specifically, in the present invention, 80-95 parts of phenolic resin, 5-25 parts of graphite antistatic material and 0.5-5 parts of coupling agent are added together, and mixed by mechanical stirring under the condition of 25-65°C Uniform, prepared antistatic ph...

Embodiment 1

[0044] a. Add 85 parts of cardanol-modified phenolic resin, 10 parts of graphite oxide, and 3 parts of coupling agent, add various materials into the reaction kettle, and mix them uniformly by mechanical stirring under the condition of 35°C to prepare antistatic phenolic resin Resin adhesive.

[0045] b. The bleached wood pulp paper was impregnated with the antistatic phenolic resin adhesive, and at a temperature of 130°C and a vehicle speed of 23m / min, an antistatic lubricating phenolic resin impregnated paper prepreg with a glue content of 42% was prepared. 6% degree, 7% volatility;

[0046]c. Take two prepregs and stack them in a hot press, press them at a temperature of 160°C, a pressure of 7 MPa, and a time of 60 minutes to obtain a finished antistatic self-lubricating cover plate.

Embodiment 2

[0048] a. Add 80 parts of alcohol-soluble phenolic resin, 5 parts of graphite antistatic material, and 0.5 parts of coupling agent, and add various materials into the reaction kettle, and mix them uniformly by mechanical stirring under the condition of 25°C to prepare antistatic phenolic resin Resin adhesive.

[0049] b. The bleached wood pulp paper was impregnated with antistatic phenolic resin adhesive, under the conditions of temperature 100 ℃ and vehicle speed 20m / min, an antistatic self-lubricating phenolic resin impregnated paper prepreg with a glue content of 40% was prepared. 4%, volatility 3%;

[0050] c. Take two prepregs and stack them in a hot press, press them at a temperature of 120°C, a pressure of 6 MPa, and a time of 50 minutes to obtain a finished antistatic self-lubricating cover plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com