Equipment used for crushing fluorite tailings, crushing method and fluorite flotation method

A technology for fluorite tailings and equipment, which is applied in the field of equipment for grinding fluorite tailings, can solve the problems of high energy consumption, strong vibration and noise, large and heavy volume, etc., and achieves low cost, high recovery rate and good concentrate quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

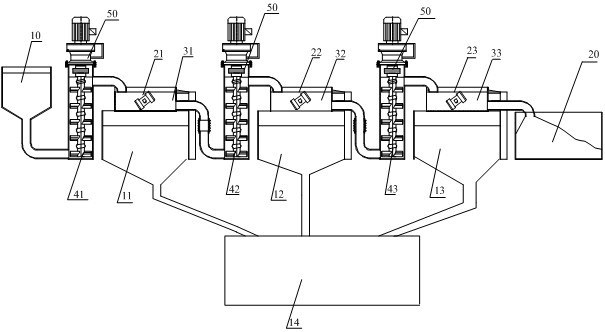

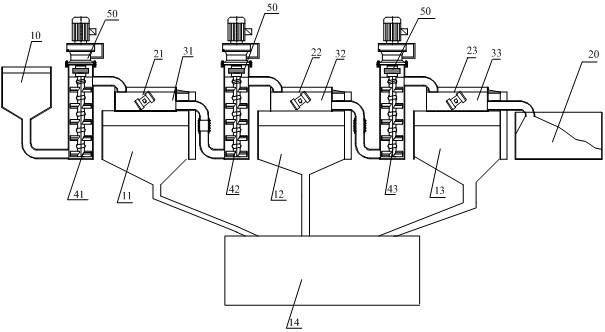

[0016] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in further detail: a kind of equipment for crushing fluorite tailings, comprises: tailings receiver 10 and first agitator 41, described first agitator 41 is connected with a first vibrating sieve 21, which contains primary coarse fluorite powder particles and steel balls 31, and a first collector 11 is arranged below the first vibrating sieve 21, and the first vibrating sieve 21 is connected with a second stirring device 42, the second agitator 42 is connected with a second vibrating sieve 22, which contains secondary coarse fluorite powder particles and steel balls 32. A second collector 12 is arranged at the bottom 22 of the second vibrating sieve. The second vibrating sieve 22 is connected with a third agitator 43, and the third agitator 43 is connected with a third vibrating sieve 23, which contains three times coarse fluorite powder particles and steel balls 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com