Sodium bichromate waste residue treatment method

A treatment method and a technology of sodium alumite, applied in chemical instruments and methods, solid waste removal, magnetic separation and other directions, can solve problems such as high economic benefits and chromium slag pollution, reduce environmental pollution, reduce ore consumption, and save storage and disposal. effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for treating waste slag of sodium red alum. After the waste slag of sodium red alum is subjected to an N-level magnetic separation and washing step, the magnetic substances that do not adsorb hexavalent chromium are separated from the non-magnetic substances that have adsorption force to hexavalent chromium, and a hexavalent chromium-enriched solution, non-magnetic, is obtained. Magnetic slag and standard non-toxic waste slag, enriched hexavalent chromium solution can be returned to the red alum sodium production process for reuse, standard non-toxic waste slag enters the next step of comprehensive utilization, and non-magnetic slag enters the next step of harmless treatment. The mass ratio of the magnetic non-adsorbing hexavalent chromium to the non-magnetic material having hexavalent chromium adsorption is 9:1.

[0027] After the non-magnetic mixed liquid is treated by a filter press, the enriched hexavalent chromium solution is returned to the production proc...

Embodiment 2

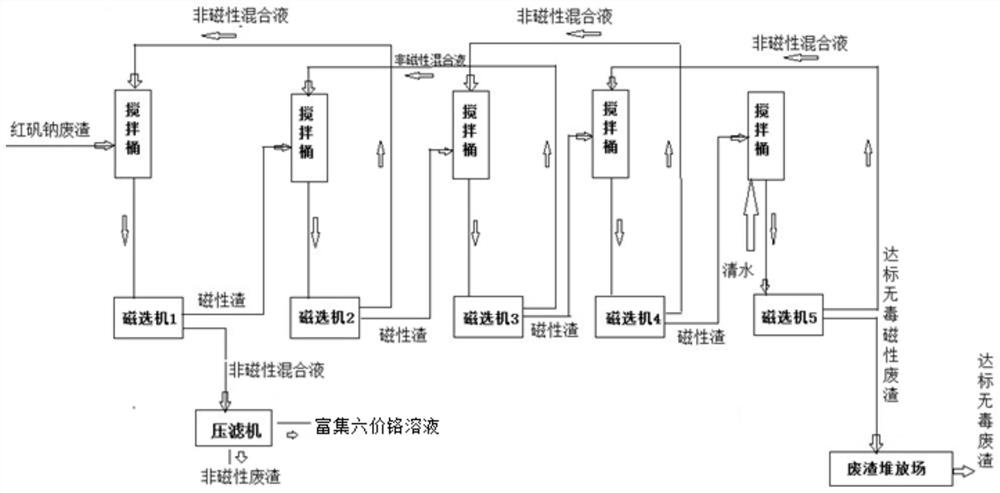

[0030] When N=3, the waste slag enters the first magnetic separator after being evenly stirred by the non-magnetic mixed liquid produced by the first mixing tank and the second magnetic separator, and the magnetic slag enters the second mixing tank and the third magnetic separator. The non-magnetic mixed liquid produced by the separator is stirred evenly and then enters the second magnetic separator, and the non-magnetic mixed liquid in the magnetic separator is returned to the first stirring tank as waste residue washing liquid for recycling; in the second magnetic separator The magnetic slag enters the third mixing tank, and a certain amount of clear water is added at the same time, and then enters the third magnetic separator after stirring evenly, and the non-magnetic mixed liquid produced enters the second mixing tank for recycling; the first magnetic machine The medium and non-magnetic mixed liquid (containing sodium chromate solution) enters the filter press for recyclin...

Embodiment 3

[0032] In this embodiment, 5 magnetic separators are provided. Chromium slag contains 0.1% of hexavalent chromium, and the national standard for general industrial solid waste is that the hexavalent chromium content of waste slag leachate is less than 5ppm.

[0033] The red alum sodium waste residue is a calcium-free roasting method waste residue, and the magnetic separation washing method is a wet magnetic separation process, which is realized by a magnetic separator. The magnetic separator is an electromagnetic separator and / or a permanent magnet magnetic separator; wherein the magnetic force is electromagnetic and / or permanent magnet.

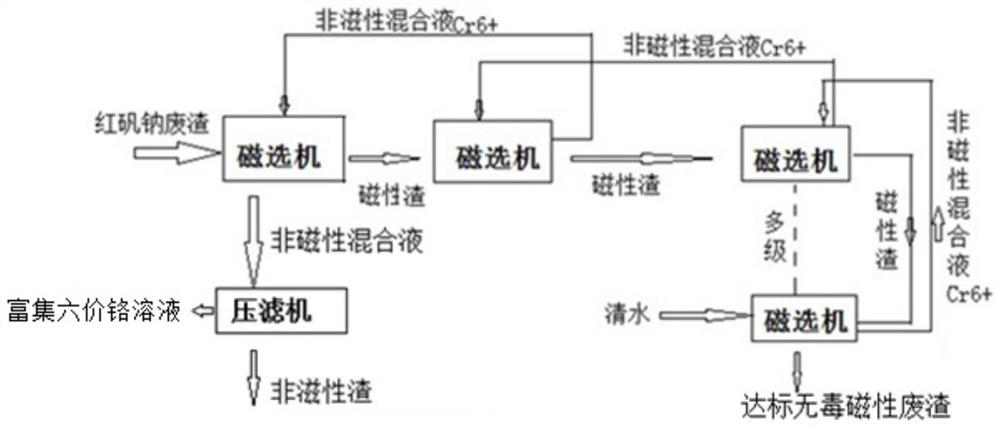

[0034] Specific process such as figure 1 Shown:

[0035] (1) The red alum sodium waste residue is sent into No. 1 mixing tank, mixed with the non-magnetic mixed liquid from No. 2 magnetic separator, and enters into No. 1 magnetic separator after being vigorously stirred into a slurry, and is divided into magnetic slag and non-magnetic slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com