Patents

Literature

44results about How to "Stable production conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

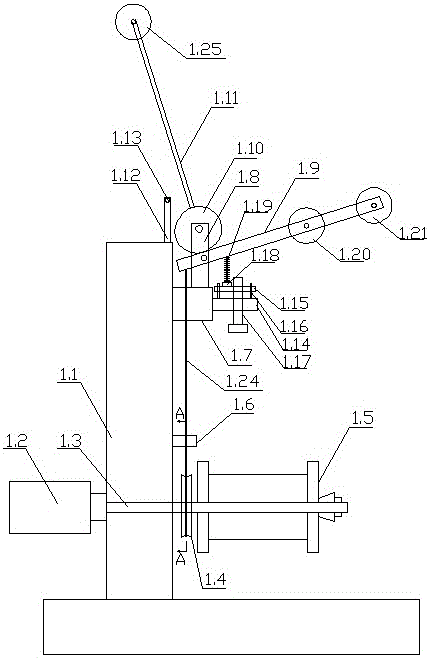

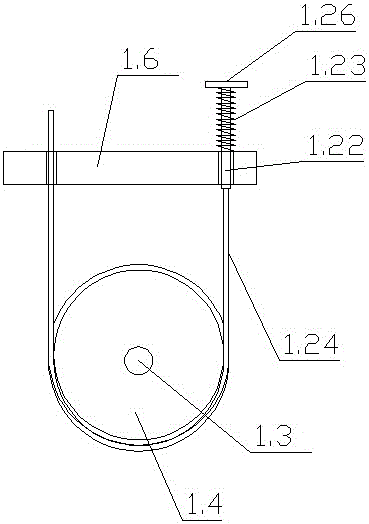

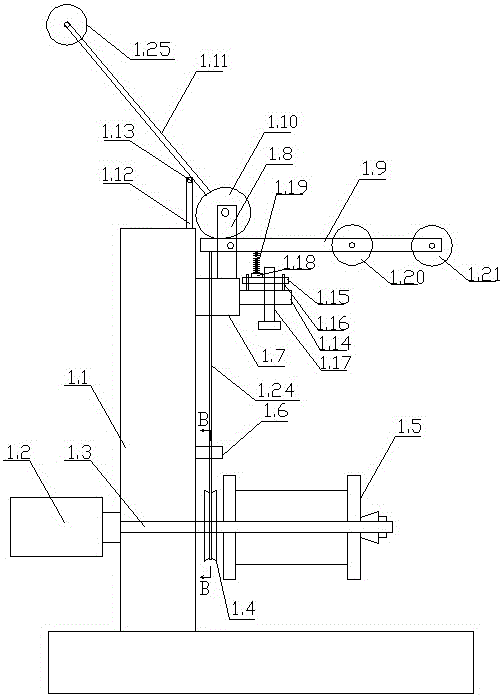

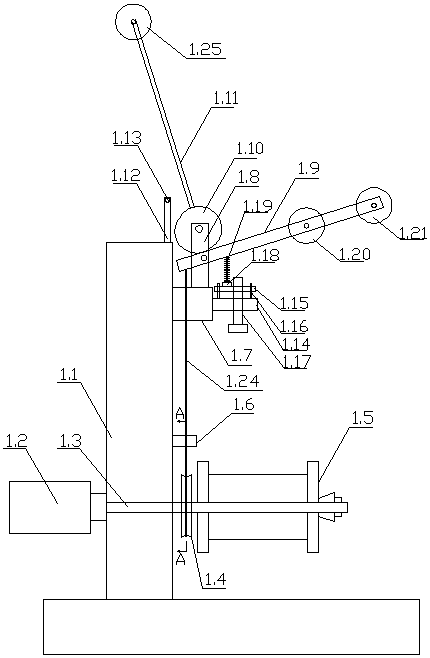

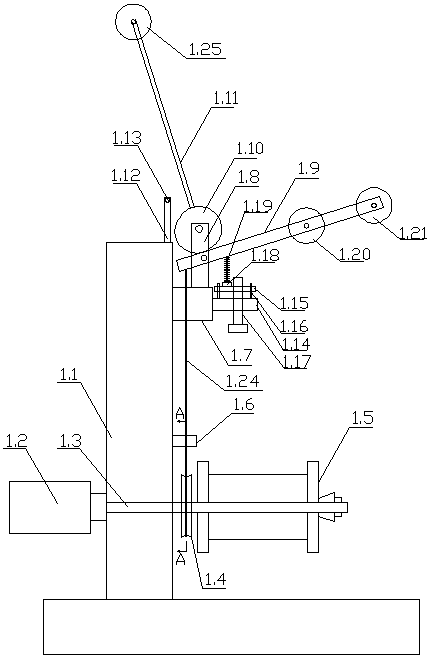

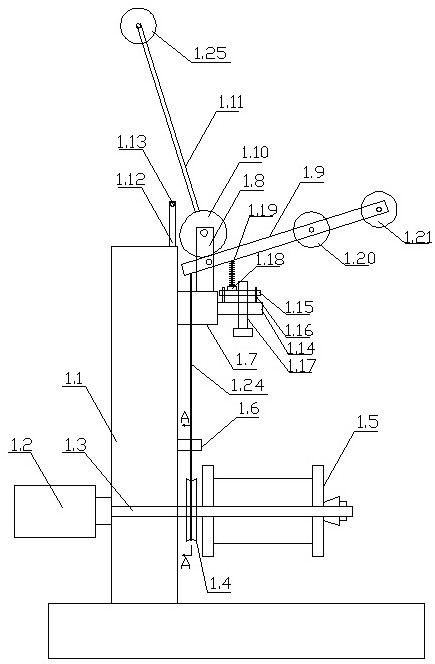

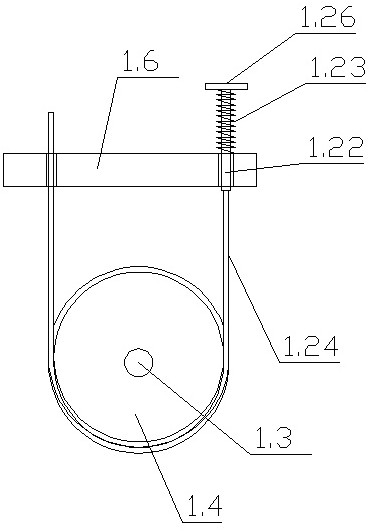

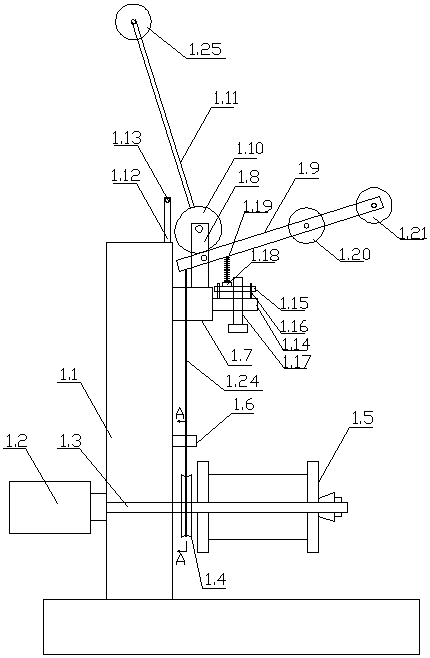

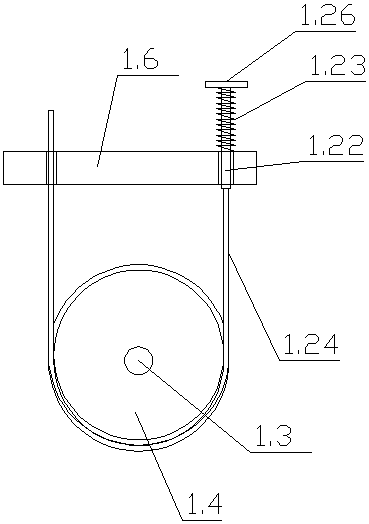

Unwinding self-adaptive coaxial cable unwinding device and unwinding method thereof

ActiveCN106710715AStable production conditionsGood product qualityApparatus for feeding conductors/cablesManufacturing co-axial cablesSelf adaptiveEngineering

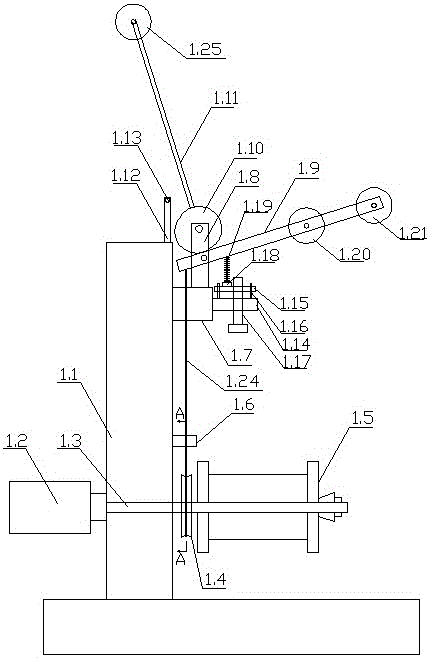

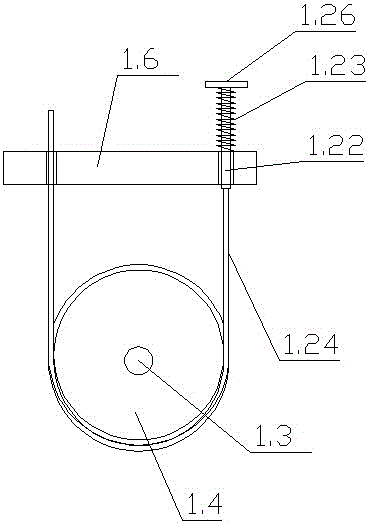

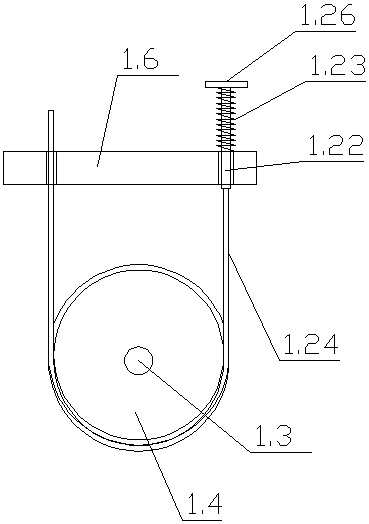

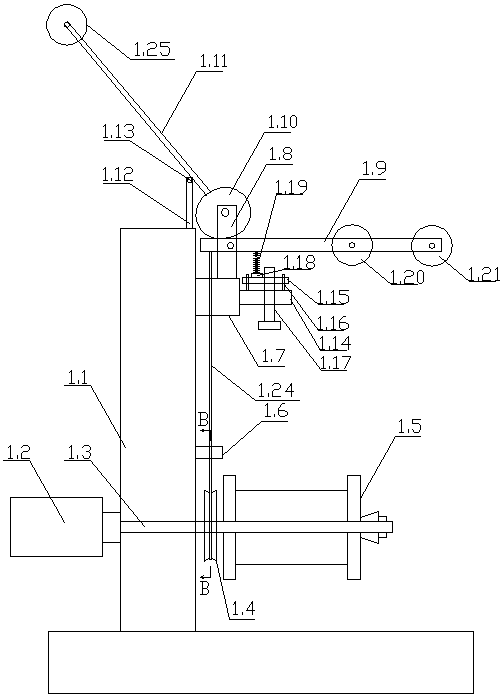

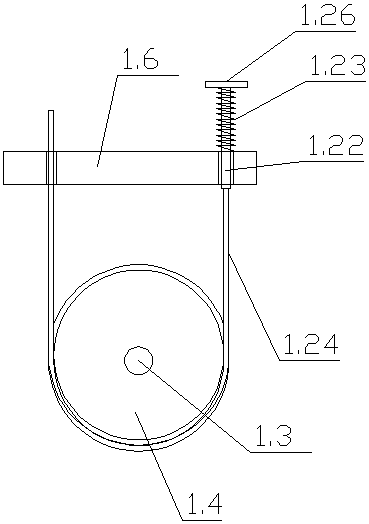

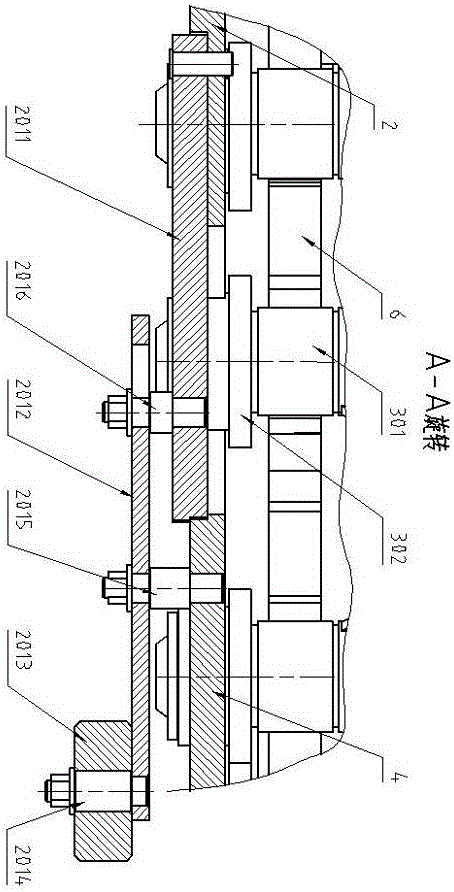

The invention relates to an unwinding self-adaptive coaxial cable unwinding device which is characterized by comprising a rack (1.1), a motor (1.2), an unwinding shaft (1.3), a locking wheel (1.4), a fixed plate (1.6), a supporting base (1.7), a supporting frame (1.8), a floating rod (1.9), a cam (1.10), a supporting rod (1.11), a vertical bracket (1.12), a stop rod (1.13), an adjusting frame fixing base (1.14), an adjusting frame (1.15), a spring pedestal (1.18), a floating rod spring (1.19), a floating rod first guide wheel (1.20), a floating rod second guide wheel (1.21), a locking rope (1.24), a supporting rod guide wheel (1.25) and a stop block (1.26). The unwinding self-adaptive coaxial cable unwinding device and an unwinding method thereof have the advantages of being stable in production condition and great in product quality.

Owner:SHENYU COMM TECH

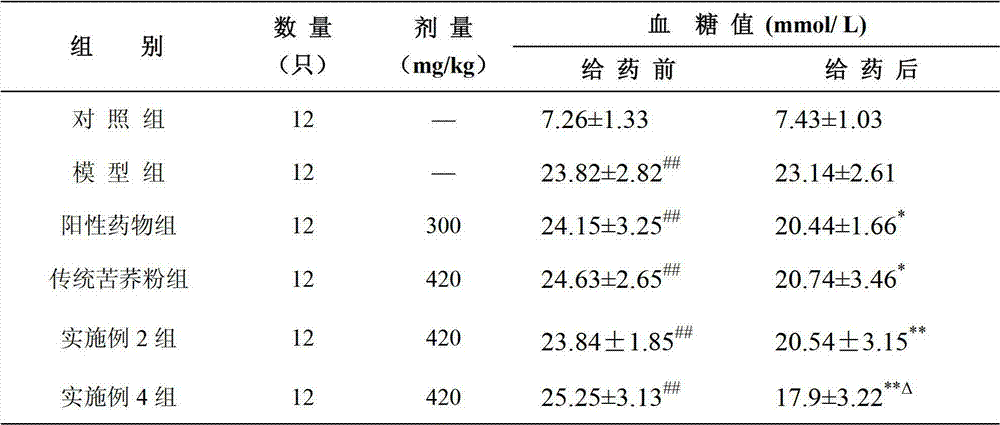

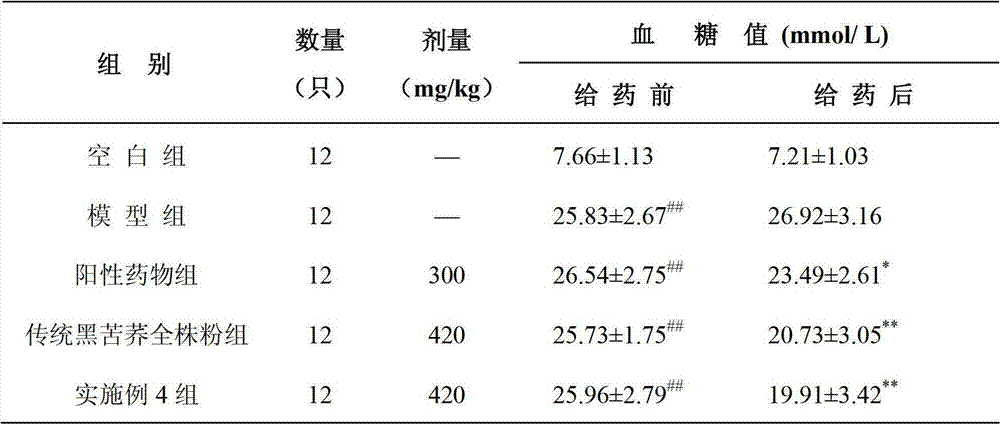

Method for culturing Fagopyrum tataricum(L.)Gaertn, Fagopyrum tataricum(L.)Gaertn powder and preparation thereof

InactiveCN102893783AShorten flowering timeShorten the harvest timeFood preparationHorticultureHarvest timeGreenhouse

The invention provides a method for culturing Fagopyrum tataricum(L.)Gaertn, which comprises the following operating steps: (1) taking Fagopyrum tataricum(L.)Gaertn seeds, removing impurities, soaking, standing until germination, and culturing with water at the temperature of between 25 and 35 DEG C in a greenhouse; and (2) culturing to a period 5 to 10 days before blossom, and collecting fresh stem leaves of Fagopyrum tataricum(L.)Gaertn. The invention also provides Fagopyrum tataricum(L.)Gaertn powder and a preparation method thereof. The invention also provides a Fagopyrum tataricum(L.)Gaertn food or health product. By the culture method, the flowering time of the Fagopyrum tataricum(L.)Gaertn can be obviously shortened, so that the harvest time of the Fagopyrum tataricum(L.)Gaertn is effectively shortened; meanwhile, the fresh stem leaves of the Fagopyrum tataricum(L.)Gaertn before blossom are only collected, the yield of raw materials is greatly improved (by 100-200 times) on the basis of ensuring the health effect of the Fagopyrum tataricum(L.)Gaertn, the profit of the Fagopyrum tataricum(L.)Gaertn product is improved by about 150 times, and the commercial value is high; and meanwhile, the culture method is implemented in the greenhouse, production conditions are stable, and the culture method has good industrial application prospect.

Owner:INVESTEMENT MANAGEMENT LTD

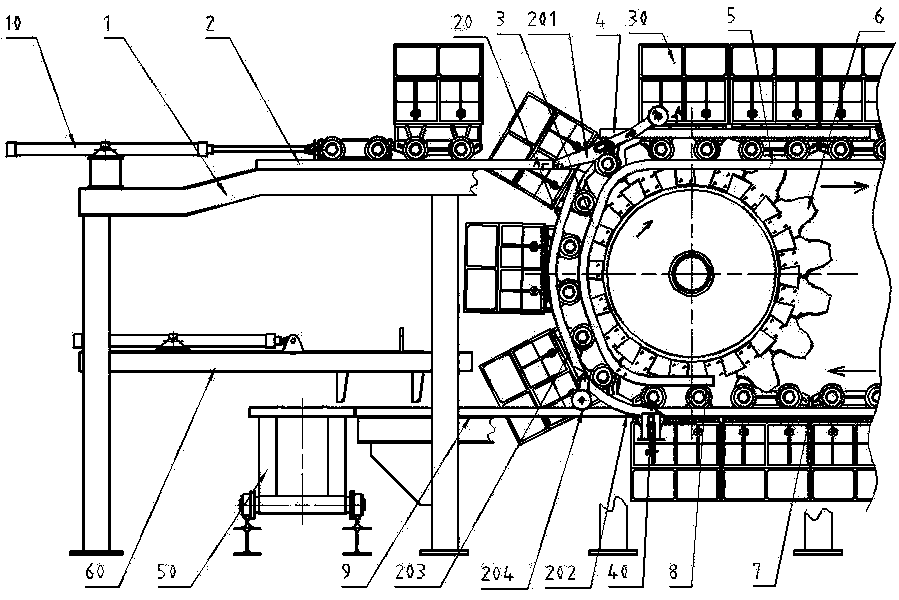

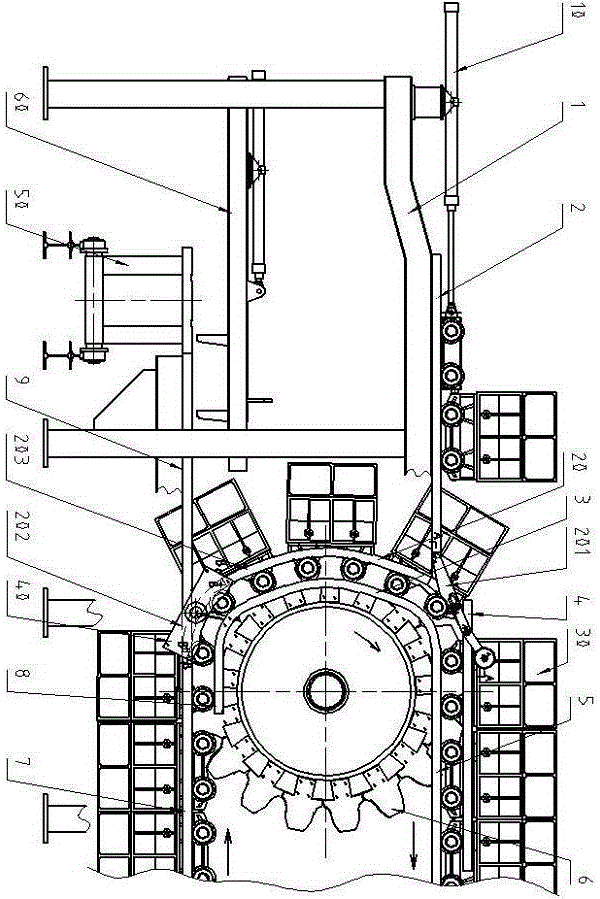

Trolley changing device

ActiveCN104236310AAchieve replacementIncrease productivityCharge manipulationFurnace typesStructural engineeringIndustrial engineering

The invention relates to a trolley changing device and belongs to the technical fields of trolley changing of metallurgical industry sintering machines and belt type roasting machines. The device comprises a trolley, an inner straight rail, an inner curved rail, an outer straight rail, an outer curved rail, a main transmission wheel, a trolley moving-out rail and a trolley moving-in rail. The outer curved rail on two sides of the main transmission wheel are segmented into a lower movable outer curved rail, a middle fixed outer curved rail and an upper movable outer curved rail; the upper end of the lower movable outer curved rail is hinged to the lower end of the middle fixed outer curved rail, and one end of the upper movable outer curved rail is hinged to one end of the trolley moving-in rail. By the aid of the device, the trolley of the sintering machine or belt type roasting machine can be changed without shutdown, the additional trolley changing time can be omitted, and producing efficiency is improved; the shutdown and blowing reducing or stopping operations of the sintering machine or belt type roasting machine are avoided, and the producing state is unchanged and is stable correspondingly; since the production condition is stable, the product qualifying rate and drum revolving index are not decreased.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

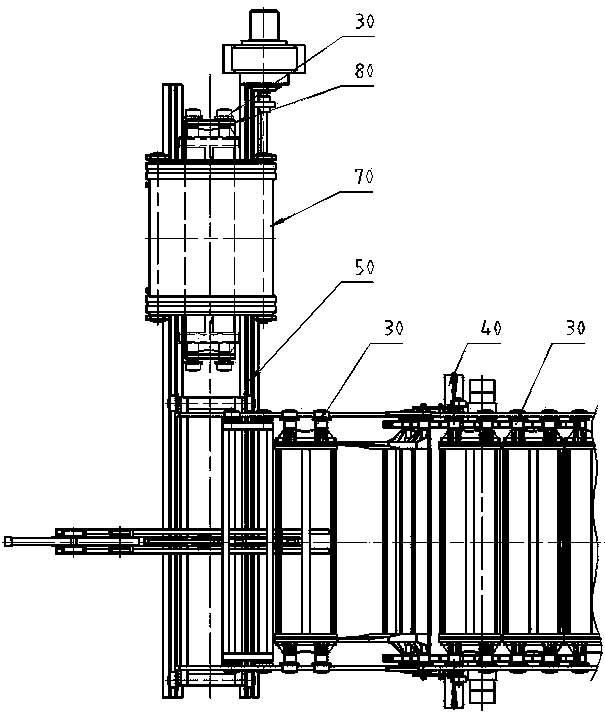

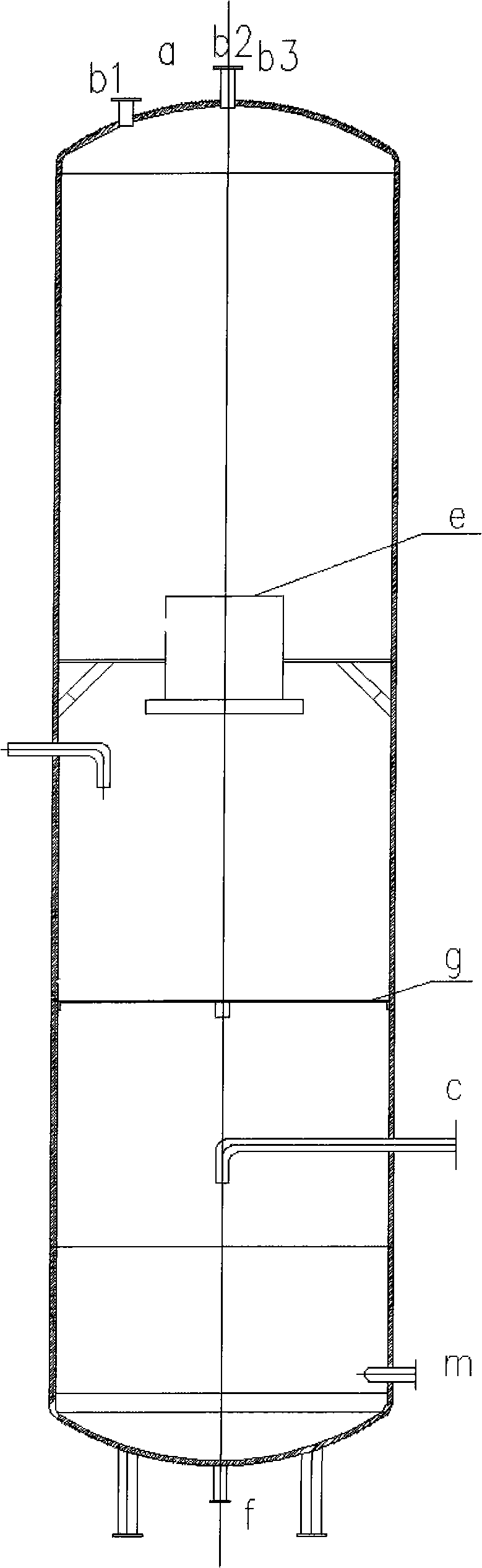

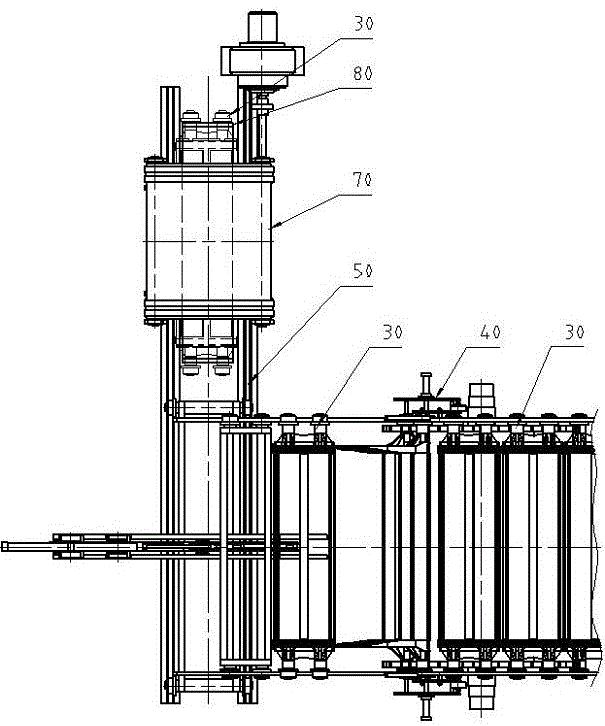

Preparation method and preparation device for synthesis ammonia prereduction catalyst

InactiveCN105435861AHigh strengthKeep aliveCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrogenNitrogen

The invention provides a preparation method and a preparation device for a synthesis ammonia prereduction catalyst. The preparation method comprises the following steps: feeding a synthesis ammonia Fe catalyst into a reduction tower, and introducing mixed hydrogen and nitrogen; then heating at a heating rate of 30-40 DEG C / h, and performing reduction reaction when the temperature raises to 365-380 DEG C; after the reduction reaction is over, discharging the mixed hydrogen and nitrogen out of the reduction tower; when the temperature is reduced to be not higher than 50 DEG C and normal pressure is achieved, introducing oxygen for passivating, wherein the pressure during the passivation process is kept between 0.018MPa and 0.02MPa; and after the temperature is reduced to be not higher than 46 DEG C, finishing passivation, thereby obtaining the synthesis ammonia prereduction catalyst. In the preparation device, in-parallel double towers are adopted for the reduction tower, a passivation groove is omitted, heating reduction and passivation are performed in the reduction tower, and a method of negative pressure extraction by use of a circulating fan is adopted during the passivation process, so that the effective production time is obviously increased, the reducing capacity is greatly improved, the operation difficulty is simplified, power consumption is reduced, and the air inflow stability of a system is ensured.

Owner:HENAN ZHONGHONG CLEAN ENERGY CO LTD

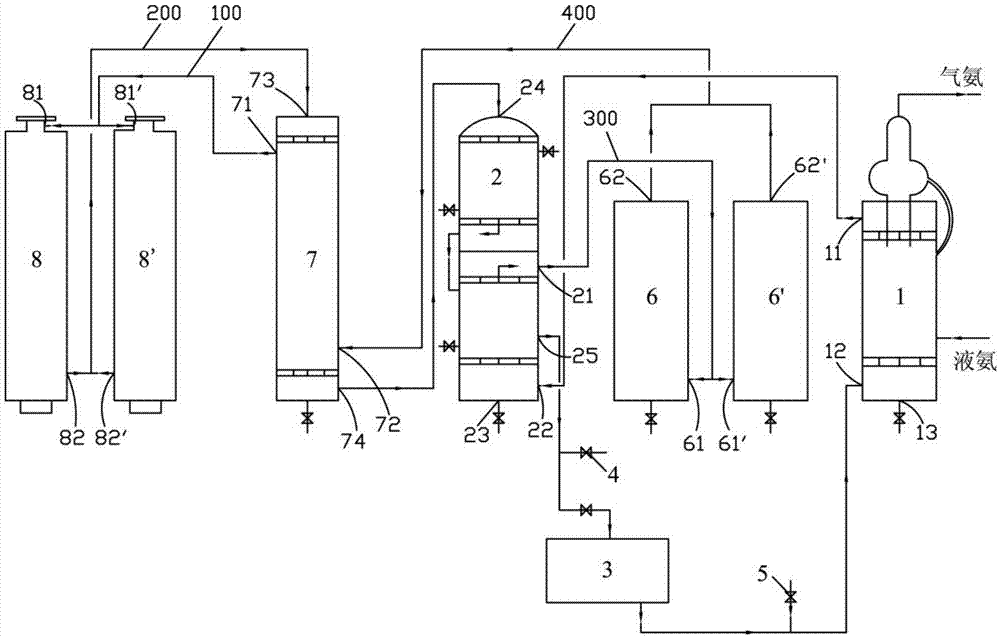

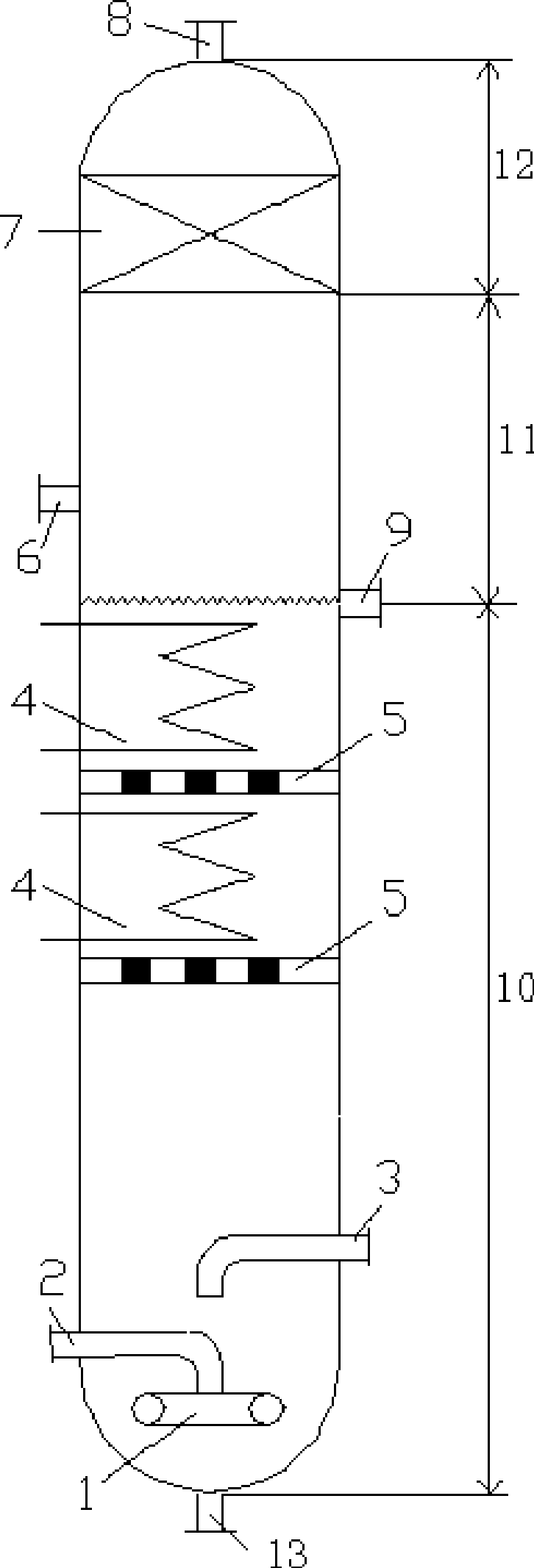

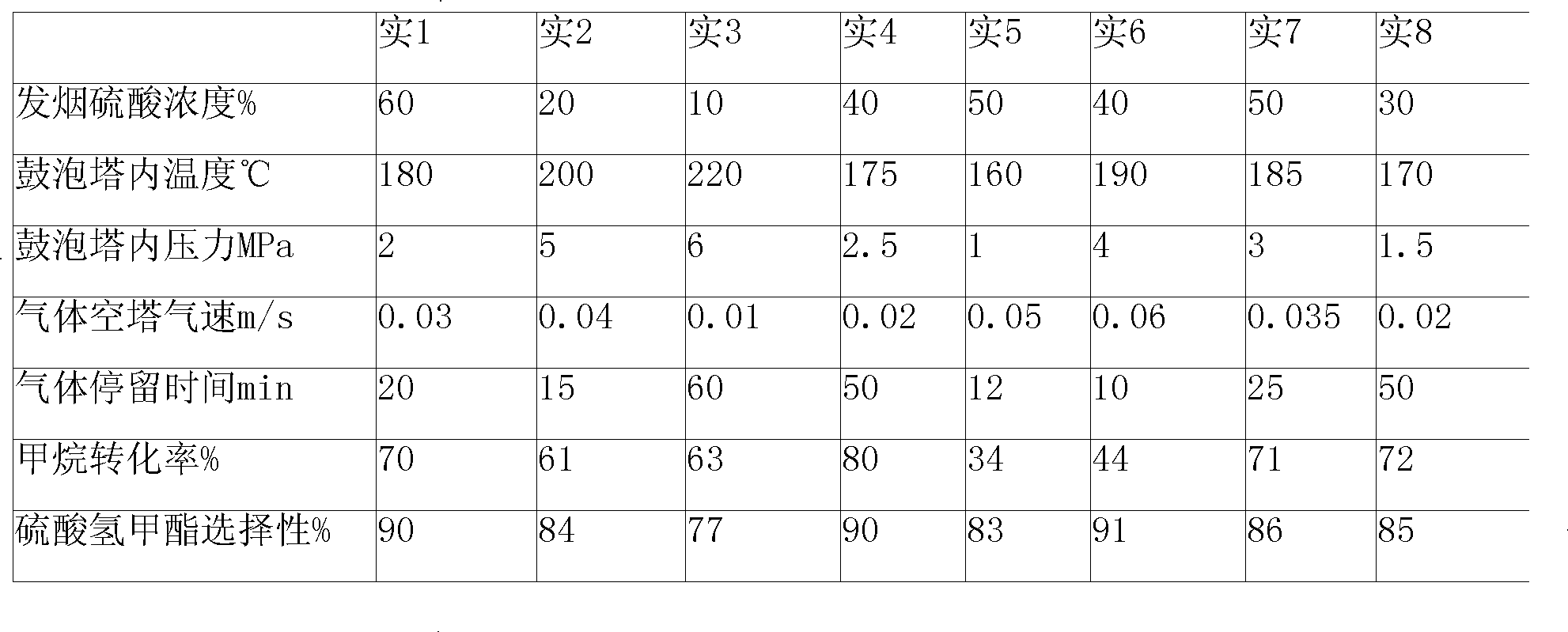

Method for preparing methyl alcohol by continuous methane liquid phase oxidation

InactiveCN101434514ASimple processLow reaction pressurePreparation by oxidation reactionsHydrogen SulfateAlcohol

The invention discloses a preparation method of methanol by methane liquid phase continuous oxidation; and the method adopts a bubble tower or other gas-liquid reactors. In the reaction conditions that the temperature is 160 to 220 DEG C and the pressure is 1 to 6Mpa, the methanol and oleum containing a catalyst are continuously added into a reactor; the methanol is oxidized by SO3 and sulphuric acid, and methyl-hydrogen-sulfate is generated after the reaction; and the methyl-hydrogen-sulfate is hydrolyzed and then methanol can be prepared. Compared with an interval process, the continuous liquid phase oxidation process is characterized by low reaction pressure, stable producing conditions and being more suitable for industrialized production.

Owner:HANERGY TECH

Exhaust steam trap and method of use thereof

InactiveCN101284771AReduce frequency of tuning operationsEmission reductionChemical industryChemical/physical/physico-chemical processesBenzoic acidSteam trap

The invention relates to the utilization of steam, in particular to the utilization of boiler steam during the benzoic acid production process, which provides a dead steam catcher and the application thereof. The dead steam catcher adopts the structure that a steam-water separating valve is arranged at the middle upper part of the dead steam catcher, a steam-water separating disk is arranged at the middle lower part of the dead steam catcher, an steam inlet is formed between the steam-water separating valve and the steam-water separating disk, three steam outlets are formed at the top part of the dead steam catcher, and two water outlets are formed at the lower part of the dead steam catcher. The novel energy-saving equipment of the dead steam catcher (for short: boiling boiler) is adopted during the benzoic acid production process to collect the dead steam, which is generated after the toluene in an oxidation column is heated by the saturated boiler steam, so that the pressure of the dead steam is effectively maintained, and the maximum temperature of the dead steam, namely the enthalpy of the dead steam is also maintained, and can be reused for the production system.

Owner:TIANJIN DONGDA CHEM GRP

Catalyst and preparation method thereof and regeneration method of anthraquinone degradation product

ActiveCN110102276ALow costImprove regenerative abilityOrganic compound preparationHeterogenous catalyst chemical elementsWorking fluidAlkaline earth metal

The invention relates to the field of the regeneration of anthraquinone degradation products, and discloses a catalyst and a preparation method thereof and a regeneration method of a anthraquinone degradation product. The preparation method of the catalyst comprises the following steps that S1, activated alumina, an alkaline earth metal compound and an optional squeezing aid are mixed to obtain afirst dry material; S2, an acid solution and a silicon source are mixed to obtain a first liquid; S3, the first dry material and the first liquid are mixed and subjected to kneading, extruding and shaping, drying and roasting. The preparation method of the catalyst is simple and low in cost, can effectively improve the regeneration efficiency of the anthraquinone degradation product in a hydrogenperoxide working fluid containing 2-methyl cyclohexyl acetate, obviously reduces the accumulation of the anthraquinone degradation product in the working fluid, and increases the content of effectiveanthraquinone in the working fluid, thereby being conductive to improving the production efficiency.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

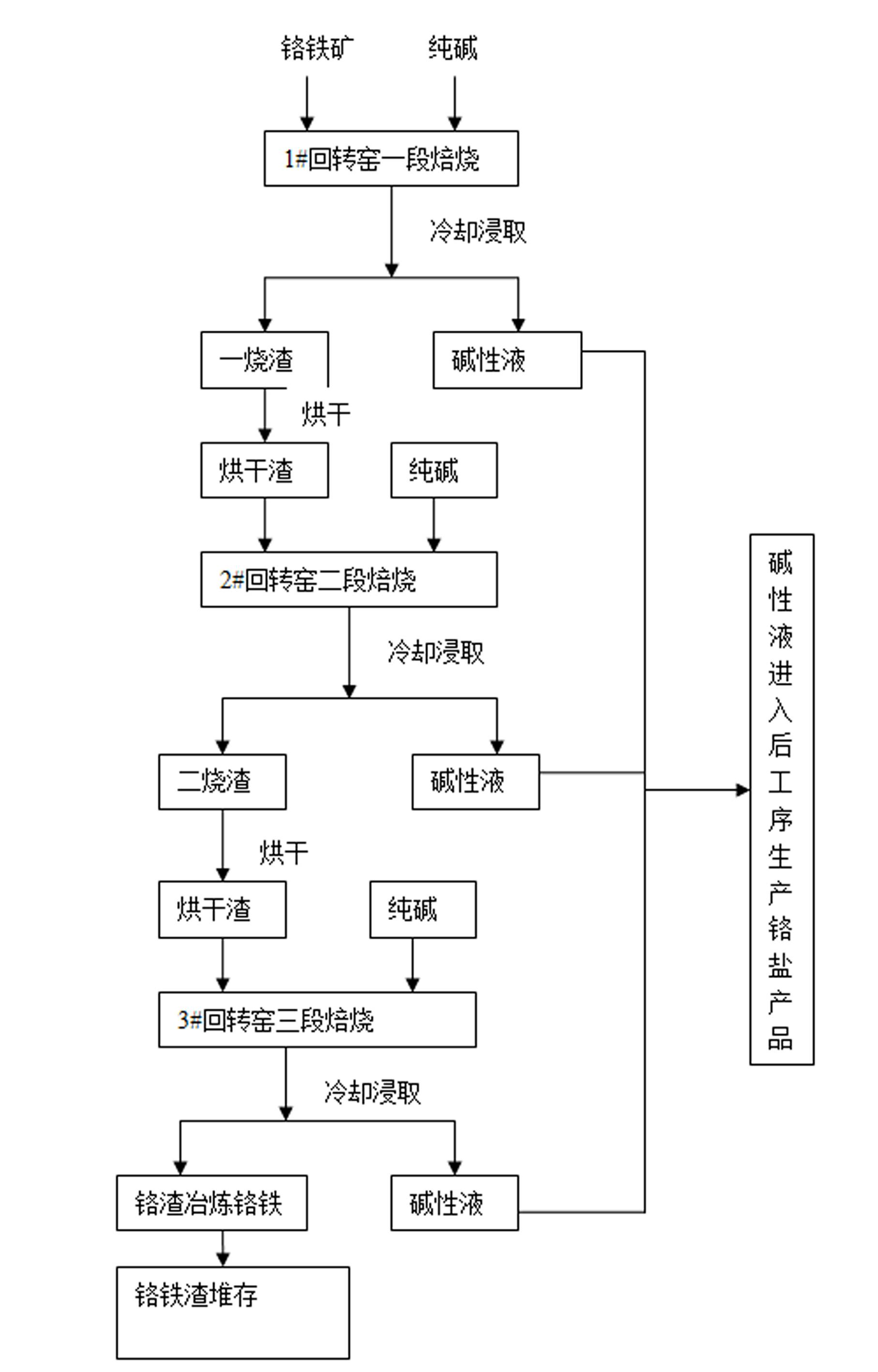

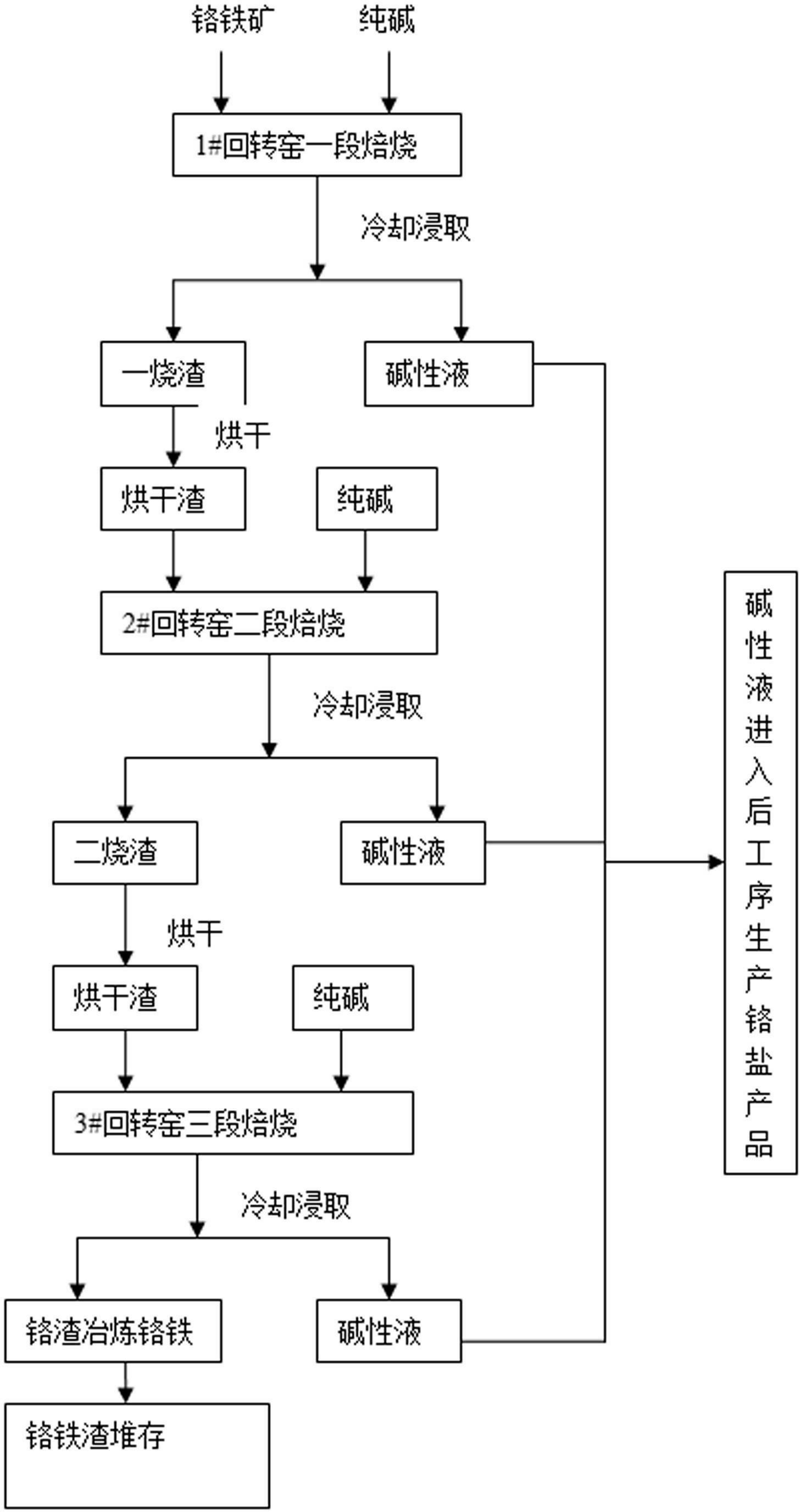

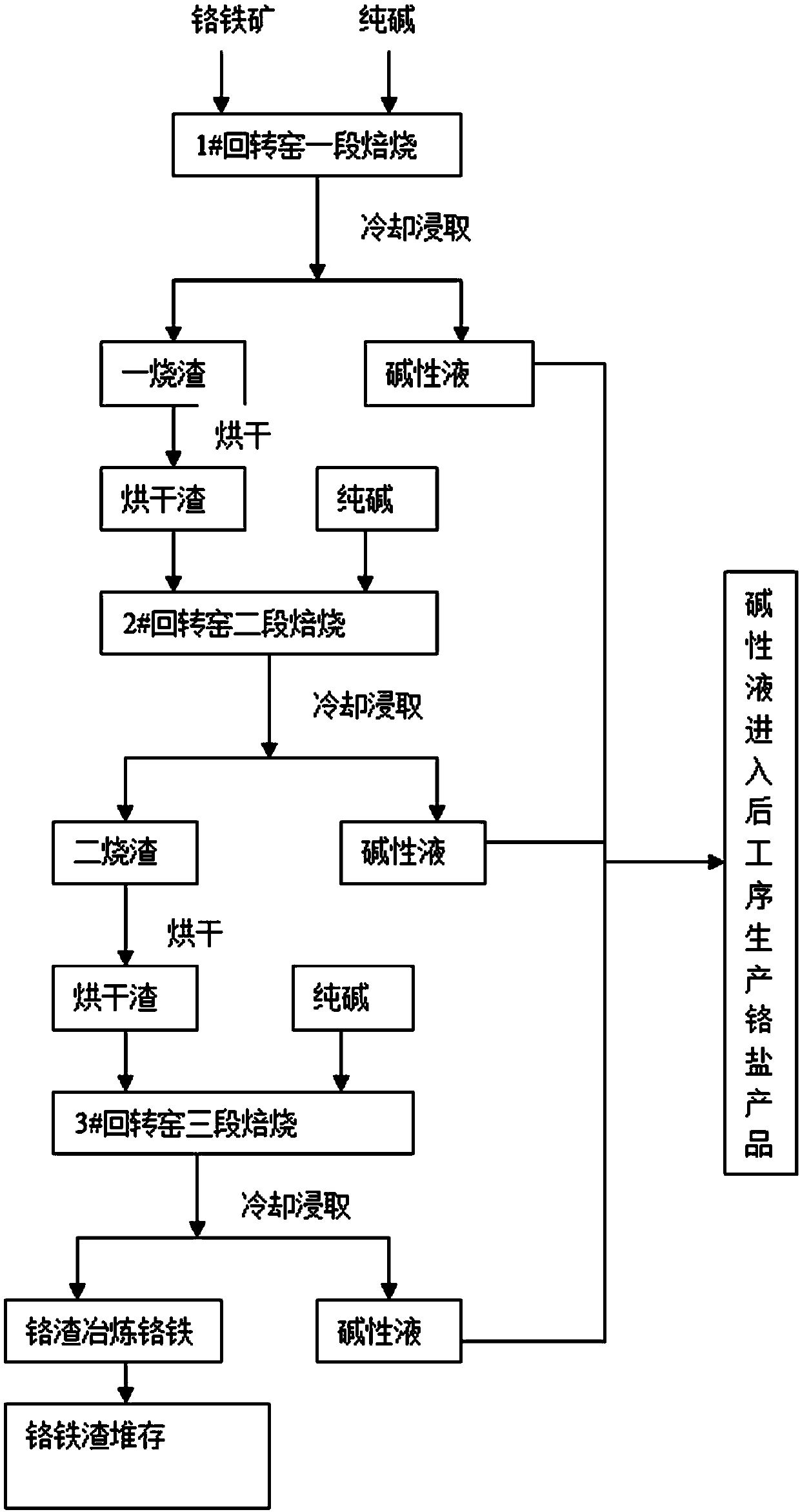

Method for producing sodium chromate and co-producing chrome-containing cast iron by three-stage process through un-calcium roasting

InactiveCN102557137AMine consumption reductionReduce alkali consumptionChromates/bichromatesSlagMixed materials

The invention discloses a method for producing sodium chromate and co-producing chrome cast iron by a three-stage process through un-calcium roasting, aiming at solving the problems of low roasting efficiency and high energy consumption in the existing method for producing chromic salt by un-calcium roasting. The method for producing sodium chromate by the three-stage process through un-calcium roasting comprises the following steps of: A, mixing roasting material in a first stage, mixing chromite and sodium carbonate in proportion; B, roasting in the first stage, putting the mixed material in the first stage into a rotary kiln and performing oxidizing roasting; C, leaching and filtering in the first stage; D, performing second-stage roasting technology; and E, performing third-stage roasting technology. The leaching of clinker after roasting for three times is same as the roasting leaching in the first time and the second time, the grinding leaching is performed to the clinker by a wet grinding ball mill, the clinker is filtered by a belt type filter and the filtered chromium slag by three-stage roasting is obtained by filtering of the belt type filter, the filter liquor is sodium chromate alkali solution. Compared with the traditional un-calcium roasting technology, the method in the invention adopts the three-stage process un-calcium roasting technology and effectively reduces the mine consumption and the alkali consumption and has the energy-saving and emission-reducing effect.

Owner:INNER MONGOLIA CHROMIUM

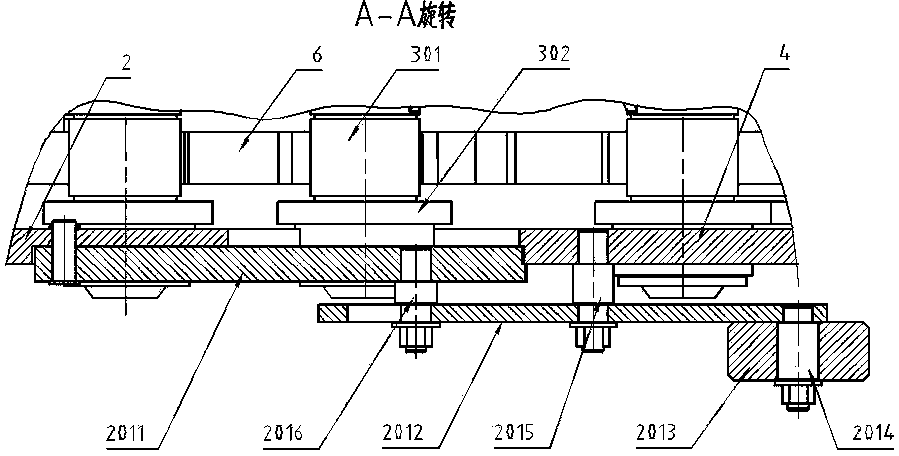

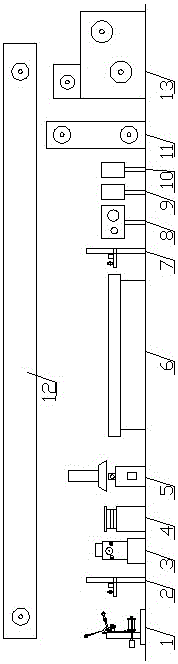

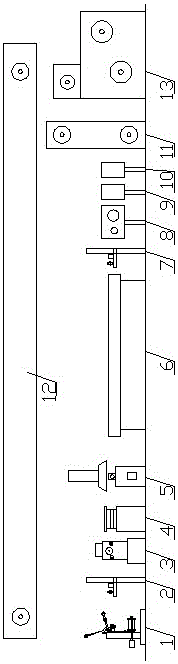

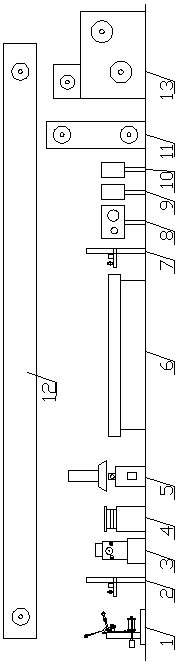

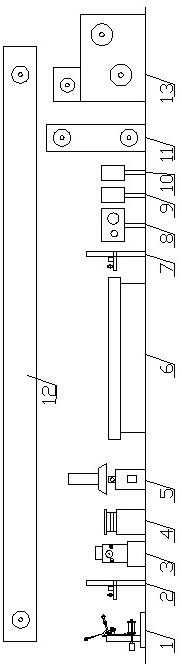

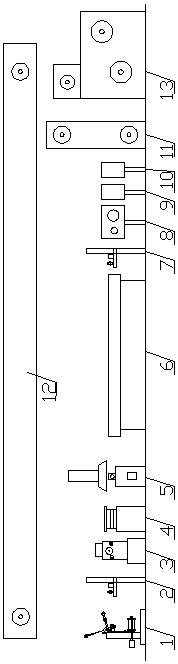

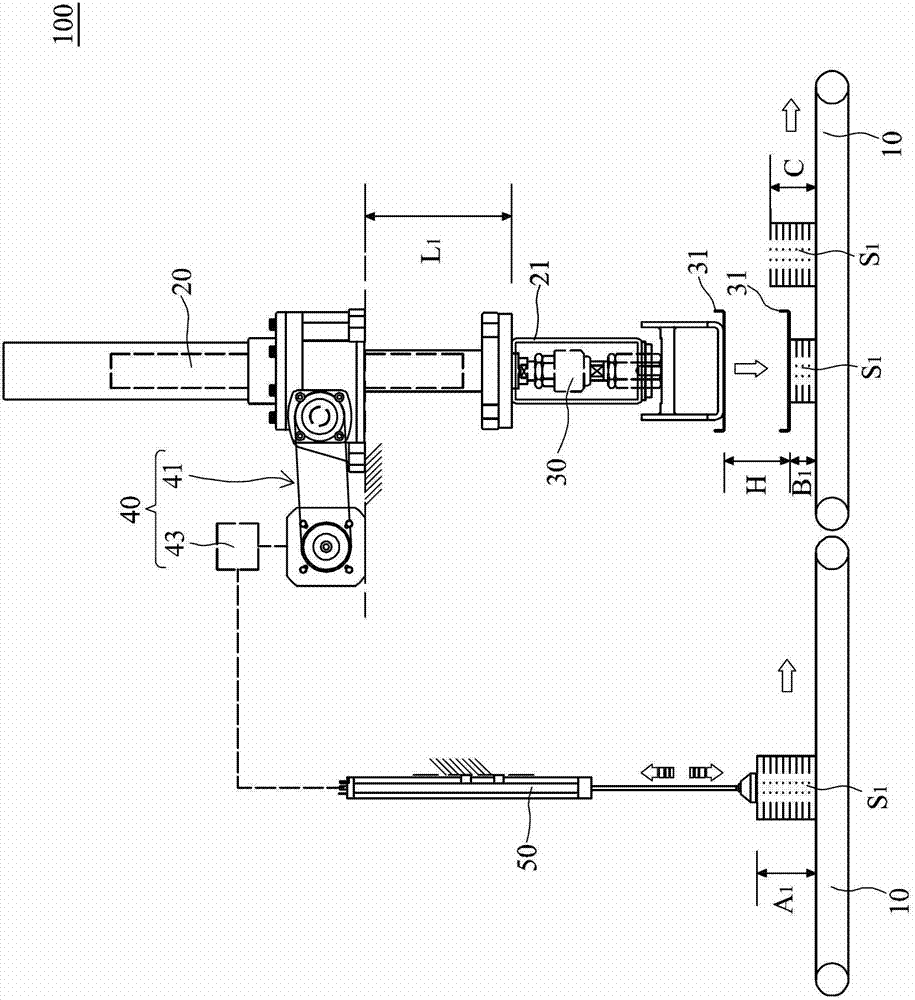

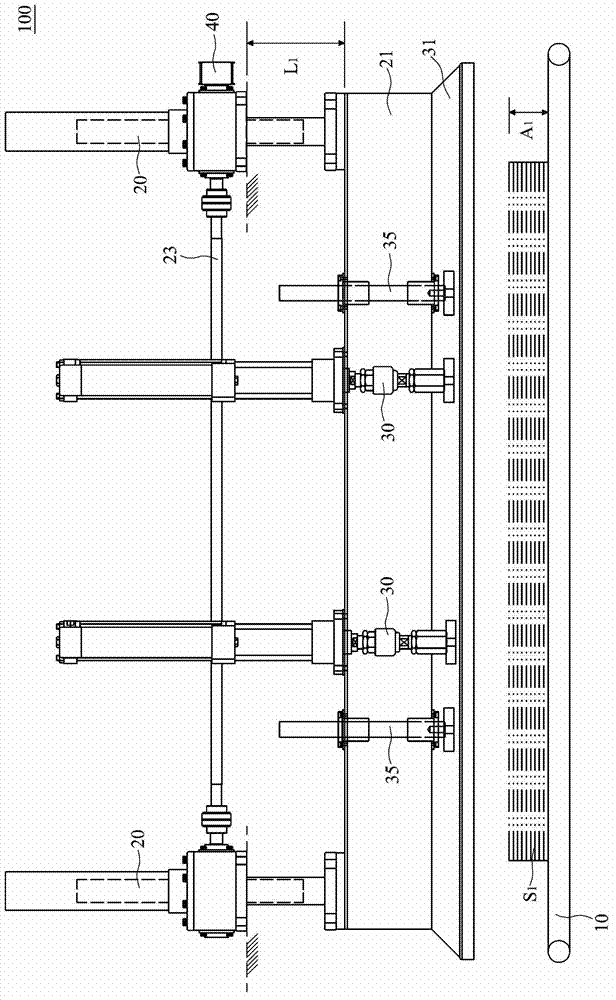

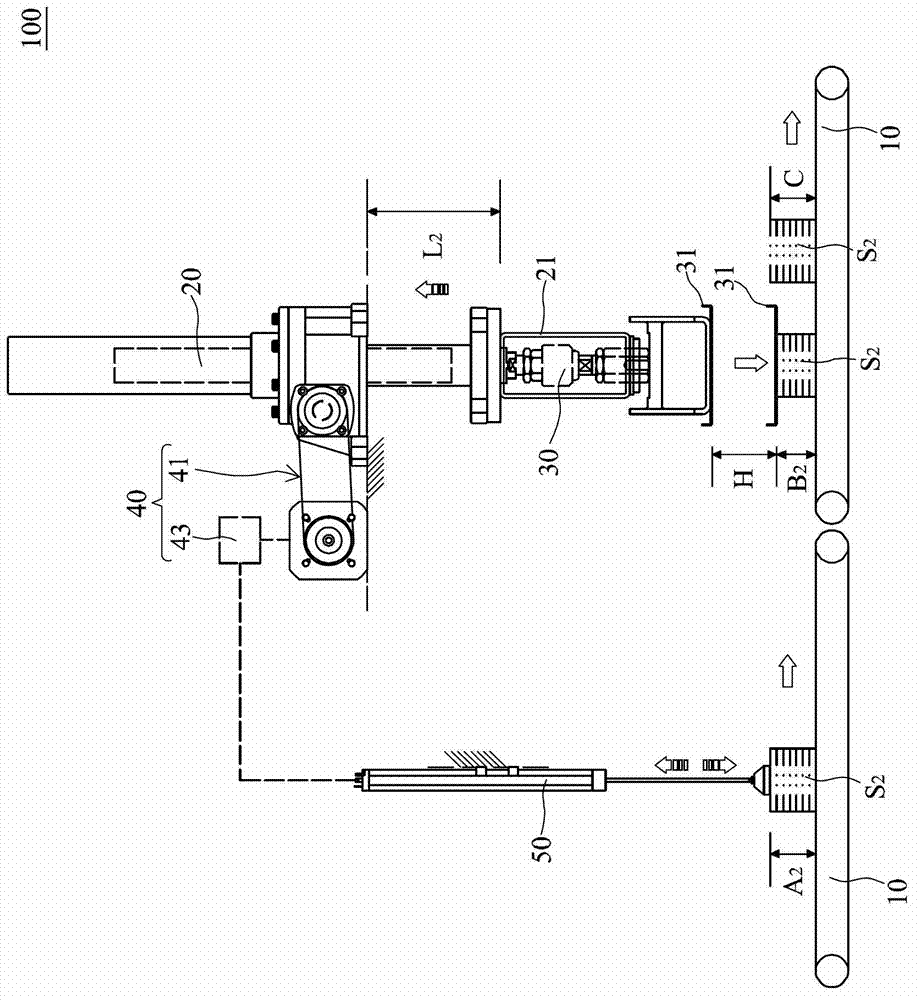

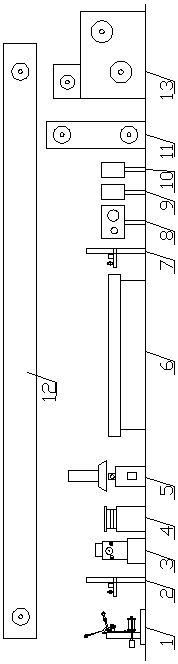

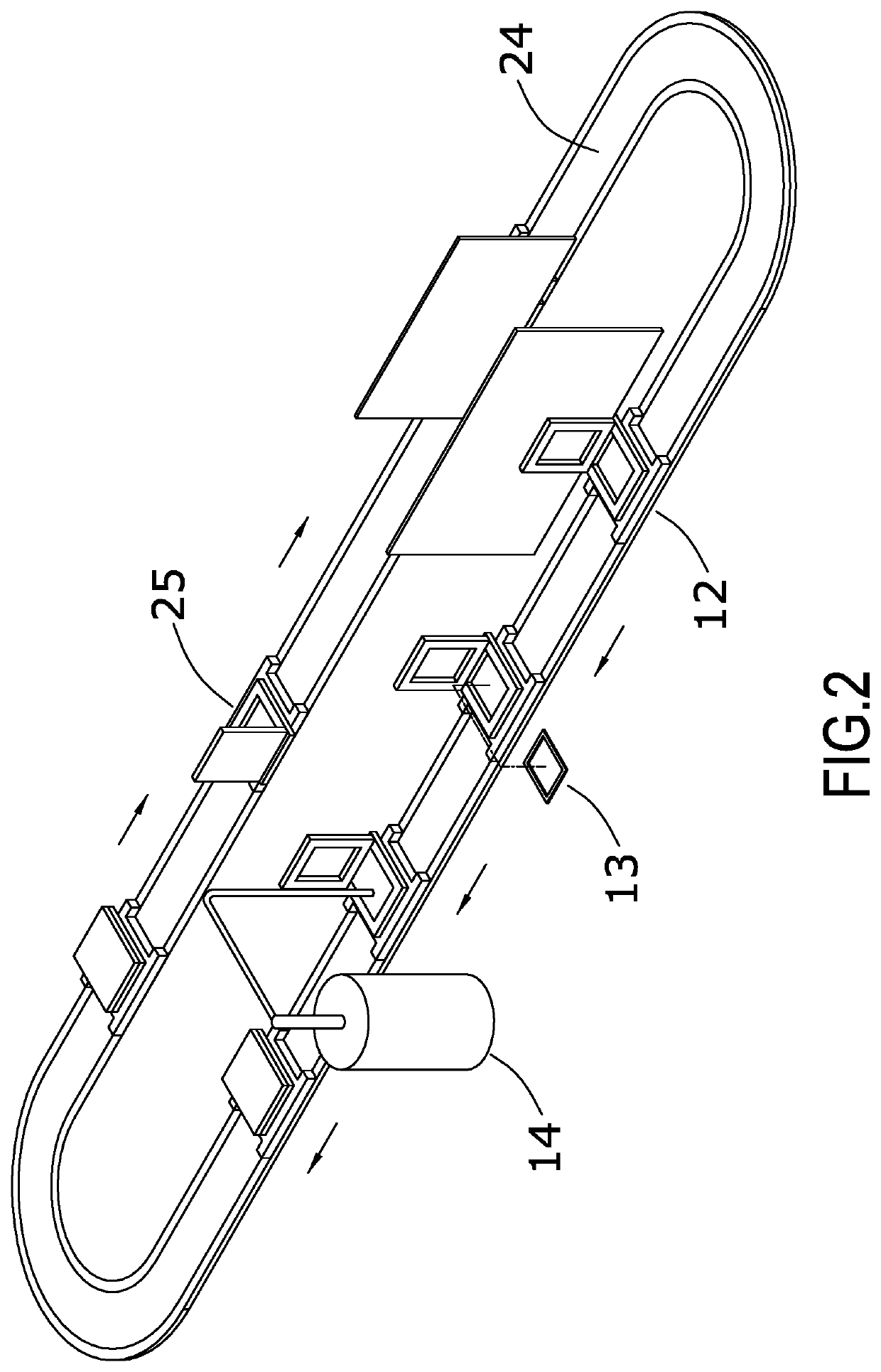

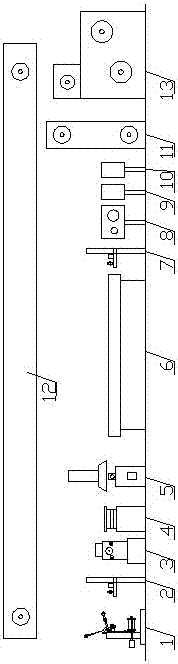

MCC extremely fine coaxial cable production line and production method thereof

ActiveCN106782903AStable production conditionsGood extrusion qualityManufacturing co-axial cablesProduction lineCoaxial cable

The invention relates to a MCC extremely fine coaxial cable production line which is characterized in that the MCC extremely fine coaxial cable production line comprises a wire releasing device (1), a first diameter measuring instrument (2), a first tension meter (3), a preheater (4), an extruder (5), a cooling device (6), a second diameter measuring instrument (7), a second tension meter (8), an electric spark detector (9), a concave and convex extent meter (10), a longitudinal wire storage device (11), a lateral wire storage device (12), and a wire take-up device (13), the adaptive wire release is realized through the wire releasing device (1), the production stability is improved, and an extruded product is cooled well through the cooling device (6). The MCC extremely fine coaxial cable production line and a production method thereof have the advantages of a stable production working condition and good extrusion quality.

Owner:SHENYU COMM TECH

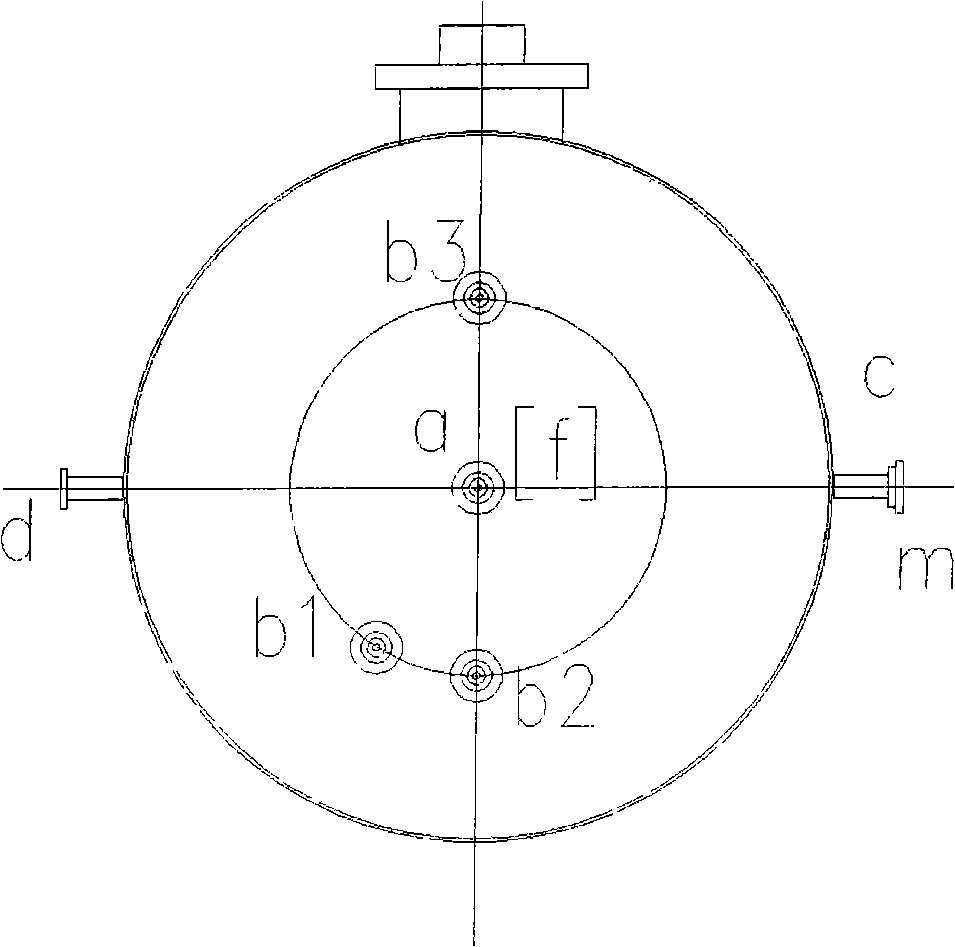

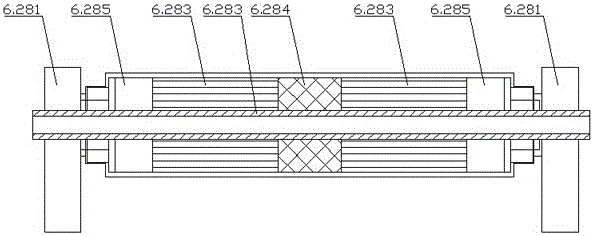

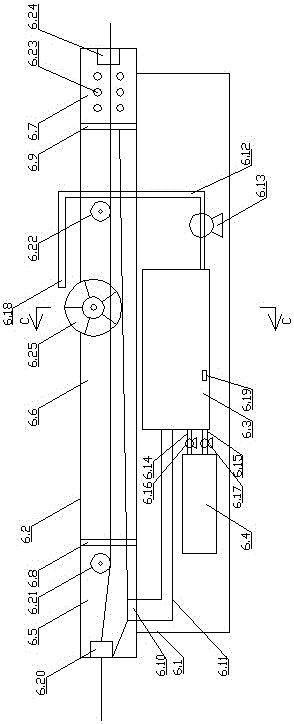

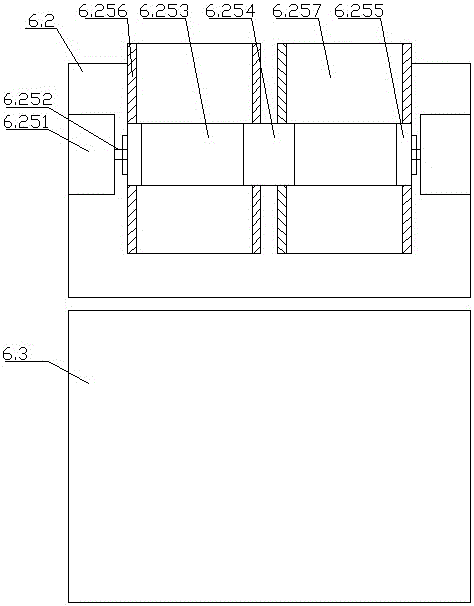

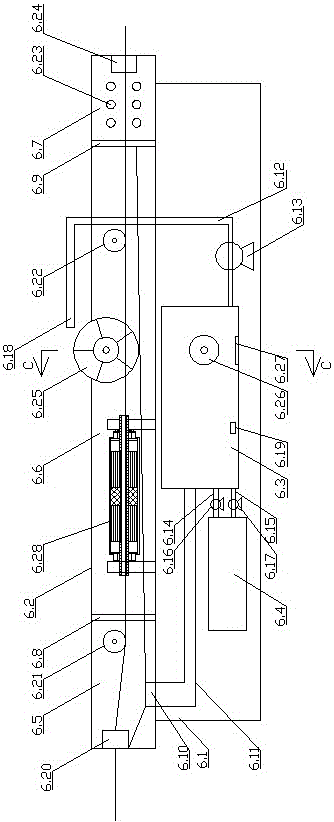

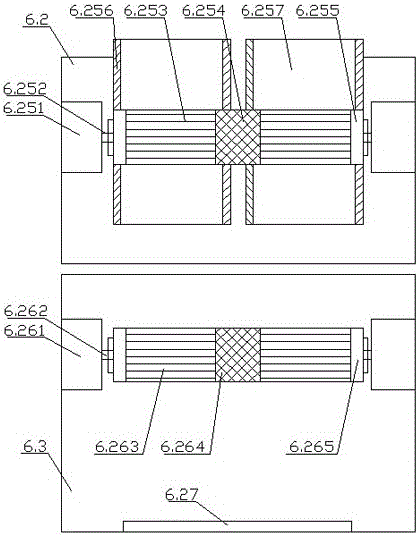

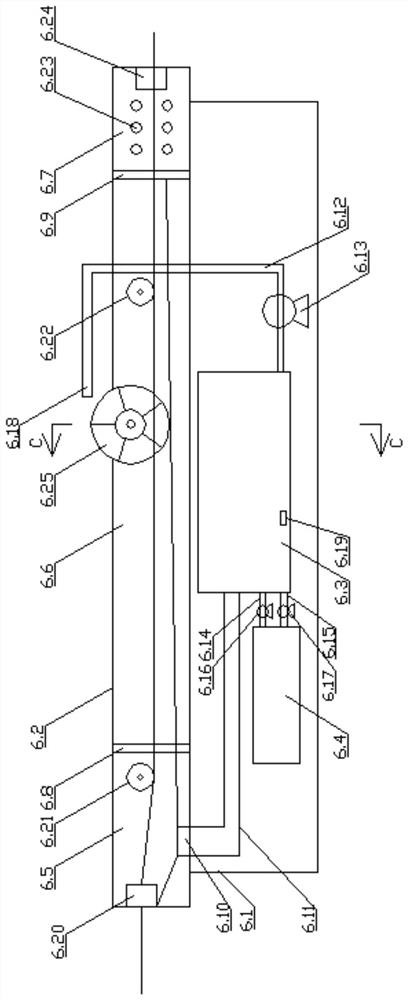

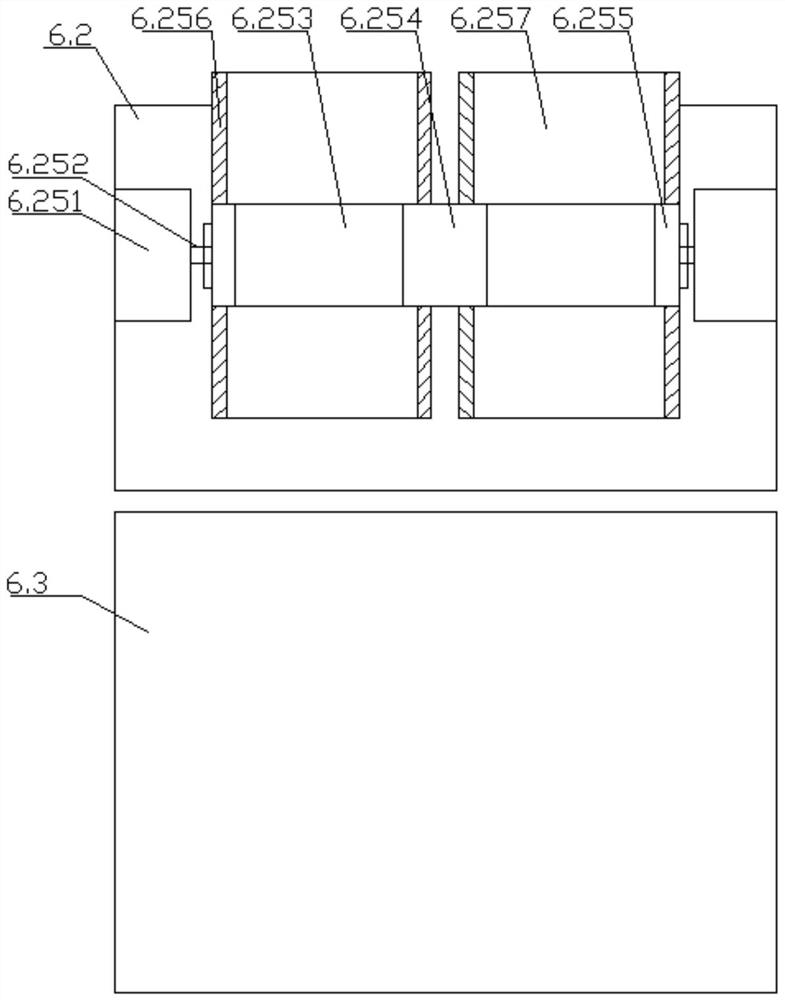

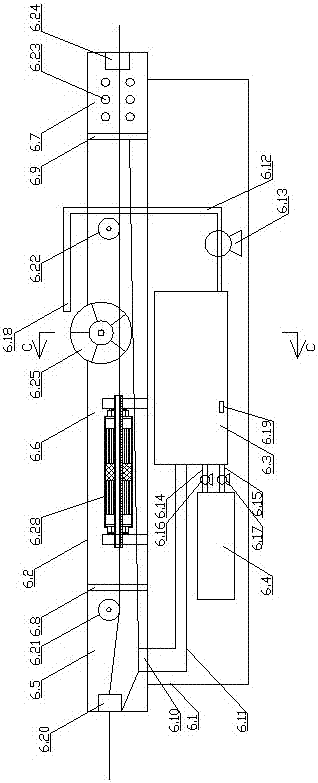

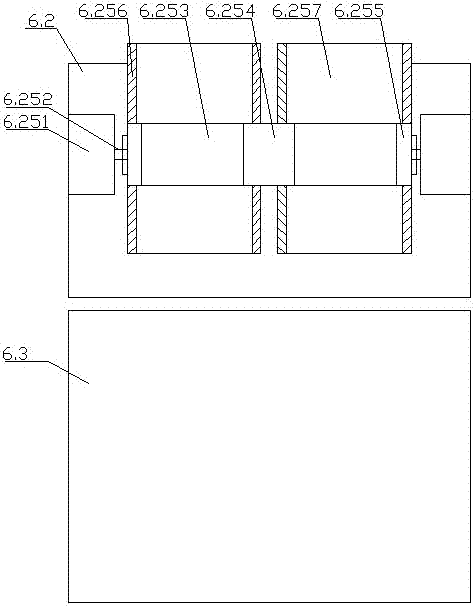

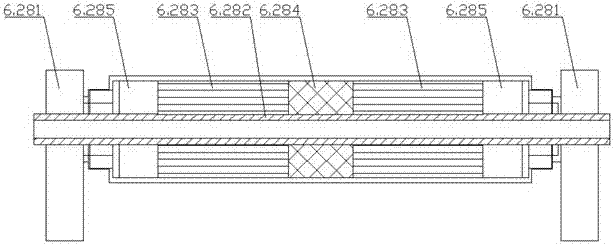

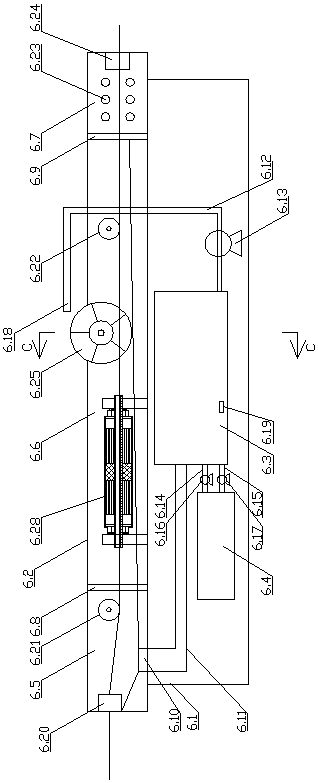

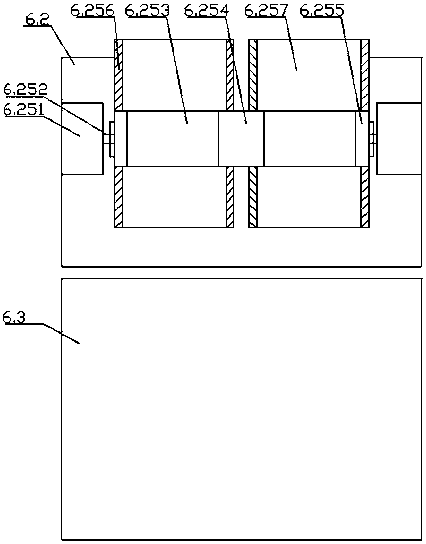

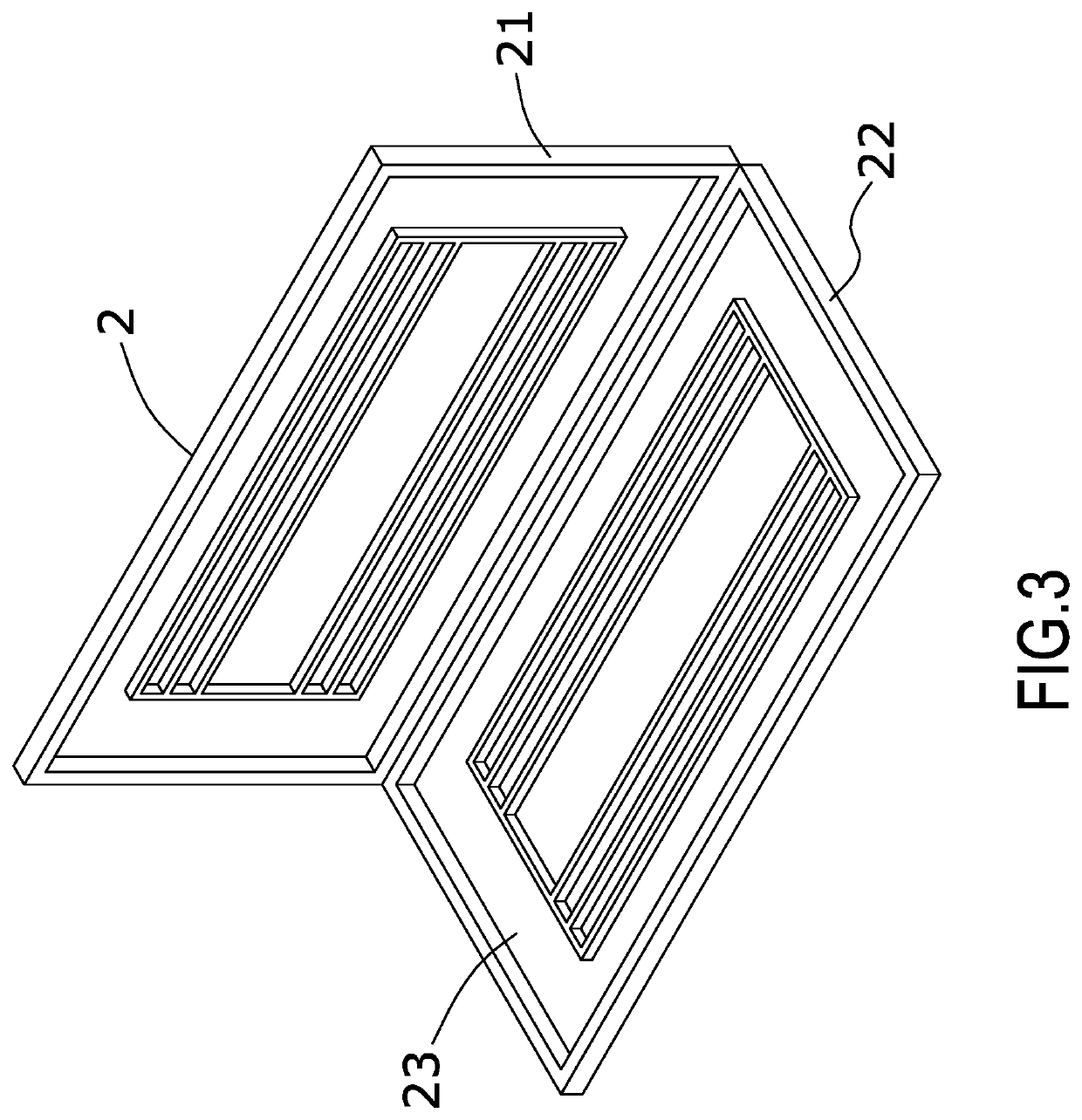

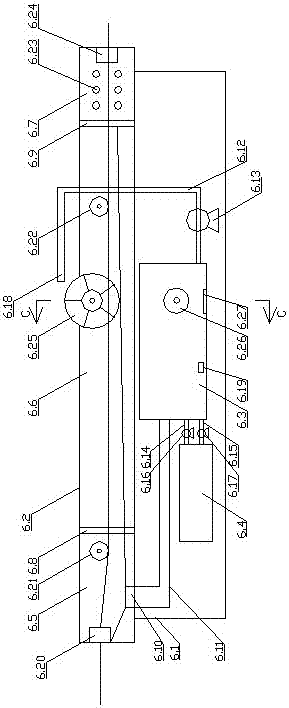

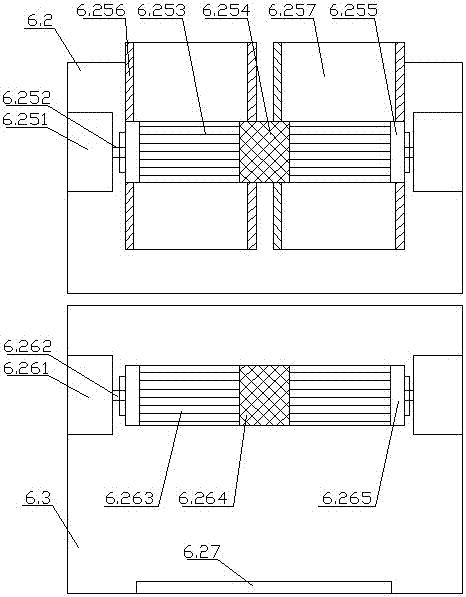

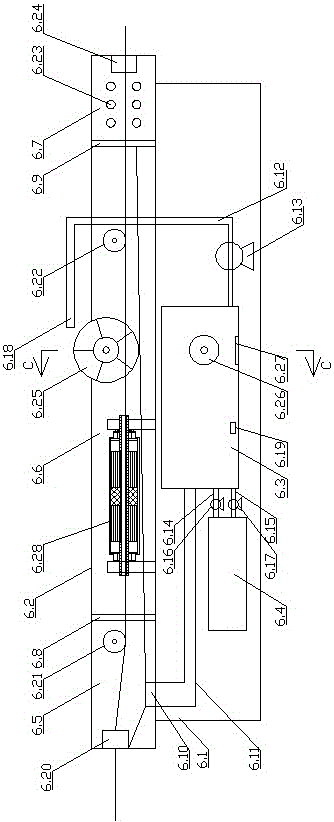

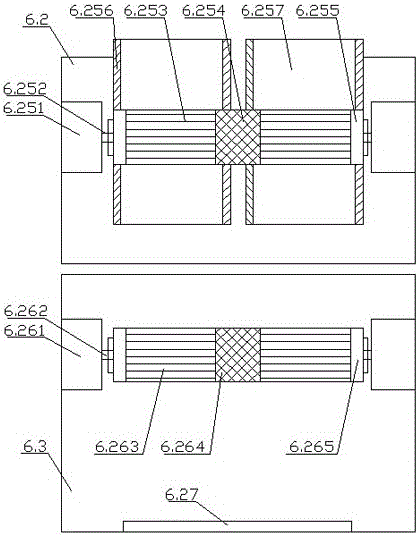

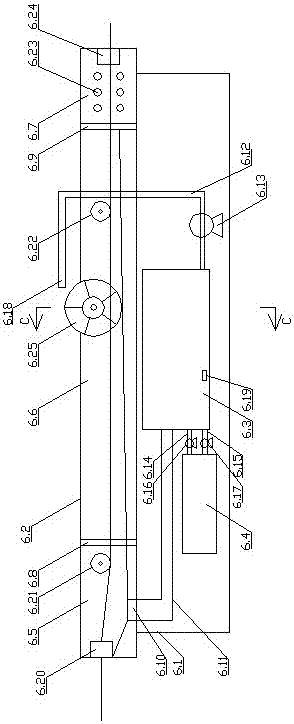

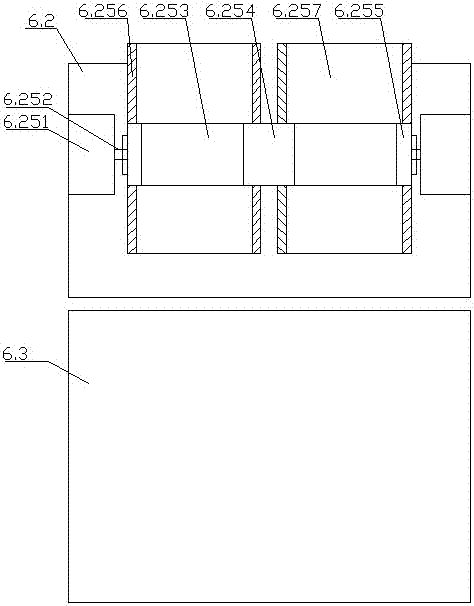

Cooling device and cooling method of extremely-slim coaxial cable

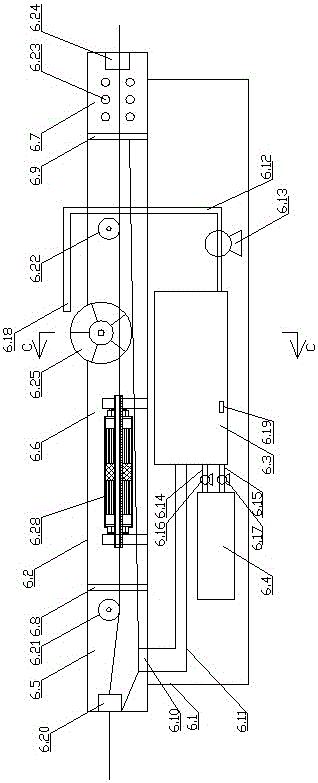

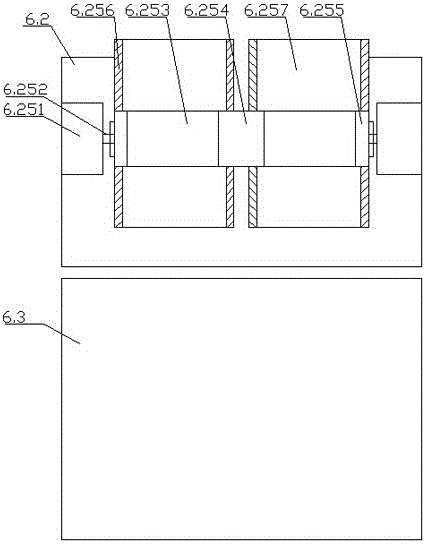

ActiveCN106531355AStable production conditionsGood extrusion qualityCable/conductor manufactureWater storageCoaxial cable

The invention relates to a cooling device of an extremely-slim coaxial cable. The cooling device is characterized by comprising a cooling device rack (6.1), wherein a horizontal cooling groove (6.2) is formed in an upper half segment of the cooling device rack (6.1), a water storage box (6.3) is formed in a lower half segment of the cooling device rack (6.1), the cooling groove (6.2) comprises a feeding region (6.5) at a left end, a cooling region (6.6) at an intermediate segment and a drying region (6.7) at a right end, a first magnetic mechanism (6.25) is arranged at a right segment of the cooling region (6.6) and is longitudinally arranged, and a third magnetic mechanism (6.28) is arranged at a left segment of the cooling region (6.6) and is longitudinally arranged. The cooling device and the cooling method of the extremely-slim coaxial cable have the advantages of stable production working condition and relatively good plastic extruding quality.

Owner:SHENYU COMM TECH

Method for producing sodium chromate and co-producing chrome-containing cast iron by three-stage process through un-calcium roasting

InactiveCN102557137BMine consumption reductionReduce alkali consumptionChromates/bichromatesHigh energySlag

The invention discloses a method for producing sodium chromate and co-producing chrome cast iron by a three-stage process through un-calcium roasting, aiming at solving the problems of low roasting efficiency and high energy consumption in the existing method for producing chromic salt by un-calcium roasting. The method for producing sodium chromate by the three-stage process through un-calcium roasting comprises the following steps of: A, mixing roasting material in a first stage, mixing chromite and sodium carbonate in proportion; B, roasting in the first stage, putting the mixed material in the first stage into a rotary kiln and performing oxidizing roasting; C, leaching and filtering in the first stage; D, performing second-stage roasting technology; and E, performing third-stage roasting technology. The leaching of clinker after roasting for three times is same as the roasting leaching in the first time and the second time, the grinding leaching is performed to the clinker by a wet grinding ball mill, the clinker is filtered by a belt type filter and the filtered chromium slag by three-stage roasting is obtained by filtering of the belt type filter, the filter liquor is sodium chromate alkali solution. Compared with the traditional un-calcium roasting technology, the method in the invention adopts the three-stage process un-calcium roasting technology and effectively reduces the mine consumption and the alkali consumption and has the energy-saving and emission-reducing effect.

Owner:INNER MONGOLIA CHROMIUM

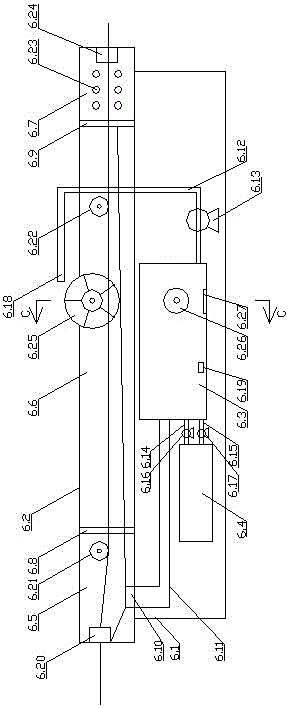

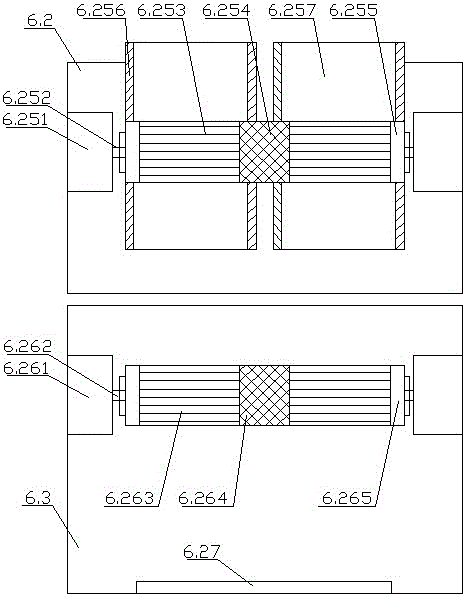

RF coaxial cable cooling device and cooling method thereof

ActiveCN106785297AStable production conditionsGood extrusion qualityWaveguide type devicesWater storage tankEngineering

The invention relates to an RF coaxial cable cooling device. The device is characterized in that the device comprises a cooling device frame (6.1), the upper half section of the cooling device frame (6.1) is provided with a horizontal cooling groove (6.2), the lower half section of the cooling device frame (6.1) is provided with a water storage tank (6.3), the cooling groove (6.2) comprises a feeding area (6.5) at a left end, a cooling area (6.6) at a middle section, and a drying area (6.7) at a right end, and the right section of the cooling area (6.6) is provided with a first magnetic mechanism (6.25) in a longitudinal arrangement. The RF coaxial cable cooling device and the cooling method have the advantages of stable production working condition and good extrusion quality.

Owner:SHENYU COMM TECH

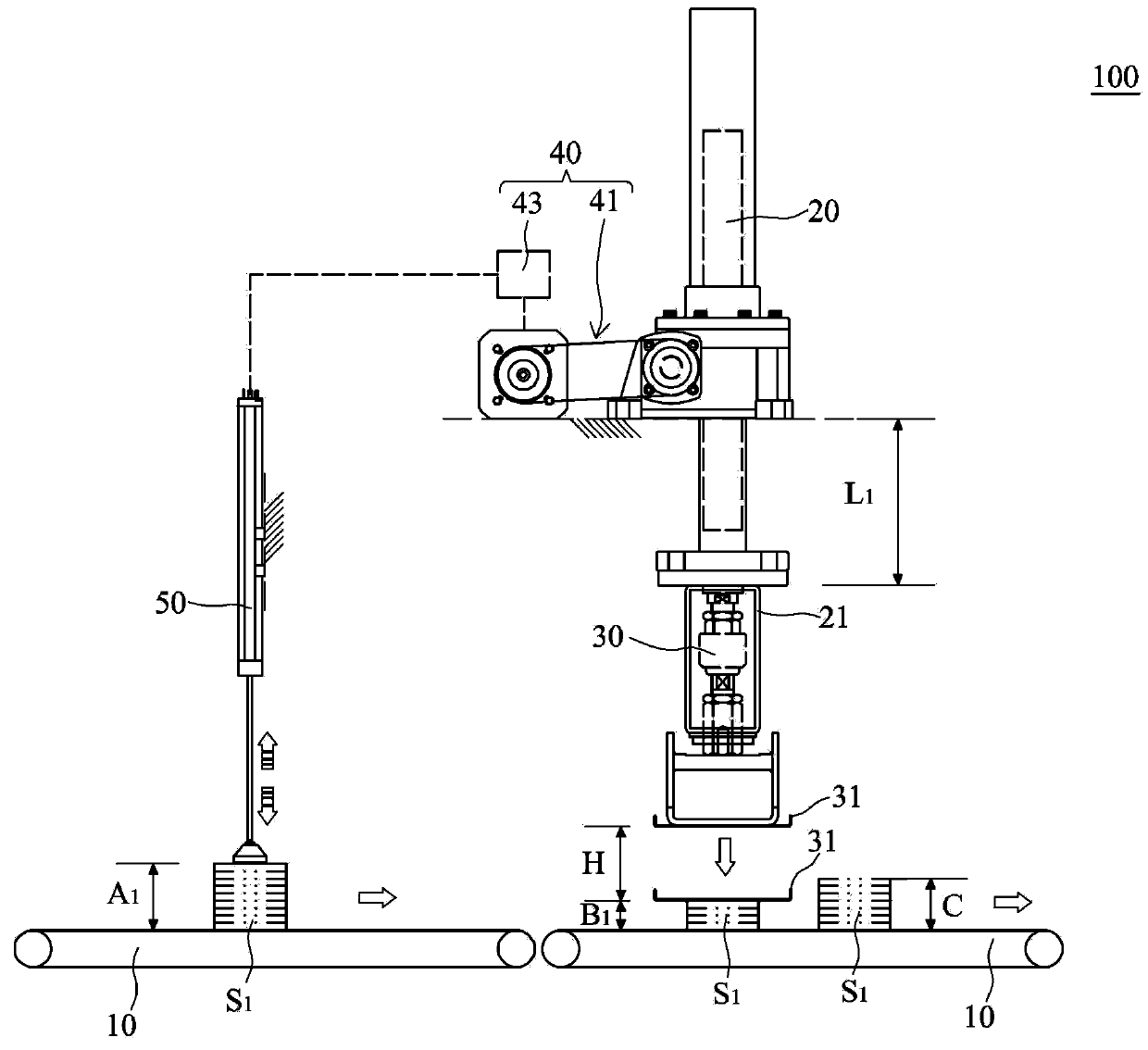

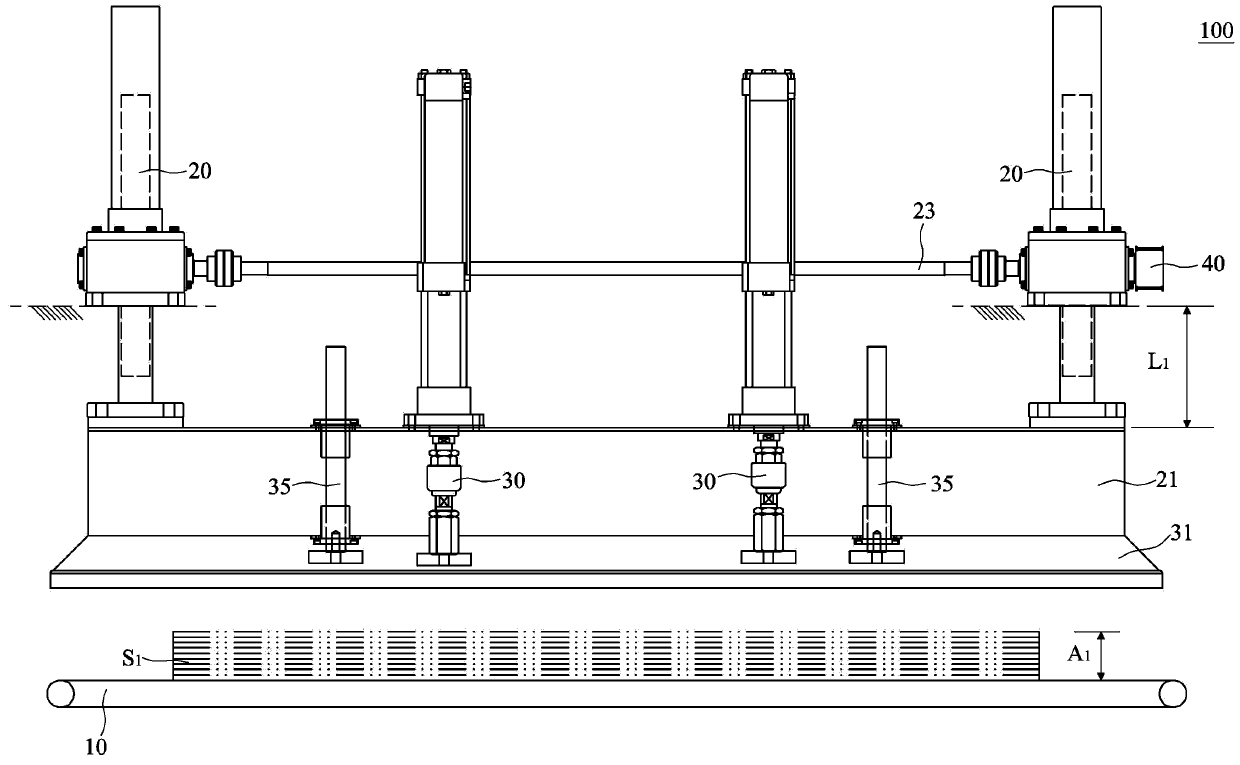

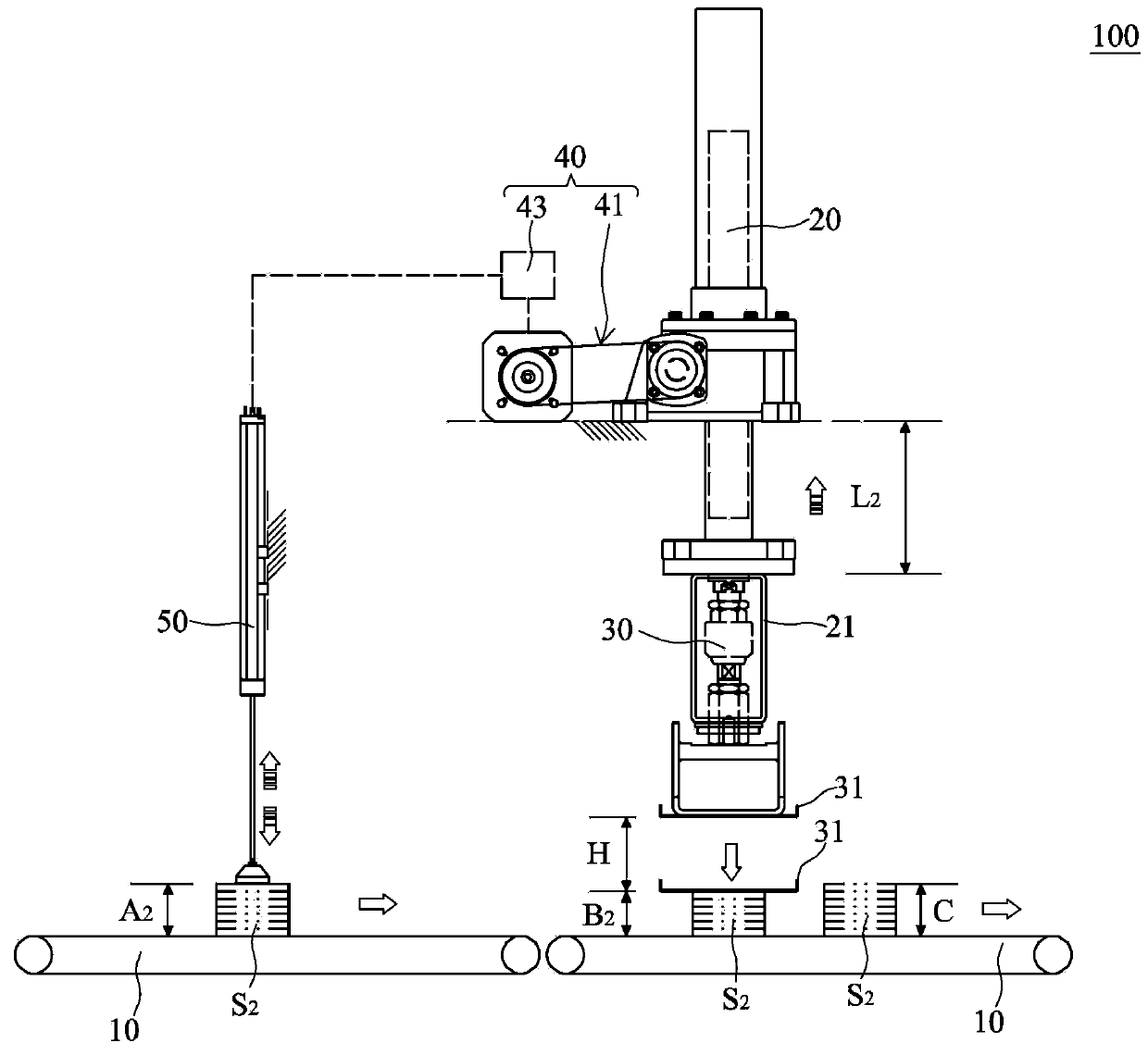

Paper sheet stacking height compressing mechanism and paper sheet stacking height control method for paper products

InactiveCN103465494AStable production conditionsImprove product qualityPressesPulp and paper industryPaper sheet

The invention provides a paper sheet stacking height compressing mechanism and a paper sheet stacking height control method for paper products. The mechanism mainly comprises at least one pressurizer and at least one lifter; the lifter relatively adjusts the upper and lower positions of the pressurizer according to the paper sheet stacking height of the paper products; after being adjusted in position, the pressurizer sequentially utilizes a press plate to compress all paper products, so the paper sheet stacking height of all the paper products can be compressed to a preset height, namely every produced paper product and the paper sheet height stacking height of the paper product can be homogenized, so the production condition of the paper products can be stabilized, the production quality of the paper products is improved, and the fault chance of production equipment is reduced.

Owner:CHAN LI MACHINERY

Pay-off self-adaptive coaxial cable pay-off device and pay-off method

ActiveCN106710715BStable production conditionsImprove product qualityApparatus for feeding conductors/cablesManufacturing co-axial cablesCoaxial cableEngineering

The invention relates to an unwinding self-adaptive coaxial cable unwinding device which is characterized by comprising a rack (1.1), a motor (1.2), an unwinding shaft (1.3), a locking wheel (1.4), a fixed plate (1.6), a supporting base (1.7), a supporting frame (1.8), a floating rod (1.9), a cam (1.10), a supporting rod (1.11), a vertical bracket (1.12), a stop rod (1.13), an adjusting frame fixing base (1.14), an adjusting frame (1.15), a spring pedestal (1.18), a floating rod spring (1.19), a floating rod first guide wheel (1.20), a floating rod second guide wheel (1.21), a locking rope (1.24), a supporting rod guide wheel (1.25) and a stop block (1.26). The unwinding self-adaptive coaxial cable unwinding device and an unwinding method thereof have the advantages of being stable in production condition and great in product quality.

Owner:SHENYU COMM TECH

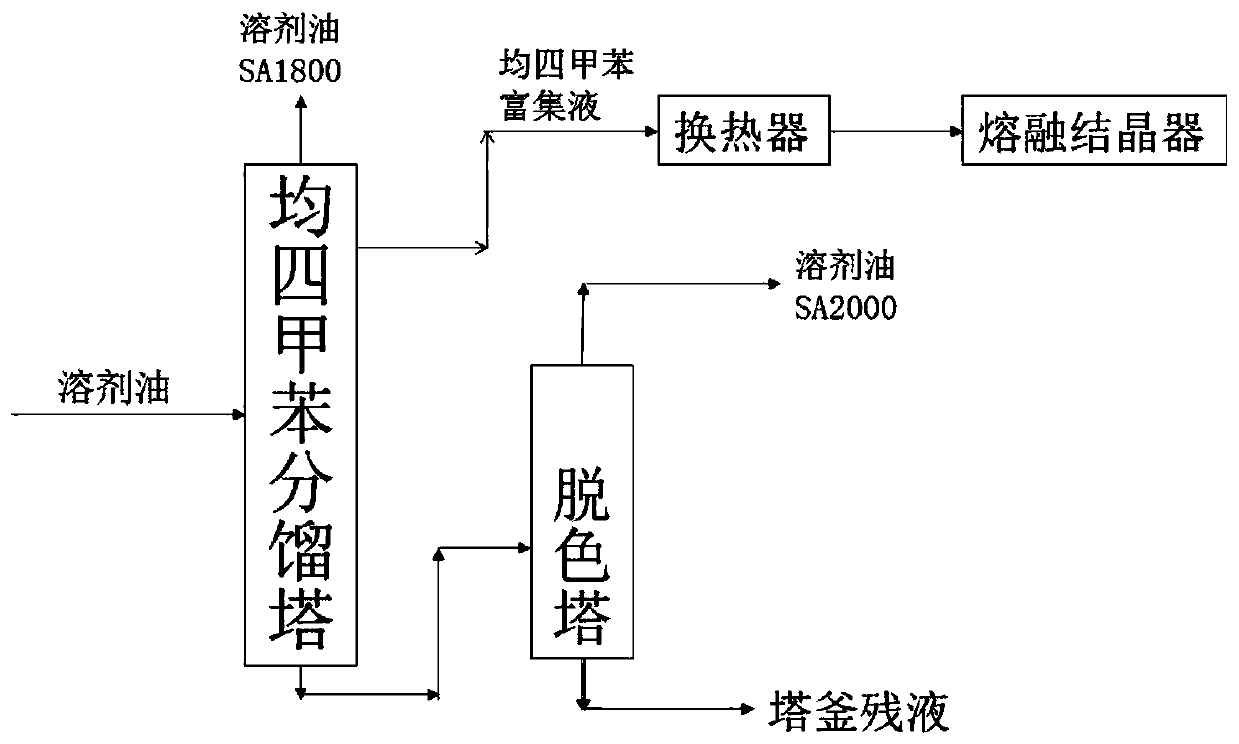

Method for decolorizing solvent oil and extracting durene

PendingCN111377793AImprove securityHigh industrial feasibilityDistillation purification/separationHydrocarbonsProcess engineeringSolvent

The invention provides a method for decolorizing solvent oil and extracting durene, which comprises the following steps of feeding a solvent oil raw material into a durene fractionating tower, extracting durene enrichment liquid from a side line, feeding the durene enrichment liquid into a multi-stage melting crystallizer for melting crystallization after passing through a heat exchanger, and refining to obtain durene, fractionating at the top of a durene fractionating tower to obtain solvent oil SA1800, sending the tower bottom liquid of the durene fractionating tower into a decolorizing tower, separating from the top of the decolorizing tower to obtain solvent oil SA2000, and sending the tower bottom residual liquid of the decolorizing tower into a coking system. According to the method,continuous rectification and melting crystallization are coupled, durene is purified from the solvent oil, the solvent oil is decolorized, heavy aromatics are further deeply processed from the solvent oil stage, and economic benefits are improved. The method is simple to operate, high in safety, low in energy consumption and high in industrial feasibility.

Owner:NORTH HUAJIN CHEM IND CO LTD

High quality coaxial cable extrusion production assembly line and production method thereof

ActiveCN106782922AStable production conditionsGood extrusion qualityInsulating conductors/cablesCoaxial cableMeasuring instrument

The invention relates to a high quality coaxial cable extrusion production assembly line which is characterized in that the high quality coaxial cable extrusion production assembly line comprises a wire releasing device (1), a first diameter measuring instrument (2), a first tension meter (3), a preheater (4), an extruder (5), a cooling device (6), a second diameter measuring instrument (7), a second tension meter (8), an electric spark detector (9), a concave and convex extent meter (10), a longitudinal wire storage device (11), a lateral wire storage device (12), and a wire take-up device (13), and an extruded product is cooled well through the cooling device (6). The high quality coaxial cable extrusion production assembly line and a production method thereof have the advantages of stable production working condition and good extrusion quality.

Owner:SHENYU COMM TECH

MCC very-fine coaxial cable cooling device and cooling method thereof

ActiveCN106531354AStable production conditionsGood extrusion qualityCable/conductor manufactureWater storage tankCooling methods

The invention relates to an MCC very-fine coaxial cable cooling device. The cooling device is characterized by comprising a cooling device rack (6.1), wherein an upper half segment of the cooling device rack (6.1) is provided with a transverse cooling groove (6.2), a lower half segment of the cooling device rack (6.1) is provided with a water storage tank (6.3), the cooling groove (6.2) comprises a left charging region (6.5), a middle cooling region (6.6) and a right drying region (6.7), a right segment of the cooling zone (6.6) is provided with a vertically-arranged first magnetic mechanism (6.25), and the water storage tank (6.3) is internally provided with a vertically-arranged second magnetic mechanism (6.26). The device and the method are advantaged in that production conditions are stable, and plastic extrusion quality is relatively good.

Owner:SHENYU COMM TECH

Catalyst and its preparation method and regeneration method of anthraquinone degradation products

ActiveCN110102276BLow costImprove regenerative abilityOrganic compound preparationHeterogenous catalyst chemical elementsAnthraquinonesAlkaline earth metal

The invention relates to the field of regeneration of anthraquinone degradation products, and discloses a catalyst, a preparation method thereof and a regeneration method of anthraquinone degradation products. The preparation method of the catalyst comprises the following steps: S1, mixing the quick-release powder, the alkaline earth metal compound and an optional extrusion aid to obtain the first dry material; S2, mixing the acid solution and the silicon source to obtain the first Liquid; S3, mixing the first dry material with the first liquid, followed by kneading, extruding, drying and roasting. The preparation method of the catalyst is simple and low in cost, and can effectively improve the regeneration efficiency of anthraquinone degradation products in the hydrogen peroxide working solution containing o-methylcyclohexyl acetate, significantly reduce the accumulation of anthraquinone degradation products in the working solution and improve the working efficiency. The content of effective anthraquinone in the liquid is beneficial to improve production efficiency.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

RF coaxial cable cooling method

ActiveCN113937453AStable production conditionsGood extrusion qualityWaveguide type devicesWater storageImpeller

The invention relates to an RF coaxial cable cooling method, which is characterized in that in the whole cooling process, cooling water flows out from a water supply port at the right upper part of a first magnetic mechanism, the cooling water flowing out from the water supply port falls onto a rightward impeller plate of the first magnetic mechanism to drive a first rotating shaft to rotate clockwise, at the moment, due to changes of magnetic lines of magnets, cooling water in a cooling tank flows leftwards from a cooling area to a feeding area and returns to a water storage tank from a water outlet through a water supply pipeline, and then the cooling water in the water storage tank is supplied through the water supply pipeline and falls down from the water supply port. The RF coaxial cable cooling method has the advantages of being stable in production working condition and good in extrusion molding quality.

Owner:SHENYU COMM TECH

High-quality coaxial cable production line and production method thereof

ActiveCN106782905BStable production conditionsGood extrusion qualityApparatus for feeding conductors/cablesManufacturing co-axial cablesCoaxial cableManufacturing line

The invention relates to a high quality coaxial cable production line. The high quality coaxial cable production line is characterized in that the high quality coaxial cable production line comprises a wire releasing device (1), a first diameter measuring instrument (2), a first tension meter (3), a preheater (4), an extruder (5), a cooling device (6), a second diameter measuring instrument (7), a second tension meter (8), an electric spark detector (9), a concave and convex extent meter (10), a longitudinal wire storage device (11), a lateral wire storage device (12), and a wire take-up device (13), the adaptive wire release is realized through the wire releasing device (1), the production stability is improved, and an extruded product is cooled well through the cooling device (6). The high quality coaxial cable production line and a production method thereof have the advantages of a stable production working condition and good extrusion quality.

Owner:SHENYU COMM TECH

rf radio frequency coaxial cable production line and its production method

ActiveCN106785296BStable production conditionsGood extrusion qualityWaveguidesCoaxial cableRadio frequency

The present invention relates to an RF radio frequency coaxial cable production line, which is characterized in that it includes a pay-off device (1), a first diameter measuring instrument (2), a first tension meter (3), a preheater (4), an extruder Plastic machine (5), cooling device (6), second diameter measuring instrument (7), second tension meter (8), electric spark detector (9), concave-convex meter (10), vertical wire storage device (11 ), the horizontal wire storage device (12) and the wire take-up device (13), the self-adaptive wire release is realized through the wire release device (1), and the production stability is improved, and the extruded product is better processed through the cooling device (6). cooling. The RF coaxial cable production line and the production method thereof of the present invention have the advantages of stable production conditions and good extrusion quality.

Owner:SHENYU COMM TECH

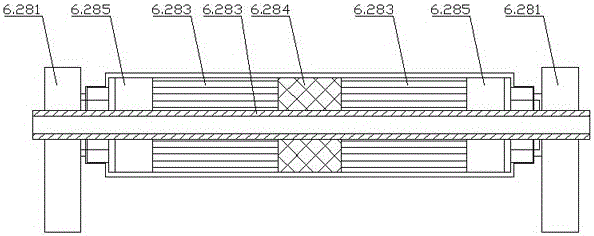

Ultra-thin coaxial cable cooling device and cooling method thereof

ActiveCN106531355BStable production conditionsGood extrusion qualityCable/conductor manufactureWater storageCoaxial cable

The invention relates to a cooling device of an extremely-slim coaxial cable. The cooling device is characterized by comprising a cooling device rack (6.1), wherein a horizontal cooling groove (6.2) is formed in an upper half segment of the cooling device rack (6.1), a water storage box (6.3) is formed in a lower half segment of the cooling device rack (6.1), the cooling groove (6.2) comprises a feeding region (6.5) at a left end, a cooling region (6.6) at an intermediate segment and a drying region (6.7) at a right end, a first magnetic mechanism (6.25) is arranged at a right segment of the cooling region (6.6) and is longitudinally arranged, and a third magnetic mechanism (6.28) is arranged at a left segment of the cooling region (6.6) and is longitudinally arranged. The cooling device and the cooling method of the extremely-slim coaxial cable have the advantages of stable production working condition and relatively good plastic extruding quality.

Owner:SHENYU COMM TECH

Ultra-fine coaxial cable extrusion production line and production method thereof

ActiveCN106782904BStable production conditionsGood extrusion qualityManufacturing co-axial cablesInsulating conductors/cablesProduction lineCoaxial cable

The invention relates to an extremely fine coaxial cable extrusion production assembly line which is characterized in that the extremely fine coaxial cable extrusion production assembly line comprises a wire releasing device (1), a first diameter measuring instrument (2), a first tension meter (3), a preheater (4), an extruder (5), a cooling device (6), a second diameter measuring instrument (7), a second tension meter (8), an electric spark detector (9), a concave and convex extent meter (10), a longitudinal wire storage device (11), a lateral wire storage device (12), and a wire take-up device (13), and an extruded product is cooled well through the cooling device (6). The extremely fine coaxial cable extrusion production assembly line and a production method thereof have the advantages of a stable production working condition and good extrusion quality.

Owner:SHENYU COMM TECH

Trolley replacement device

ActiveCN104236311BAchieve replacementIncrease productivityFurnace typesPass ratePulp and paper industry

The present invention relates to a trolley replacing device and a trolley replacing method, which belong to the technical field of the replacement of a trolley of a sintering machine or a belt type roasting machine in the metallurgical industry. The trolley replacing device comprises a trolley, an inner straight rail, an inner curved rail, an outer straight rail, an outer curved rail, a main driving wheel, a trolley moving-out rail, and a trolley moving-in rail, wherein the outer curved rail arranged on both sides of the main driving wheel is divided into a lower movable outer curved rail, a middle fixed outer curved rail, and an upper movable outer curved rail; the lower movable outer curved rail is outwardly separated from the middle fixed outer curved rail and a lower outer straight rail on both sides vertical to the operating direction of the trolley, or is connected with the middle fixed outer curved rail and the lower outer straight rail; and one end of the upper movable outer curved rail is connected with one end of the trolley moving-in rail. The present invention enables the sintering machine or the belt type roasting machine to replace the trolley without stalling, and no additional time to replace the trolley is needed, thus increasing the production efficiency; because there are no operations such as stalling the sintering machine or the belt type roasting machine and reducing or stopping the wind, the production condition will not be changed and will be stable relatively; and because of the stable production condition, the production pass rate and the tumbler index will not be reduced.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

Paper stack height compression mechanism for paper products and paper stack height control method

InactiveCN103465494BStable production conditionsImprove product qualityPressesPulp and paper industryDevice failure

Owner:CHAN LI MACHINERY

Pay-off self-adaptive coaxial cable production line and production method thereof

ActiveCN106531353BStable production conditionsImprove product qualityApparatus for feeding conductors/cablesApparatus for heat treatmentProduction lineCoaxial cable

The invention relates to an unwinding self-adaptive production assembly line of a coaxial cable. The production assembly line is characterized by comprising an unwinding device (1), a first diameter measurement gauge (2), a first tension meter (3), a preheater (4), an plastic extruding machine (5), a cooling device (6), a second diameter measurement gauge (8), an electric spark detector (9), a concave-convex meter (10), a vertical wire storage device (11), a transverse wire storage device (12) and a winding device (13), wherein self-adaptive unwinding is achieved by the unwinding device (1), and the production stability is improved. The unwinding self-adaptive production assembly line of the coaxial cable and a production method of the coaxial cable have the advantages of stable production working condition and relatively good product quality.

Owner:SHENYU COMM TECH

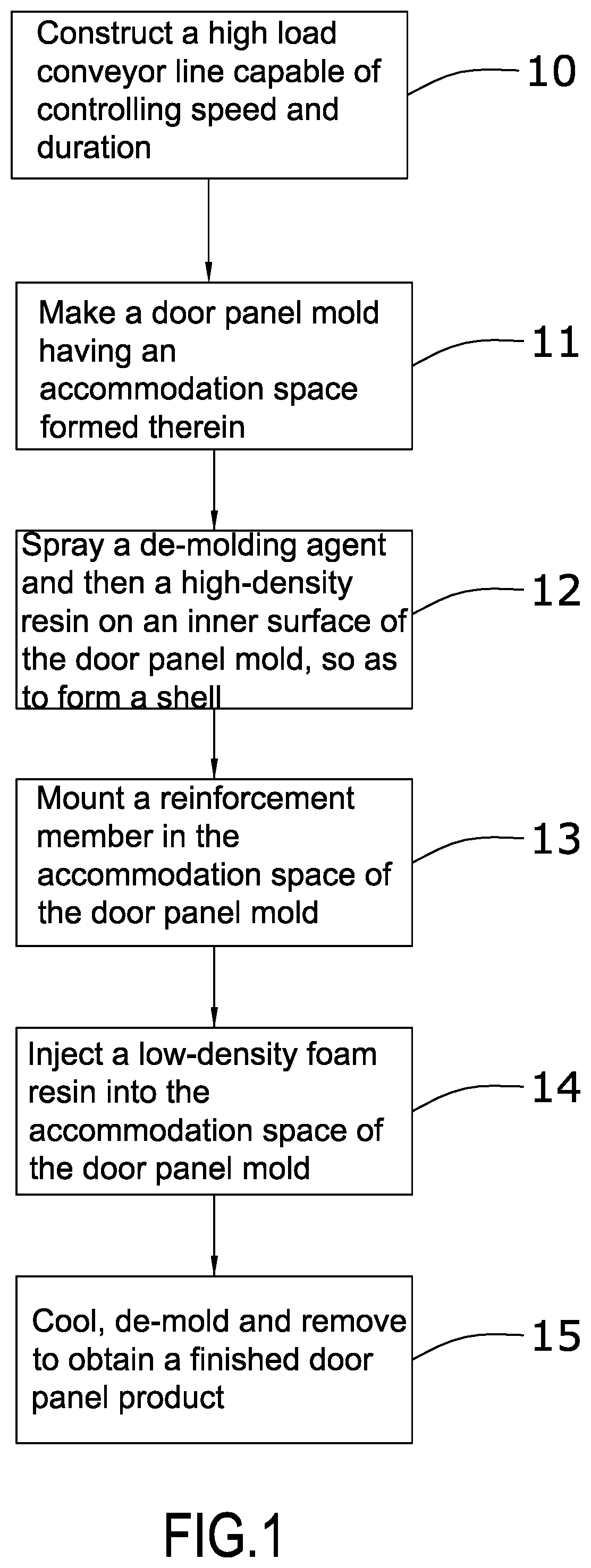

Door panel manufacturing process

InactiveUS20210138700A1High defective rateLarge amount of cuttingDomestic articlesCoatingsHigh densityElectric consumption

A door panel manufacturing process is provided by constructing a high load conveyor line capable of controlling speed and duration, subsequently placing a finished door panel mold on the high load conveyor line. The conveyor line can be used to control a shifting speed and duration, and a de-molding agent can be sprayed inside the door panel mold, followed by spraying a high-density foam resin to form a shell. The door panel mold further has a framework or a reinforcement member mounted therein, and a low-density foam resin is injected; after the foam resin is formed and cooled, the door panel made of foam resin is completed. The process solve issues of high defective rate and insufficient surface strength associated with the conventional foam door panel, and is capable of significantly reducing the electricity required as well as reducing logging of woods, thereby realizing environmental protection.

Owner:EVERTRADE VIETNAM CO LTD

MCC ultra-thin coaxial cable cooling device and cooling method thereof

ActiveCN106531354BStable production conditionsGood extrusion qualityCable/conductor manufactureCoaxial cableWater storage tank

The invention relates to an MCC very-fine coaxial cable cooling device. The cooling device is characterized by comprising a cooling device rack (6.1), wherein an upper half segment of the cooling device rack (6.1) is provided with a transverse cooling groove (6.2), a lower half segment of the cooling device rack (6.1) is provided with a water storage tank (6.3), the cooling groove (6.2) comprises a left charging region (6.5), a middle cooling region (6.6) and a right drying region (6.7), a right segment of the cooling zone (6.6) is provided with a vertically-arranged first magnetic mechanism (6.25), and the water storage tank (6.3) is internally provided with a vertically-arranged second magnetic mechanism (6.26). The device and the method are advantaged in that production conditions are stable, and plastic extrusion quality is relatively good.

Owner:SHENYU COMM TECH

High-quality coaxial cable cooling device and cooling method

ActiveCN106531359AStable production conditionsGood extrusion qualityManufacturing co-axial cablesCoaxial cableWater storage tank

The invention relates to a high-quality coaxial cable cooling device, which is characterized in that the device includes a cooling device rack (6.1), an upper half section of the cooling device rack (6.1) is provided with a transverse cooling groove (6.2), a lower half section of the cooling device rack (6.1) is provided with a water storage tank (6.3), the cooling groove (6.2) includes a feeding zone (6.5) at the left end, a cooling zone (6.6) in the middle section and a drying zone (6.7) at the right end, the right section of the cooling zone (6.6) is provided with a longitudinally arranged first magnetic mechanism (6.25), the water storage tank (6.3) is internally provided with a longitudinally arranged second magnetic mechanism (6.26), and the left section of the cooling zone (6.6) is provided with a longitudinally arranged third magnetic mechanism (6.28). The high-quality coaxial cable cooling device and cooling method have the advantages of stable production working condition and relatively good extrusion molding quality.

Owner:SHENYU COMM TECH

rf radio frequency coaxial cable extrusion production line and its production method

ActiveCN106531352BStable production conditionsGood extrusion qualityApparatus for feeding conductors/cablesApparatus for heat treatmentProduction lineCoaxial cable

The invention relates to a RF (Radio Frequency) coaxial cable extrusion production line. The characteristics lie in that the RF coaxial cable extrusion production line comprises a pay-off device (1), a first diameter measuring instrument (2), a first tension meter (3), a preheater (4), an extruding machine (5), a cooling device (6), a second diameter measuring instrument (7), a second tension meter (8), an electric spark detector (9), a concave-convex instrument (10), a vertical storage device (11), a transverse storage device (12) and a take-up device (13), wherein the cooling device (6) realizes well cooling for extruded products. The RF coaxial cable extrusion production line and the production method thereof have the advantages that the production condition is stable, and the extrusion quality is good.

Owner:SHENYU COMM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com