Paper stack height compression mechanism for paper products and paper stack height control method

A compression mechanism and highly controlled technology, applied in the direction of presses, manufacturing tools, etc., can solve problems such as affecting the production quality of paper products, equipment affecting production efficiency, and unstable production conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

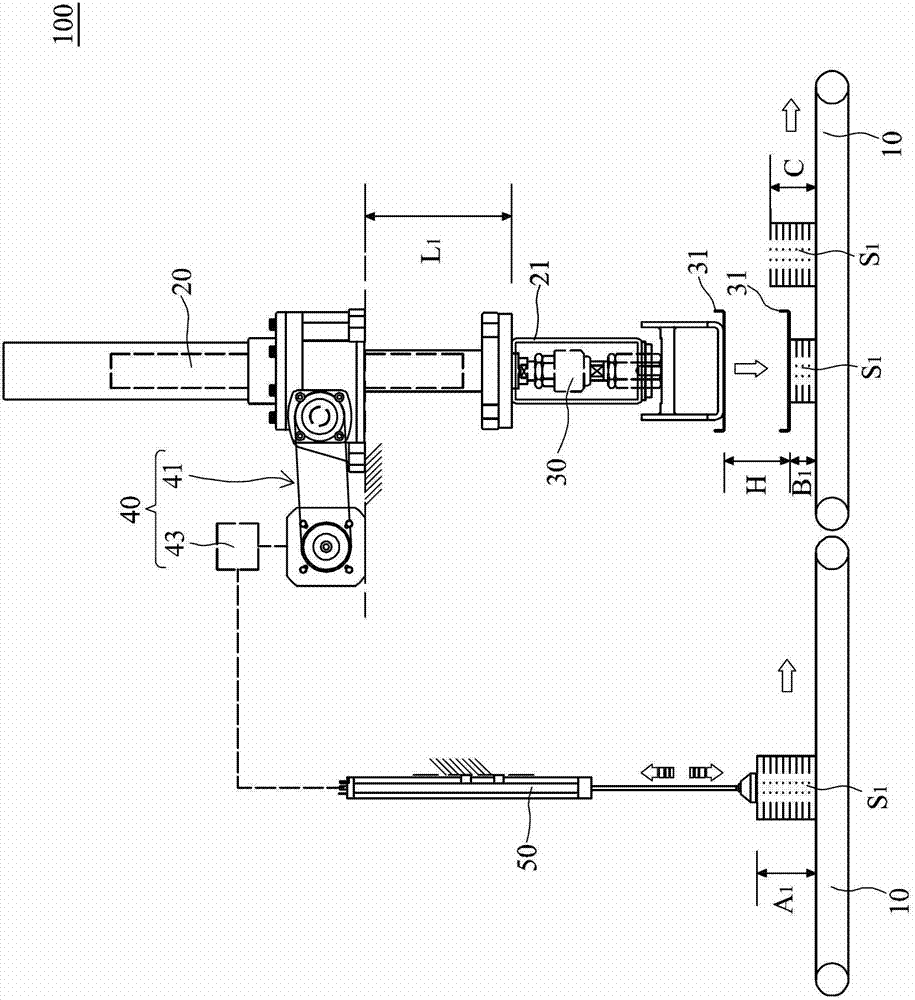

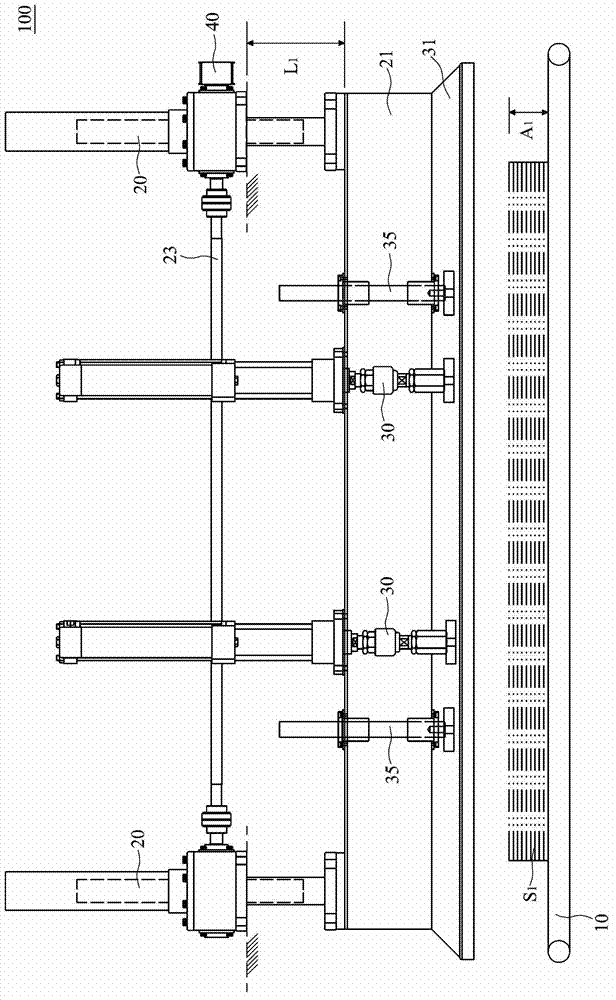

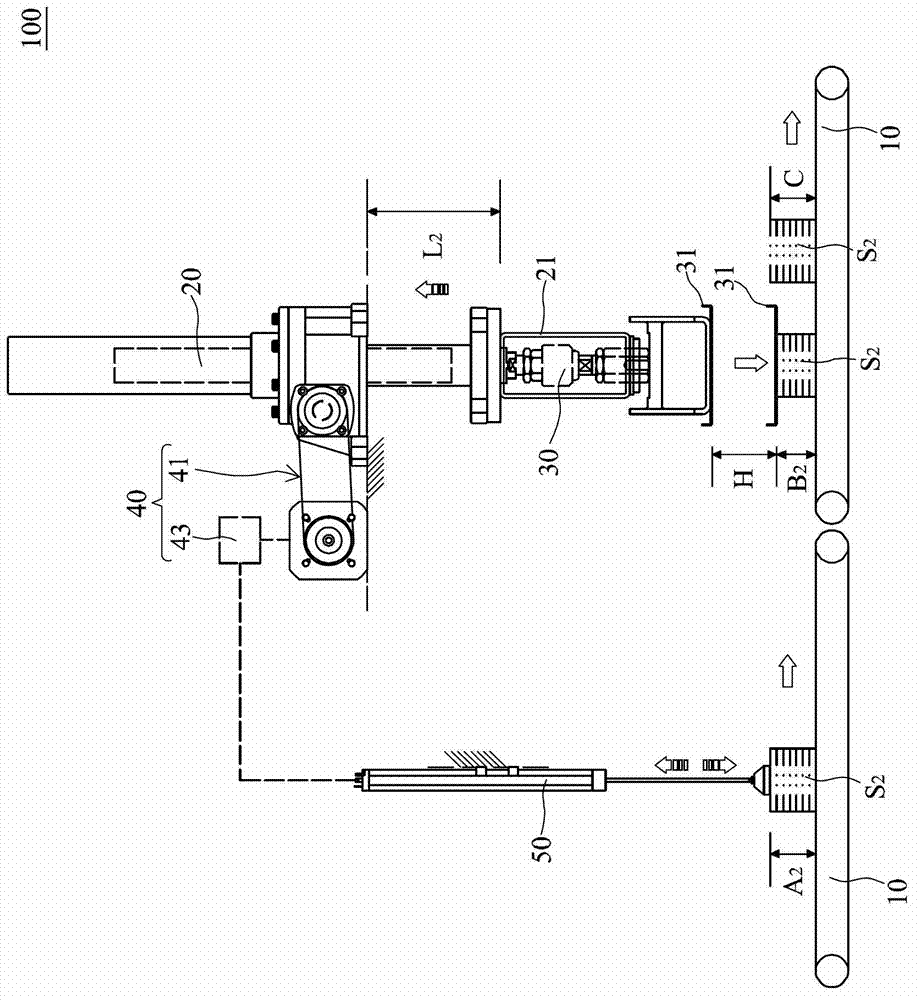

[0032] see Figure 1A to Figure 1B and Figure 2A to Figure 2B , are respectively a structural side view and a structural front view of a pressurization program and a structural side view and structural front view of another pressurization program of a preferred embodiment of the paper stack height compression mechanism of the paper product of the present invention. As shown in the figure, a conveying platform 10 is arranged below the paper stack height compressing mechanism 100 . The delivery platform 10 will be used to transport each paper product S 1 , S 2 …S N-1 , S N , each paper product S 1 , S 2 …S N-1 , S N It is made sequentially from a curled raw paper. Each paper product S 1 , S 2 …S N-1 , S N All have the same number of sheets stacked, and their sheets are stacked flat or folded. Here, the paper stack height compression mechanism 100 will 1 , S 2 …S N-1 , S N Pressurize in sequence so that each paper product S 1 , S 2 …S N-1 , S N The paper sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com