Patents

Literature

40results about How to "Increase effective production time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for inducing diapause of Trichogramma ostriniae by constant temperature and storage method

ActiveCN101326902AIncrease effective production timeSave solutionAnimal husbandryDiapauseTrichogramma ostriniae

The invention provides a constant-temperature inducing maize-borer oophagous trichogrammae diapause storage method. The collected maize-borer oophagous trichogrammaes which have developed to the ovum telophase from the middle larva stage adopt constant-temperature inducing maize-borer oophagous trichogrammae diapause, and are stored under a specific temperature and humidity, and the development of the maize-borer oophagous trichogrammae is restored by changing the prior temperature to use. The method is applicable to oophagous trichogrammae breeding by using small gelechiid ovum; the technology matches large-scale oophagous trichogrammae production; the method is applicable to long-term production and storage of maize-borer oophagous trichogrammaes; thereby, sufficient maize-borer oophagous trichogrammaes are prepared for pest control, and the method can also be used to store breeding maize-borer oophagous trichogrammaes.

Owner:DRY LAND FARMING INST OF HEBEI ACAD OF AGRI & FORESTRY SCI

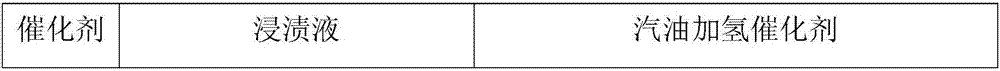

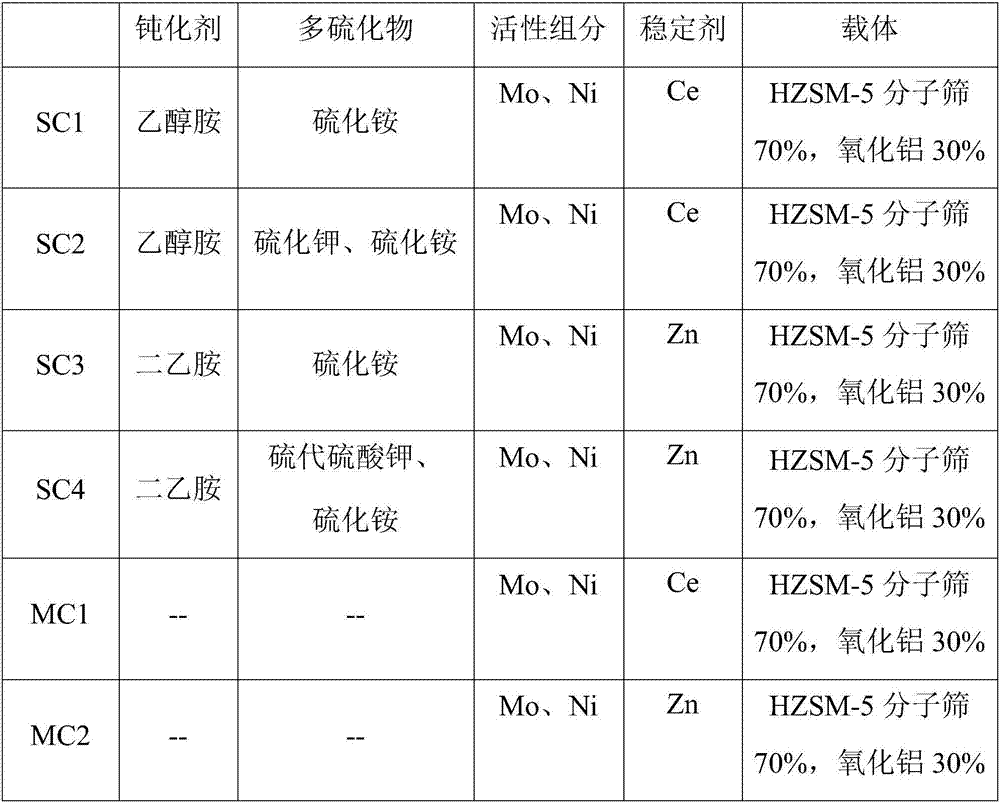

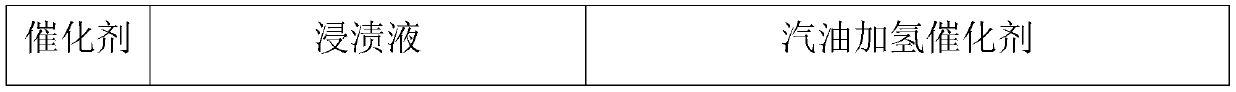

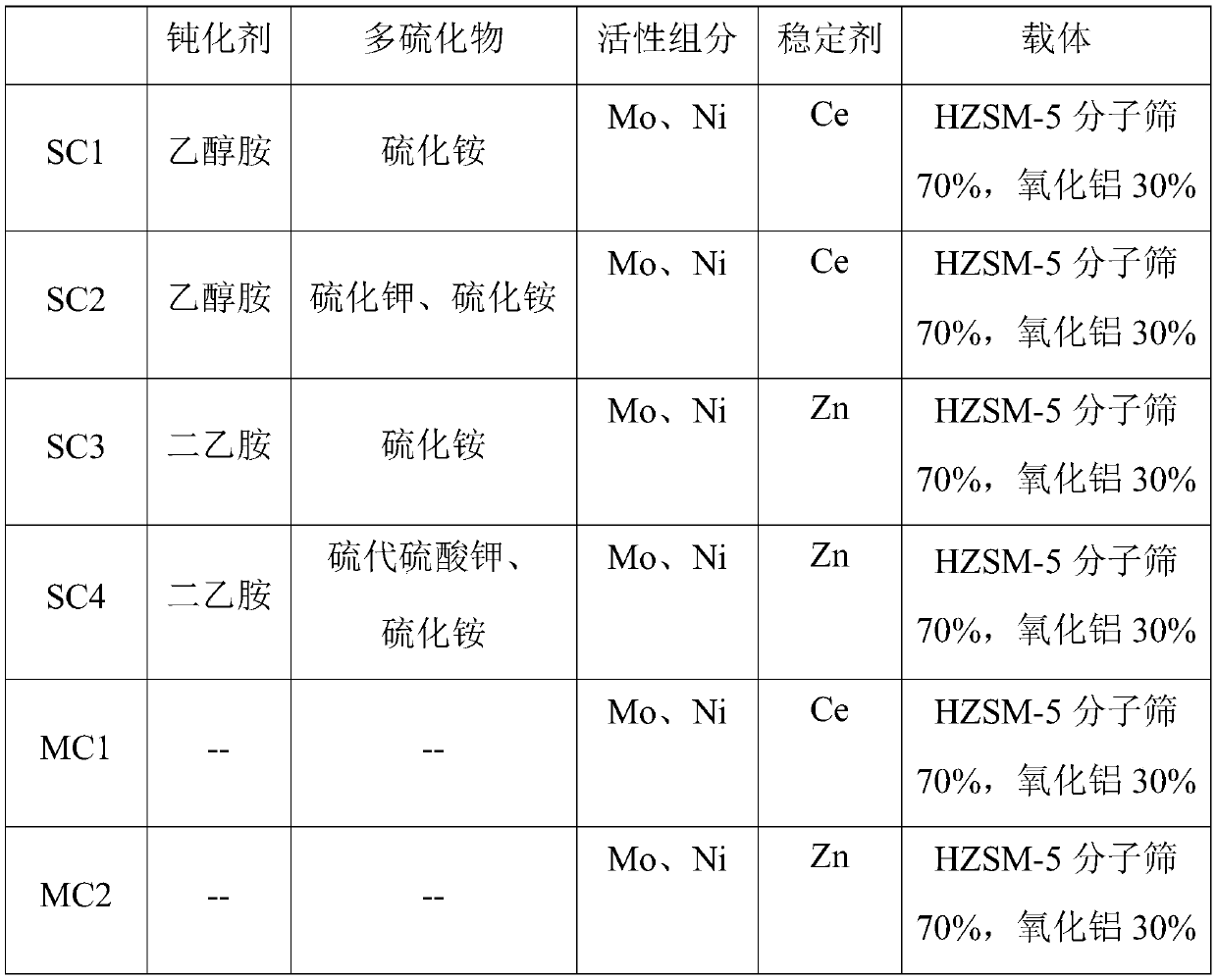

Vulcanization type gasoline hydrogenation upgrading catalyst and method for preparing same

ActiveCN107185597AEasy to introduceEasy to implementMolecular sieve catalystsCatalyst activation/preparationVulcanizationRare earth

The invention relates to a method for preparing a vulcanization type gasoline hydrogenation upgrading catalyst. Gasoline hydrogenation catalysts are treated by vulcanizing agents with multiple sulfur ions and organic nitride which is used as a passivator at the low temperatures, active components in the gasoline hydrogenation catalysts comprise a type or a plurality of types of Mo and W of VI B groups and Co and Ni of VIII B groups, and stabilizers comprise a type or a plurality of types of Zn and Cd of II B groups, Na and K of I A groups and rare earth metal La and Ce. The method has the advantages that cascade full vulcanization can be carried out on metal oxide or precursors of the metal oxide, and strong acidic sites in ZSM-5 molecular sieve composite carriers can be selectively passivated; the vulcanization type gasoline hydrogenation upgrading catalyst prepared by the aid of the method is short in on-stream time, high in hydrogenation and olefin reduction upgrading activity, selectivity, carbon deposition resistance and liquid yield and low in octane number loss, and accordingly the method and the vulcanization type gasoline hydrogenation upgrading catalyst are particularly applicable to producing clean gasoline components from inferiorly catalytically cracked gasoline by means of hydrogenation and olefin reduction upgrading at a low cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

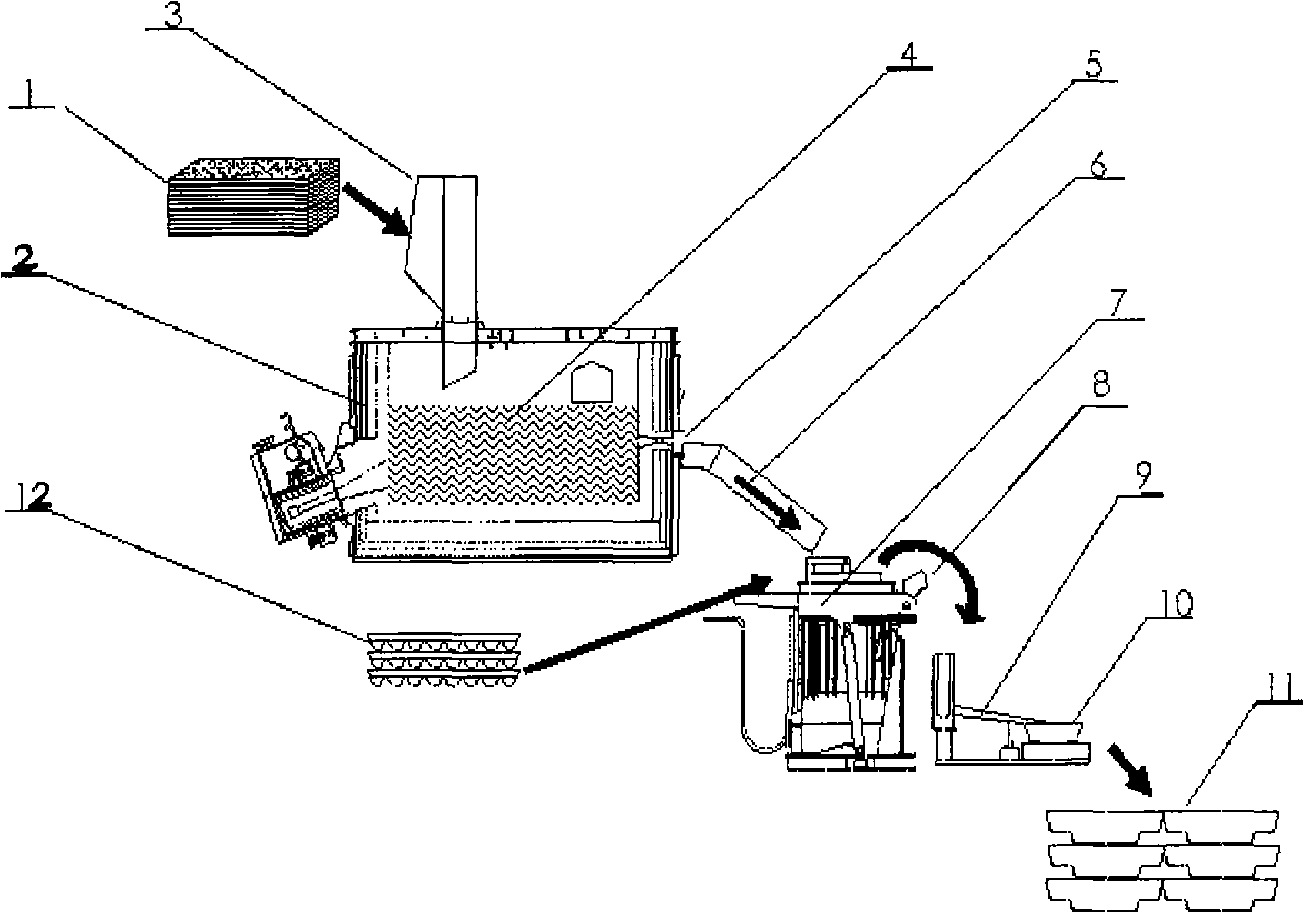

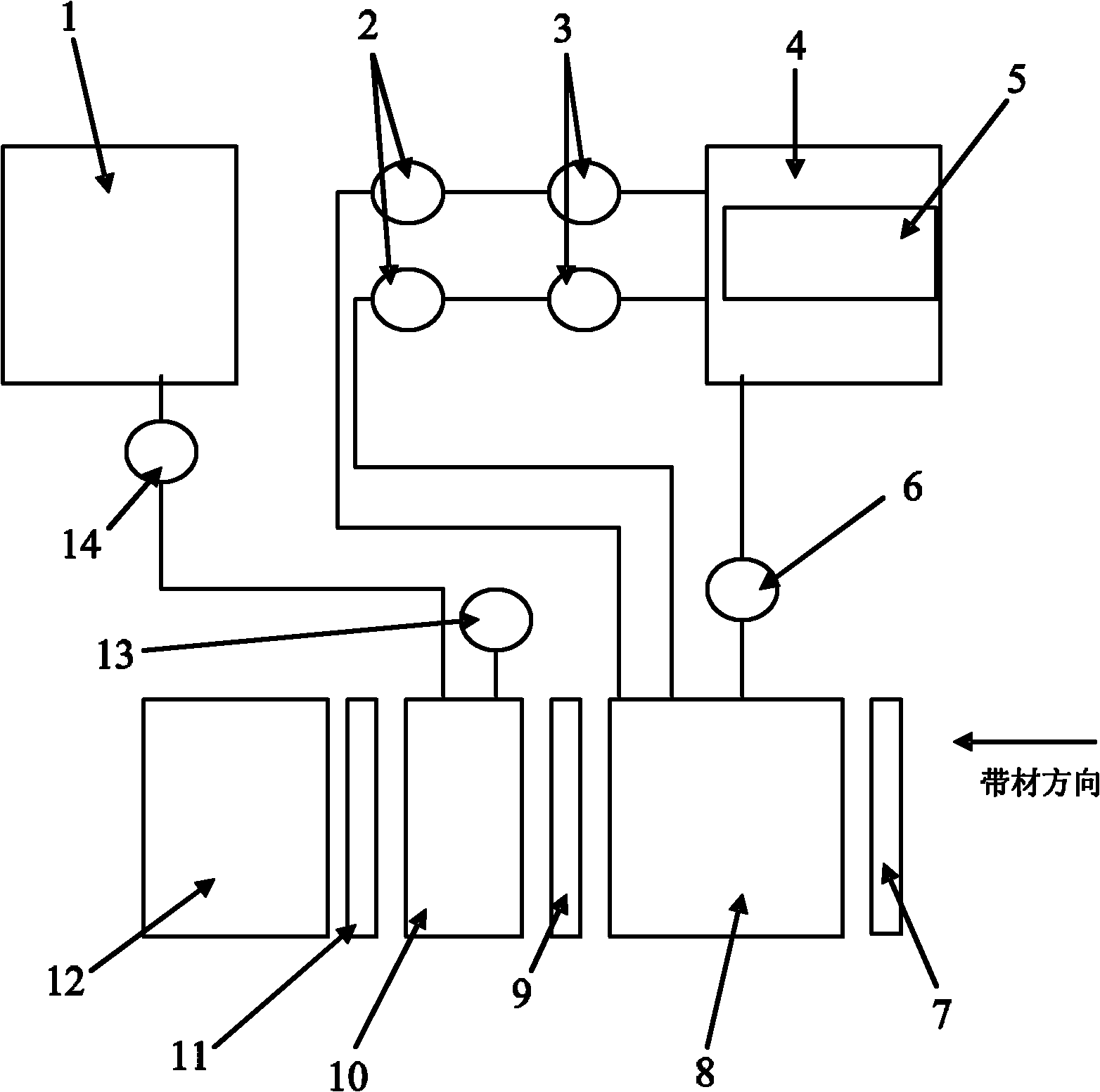

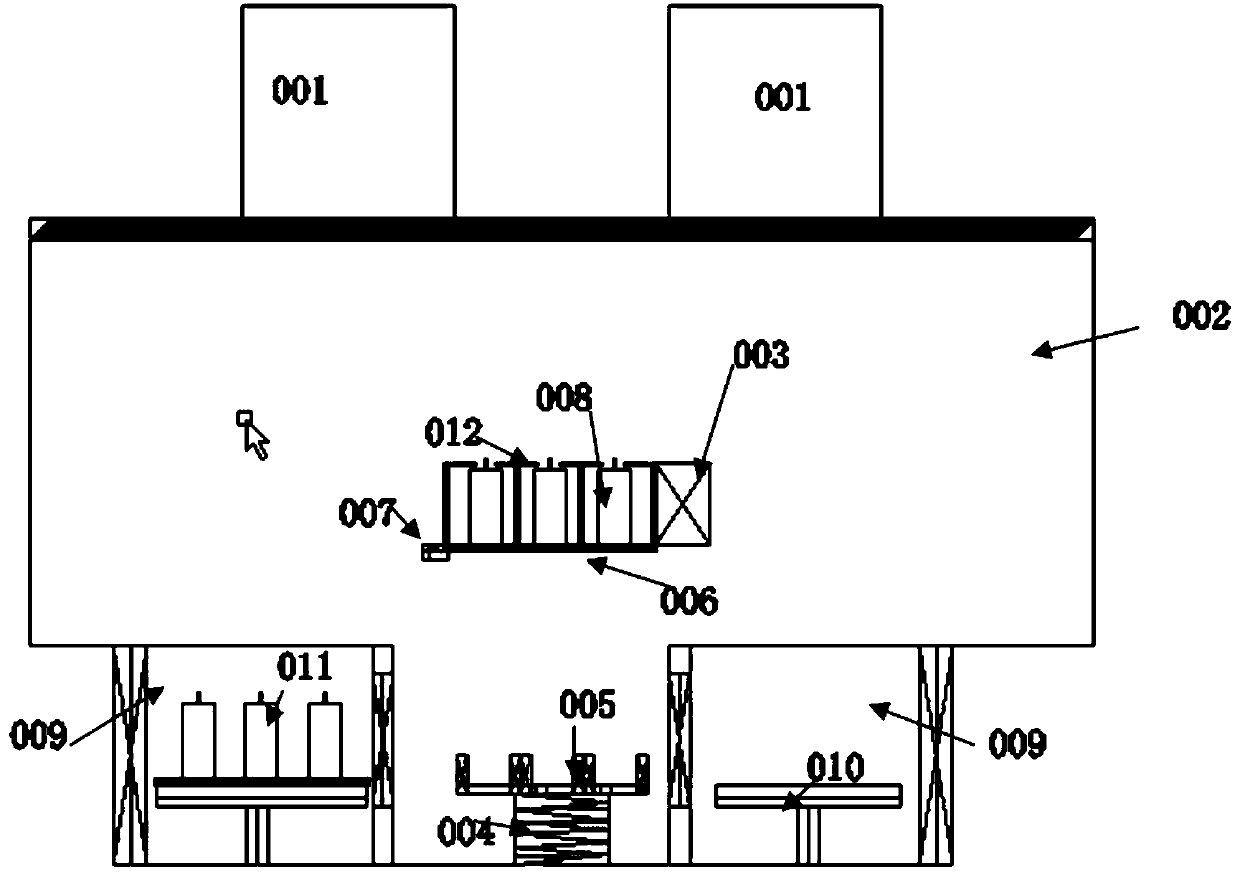

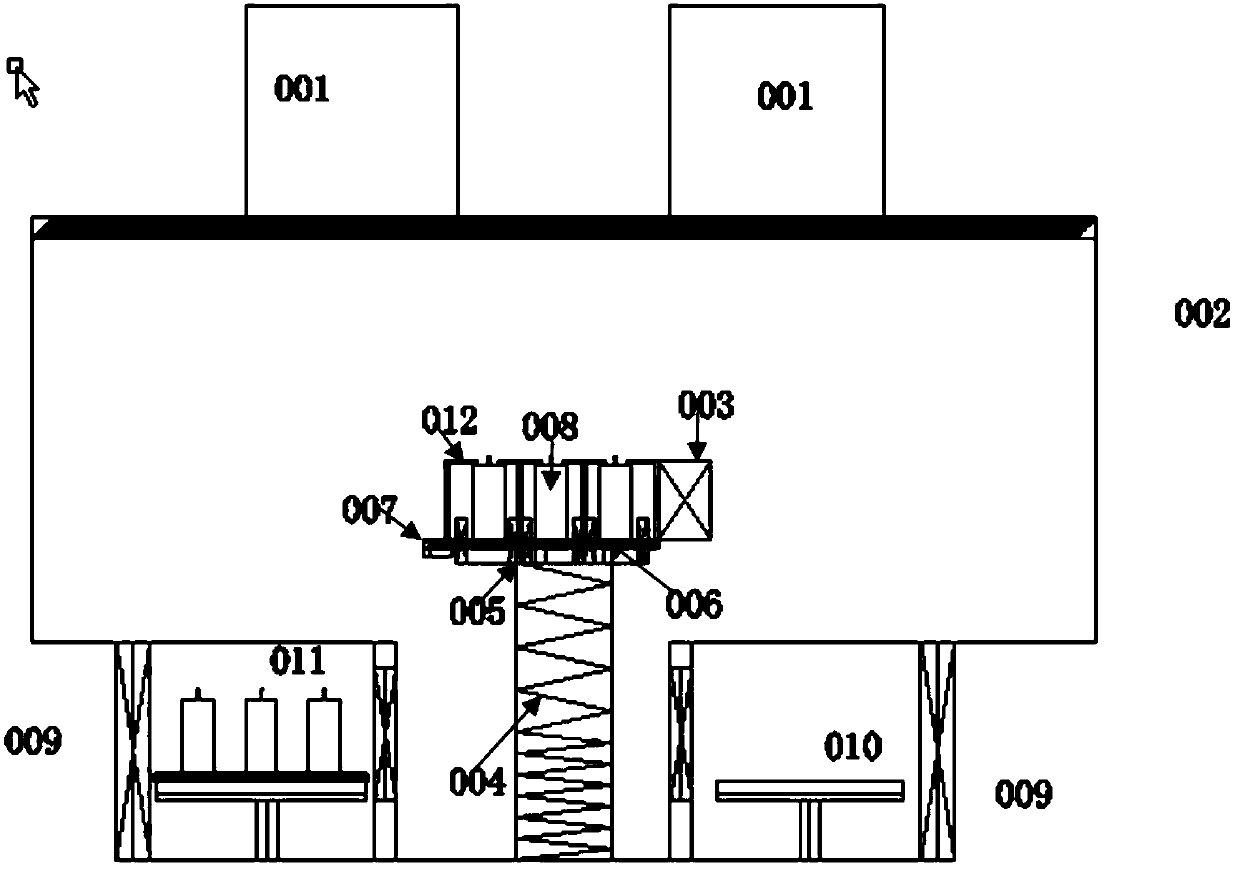

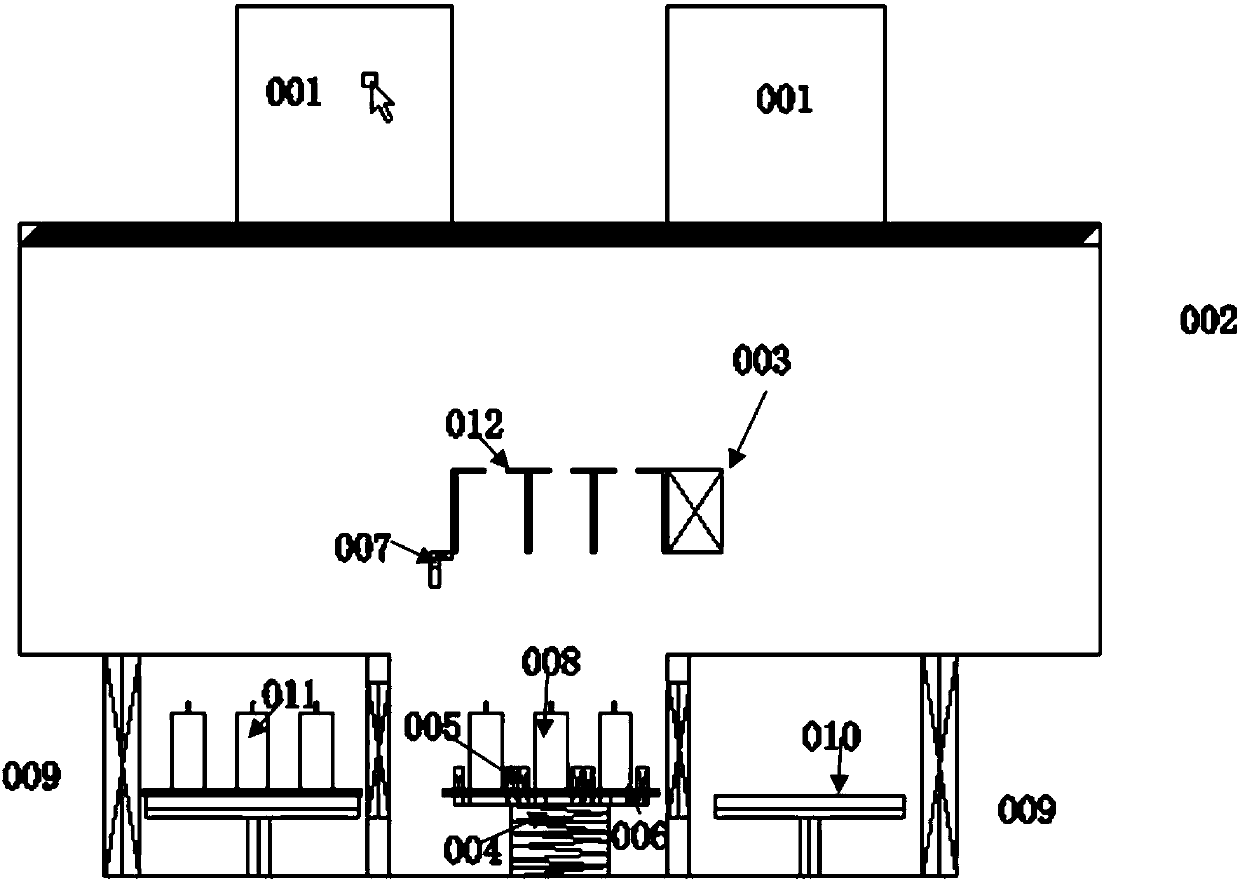

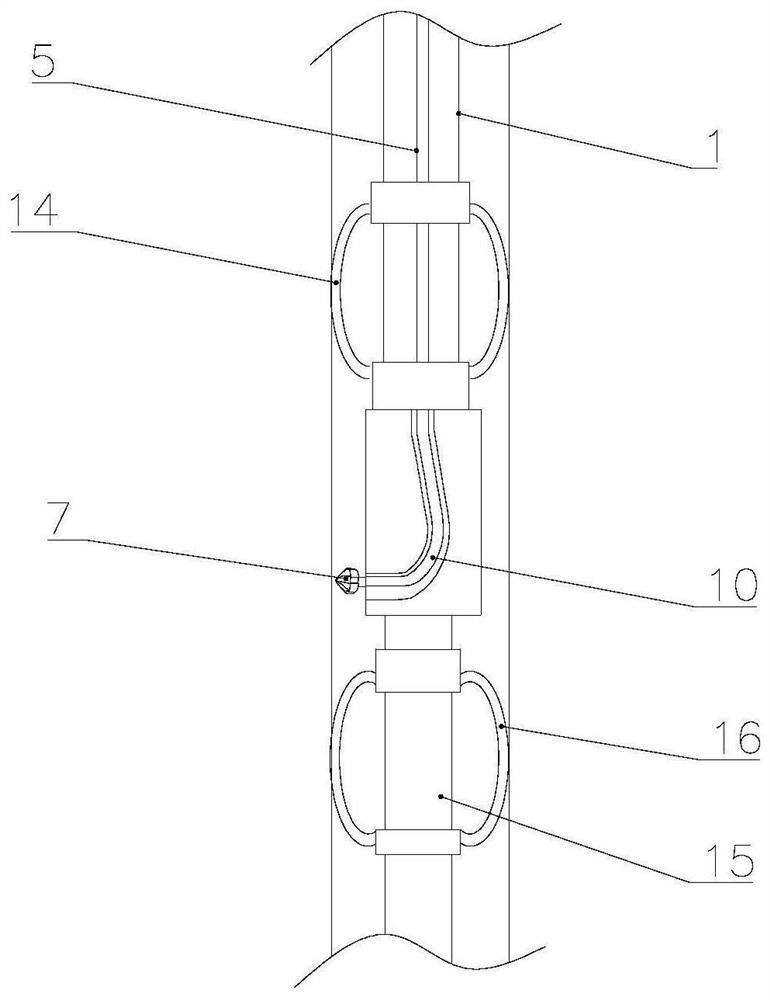

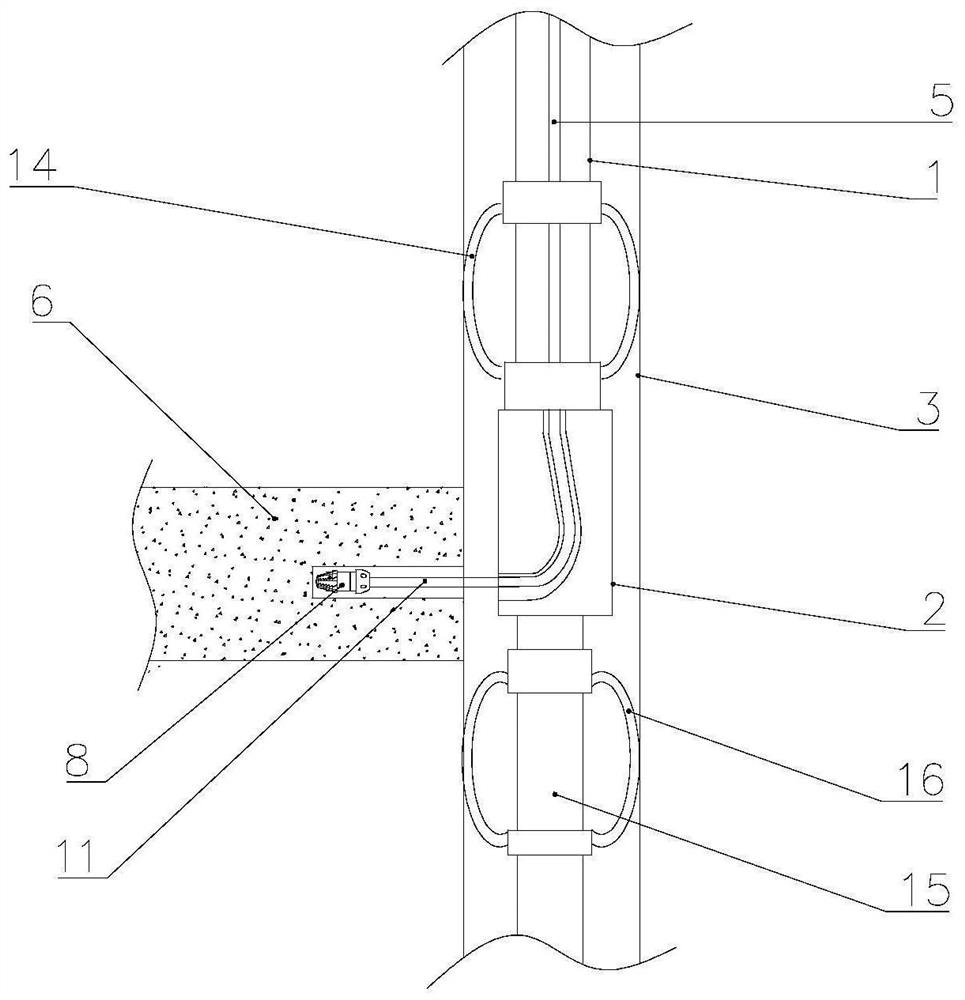

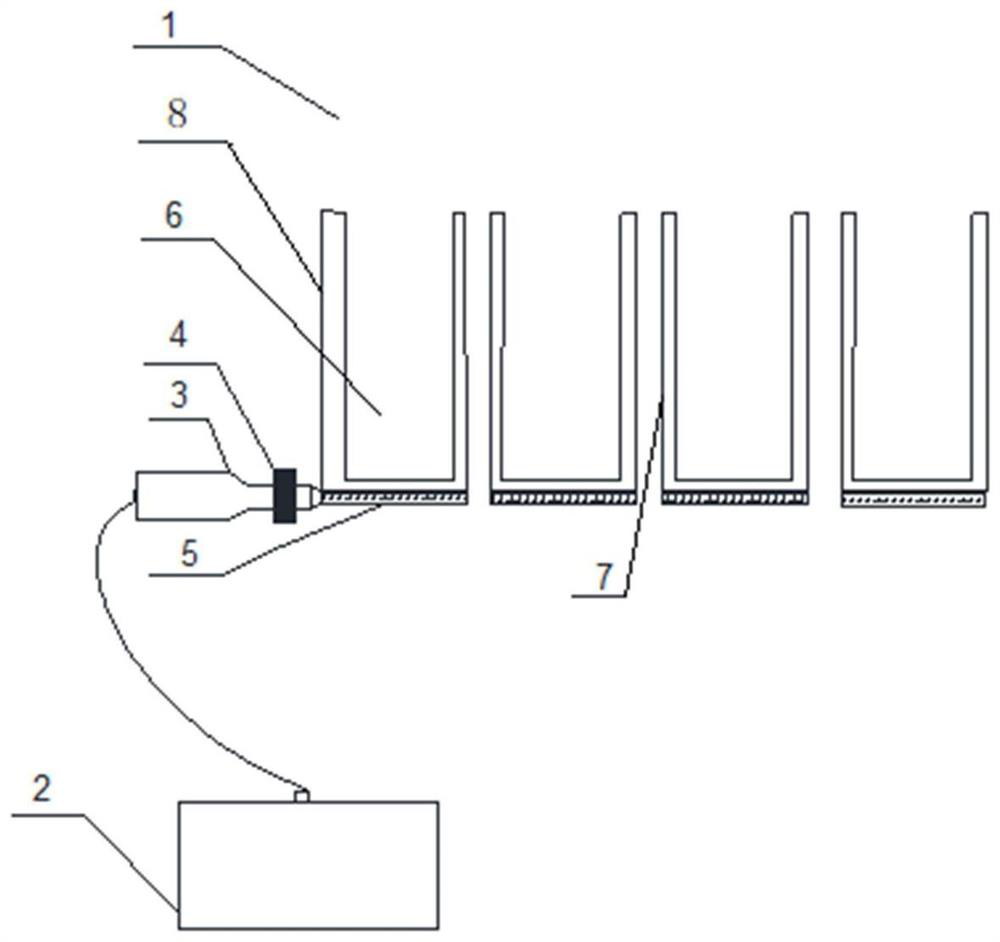

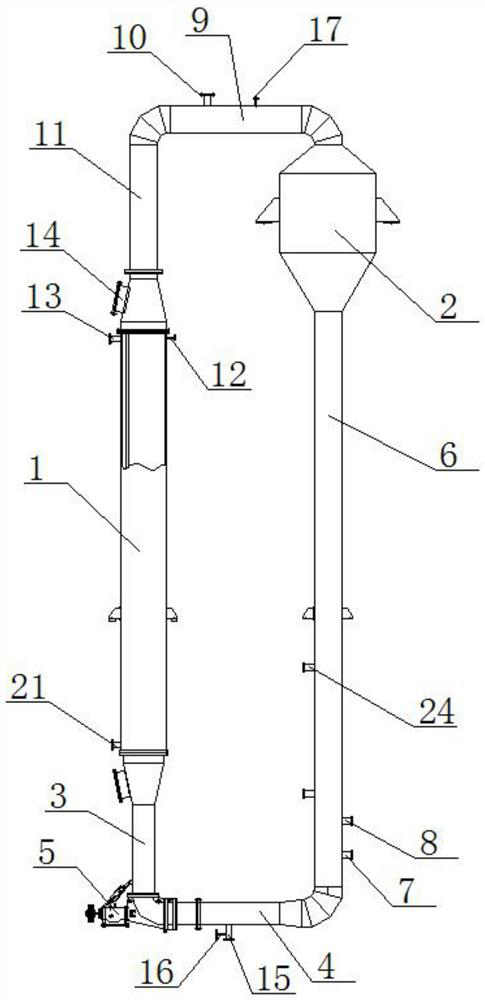

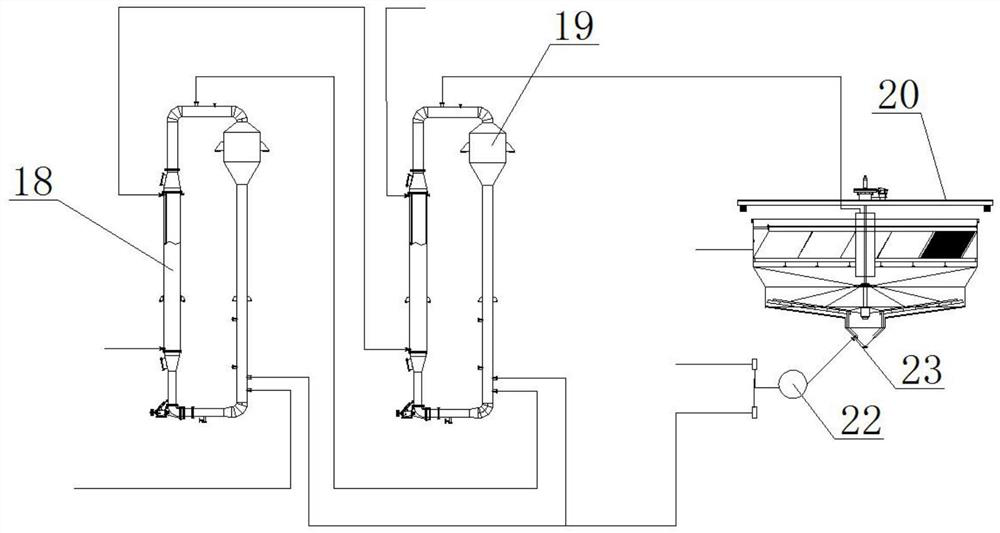

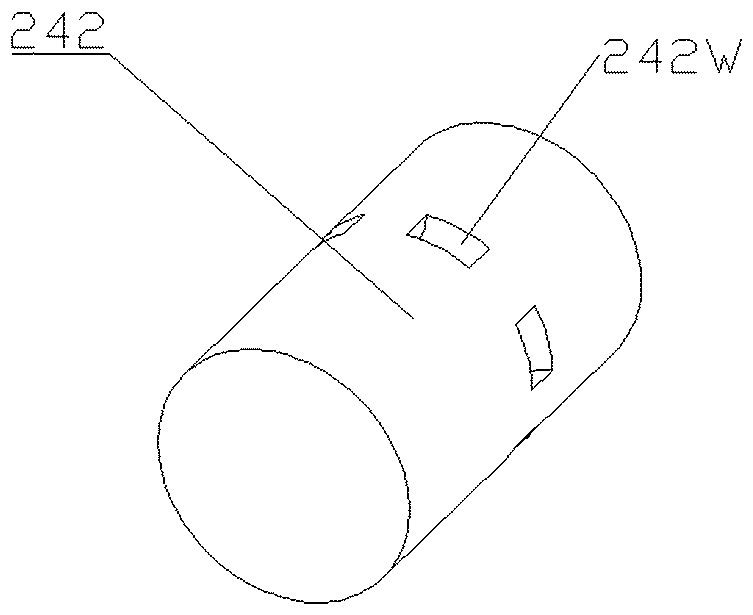

Combination metallurgical furnace for producing zinc alloy and zinc alloy combination producing method

InactiveCN101509727AStrong continuous melting abilityFast heatingIncreasing energy efficiencyCrucible furnacesZinc alloysIngot

The invention provides a combined metallurgical furnace and a combined production method for zinc alloy, comprising a cored line-frequency induction furnace (2) and at least two line-frequency coreless induction furnaces (7) with dumping devices (13); a convertible chute (6) is connected between a liquid outlet of the cored line-frequency induction furnace and a liquid inlet (14) of the line-frequency coreless induction furnaces; and a casting mechanism (9) is arranged correspondingly to a sprue (8) of the line-frequency coreless induction furnaces. The production method comprises the steps as follows: the zinc liquid which is melted in the cored line-frequency induction furnace is injected into each line-frequency coreless induction furnace in turn by the convertible chute and is then mixed with the middle alloy liquid which is smelted in advance in the line-frequency coreless induction furnaces; the non-contact melt mixing is realized by the electromagnetic induction force of the line-frequency coreless induction furnaces, thus preparing the zinc alloy ingot by pouring the zinc alloy liquid. The combined metallurgical furnace and the combined production method have high production efficiency, high yield, good quality of the produced zinc alloy, low energy consumption and small damage to the furnace body.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

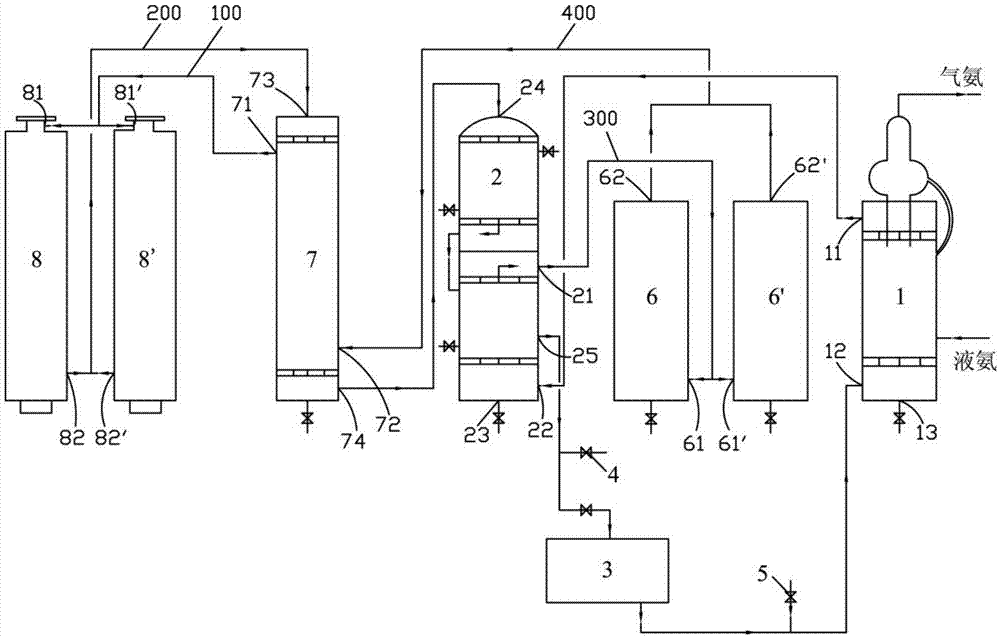

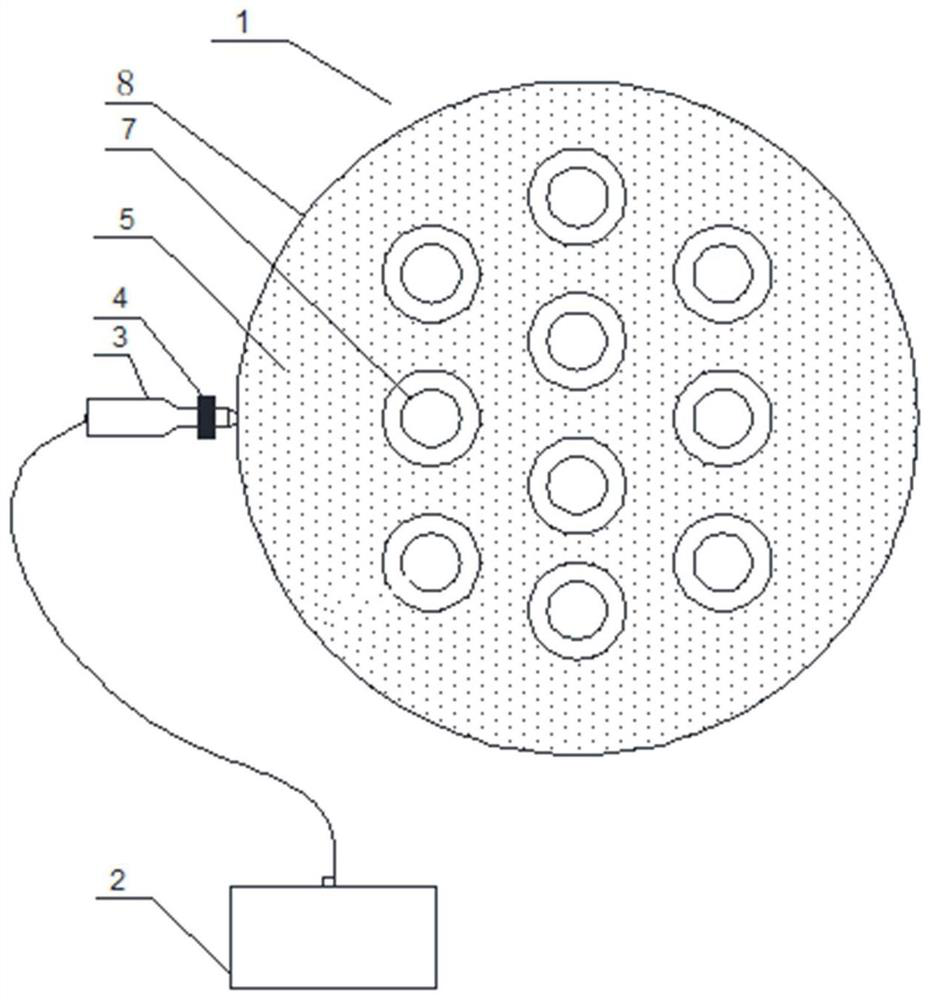

Preparation method and preparation device for synthesis ammonia prereduction catalyst

InactiveCN105435861AHigh strengthKeep aliveCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrogenNitrogen

The invention provides a preparation method and a preparation device for a synthesis ammonia prereduction catalyst. The preparation method comprises the following steps: feeding a synthesis ammonia Fe catalyst into a reduction tower, and introducing mixed hydrogen and nitrogen; then heating at a heating rate of 30-40 DEG C / h, and performing reduction reaction when the temperature raises to 365-380 DEG C; after the reduction reaction is over, discharging the mixed hydrogen and nitrogen out of the reduction tower; when the temperature is reduced to be not higher than 50 DEG C and normal pressure is achieved, introducing oxygen for passivating, wherein the pressure during the passivation process is kept between 0.018MPa and 0.02MPa; and after the temperature is reduced to be not higher than 46 DEG C, finishing passivation, thereby obtaining the synthesis ammonia prereduction catalyst. In the preparation device, in-parallel double towers are adopted for the reduction tower, a passivation groove is omitted, heating reduction and passivation are performed in the reduction tower, and a method of negative pressure extraction by use of a circulating fan is adopted during the passivation process, so that the effective production time is obviously increased, the reducing capacity is greatly improved, the operation difficulty is simplified, power consumption is reduced, and the air inflow stability of a system is ensured.

Owner:HENAN ZHONGHONG CLEAN ENERGY CO LTD

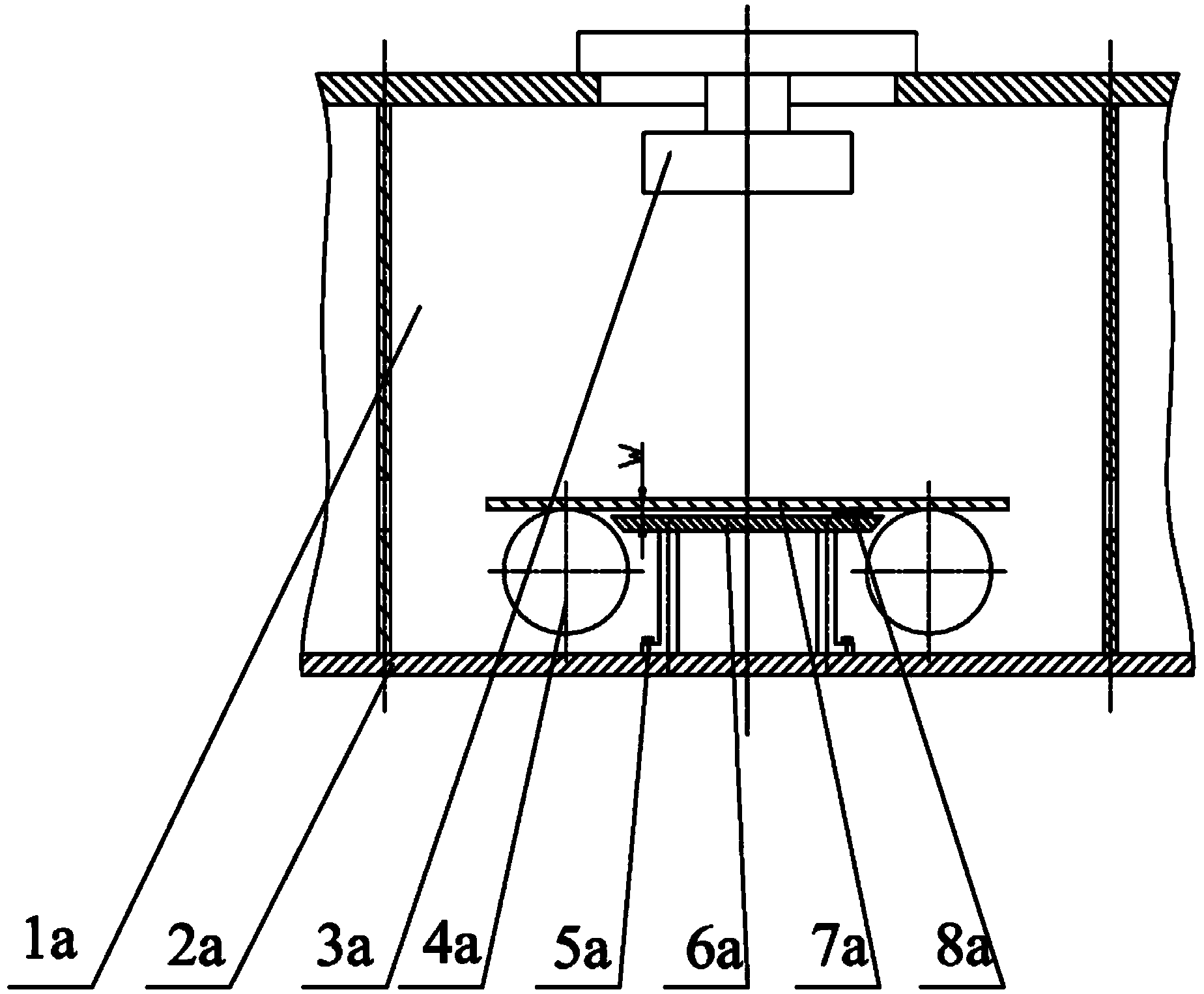

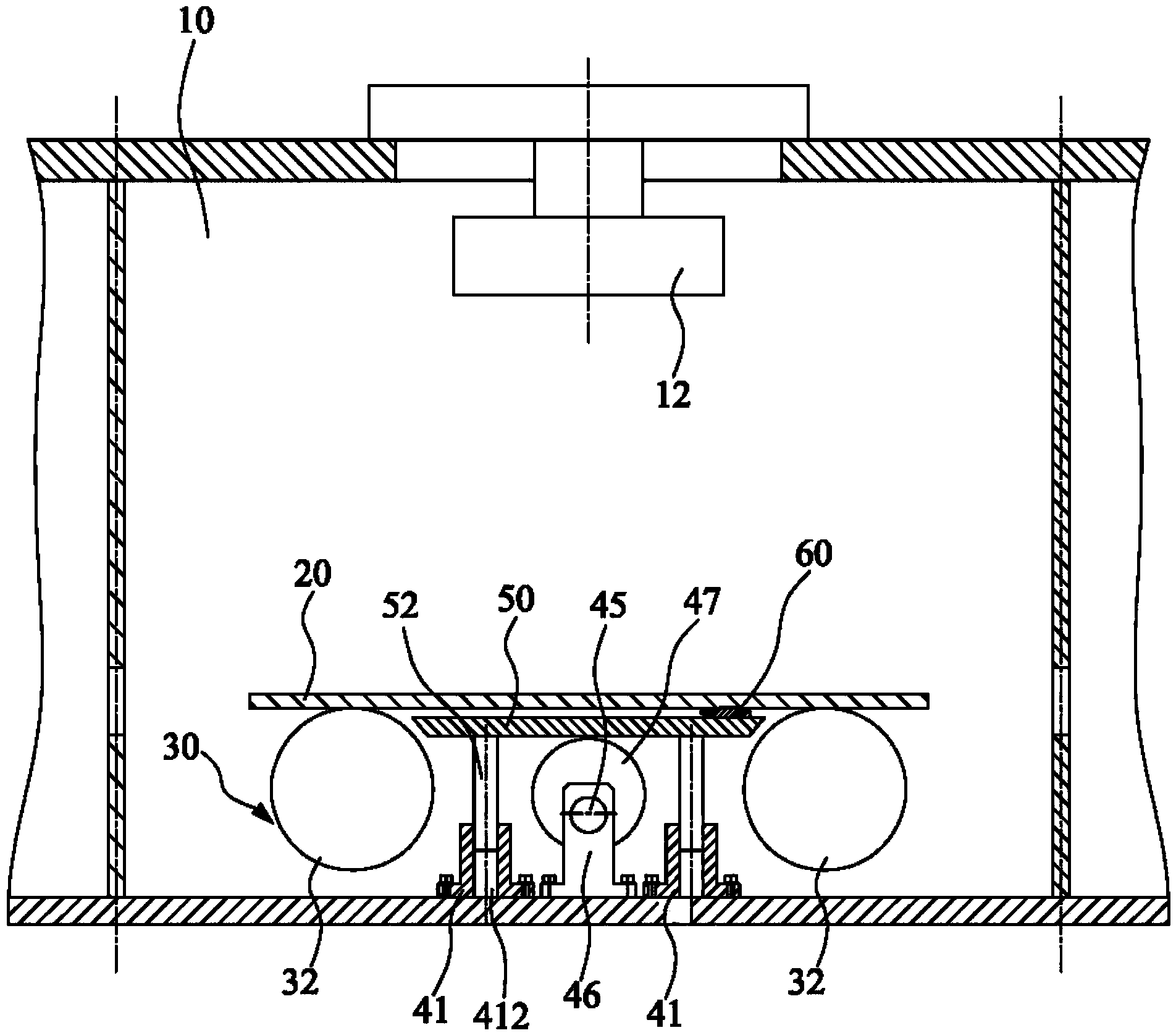

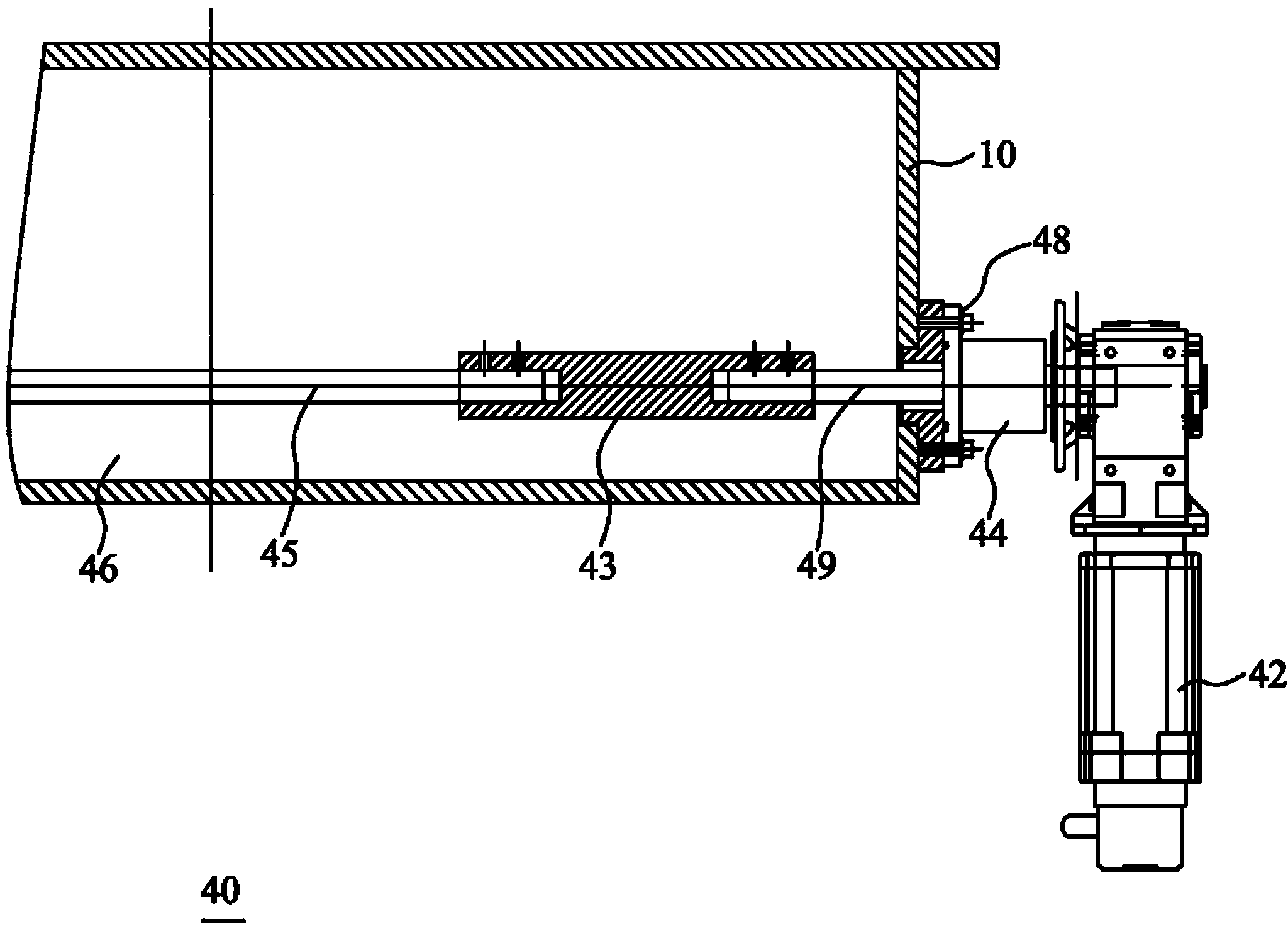

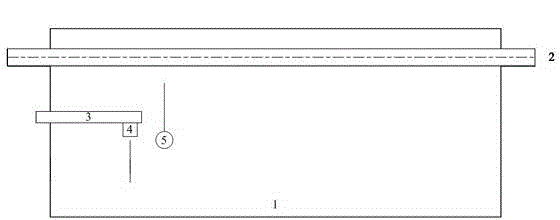

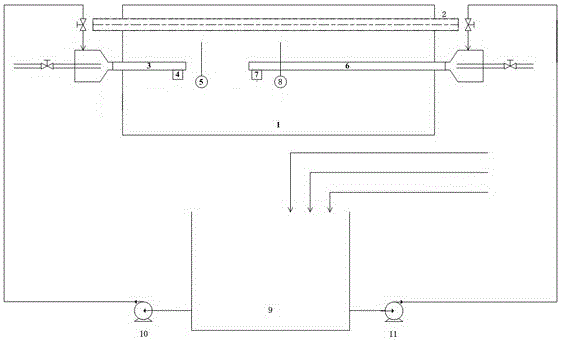

Glass film coating device and bottom plate die set

ActiveCN103663997AAvoid downtimeIncrease effective production timeElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringVacuum chamber

The invention relates to a glass film coating device which is used for coating to-be-film-coated glass with a film and comprises a film coating cabin, a transmission unit and a bottom plate die set, wherein the transmission unit is positioned at the lower end of the film coating cabin and comprises a plurality of roller ways; the bottom plate die set is arranged among the roller ways; the to-be-film-coated glass is transmitted to the film coating cabin through the roller ways; the bottom plate die set comprises a bottom plate and a lifting element; the lifting element is connected with the bottom plate, so as to adjust the relative distance between the bottom plate and the to-be-film-coated glass. The invention further provides the bottom plate die set of the glass film coating device. According to the glass film coating device, as the bottom plate has the characteristic of being liftable in a vacuum chamber, and when the cumulate film thickness is increased, the bottom plate can be adjusted downwards so as to enable the thickened film not to affect the to-be-film-coated glass. As a result, halt overhaul is avoided, and the effective production time is greatly increased. The glass film coating device can be widely applied to a continuous glass film coating production line.

Owner:CSG HOLDING

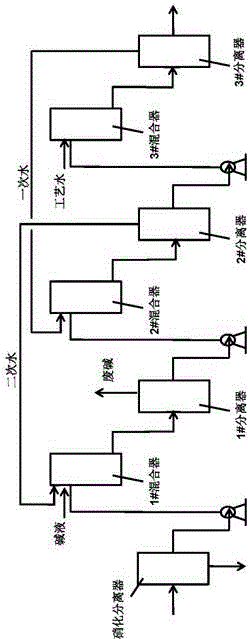

Washing production method for crude nitrochlorobenzene

ActiveCN106278903ALess investmentReduce dosageOrganic chemistryOrganic compound preparationNitrationStatic mixer

The invention relates to a washing production method for crude nitrochlorobenzene. After completion of a nitration reaction, nitration products and waste acid enter a nitration separator for separation; a separated organic phase successively undergoes alkali washing and water washing in a static mixer; and the obtained organic phase is subjected to subsequent treatment. Since the static mixer is used for alkali washing and water washing and pipelization is realized in the process of washing, so equipment investment can be reduced; washing water is connected in series for washing of crude nitrochlorobenzene, so the usage amount of water can be reduced, and washing effect is improved; and except a delivery pump, the whole set of apparatuses used in the method is free of movable articles, so a fault rate is low and effective production time can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

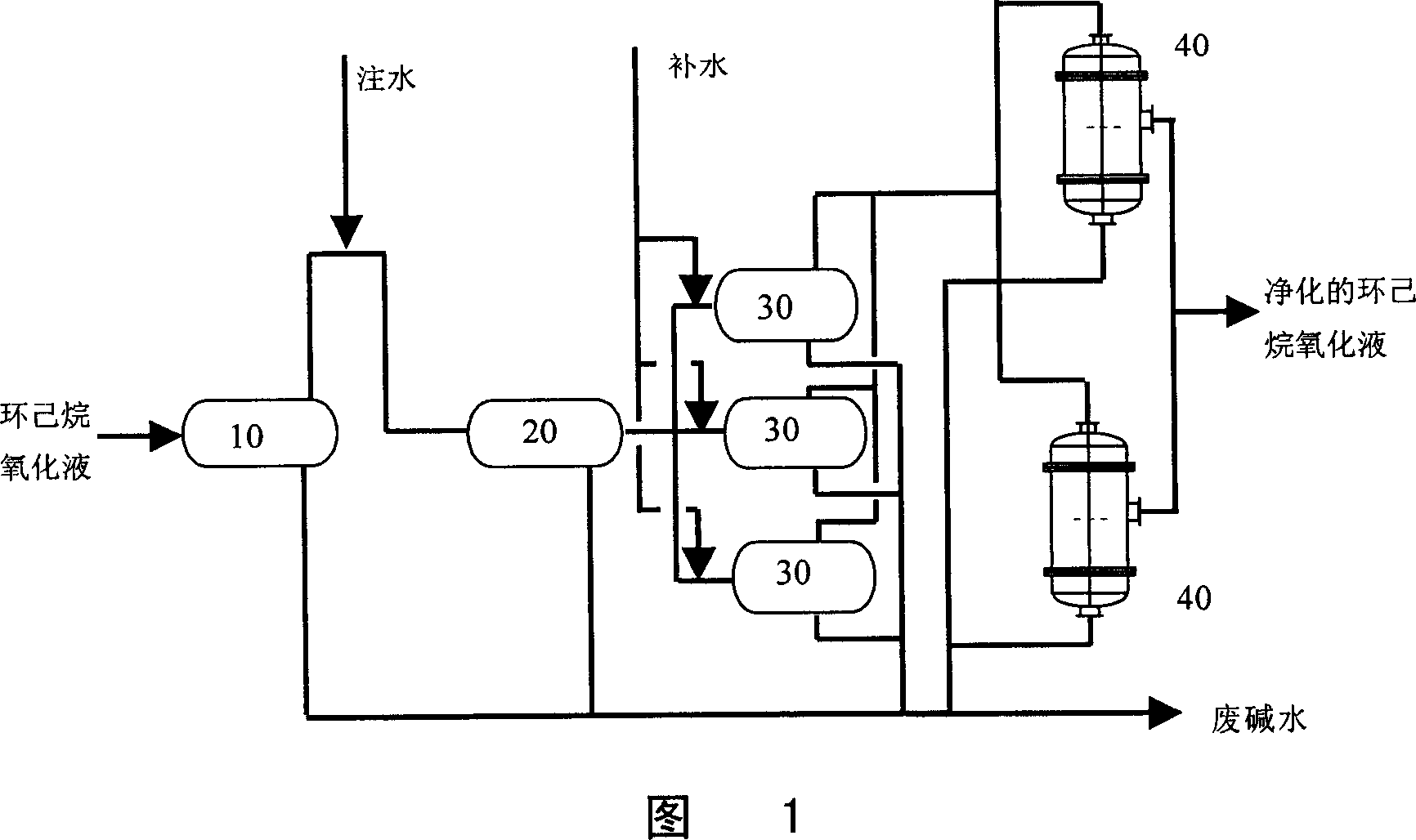

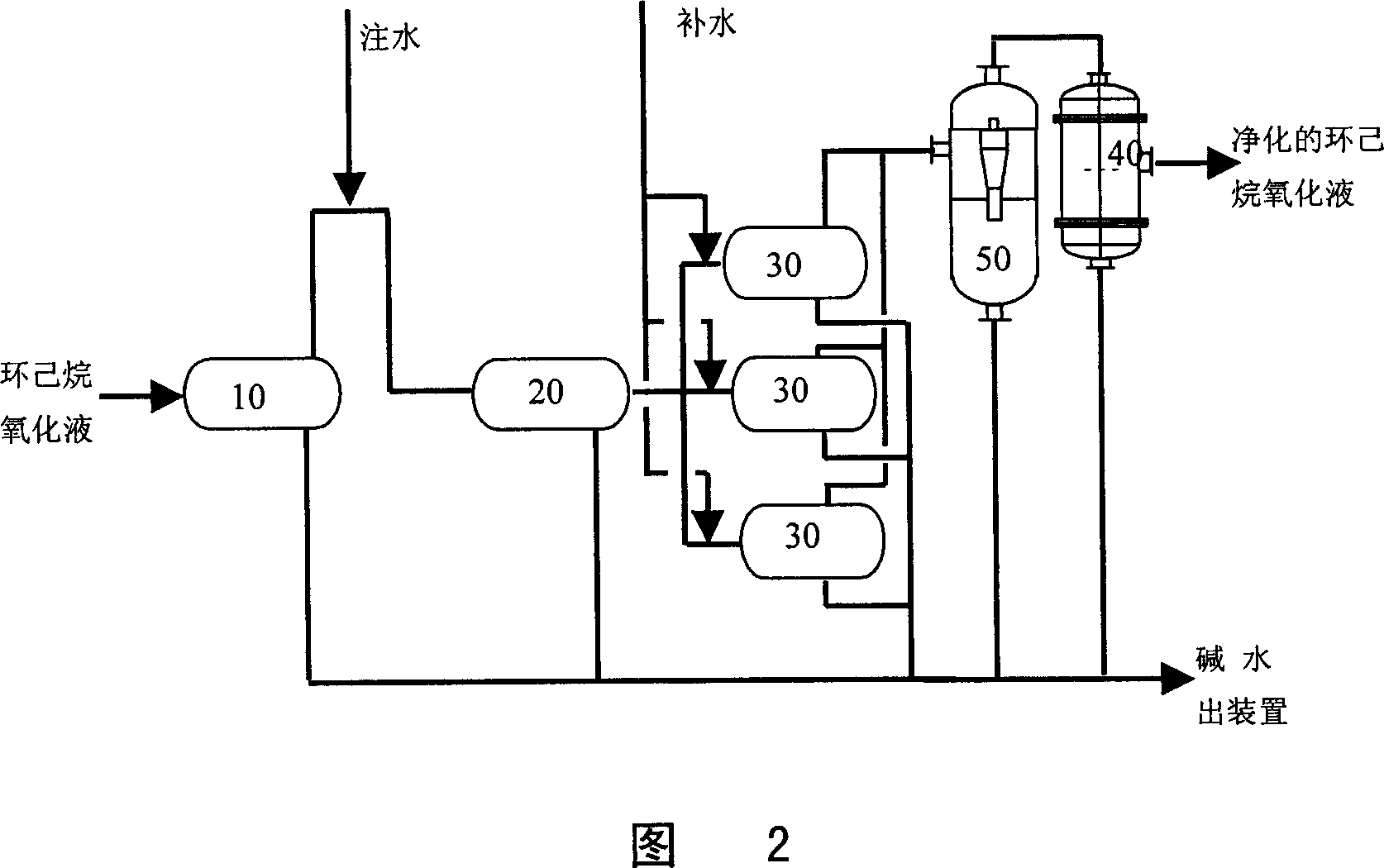

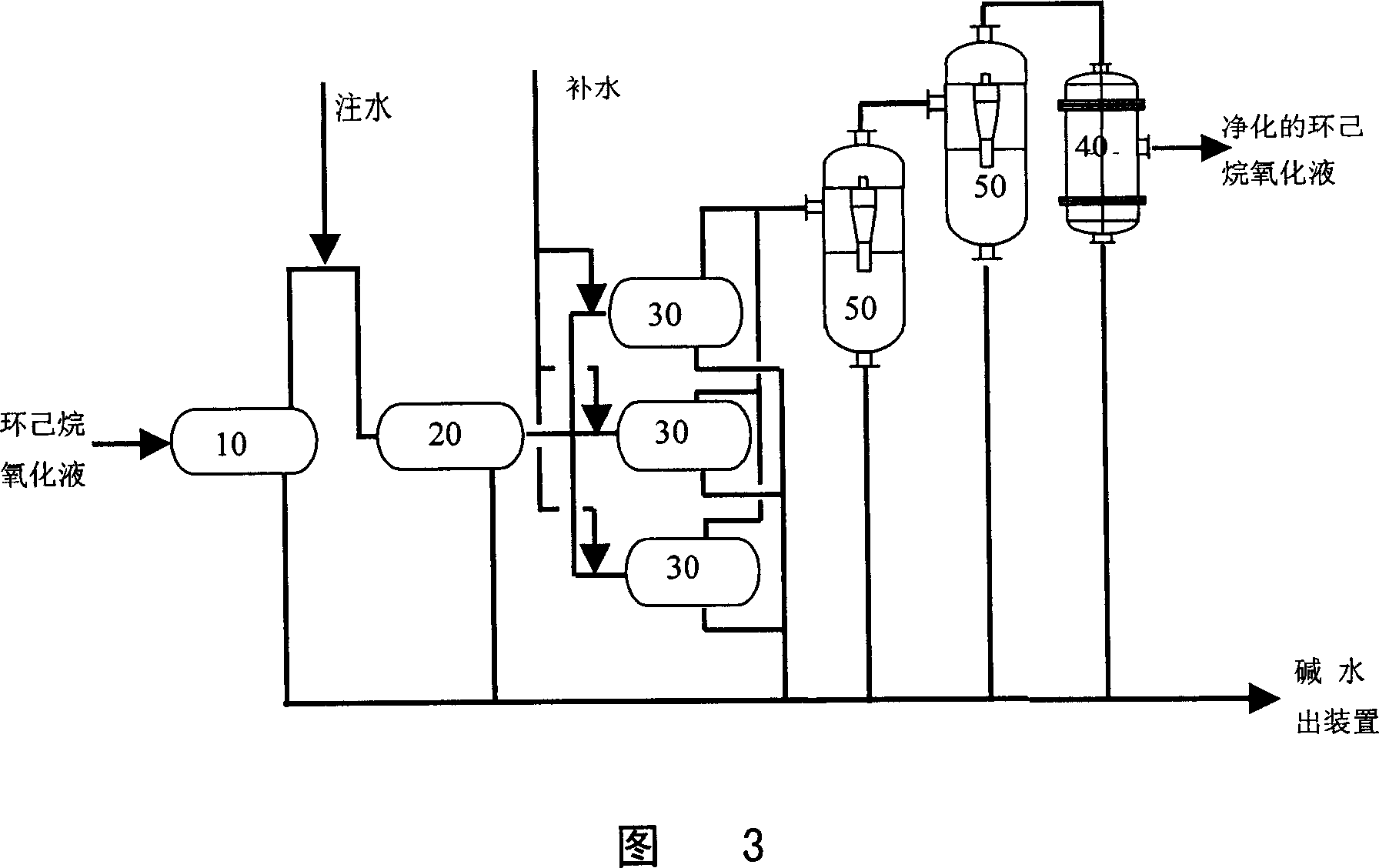

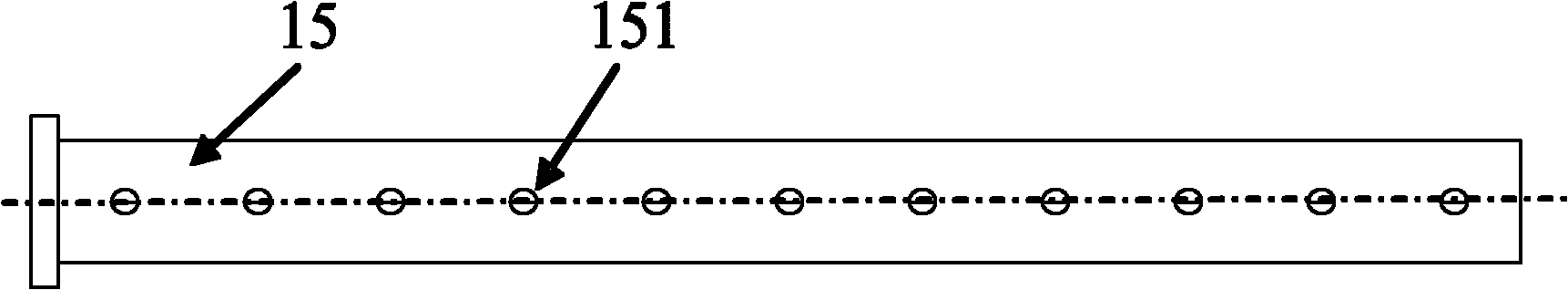

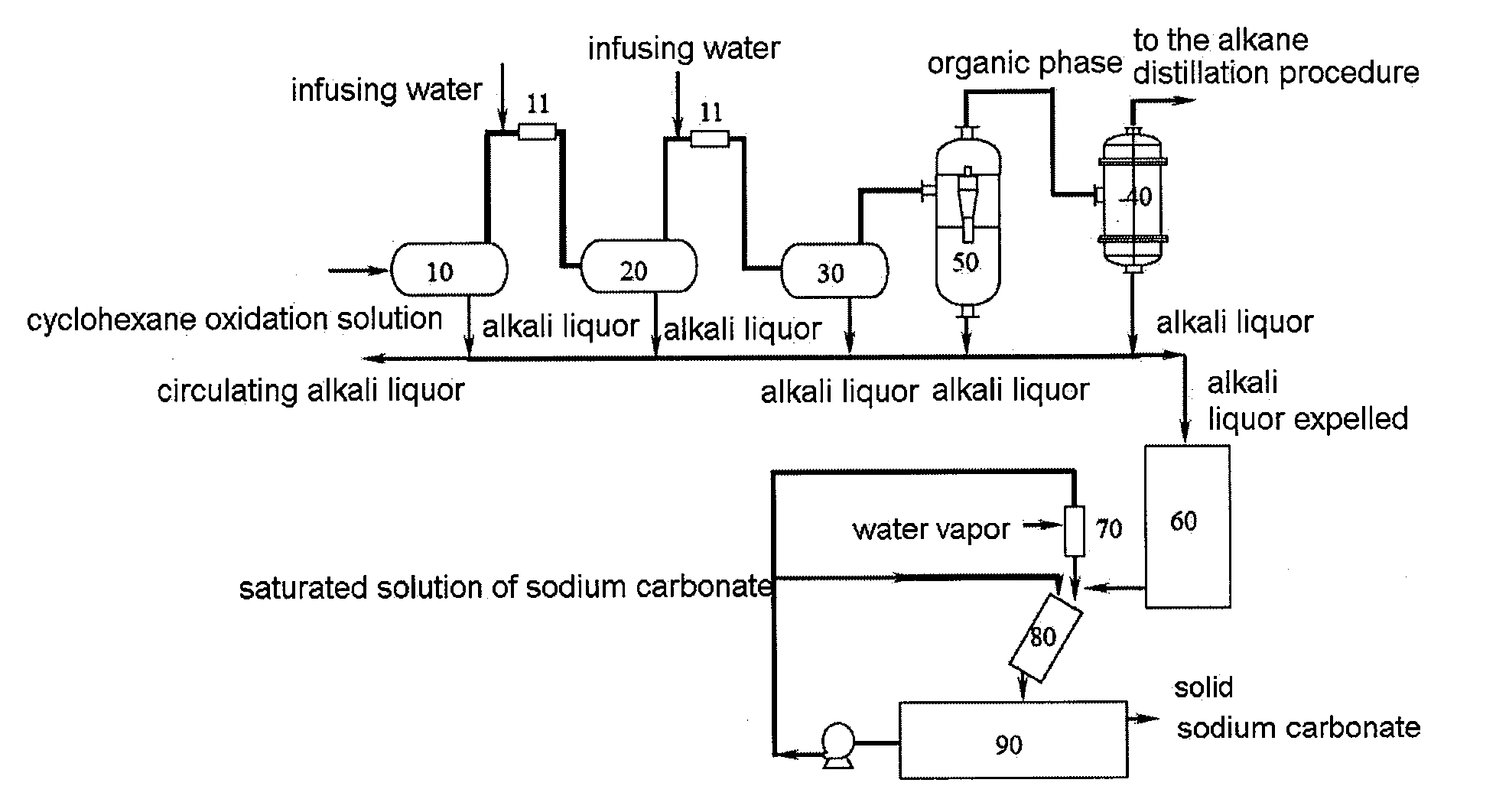

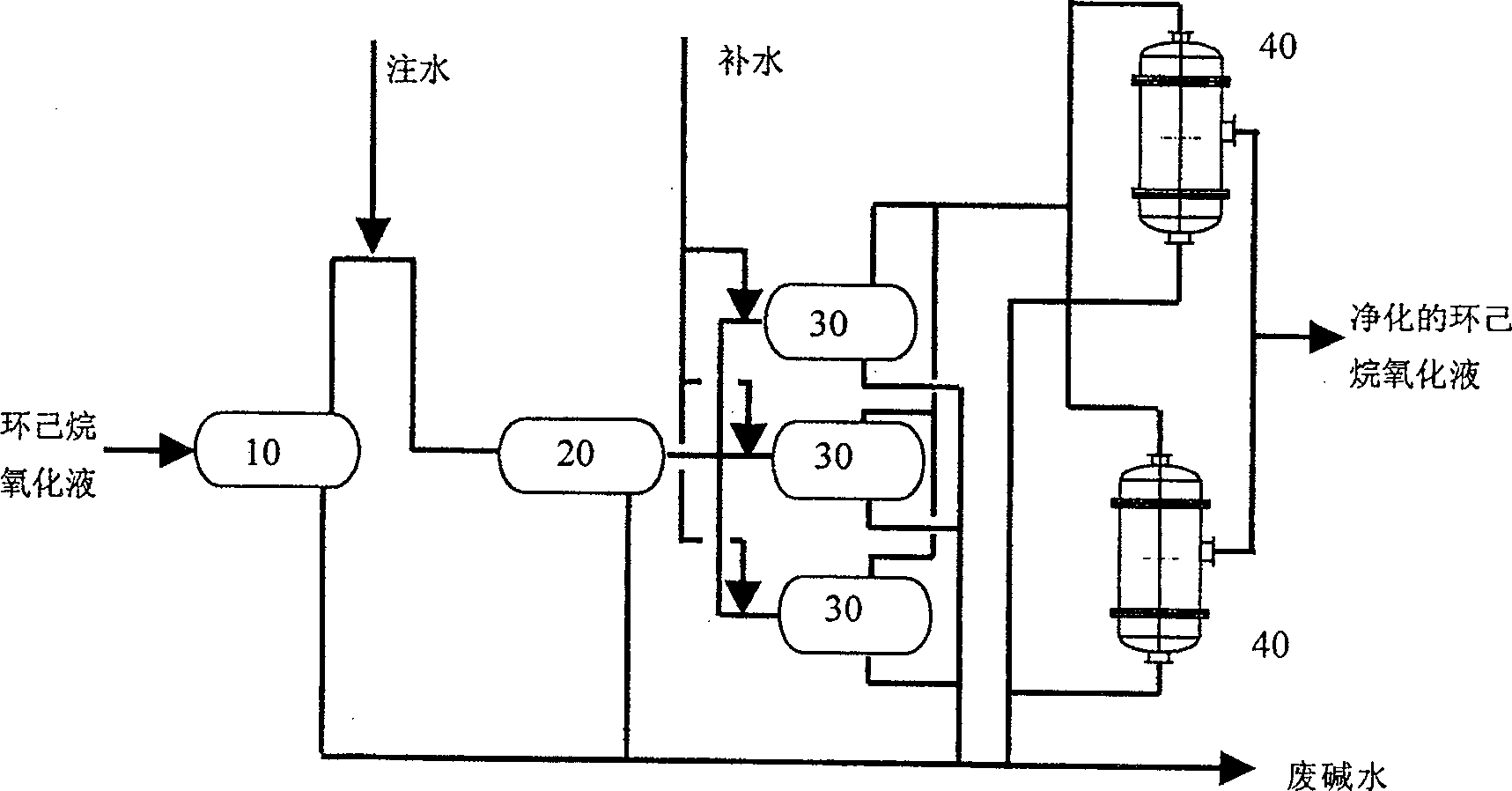

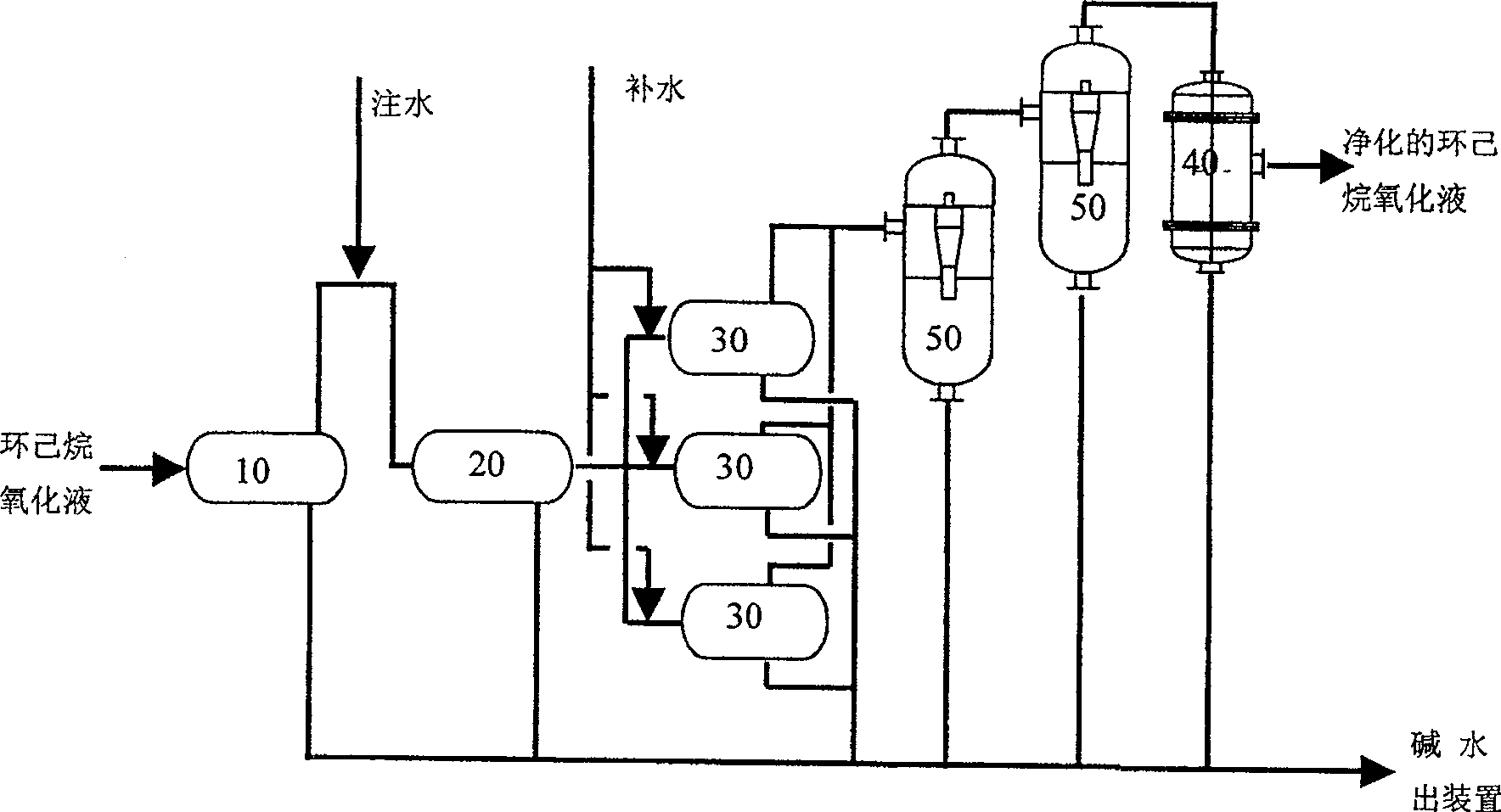

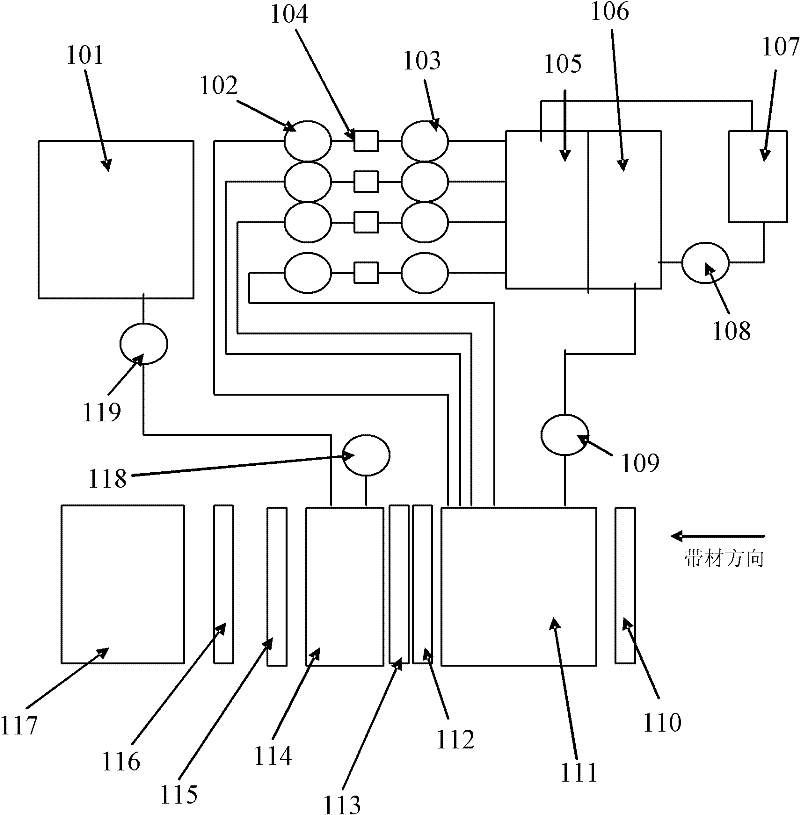

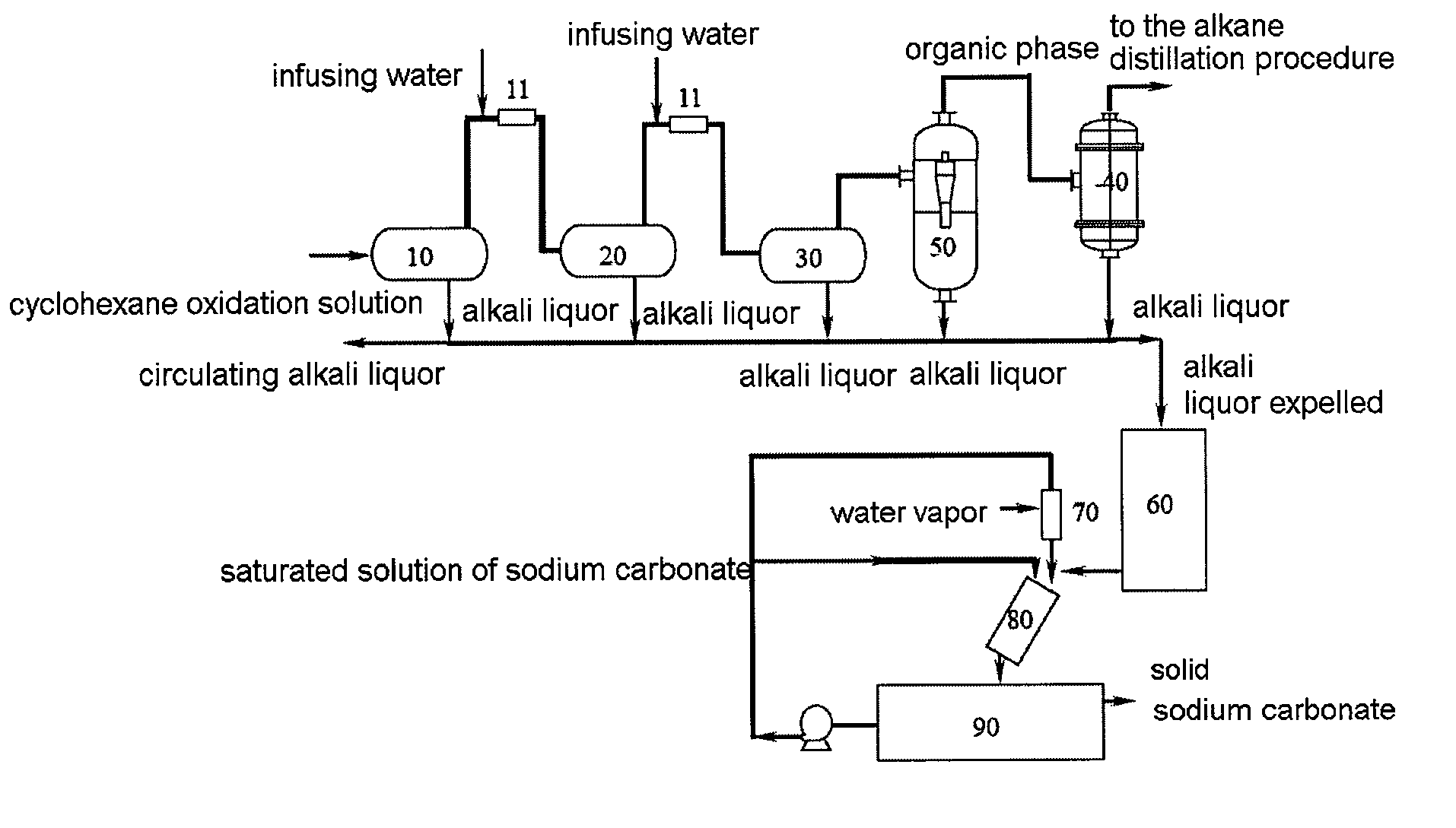

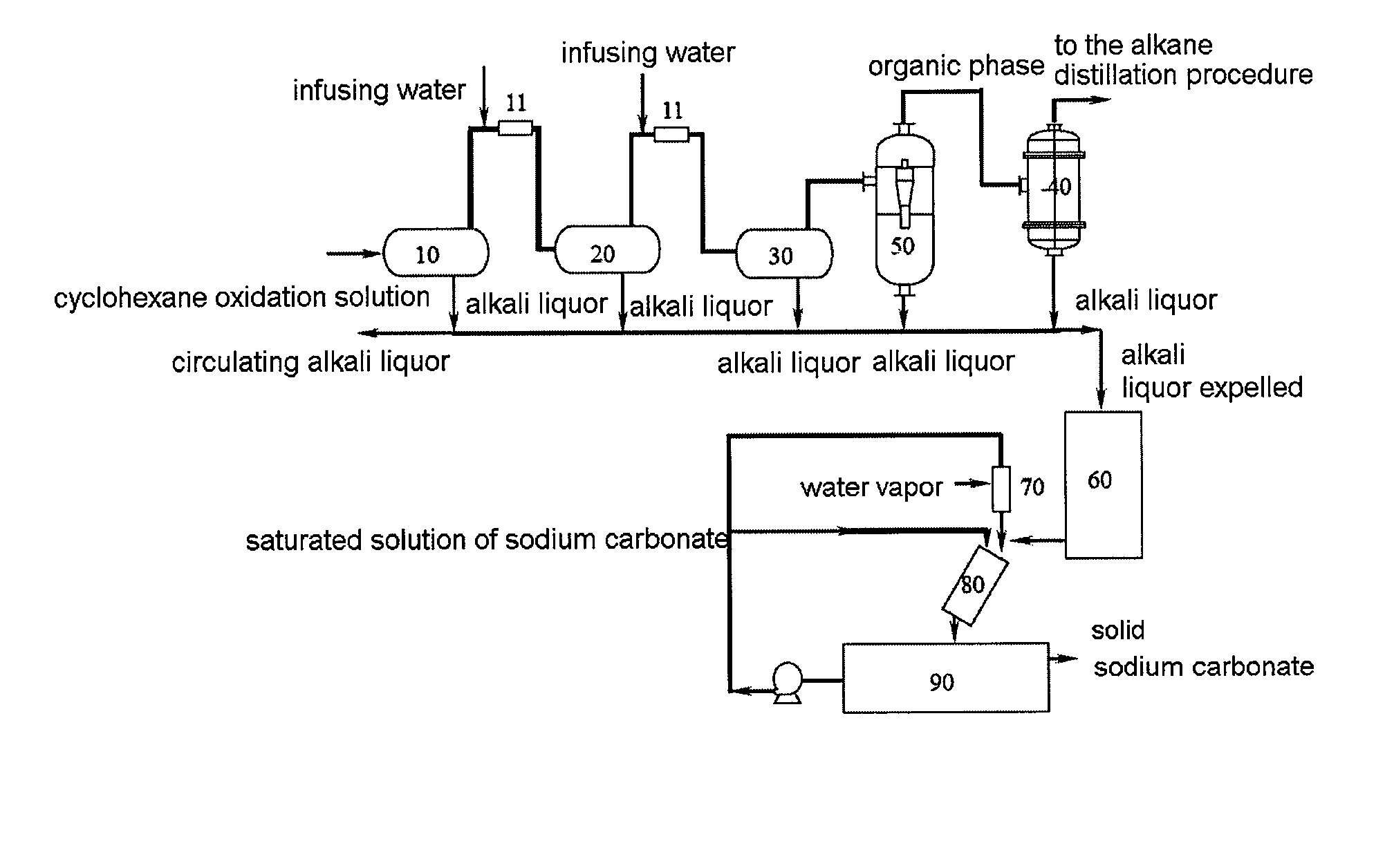

Method and apparatus for separating cyclo-hexane oxidation waste alkali

ActiveCN1978345ASolve the incomplete separationIncrease effective production timeWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentDistillationCombined use

This invention provides a method and a device for separating waste alkali of cyclohexane oxidation liquid by a spiral-flow coalescence serial combination technology, which separates it in three steps in gravity sedimentation tank, a cyclone separator and a coalescence separator to separate it completely, which overcomes the shortcomings of gravity deposition method and the coalescence separation method and prolongs the effective production time of alkyl distillation tower greatly.

Owner:EAST CHINA UNIV OF SCI & TECH

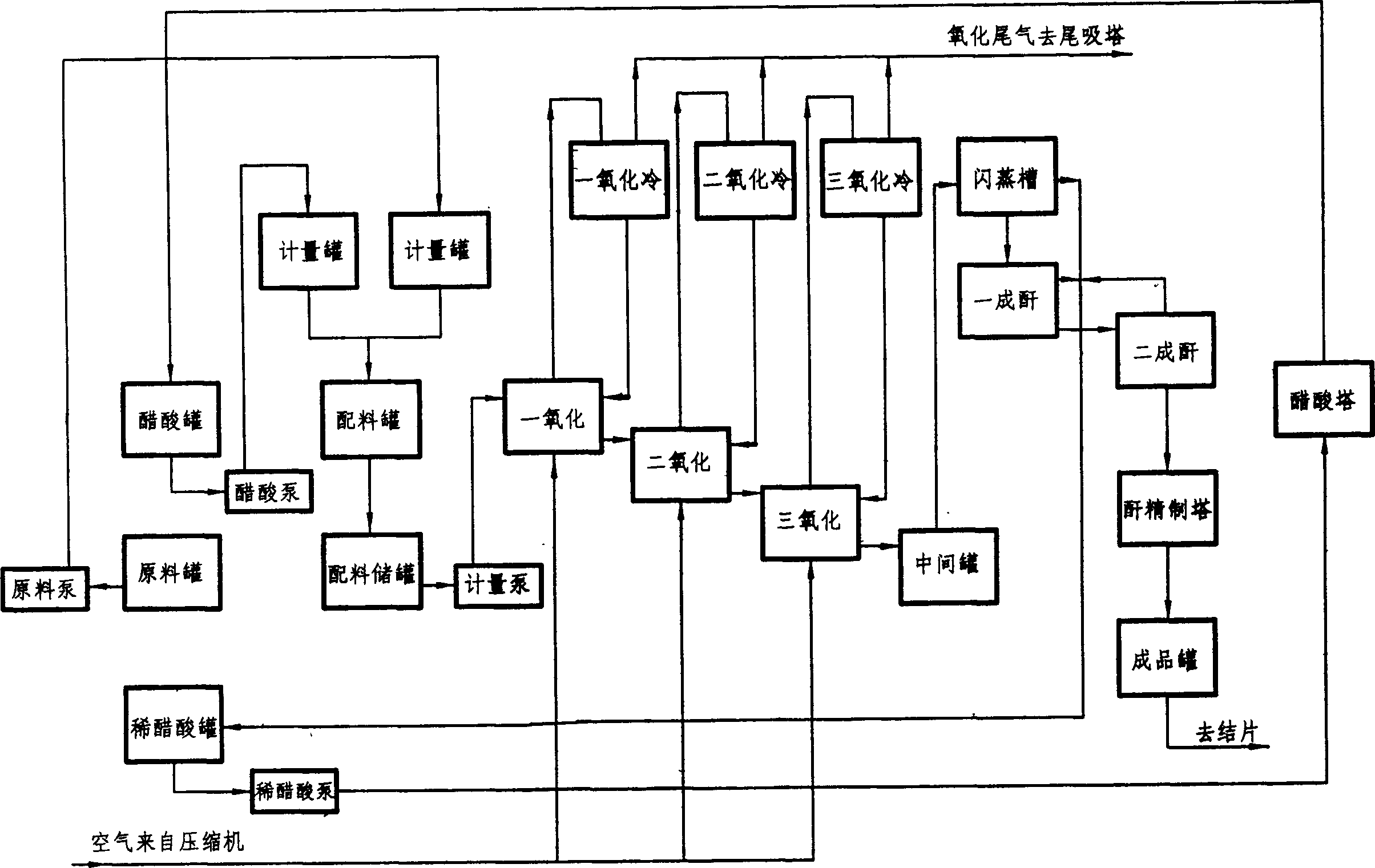

Process of producing monocholo benzen anhydride by continuous liquid phase oxydation

InactiveCN1560045AAvoid fatigue damageExtended service lifeOrganic chemistryMANGANESE ACETATESolvent

The invention relates to a method of producing monochlorophthalic anhydride by liquid-phase continuous oxidization, using monochloro-ortho-xylene as raw material, using cobalt acetate and manganese acetate as catalyst, using acetylene tetrachloride and hydrogen bromide as accelerant, feeding the above materials in proportion into a multistage serial stirring reaction kettle, and at a certain pressure and temperature, simultaneously charging compressed air to make the liquid-phase continuous oxidization reaction so as to make monochlorophthalic acid, which passes through a medium jar to a flash vaporization tank for temperature and pressure reduction, then obtaining crude anhydride by a multistage serial anhydride-forming reaction kettle dehydrating and deacidifying, continuously rectifying to obtain refined anhydride, and finally flaking to make the finished product. The waste residues are continuously discharged. The acetic acid is rectified and circulates. It adopts multistage serial stirring reaction kettle and multiage anhydride-forming reaction kettle, and the continuity of the reacting steps does not require repeated pressure boost, and temperature increase, and the production indicator is stable.

Owner:天津市利维科技有限公司

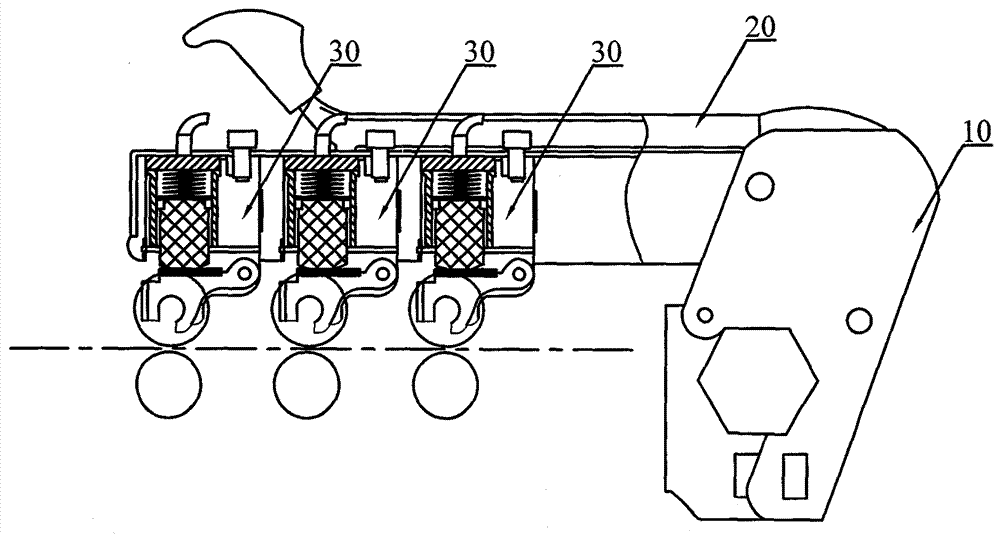

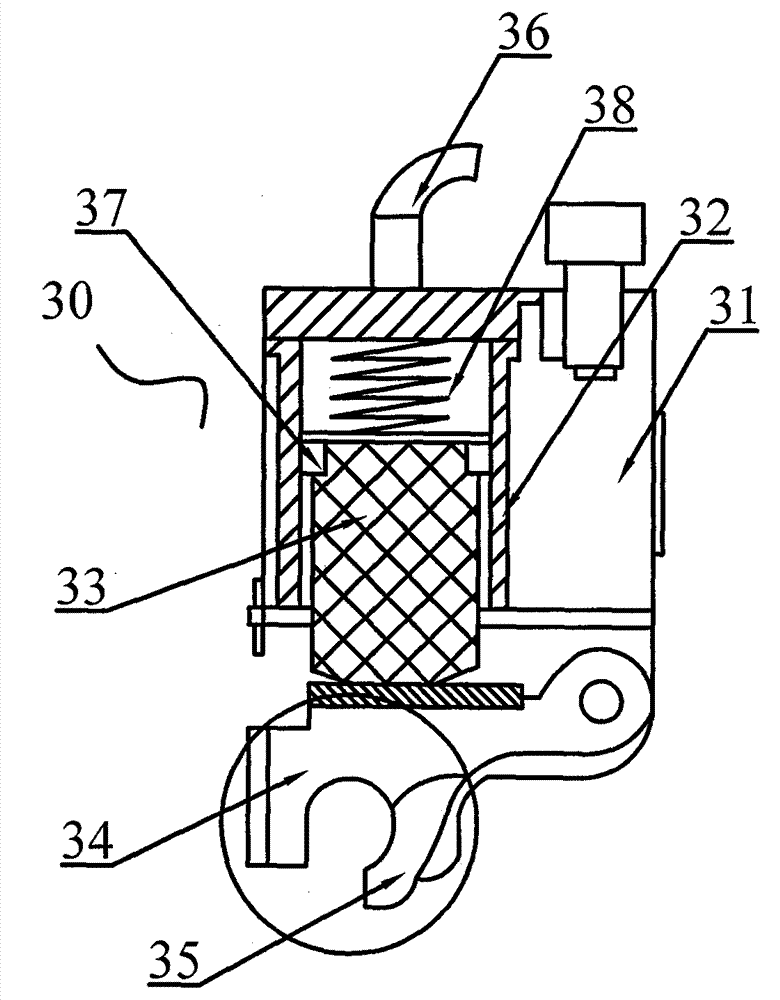

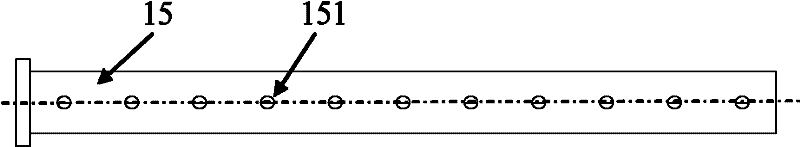

Pressurized rocking frame of ring spinning frame drafting system

InactiveCN104120518AReduce stepless voltage regulation functionWith stepless pressure regulation functionDrafting machinesEngineeringMechanical engineering

The invention relates to a pressurized rocking frame of a ring spinning frame drafting system. The pressurized rocking frame comprises a rocking frame base and a rocking frame body, wherein the rocking frame body is arranged on the rocking frame base. The pressurized rocking frame further comprises multiple air cylinder pressurizing devices, wherein the multiple air cylinder pressurizing devices are arranged and installed on the rocking frame body and comprise assembling supports, air cylinders, pistons with rods, pressurizing rods and holding jaws. The assembling supports are fixed on the rocking frame body through bolts, the air cylinders are fixed on the assembling supports, the piston ends of the pistons with the rods are arranged in the air cylinders, the other end of each of the pistons with the rods are arranged above the pressurizing rods, the pressurizing rods are located under the air cylinder, the holding jaws are arranged on the pressurizing rods, and the air cylinders of the air cylinder pressurizing devices are respectively provided with an independent air pressure source connecting end. By adopting the pressurized rocking frame, the consistency of pressurized pressure of each rocking frame set is improved, unified pressure regulation and stepless pressure regulation of the same pressurized positions of all of rocking frames of a whole machine can be achieved, and the spinning quality is improved. In addition, the production efficiency is effectively improved, and the labor intensity is reduced.

Owner:HUNAN SHENGKAIRUI MACHINERY CO LTD

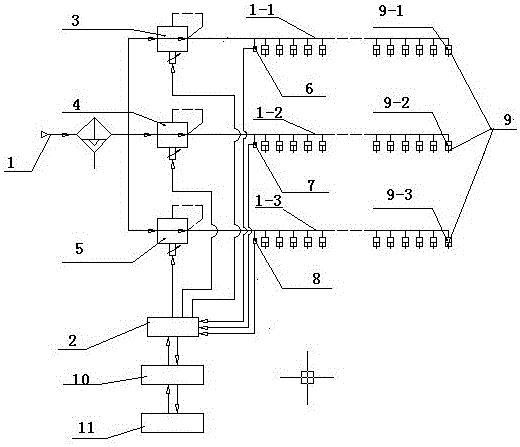

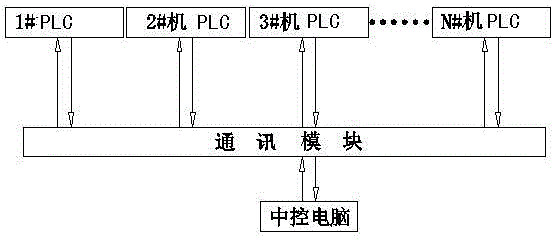

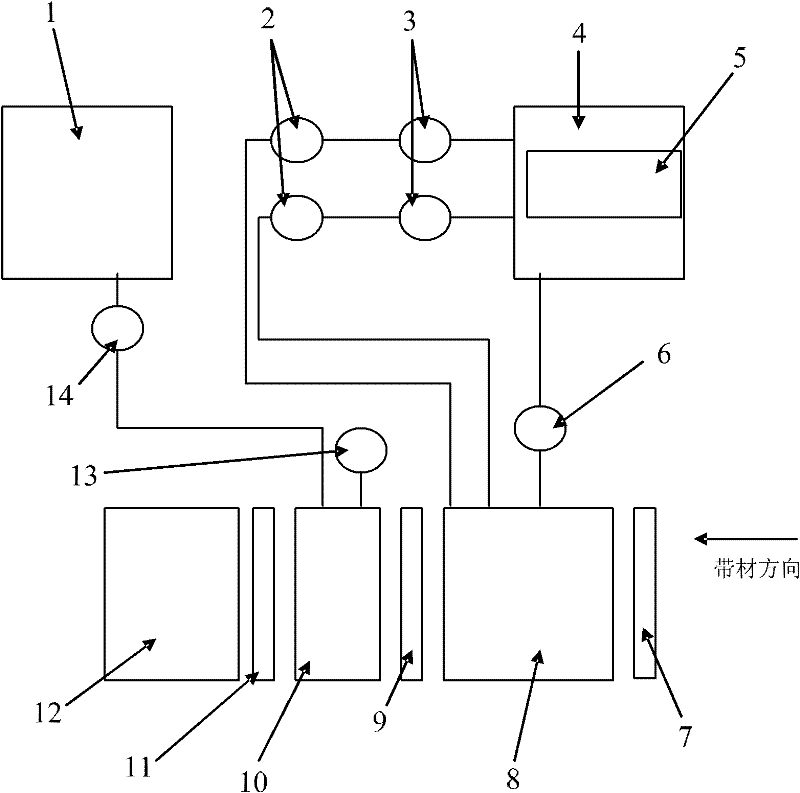

Automatic control system for ring spinning draft pressure

InactiveCN106120034APrecise adjustment of pressurization pressureIncrease input voltageDrafting machinesAutomatic controlAutomated control system

The invention discloses an automatic control system for ring spinning draft pressure. The automatic control system comprises cylinder pressure cradles for three branches of gas supply, three electrical proportional valves, a PLC or a special control module, a wired or wireless communication device, a central control computer and corresponding software. Each of the cylinder pressure cradles is mounted on a ring spinning frame; each of the spinning frames is provided with three columns of rollers; each of the gas branches in the three branches of gas supply supplies gas for a pressurized cylinder of each column of rollers on the corresponding spinning frame, the gas supply pressure of each branch of gas is decided by the output gas pressure of the corresponding electrical proportional valve, and the output gas pressure of each of the electrical proportional valves can be changed through changing the input voltage of the electrical proportional valve by the PLC mounted on the corresponding spinning frame; one central control computer is arranged in each workshop; wired or wireless communication can be realized between the central control computer and the PLC of the spinning frame, so that the remote automatic control of pressure onto each of the three columns of rollers on the corresponding spinning frame is realized.

Owner:HUNAN UNIV OF ARTS & SCI

Method for inducing diapause of Trichogramma ostriniae by constant temperature and storage method

InactiveCN101326902BIncrease effective production timeSave solutionAnimal husbandryDiapauseTrichogramma ostriniae

The invention provides a constant-temperature inducing maize-borer oophagous trichogrammae diapause storage method. The collected maize-borer oophagous trichogrammaes which have developed to the ovum telophase from the middle larva stage adopt constant-temperature inducing maize-borer oophagous trichogrammae diapause, and are stored under a specific temperature and humidity, and the development of the maize-borer oophagous trichogrammae is restored by changing the prior temperature to use. The method is applicable to oophagous trichogrammae breeding by using small gelechiid ovum; the technology matches large-scale oophagous trichogrammae production; the method is applicable to long-term production and storage of maize-borer oophagous trichogrammaes; thereby, sufficient maize-borer oophagous trichogrammaes are prepared for pest control, and the method can also be used to store breeding maize-borer oophagous trichogrammaes.

Owner:DRY LAND FARMING INST OF HEBEI ACAD OF AGRI & FORESTRY SCI

Granulator comprising double tubular reactors and application thereof in diammonium phosphate production

ActiveCN104860283AAvoid wear and tearExtended service lifePhosphatesAlkali orthophosphate fertiliserNuclear engineeringDiammonium phosphate

The invention provides a granulator comprising double tubular reactors. A main beam is arranged on the upper part of the granulator. A No.1 tubular reactor and a No.2 tubular reactor are respectively arranged on the two opposite sides of the granulator. According to the No.1 tubular reactor, an ammonia distributor is inserted into a granulator feed layer through a plow-type steel part welded on the main beam. A liquid ammonia delivery pipe is arranged on the end of the No.1 tubular reactor positioned on the outer side of the granulator. According to the No.2 tubular reactor, an ammonia distributor is inserted into a granulator feed layer through a plow-type steel part welded on the main beam. A liquid ammonia delivery pipe is arranged on the end of the No.2 tubular reactor positioned on the outer side of the granulator. A washing liquid circulation tank is respectively connected to the upper parts of the No.1 tubular reactor and the No.2 tubular reactor through tubular reactor feeding pumps. The working pressure of the equipment is lower than that of single tubular reactors. A blocking frequency is substantially reduced. Single tubular reactor purging frequency is reduced to once per shift. A cylinder scale phenomenon close to a spray point is inhibited.

Owner:HUBEI LIUGUO CHEM IND

Release agent used for pouring lead-acid storage battery grid and preparation method of release agent

ActiveCN102873265BImprove adhesionNot easy to fall offFoundry mouldsFoundry coresPolymer scienceGas phase

Owner:CHAOWEI POWER CO LTD

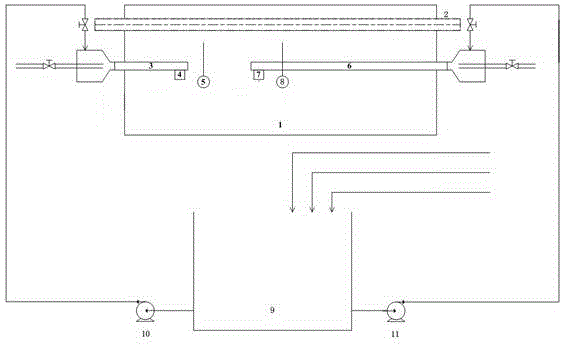

Withdrawal and straightening unit line cleaning system

ActiveCN101982249AExtended service lifeEasy to cleanCleaning using liquidsWater storage tankEngineering

The invention discloses a withdrawal and straightening unit line cleaning system comprising a high-pressure water tank, a low-pressure water tank, a water storage tank, a drying box, a squeeze roll, a filter water tank, a high-pressure wash line, a water return pipeline, a high-pressure booster pump, a high-pressure water pump, a high-pressure back water pump, a low-pressure flushing pump and a shower header, wherein the filter water tank also specifically comprises a clean water tank and a sewage tank; the water outlet of the high-pressure back water pump is connected with the sewage tank, and the sewage tank is connected with the clean water tank via a circulation line; the circulation line is provided with a filter pump and a filter device, wherein the filter pump pumps water from the sewage tank towards the clean water tank, and the filter device is positioned in the filter pump and the clean water tank; and the high-pressure wash line is respectively connected with the clean water tank and the high-pressure water tank. The invention divides the filter tank into the clean water tank and the sewage tank to separate sewage from clean water. Clean water is used for washing boards to bring good washing effect and greatly prolong the service life of the pump, a nozzle is not blocked, and thus time for cleaning the nozzle is shortened.

Owner:SOUTHWEST ALUMINUM GRP

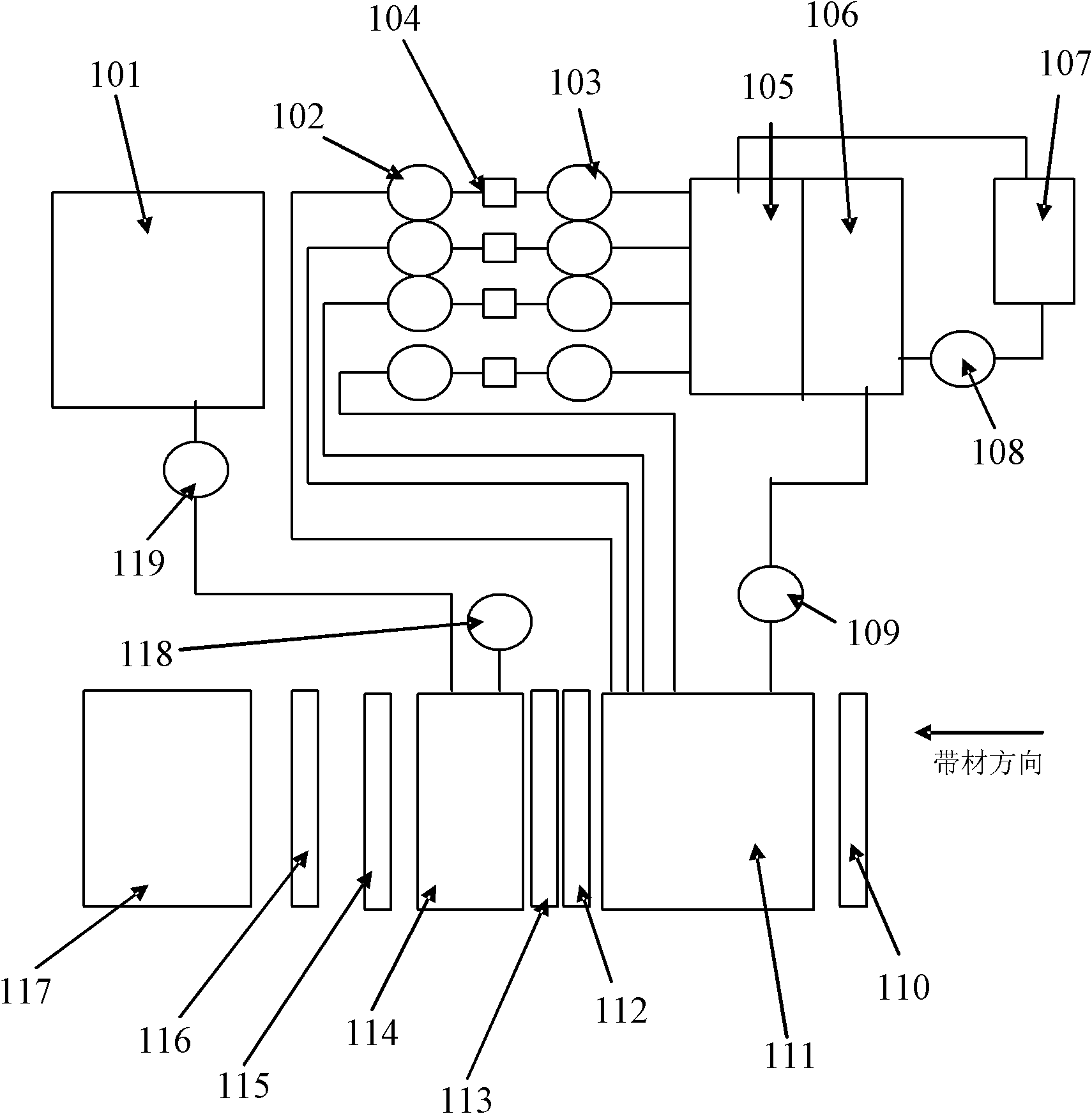

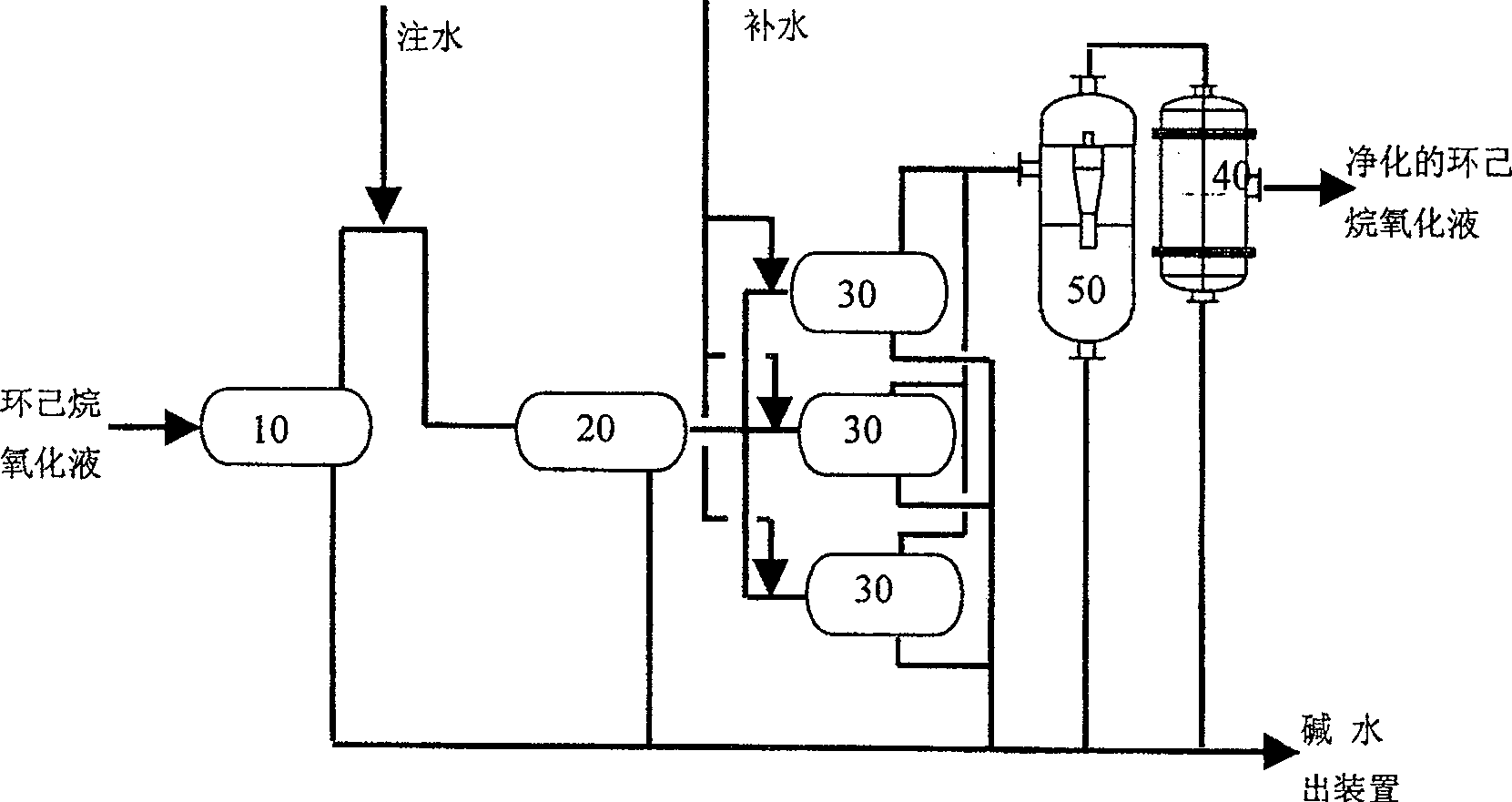

Process and apparatus for separating and recovering waste alkali from cyclohexane oxidation solution

ActiveUS20100126938A1Increase effective production timeSolve environmental pollutionReversed direction vortexPreparation by hydrogenationChemistryGravity separation

The present invention relates to a process and an apparatus for separating and recovering the waste alkali from a cyclohexane oxidation solution, and provides a process and an apparatus for separating and recovering the waste alkali from a cyclohexane oxidation solution. According to the invention, a gradient combination of the gravity separation technique, the vortex separation technique and the coalescence separation technique is used to carry out fine separation of the waste alkali liquor from the cyclohexane oxidation solution. The purified cyclohexane oxidation solution is fed into a down-stream apparatus. Most of the waste alkali liquor thus separated is recycled, while the remaining is expelled. The expelled waste alkali liquor is incinerated in an incinerator, followed by recovering the molten species using a pneumatic pulverization process. According to the invention, the content of Na+ in the cyclohexane oxidation solution fed into the alkane tower can be lowered to less than 3 mg / L, and the molten species resulting from incineration can be recovered 100%. Thus, risk of environmental pollution by the waste alkali liquor is substantially eliminated. While the invention is well suited to separate and recover the waste alkali liquor from a cyclohexane oxidation solution, it may be adapted to other chemical engineering systems for separating and recovering waste alkali liquor as well.

Owner:EAST CHINA UNIV OF SCI & TECH

Continuous vapor deposition equipment

ActiveCN107893212AAvoid pollutionImprove performanceVacuum evaporation coatingSputtering coatingCrucibleEvaporation

The invention relates to the field of vapor deposition and discloses continuous vapor deposition equipment. The equipment comprises a main cavity, a linear evaporation source located in the main cavity, a linear crucible bearing platform for bearing a linear crucible and a lifting unit and further comprises two linear crucible vacuum transfer cavities and carrying units located in the linear crucible vacuum transfer cavities correspondingly. The linear crucible vacuum transfer cavities are used for storing the linear crucible bearing platform. The carrying units are used for transferring the linear crucible bearing platform between the linear crucible vacuum transfer cavities and the lifting unit. The lifting unit is used for enabling the linear crucible platform to be separated from or beplaced into the linear evaporation source. The linear crucible vacuum transfer cavities and the main cavity are provided with independent vaccumizing devices correspondingly. By the adoption of the technical scheme, product performance is improved, effective production time of the equipment is prolonged, and the purpose of long-time continuous production is achieved.

Owner:TRULY HUIZHOU SMART DISPLAY

Well drilling method and device

PendingCN113338800AIncrease effective production timeIncrease productionDrill bitsDrilling rodsDrill bitDrilling fluid

The invention discloses a well drilling method and device, and belongs to the field of oil exploitation. The well drilling method comprises the following steps that (1) a guide assembly is connected, the guide assembly is tripped into a designated position of a casing pipe, and the guide assembly comprises an oil pipe and a guider; (2) a trepanning unit is lowered into the oil pipe through a continuous pipe, a trepanning drill bit of the trepanning unit is made to punch the casing pipe through the guider so that a first through hole can be formed, and the diameter of the trepanning drill bit ranges from 30 mm to 80 mm; (3) a drilling unit is lowered into the oil pipe through a continuous pipe, a drilling bit of the drilling unit is made to penetrate through the guider and the first through hole to punch the stratum so as to form a horizontal well hole, the diameter of the drilling bit is not larger than that of the trepanning bit, drilling fluid circulates in the drilling bit, and the horizontal well hole is formed in the oil pipe. The pressure of the drilling fluid is 40 to 60 Mpa.

Owner:DESHI ENERGY TECH GRP CO LTD +2

Method and apparatus for separating cyclo-hexane oxidation waste alkali

ActiveCN100503477CIncrease effective production timeBig investmentWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentLiquid wasteDistillation

Provided are a method and a device for separating spent caustic soda from cyclohexane oxidation liquid by using swirl coalescence series combination technology. By combining the gravity settling tank, the cyclone separator and the coalescence separator to carry out the three-step separation of the spent caustic soda of the cyclohexane oxidation solution, the problem of incomplete separation of the spent caustic solution of the cyclohexane oxidation unit in the prior art can be effectively solved, The invention overcomes the disadvantages of the unsatisfactory effect of the existing gravity sedimentation method and the frequent flushing of the coalescence separation method, greatly prolongs the effective production time of the alkane distillation tower, thereby significantly reducing the production cost.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of sulfurized gasoline hydro-upgrading catalyst

ActiveCN107185597BImplementation importAchieve selective passivationMolecular sieve catalystsCatalyst activation/preparationVulcanizationRare earth

The invention relates to a method for preparing a gasoline hydrogenation modification catalyst, which uses a polysulfide ion sulfurizing agent containing an organic nitrogen compound as a passivating agent to treat the gasoline hydrogenation catalyst at low temperature, wherein the active component in the gasoline hydrogenation catalyst is the third One or more of Group VIB Mo, W or Group VIIIB Co, Ni, the stabilizer is one or more of Group IIB Zn, Cd or Group IA Na, K or rare earth metal La, Ce, This achieves stepwise complete sulfidation of metal oxides or their precursors and selective passivation of strongly acidic sites in the ZSM-5 molecular sieve composite carrier. The sulfurized gasoline hydrogenation modification catalyst prepared by the invention has the advantages of short start-up time, high hydrogenation olefin modification activity and selectivity, strong carbon deposition resistance, small octane number loss and high liquid yield, and It is especially suitable for low-cost hydrogenation and olefin reduction modification of inferior catalytic cracking gasoline to produce clean gasoline components.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Single-tower continuous rectification method of eucalyptus oil

ActiveCN101899361BIncrease profitReduce consumptionFatty-oils/fats refiningRefluxCinnamomum camphora

The invention discloses a single-tower continuous rectification method of eucalyptus oil, which is characterized by comprising the following steps of: continuously feeding and discharging to continuously extract light components, the eucalyptus oil, reactor residues and other materials at the extracting ports of different products with the eucalyptus oil of eucalyptus globulus labill or the eucalyptus oil of cinnamomum camphora as raw materials under different processes of the single rectification tower; and continuously rectifying the eucalyptus oil in the single tower, adjusting the reflux ratio and controlling the distillation temperature according to the quality condition of the material at the extracting ports to achieve the purpose of extracting the eucalyptus oil with different contents of cineole. In the invention, the content of the cineole in the eucalyptus oil product is mostly up to 92%, the daily processing quantity of the raw materials is 10 tons per day, the production loss is not more than 1% and the yielding rate of 80% of the eucalyptus oil is more than 75%; compared with the discontinuous rectification, the production efficiency of the invention is improved by 10 times; and in addition, the invention has the advantages of great treatment capability, stable quality of product, high utilization ratio of the raw materials, lower energy consumption and the like.

Owner:FUJIAN SENFA BIOTECH

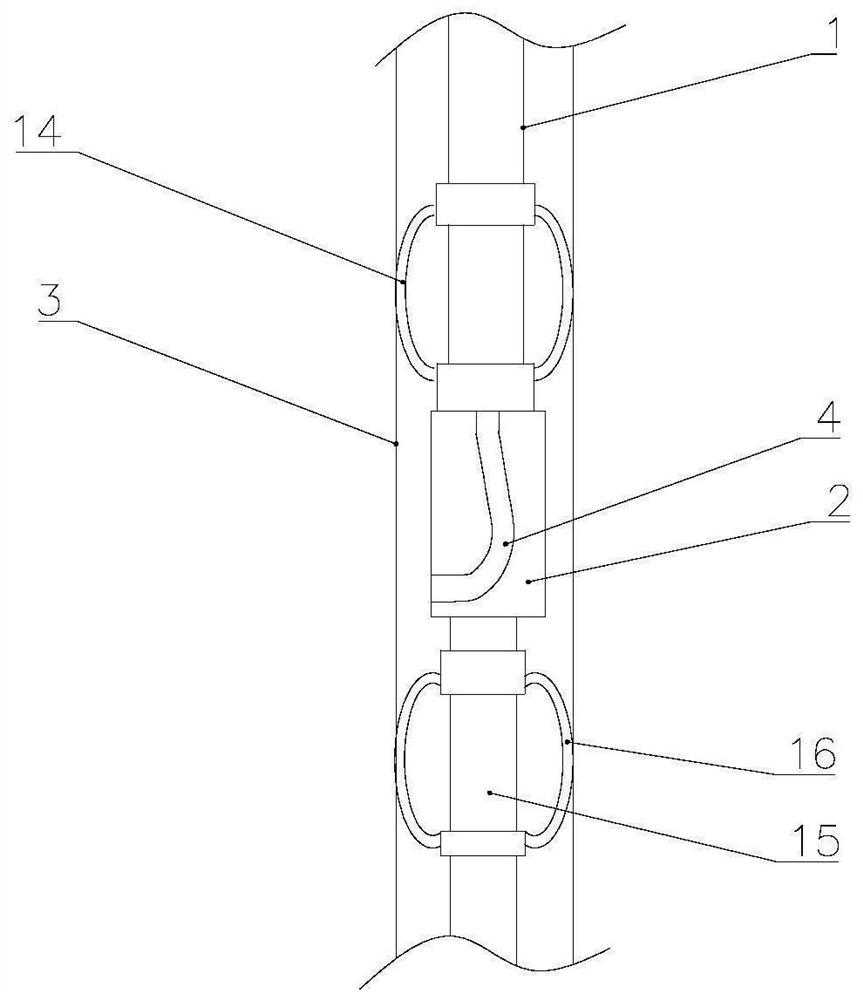

An ultrasonic quenching device capable of on-line decoking and its application

ActiveCN111073678BEfficient and uniform conductionImprove heat transfer efficiencyThermal non-catalytic crackingHollow article cleaningPetrochemicalUltrasonic technology

The invention belongs to the technical field of petrochemical cracking, in particular relates to an ultrasonic quenching device capable of online decoking, and further discloses a cracking quenching process and an online decoking process performed by the ultrasonic quenching device. The ultrasonic quenching device of the present invention combines ultrasonic technology with quenching technology to form a combination device of ultrasonic and quenching device, which not only has the function of ordinary quenching cooler, but also uses ultrasonic technology to solve the problem of easy coking at the entrance of quenching equipment, and breaks through traditional quenching In order to avoid the disadvantages of only transporting gaseous materials, the hot water is introduced into the tube side of the quencher, and the ultrasonic distributor is used to efficiently transmit the ultrasonic wave to the coke layer of the tube side of the quencher. The hot water weakens the van der Waals force of the coke layer. The coke layer is gradually decomposed into particles and falls off, realizing online decoking treatment. It can be widely used in thermal cracking process of petrochemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

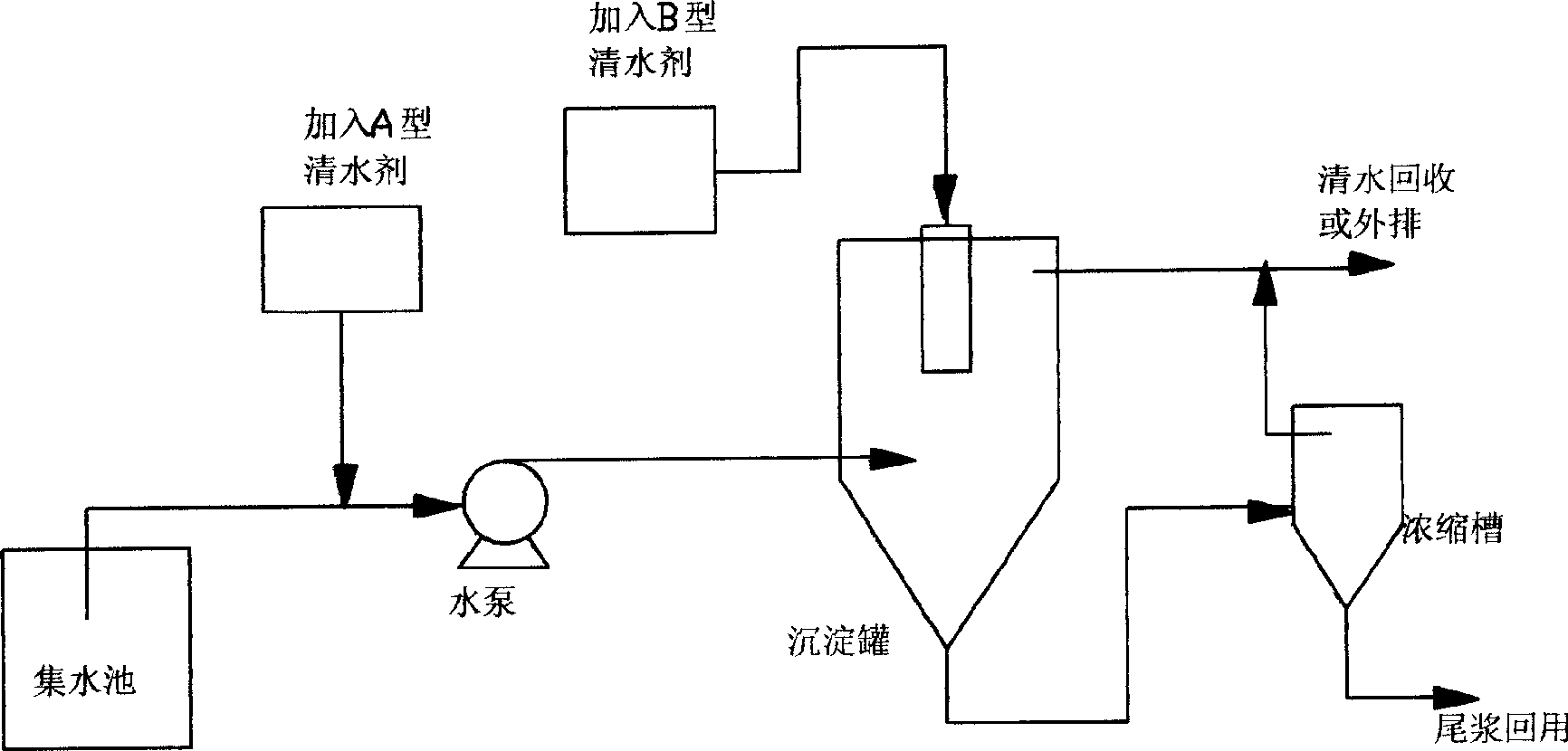

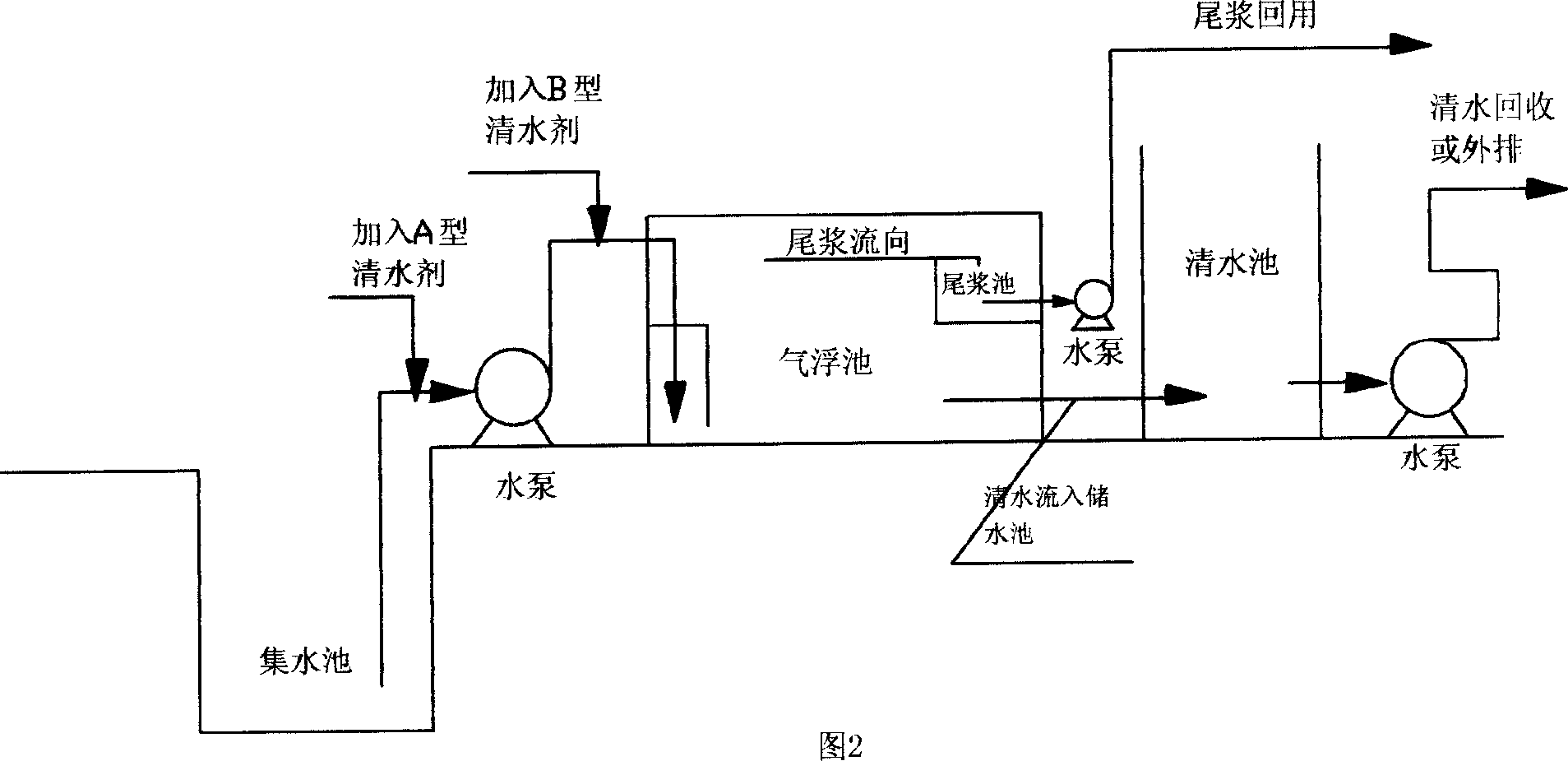

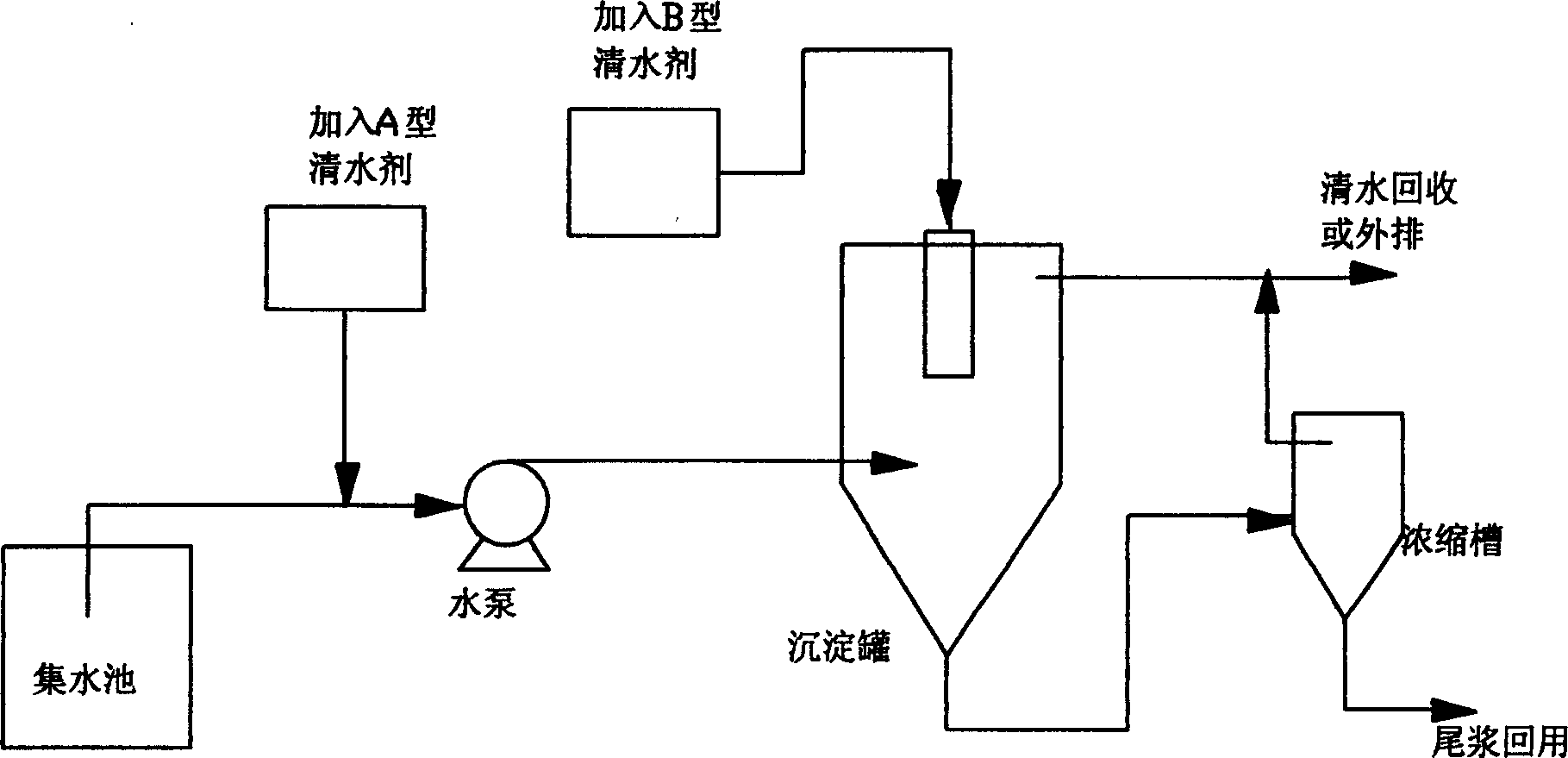

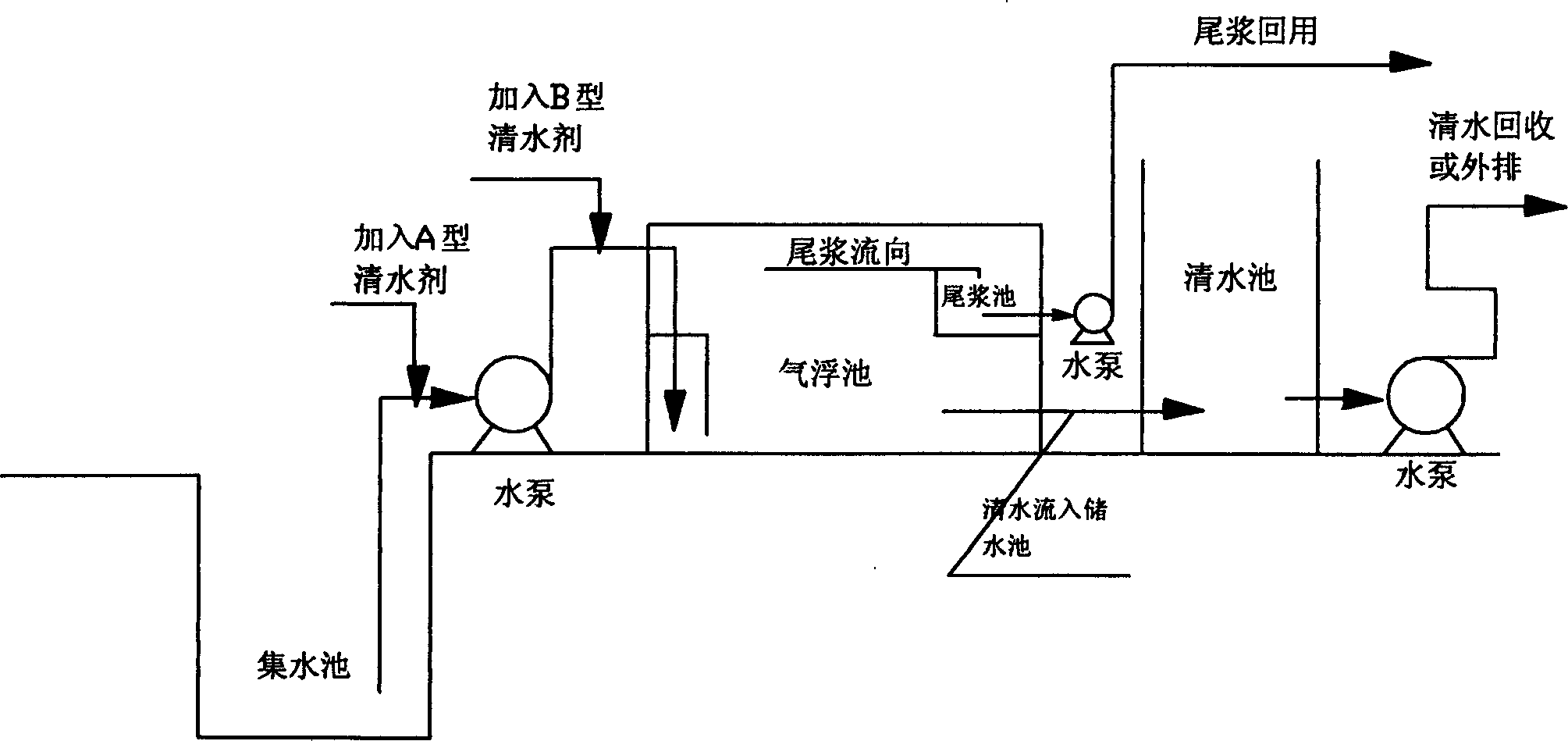

Process for preparing waste water purifying agent and application thereof

InactiveCN1569674AEasy to handleMeet emission requirementsWater/sewage treatment by flocculation/precipitationPolyamine CompoundPhosphate

The invention discloses a process for preparing waste water purifying agent characterized in that, the waste water purifying agent comprises type A water purification agent and type B water purification agent, the method for preparing the type A water purification agent consists of oxidizing ferrous aluminium salts with strong oxidation agent, hydrolyzing and polymerizing to obtain polymeric ferrum of a finite alkalization degree, charging phosphates on this basis, reacting to produce liquid polymeric compound, concentrating and drying to obtain the hoary solid product.

Owner:罗斌华 +2

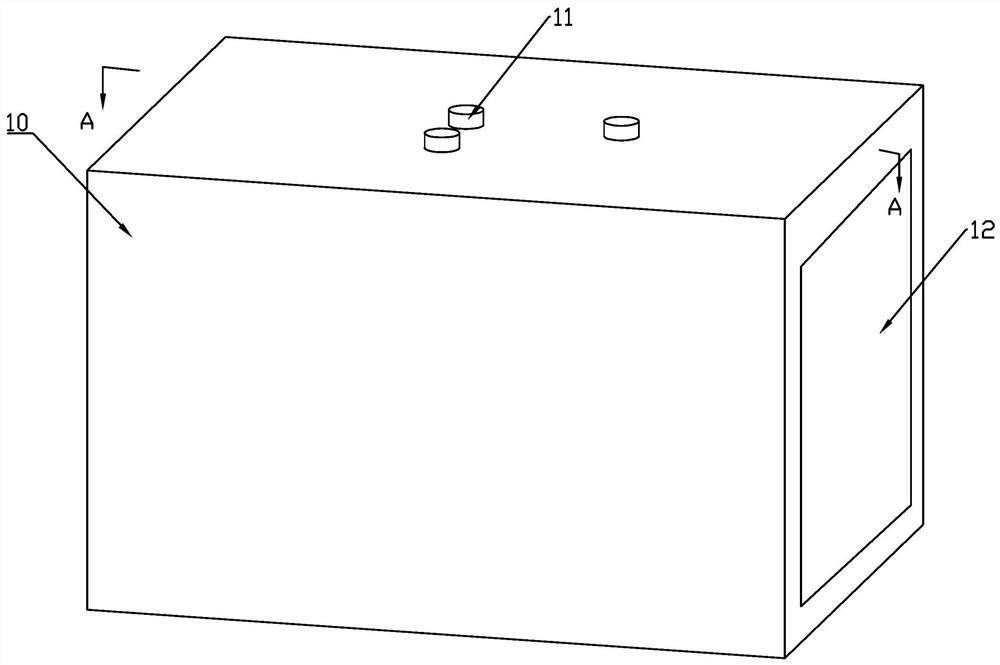

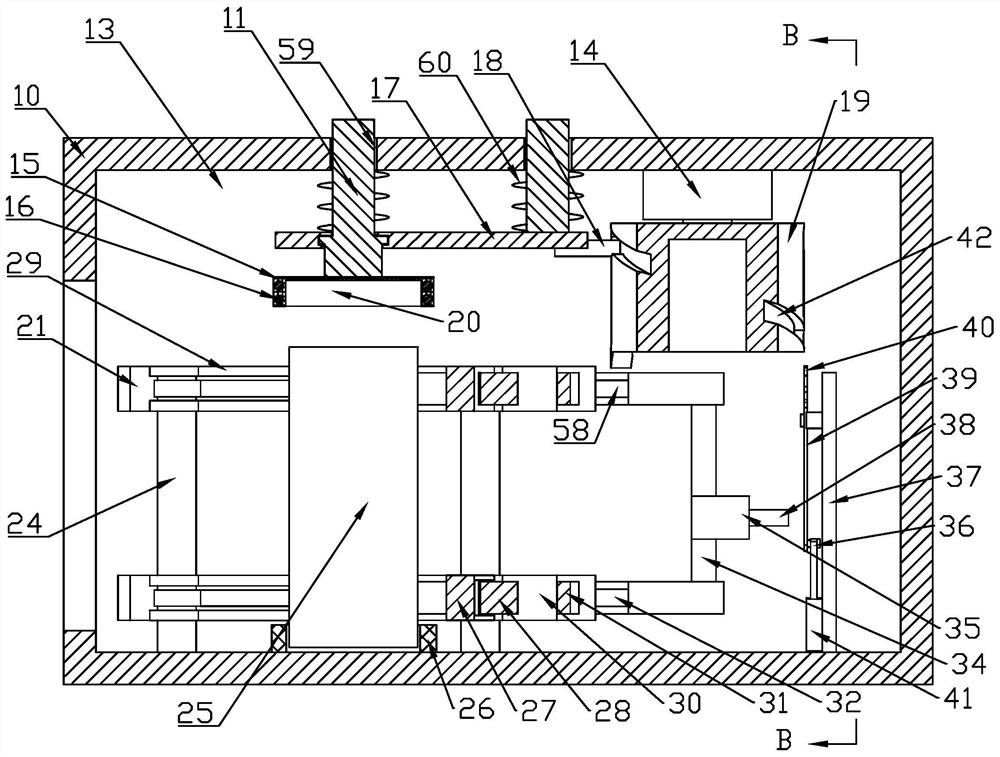

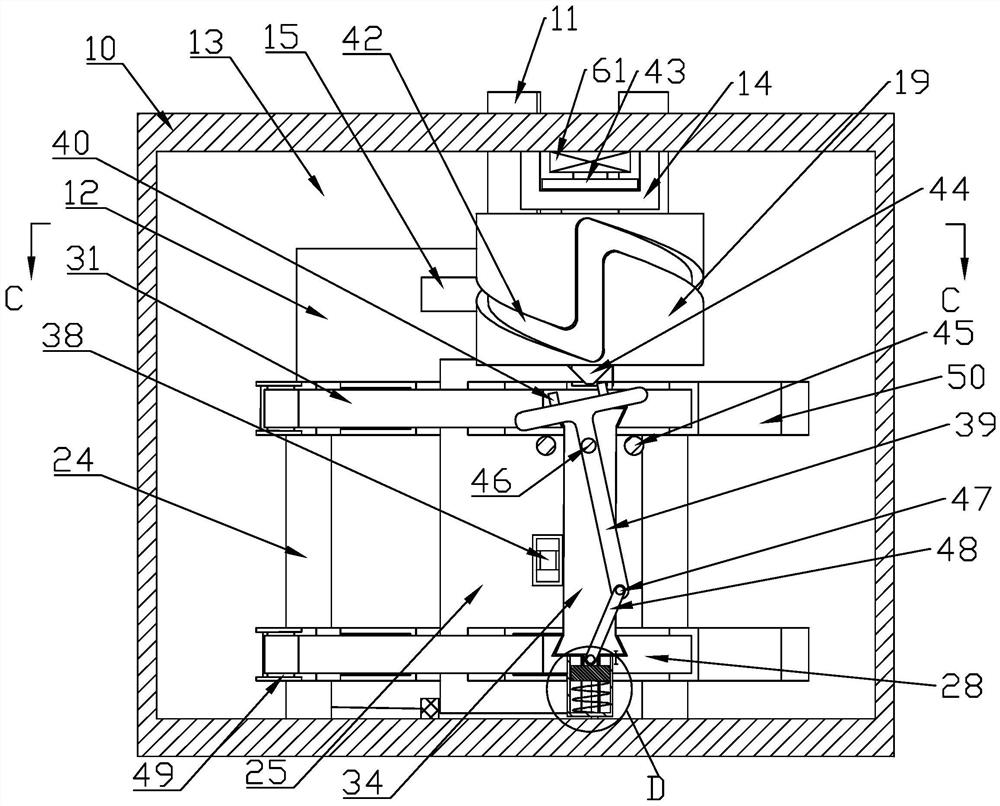

Heat-seal positioning system of printer ink cartridge

The invention belongs to the field of printer ink cartridges, and relates to a heat-seal positioning system of a printer ink cartridge. The heat-seal positioning system comprises a shell, and is characterized in that the shell is provided with an inlet and outlet, a cavity is arranged in the shell, the shell is provided with a short round hole, a long cylinder is arranged in the short round hole in a sliding manner, a connecting spring is connected between the long cylinder and the shell, a motor is fixedly arranged on the upper side of the shell, a U-shaped metal plate is fixedly arranged on the upper surface of the cavity, and fixing rods are fixedly arranged on the lower surface of the cavity in an annular array mode. When the printer ink box powder filling production is carried out, accurate positioning is carried out on the contact surface, which is in contact with the ink box, of a triangular chuck-like mechanism of the ink box, the ink box is treated by adopting a heating and sealing mode at the powder filling position, and the ink box powder can be effectively prevented from flowing out.

Owner:张全友

Process for preparing waste water purifying agent

InactiveCN1259253CEasy to handleMeet emission requirementsWater/sewage treatment by flocculation/precipitationCyclic etherPhosphate

The invention relates to a method for preparing a water purifying agent for wastewater treatment, which is characterized in that the water purifying agent for wastewater treatment is prepared by combining two parts: the preparation of type A water purifying agent and the preparation of type B water purifying agent; wherein the type A water purifying agent The preparation method of the water agent is as follows: oxidize the ferrous aluminum salt with a strong oxidant, hydrolyze and polymerize it to generate polyferric iron with a certain degree of alkalization, add phosphate on this basis, and react to form a liquid polymer. Concentrate and dry to obtain off-white solid product. The preparation method of Type B water purifier is as follows: firstly, the polyamine compound and the cyclic ether undergo hydrogen displacement polymerization to generate an intermediate product substituted amine; this product is used as a prepolymer to further react with a chain extender of a multifunctional group, and the molecular weight With the increase of the reaction time, it gradually increases, the medium viscosity increases rapidly, and finally the product is obtained. In the application process, add type A first, then add type B, and then separate. The use of the above-mentioned water purifying agent can realize full recycling and realize zero discharge.

Owner:罗斌华 +2

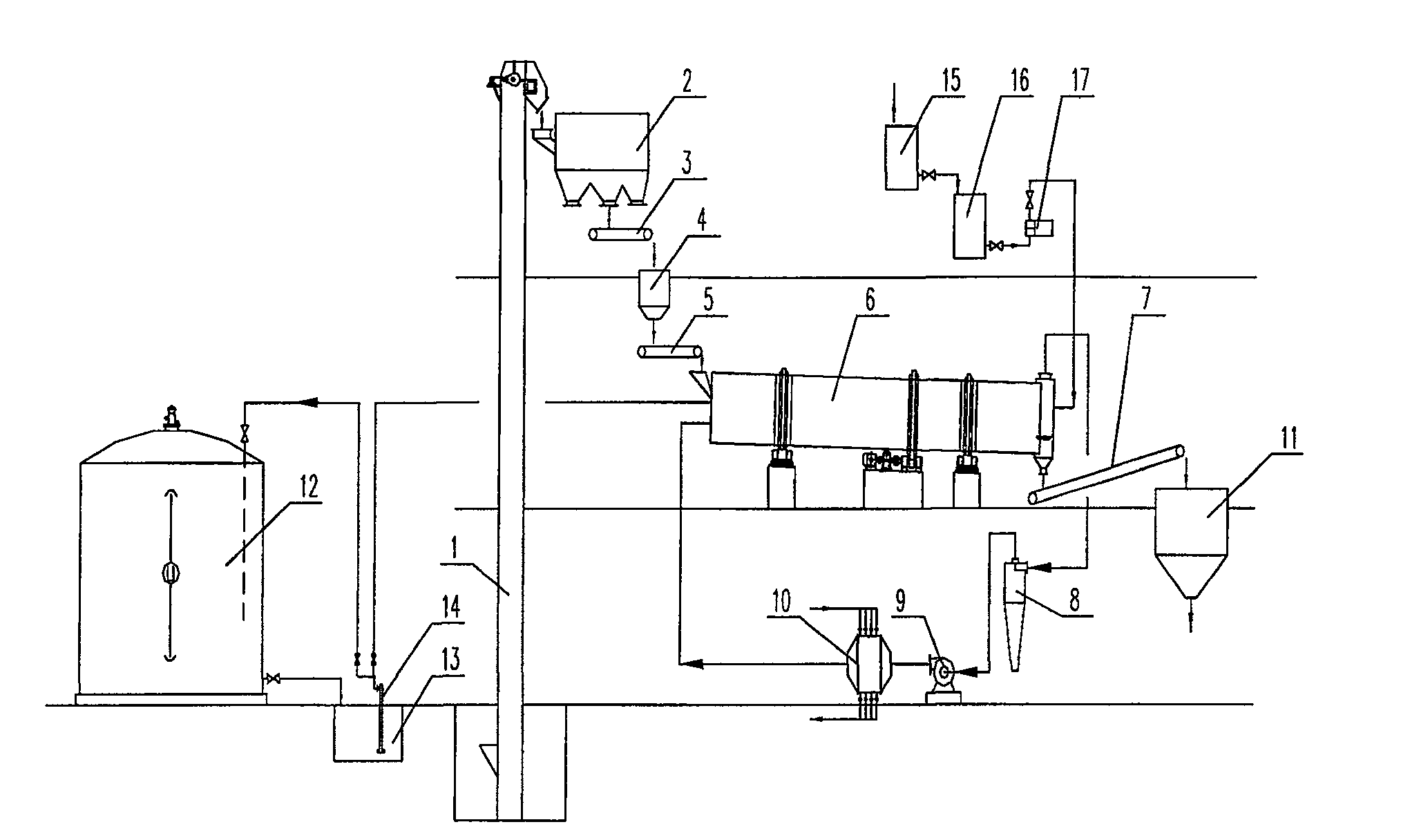

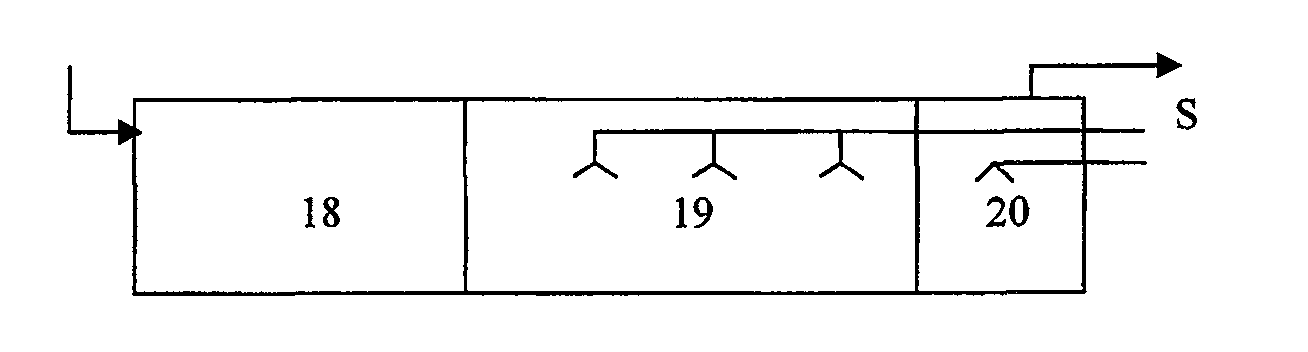

Industrial production method and apparatus of sulfur coated controlled release fertilizer

ActiveCN100546951CImprove protectionImprove working environmentFertilizer mixturesProcess equipmentBucket elevator

The invention discloses a method for industrialized production of sulfur-coated controlled-release fertilizer and a device thereof. The method comprises the following steps: after being elevated to a sieving machine to be sieved through a bucket elevator and conveyed into a raw material bin through a raw material belt conveyor, granular fertilizer is metered through a dosing scale and enters a rotary drum; liquid sulfur in a liquid sulfur storage tank enters an underground liquid sulfur tank, and enters the rotary drum after being pressurized through a liquid sulfur pump and metered through a liquid sulfur flow meter; sealant is added into a sealant dissolving tank to be heated and dissolved, is discharged into a sealant storage tank, and then enters the rotary drum after being metered through a sealant metering pump; in the rotary drum, the granular fertilizer is preheated in a preheating area, then the coating is gradually formed on the surface of the liquid sulfur atomized fertilizer granules in a sulfur coating area, and finally the sealant is coated in a sealant coating area; the sulfur-coated controlled-release fertilizer going out of the rotary drum is conveyed into an end product bin via an end product belt conveyor, and then packaged and warehoused. The invention has the advantages that the investment on technological equipment is low, continuous operation is realized in the whole technological production process, the operation is simpler and more convenient, and the sulfur can be coated more uniformly.

Owner:KINGENTA ECOLOGICAL ENG GRP

Withdrawal and straightening unit line cleaning system

ActiveCN101982249BExtended service lifeEasy to cleanCleaning using liquidsWater storage tankHigh pressure water

The invention discloses a withdrawal and straightening unit line cleaning system comprising a high-pressure water tank, a low-pressure water tank, a water storage tank, a drying box, a squeeze roll, a filter water tank, a high-pressure wash line, a water return pipeline, a high-pressure booster pump, a high-pressure water pump, a high-pressure back water pump, a low-pressure flushing pump and a shower header, wherein the filter water tank also specifically comprises a clean water tank and a sewage tank; the water outlet of the high-pressure back water pump is connected with the sewage tank, and the sewage tank is connected with the clean water tank via a circulation line; the circulation line is provided with a filter pump and a filter device, wherein the filter pump pumps water from the sewage tank towards the clean water tank, and the filter device is positioned in the filter pump and the clean water tank; and the high-pressure wash line is respectively connected with the clean water tank and the high-pressure water tank. The invention divides the filter tank into the clean water tank and the sewage tank to separate sewage from clean water. Clean water is used for washing boardsto bring good washing effect and greatly prolong the service life of the pump, a nozzle is not blocked, and thus time for cleaning the nozzle is shortened.

Owner:SOUTHWEST ALUMINUM GRP

Process and apparatus for separating and recovering waste alkali from cyclohexane oxidation solution

ActiveUS8221634B2Increase effective production timeReversed direction vortexPreparation by hydrogenationProcess engineeringGravity separation

A process and an apparatus for separating and recovering waste alkali from a cyclohexane oxidation solution are provided. A gradient combination of the gravity separation technique, the vortex separation technique and the coalescence separation technique is used to carry out fine separation of the waste alkali liquor from the cyclohexane oxidation solution. The purified cyclohexane oxidation solution is fed into a down-stream apparatus. Most of the waste alkali liquor thus separated is recycled, while the remaining is expelled. The expelled waste alkali liquor is incinerated in an incinerator, followed by recovering the molten species using a pneumatic pulverization process.

Owner:EAST CHINA UNIV OF SCI & TECH

A granulator containing double-tube reactors and its application in the production of diammonium phosphate

ActiveCN104860283BIncrease the amount of sprayingAvoid Parking HandlingPhosphatesAlkali orthophosphate fertiliserDouble tubeWorking pressure

The invention provides a granulator comprising double tubular reactors. A main beam is arranged on the upper part of the granulator. A No.1 tubular reactor and a No.2 tubular reactor are respectively arranged on the two opposite sides of the granulator. According to the No.1 tubular reactor, an ammonia distributor is inserted into a granulator feed layer through a plow-type steel part welded on the main beam. A liquid ammonia delivery pipe is arranged on the end of the No.1 tubular reactor positioned on the outer side of the granulator. According to the No.2 tubular reactor, an ammonia distributor is inserted into a granulator feed layer through a plow-type steel part welded on the main beam. A liquid ammonia delivery pipe is arranged on the end of the No.2 tubular reactor positioned on the outer side of the granulator. A washing liquid circulation tank is respectively connected to the upper parts of the No.1 tubular reactor and the No.2 tubular reactor through tubular reactor feeding pumps. The working pressure of the equipment is lower than that of single tubular reactors. A blocking frequency is substantially reduced. Single tubular reactor purging frequency is reduced to once per shift. A cylinder scale phenomenon close to a spray point is inhibited.

Owner:HUBEI LIUGUO CHEM IND

An open calcium type brine preheating system process

ActiveCN110255801BAvoid cloggingAvoid stickingTreatment involving filtrationMultistage water/sewage treatmentEngineeringThermal expansion

The present invention provides a kind of open type calcium type brine preheating system process, comprising a primary preheating device, a secondary preheating device and a settler, the primary preheating device and the secondary preheating device both include a heat exchanger ( Tube-and-tube heat exchanger) and a material storage room, the bottom of the heat exchanger is connected to the lower section of the upper draft tube through the flange, and one end of the lower section of the upper draft tube is connected to the horizontal section of the lower draft tube. One end of the horizontal section of the lower draft pipe is connected with a bottom material propeller through flange connection (the bottom material propeller is suspended from the ground, as a free end that expands with heat and contracts with cold), and the other end of the horizontal section of the lower draft tube is fixed A lower guide pipe is connected, one side of the bottom of the lower guide pipe is provided with a feed nozzle and a return nozzle, the top of the lower guide pipe is fixedly connected with the storage room, and the storage room The top is fixedly connected with the horizontal section of the upper diversion pipe. The open calcium-type brine preheating system has a reasonable process design, can work continuously, and can effectively improve the effective production time.

Owner:武汉宏达丰源分离技术有限公司

Flow control screen pipe for oil well

PendingCN114837628AEnsure daily oil productionIncrease effective production timeFluid removalThermodynamicsEngineering

The invention relates to a flow control screen for an oil well. The flow control screen has adjustable flow conductivity. The flow control screen includes one or more fluid valves each having a respective predetermined opening threshold and configured to open to open a corresponding fluid channel when a fluid pressure difference between a fluid pressure of a first side of the fluid valve and a fluid pressure of a second side of the fluid valve is greater than or equal to the respective predetermined opening threshold. The invention also relates to an oil well structure with the flow control screen, a method for operating the oil well structure and a method for modifying the oil well structure.

Owner:ANTON BAILIN OILFIELD TECH (BEIJING) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com