Glass film coating device and bottom plate die set

A technology of coating device and bottom plate, which is applied to discharge tubes, electrical components, circuits, etc., can solve problems such as affecting effective production time, and achieve the effect of improving effective production time and avoiding downtime for maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The glass coating device and its bottom plate module of the present invention will be further described in detail with reference to the accompanying drawings and embodiments.

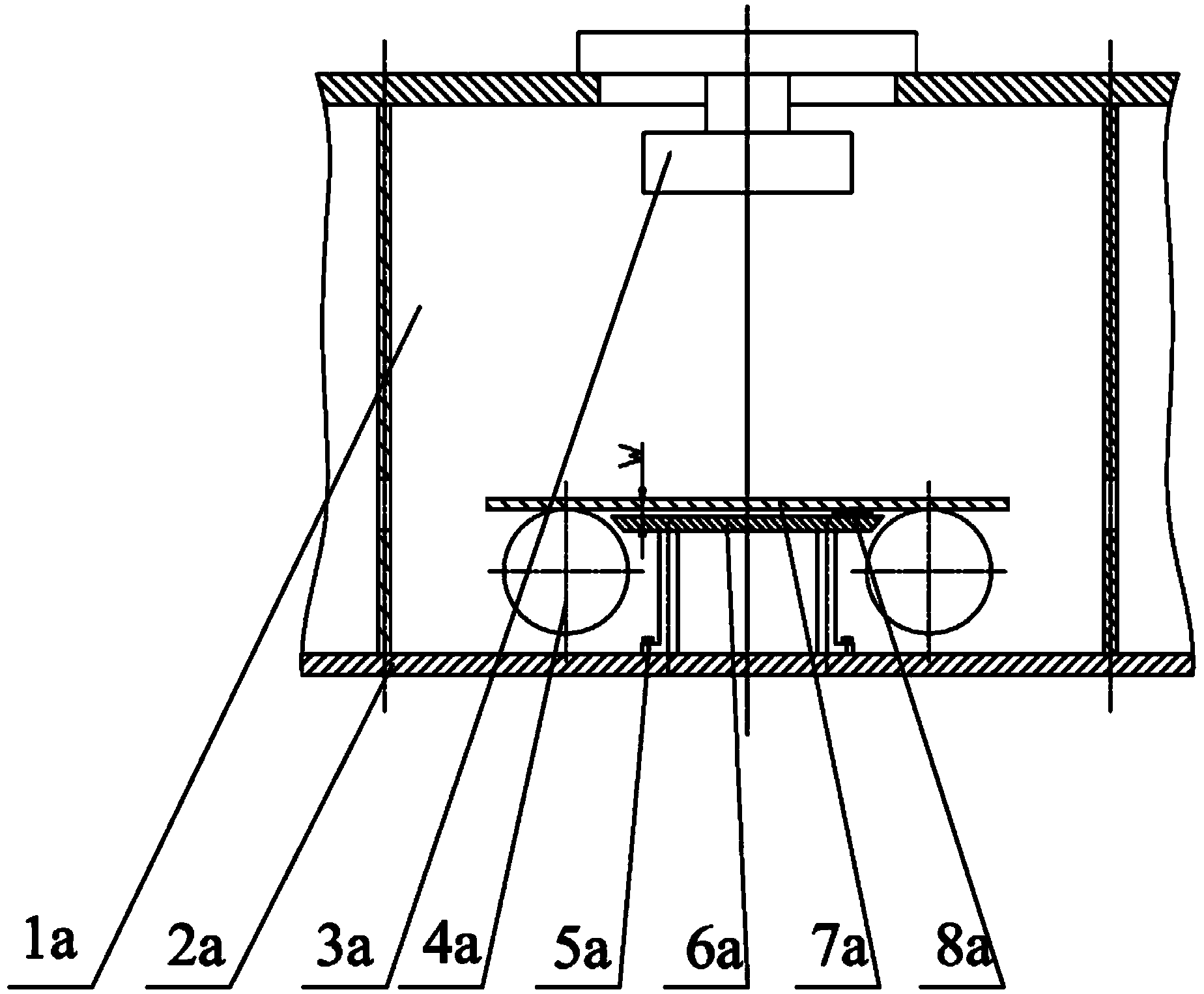

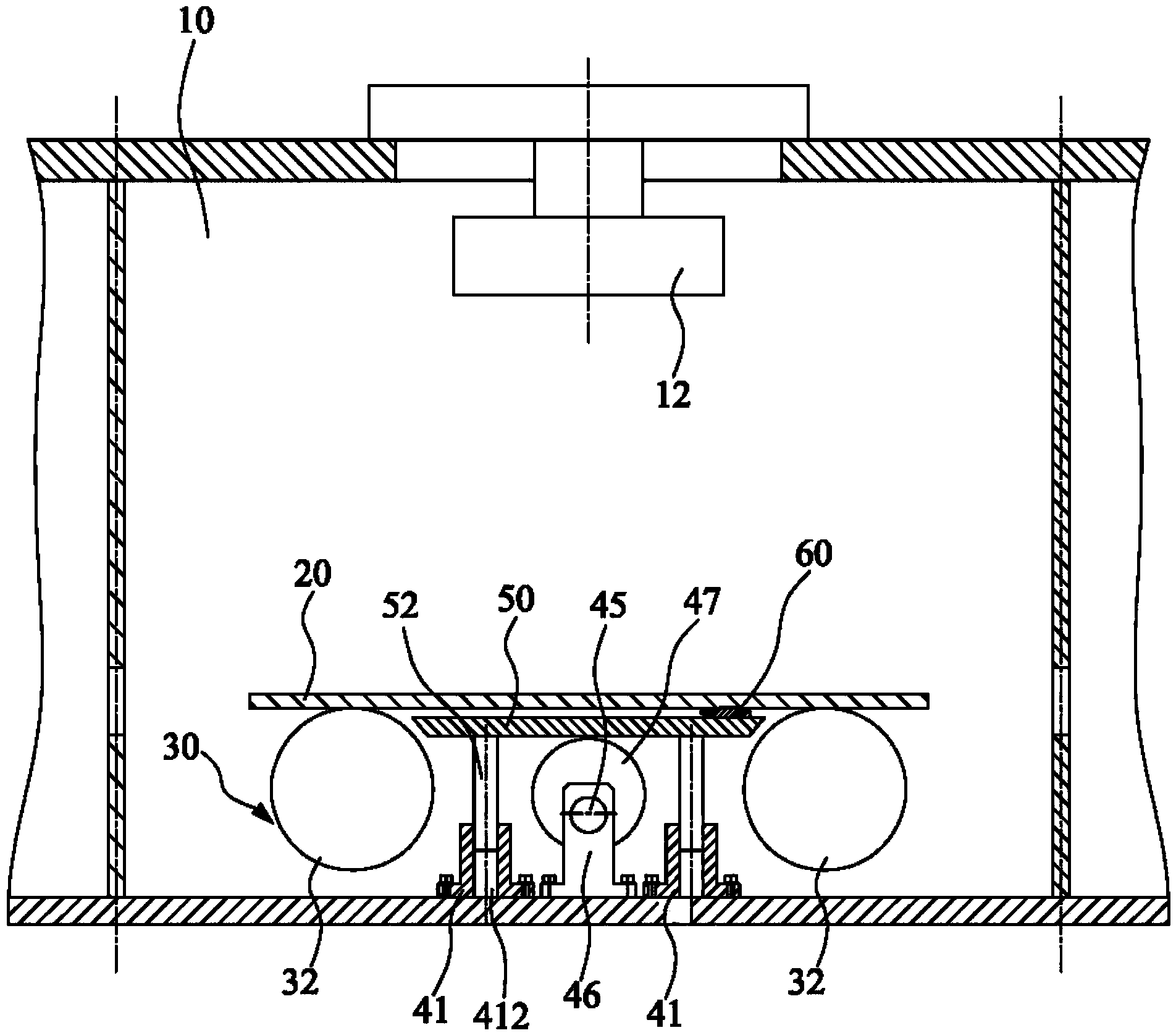

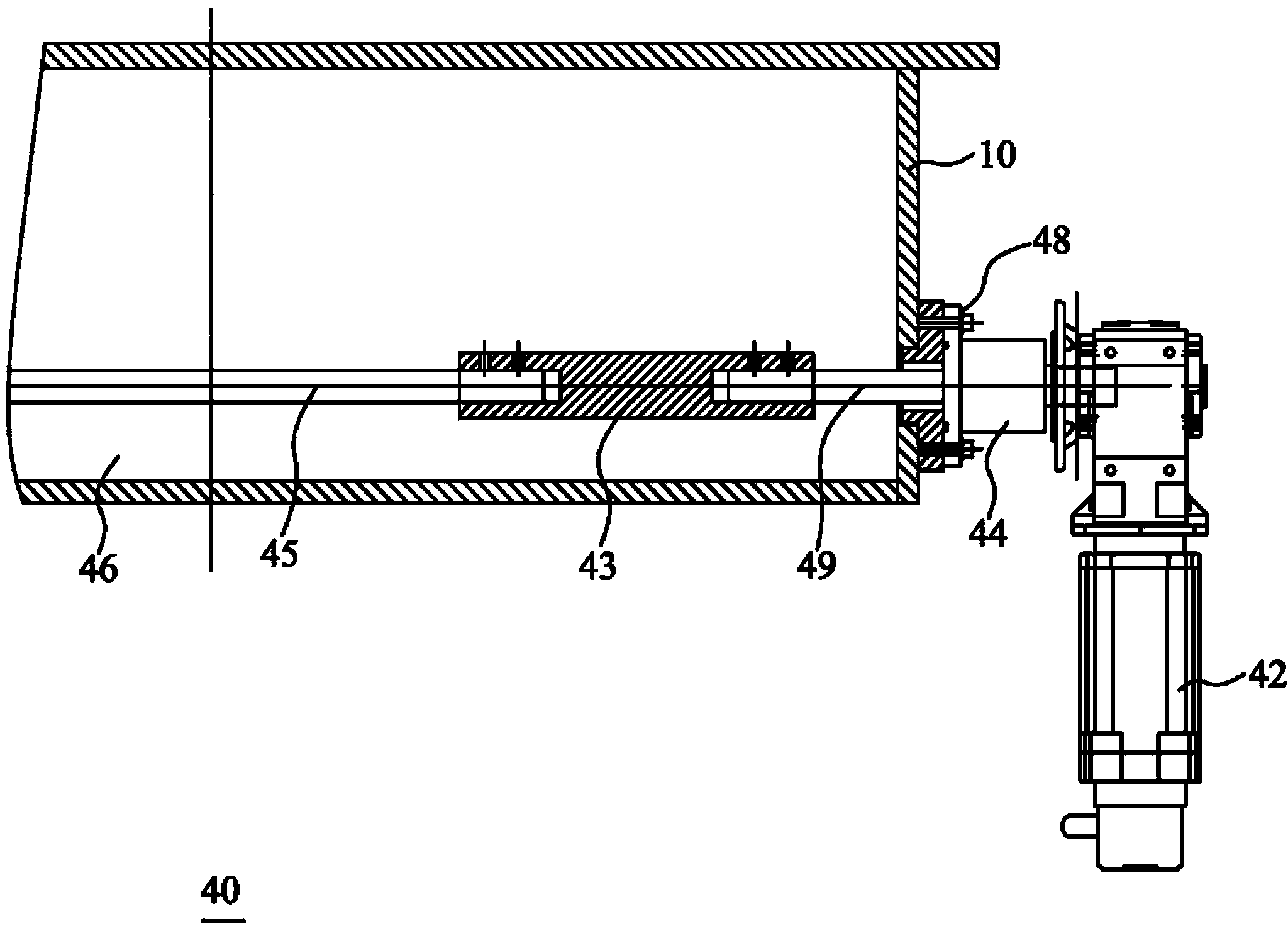

[0023] See figure 2 , image 3 , a kind of glass coating device of the embodiment of the present invention, it is used for coating the glass 20 to be coated, this glass coating device comprises coating chamber 10, transmission unit 30 and base plate module, and this transmission unit 30 is positioned at this coating cabin 10 lower end, The conveying unit 30 includes a plurality of rollers 32, the bottom plate module is arranged between the rollers 32, the glass to be coated 20 is delivered to the coating chamber 10 through the rollers 32, the bottom plate module includes a bottom plate 50 and Lifting element 40, this lifting element 40 links to each other with this base plate 50, thereby regulates the relative distance between this base plate 50 and this to-be-coated glass 20 by this lifting el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com